Passive natural circulation intensifying system and method for liquid metal cooled reactor after flow loss

A technology of liquid metal cooling and natural circulation, applied in reactors, cooling devices, nuclear power generation, etc., can solve problems such as reducing the pressure drop of the reactor, affecting the seismic performance of the reactor body, and increasing the fuel capacity of the core, to achieve enhanced natural circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

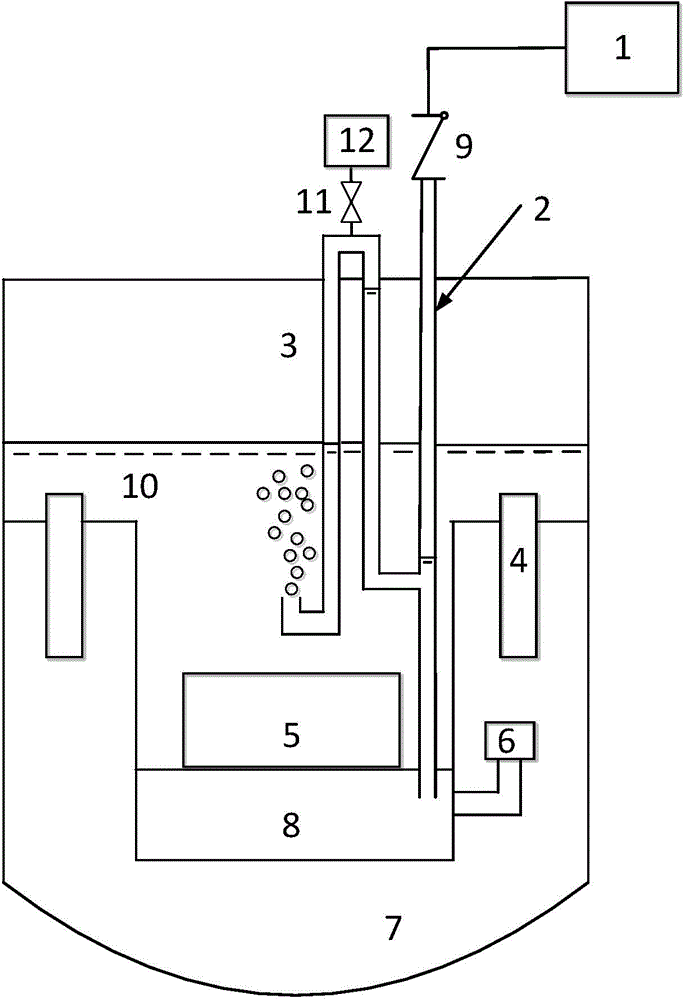

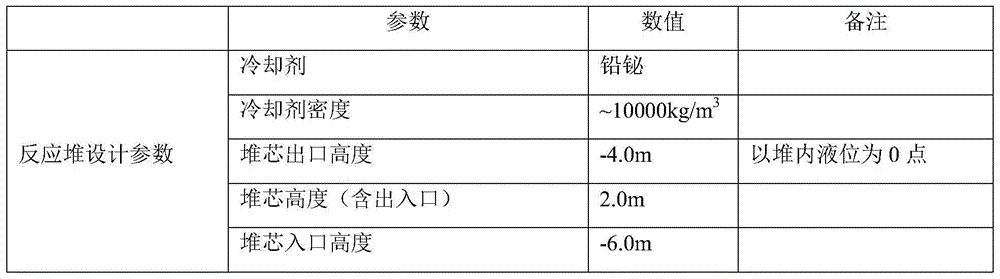

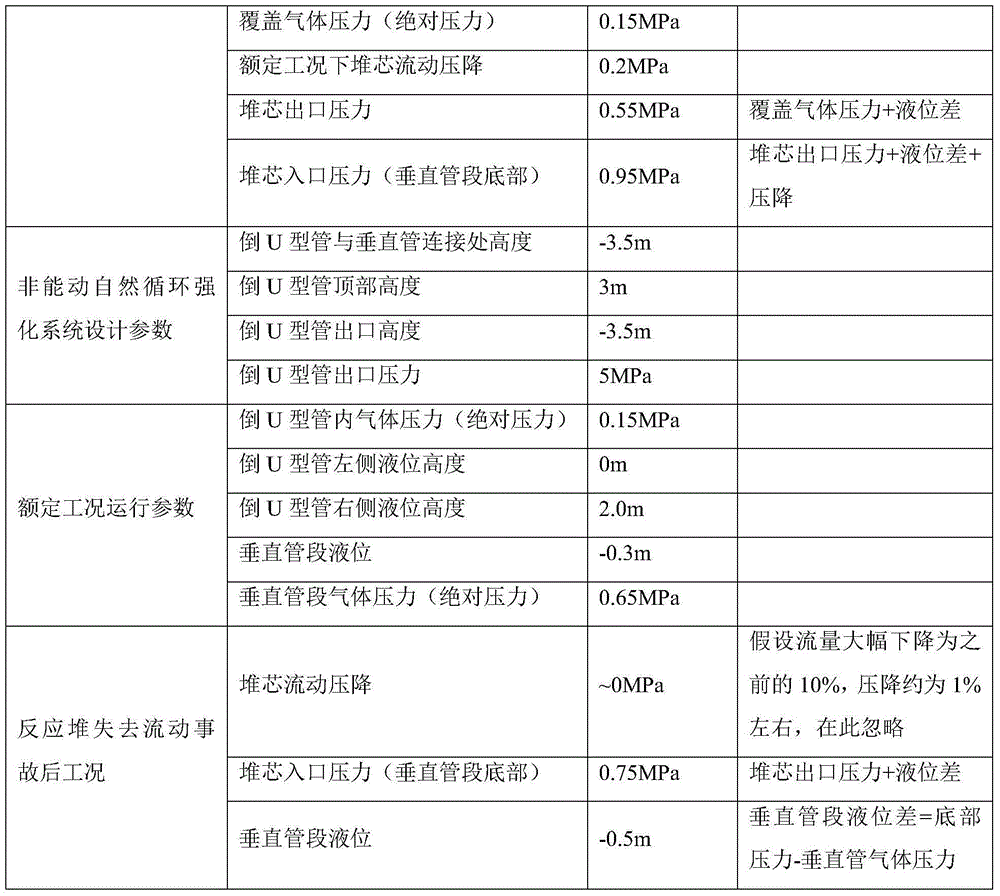

[0026] Such as figure 1 As shown, the high-pressure gas storage tank 1 is connected to the vertical pipeline 2 through the throttle valve 9, the lower end of the vertical pipeline is connected to the distribution header 8 at the inlet of the core 5, one end of the inverted U-shaped pipeline 3 is connected to the vertical pipeline 2, and the other end is as At the exit of core 5.

[0027] During normal operation, when the reactor is operating normally, the liquid level in the vertical pipe 2 is slightly higher than the connection point connecting the inverted U-shaped pipe 3, and the height needs to be less than the driving pressure head of the main pump 6, for example, for a reactor with lead-bismuth alloy as the coolant , if the pressure head of the main pump is 0.3MPa, it is necessary to maintain the liquid level difference less than 0.3m.

[0028] The liquid level and pressure in the inverted U-shaped pipe are controlled by the air valve 11 and the pressure control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com