Horizontal jacket water tank

A jacket and water tank technology, applied in solar thermal power generation, heating devices, solar thermal devices, etc., can solve the problems of potential safety hazards, affecting the heat transfer effect of the water tank system, and poor natural circulation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

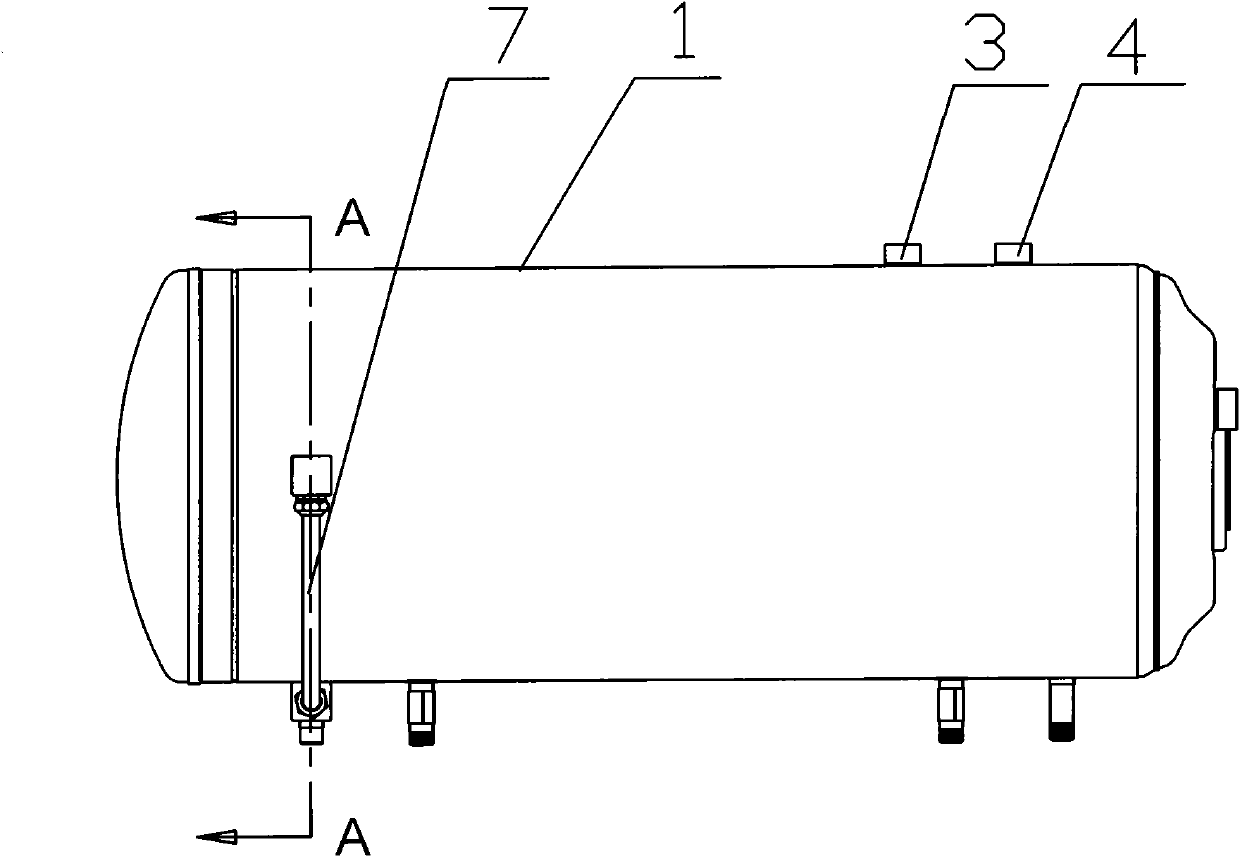

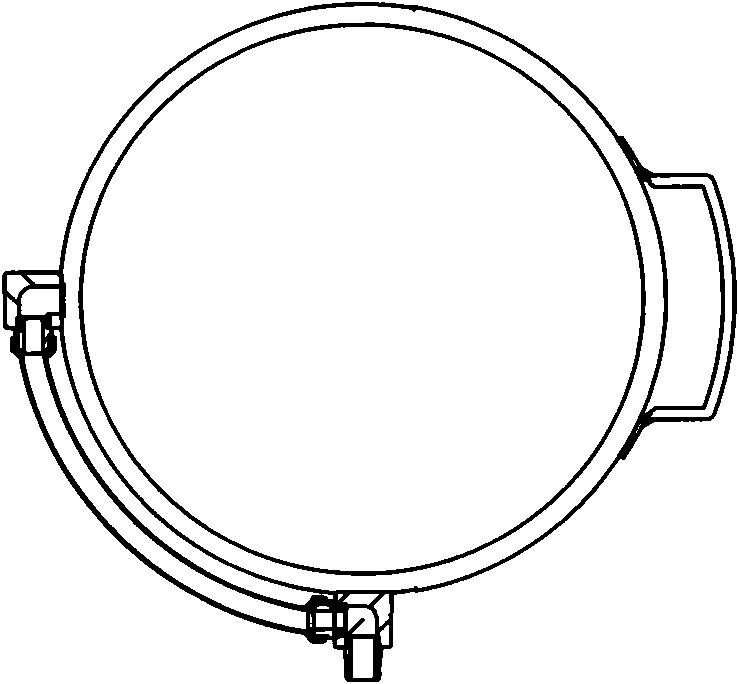

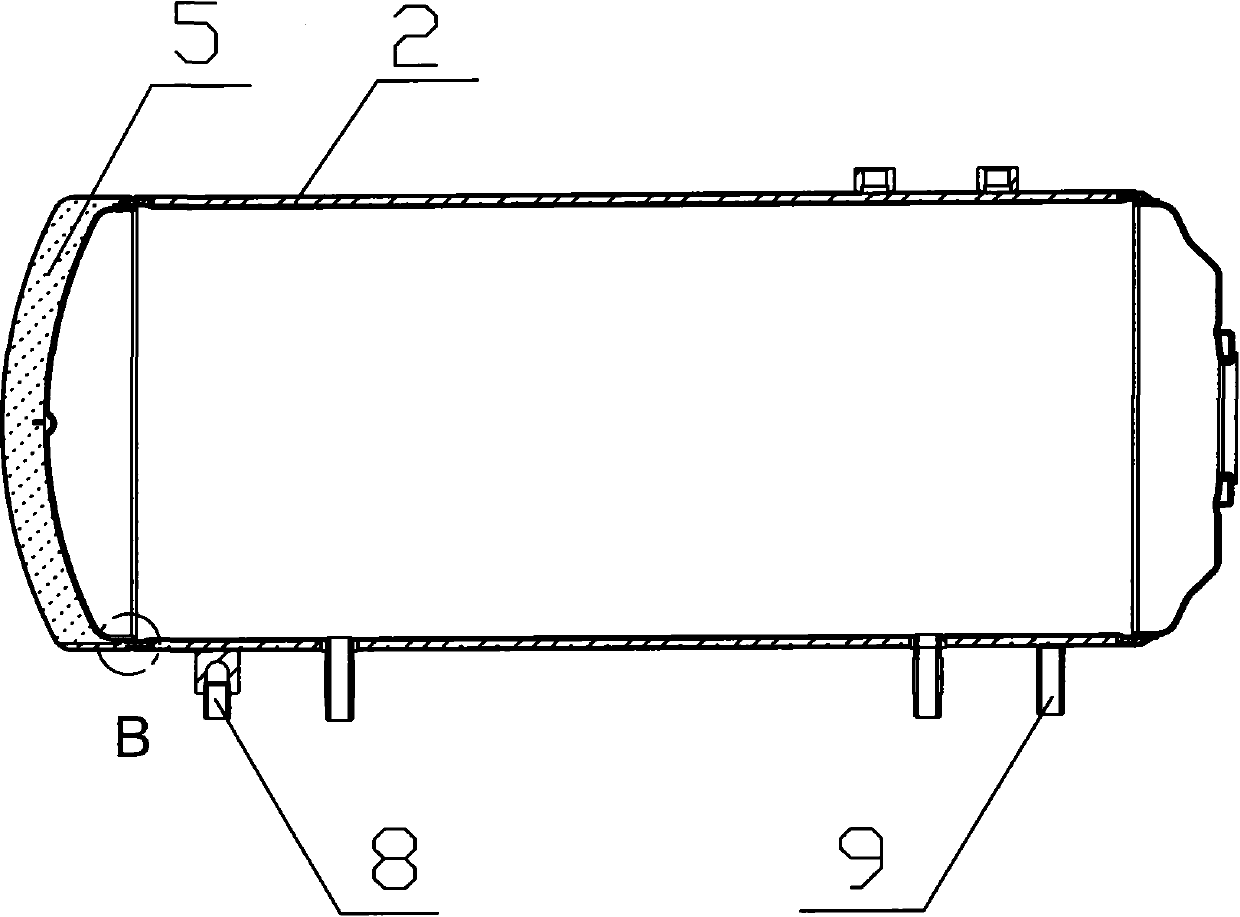

[0012] As can be seen from the drawings, the horizontal jacketed water tank includes an outer shell 1, a medium circulation port and an inner liner jacket 2 for heat exchange. It is composed of an outer cylinder and an inner cylinder. The inner jacket 2 is a heat exchange space. One end of the inner jacket 2 is fixedly welded with an expansion space 5, and a diameter is set between the expansion space and the heat exchange space. 6mm through hole 6. The water tank pours the medium into the liner jacket 2 through the filling medium port 3, and the air in the jacket is discharged through the overflow medium port 4, that is, the exhaust port. After filling up, the filling medium port 3 and the overflow medium port 4 are blocked to form closed system. When the temperature of the medium rises, causing the volume of the medium to expand, the medium will flow to the expansion space 5 through the through hole 6 with a diameter of 6 mm. The air in the expansion space 5 cannot be disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com