Steel plate for third-generation nuclear power station reactor containments and manufacturing method thereof

A technology for nuclear power plant reactors and manufacturing methods, applied in the manufacture of converters, etc., can solve problems such as complex process routes and large equipment investment, and achieve the effects of low cost, excellent welding performance, good economy and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

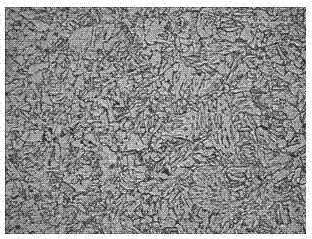

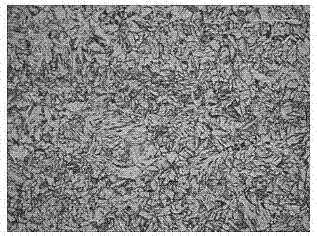

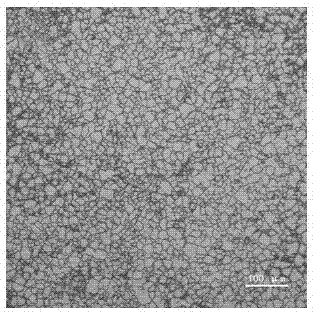

Image

Examples

Embodiment 1

[0033] Using KR hot metal pretreatment for desulfurization, after treatment, the sulfur content is 0.002%, the temperature of the hot metal is 1269°C, and the arsenic content is 0.003%;

[0034] Converter: Double slag smelting process is adopted, the oxygen flow rate during the dephosphorization period is 24,000 cubic meters per hour, and the average gun position is 1900mm. When the blowing reaches 5 minutes and 55 seconds, the dephosphorization period is over, and the slag is dumped. When the slag is poured, the state of slagging is better, and the amount of slag dumped is large. The phosphorus content at the end point of the converter is 0.0052%, and the end point temperature is 1615°C;

[0035] Tapping: Tapping adopts double slag blocking process, good slag blocking, small amount of slag dropping, 800kg top slag, 260kg fluorite, 1358kg ferromanganese, 221kg AlMnTi. CAS feeding aluminum wire 220m, phosphorus content after CAS is 0.0056%;

[0036] LF: The arrival temperatur...

Embodiment 2

[0058] Using KR hot metal pretreatment for desulfurization, after treatment, the sulfur content is 0.002%, the temperature of the hot metal is 1279°C, and the arsenic content is 0.003%;

[0059] Converter: Double slag smelting process is adopted, the oxygen flow rate during the dephosphorization period is 26,000 cubic meters per hour, and the average gun position is 2,000mm. When the blowing reaches 5 minutes and 55 seconds, the dephosphorization period is over, and the slag is dumped. The slag is in a normal state and the slag is thicker. The phosphorus content at the end of the converter is 0.0058%;

[0060] Tapping: Double slag blocking technology is adopted for tapping, which has good slag blocking and small amount of slag dropping. Tapping and topping slag 800kg, fluorite 260kg, ferromanganese 1750kg, ferroniobium 30kg, ferrochrome 300kg, ferrosilicon 430kg, AlMnTi 280kg. CAS feeding aluminum wire 300m;

[0061] LF: The arrival temperature is 1553°C, and the exit tempe...

Embodiment 3

[0081] a. Hot metal pretreatment: desulfurize it to 0.003%, after KR deep desulfurization pretreatment and slag removal, the bright side of the hot metal is greater than 90%, the temperature of the hot metal is 1300°C, and the arsenic (As) in the hot metal is ≤0.006%;

[0082] b. Dephosphorization: Converter smelting adopts double slag dephosphorization method. During the first slagging period, that is, the dephosphorization period, the oxygen blowing smelting time is 7 minutes. A converter with a nominal capacity of 120t is used, and the oxygen supply intensity during the dephosphorization period is 26000m 3 / h, the gun position is 2000mm, the way of adding ore: two-thirds of the ore is added after dephosphorization, and the last third is added after dephosphorization, so as to ensure that the process temperature is not too high, and the bottom blowing intensity is maintained at 55m 3 / h; when the carbon is 0.20%, supplementary blowing is performed once, the target carbon cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com