Steam generator for metal fast reactor

A technology of steam generators and metals, which is applied in steam generation, steam boilers, lighting and heating equipment, etc., which can solve problems such as increased requirements, inapplicability to the field of metal block piles, and increased flow resistance of liquid metal, so as to reduce manufacturing difficulty and cost, improve natural circulation ability, and improve the effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced.

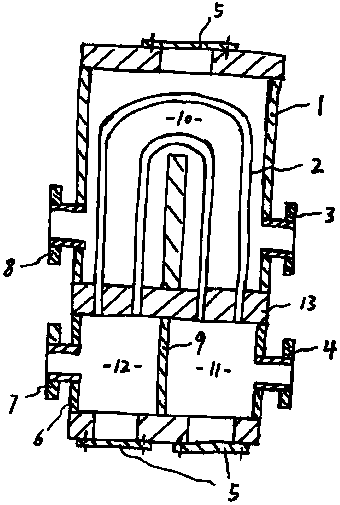

[0020] like figure 1 As shown in the figure, the steam generator includes a container body and a U-shaped heat exchange tube 2 arranged in the container body. A tube side and a shell side 10 are formed in the container body. One side of the container body is provided with a secondary side from bottom to top. Side outlet 7 and primary side inlet 8, the opposite side is provided with secondary side inlet 4 and primary side outlet 3 from bottom to top,

[0021] The high temperature medium enters the shell side 10 from the primary side inlet 8, and after cooling, it is led out from the primary side outlet 3, and the low temperature medium enters the pipe side from the secondary side inlet 4, and after heating, it is discharged from the shell side. The secondary side outlet 7 leads out.

[0022] Among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com