Reactor safe case electric thermo-couple through parts

A technology of thermocouples and penetrations, applied in the field of electrical penetrations, can solve problems such as complex manufacturing process, high gas leakage rate, and high price, and achieve the effects of mature production process, guaranteed manufacturing quality, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

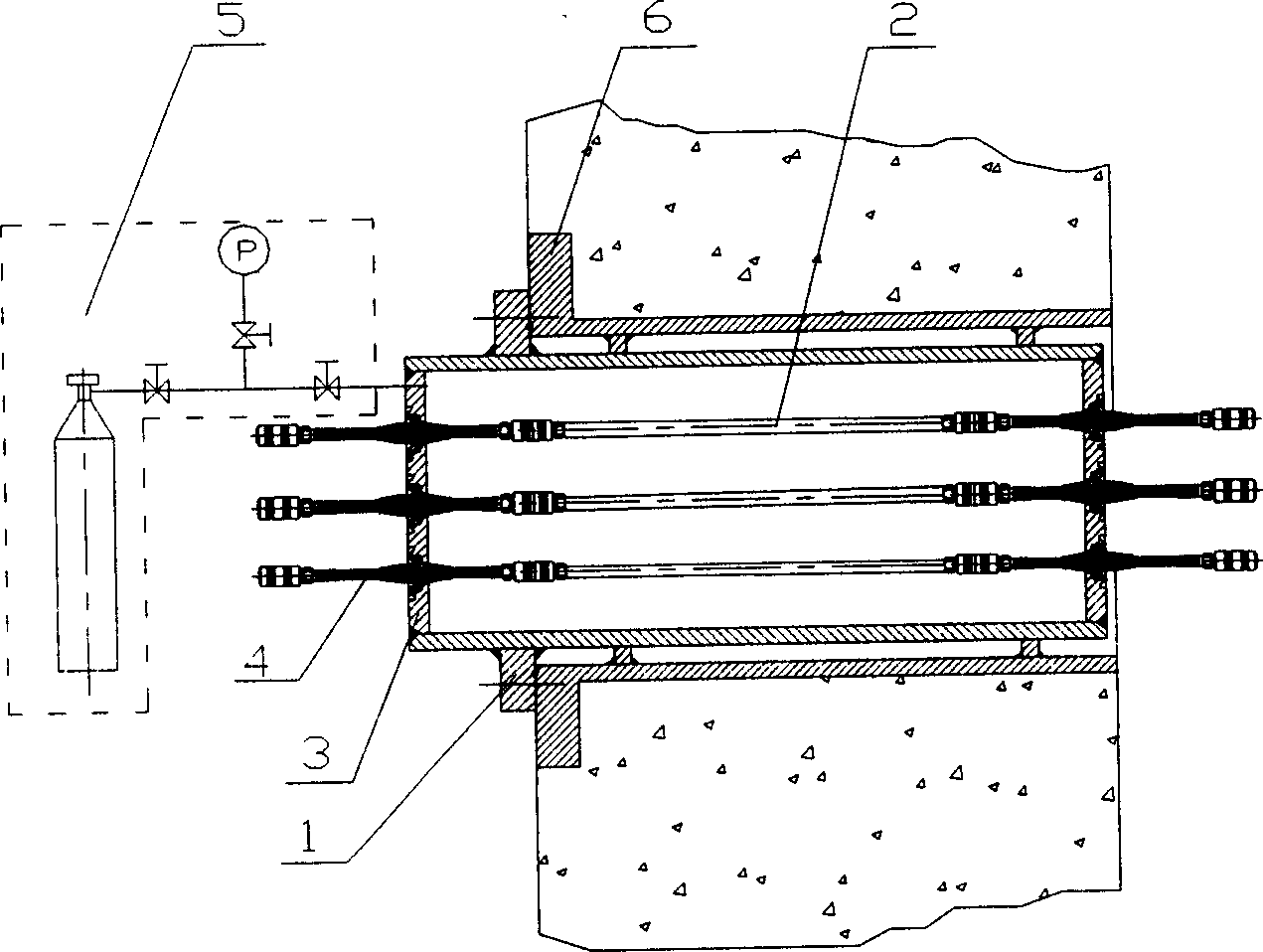

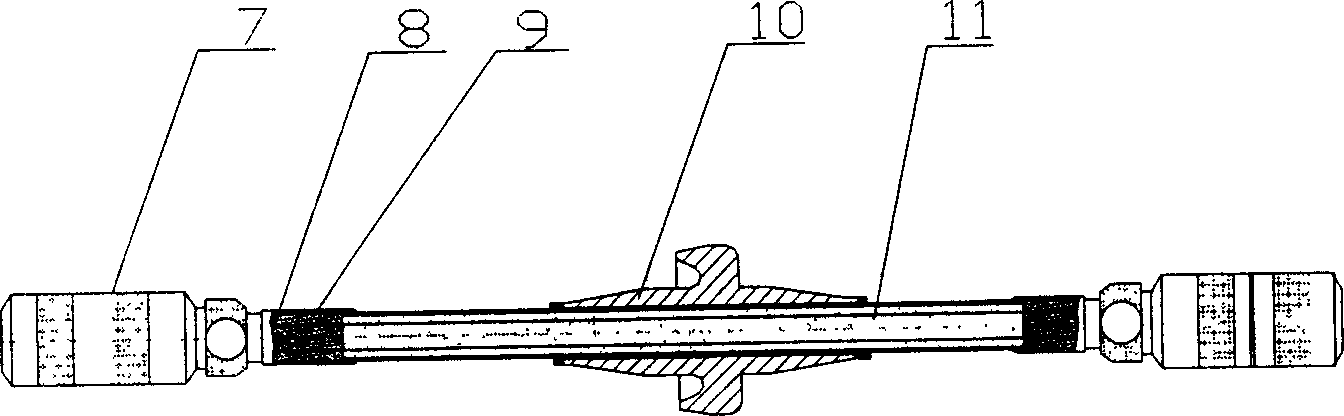

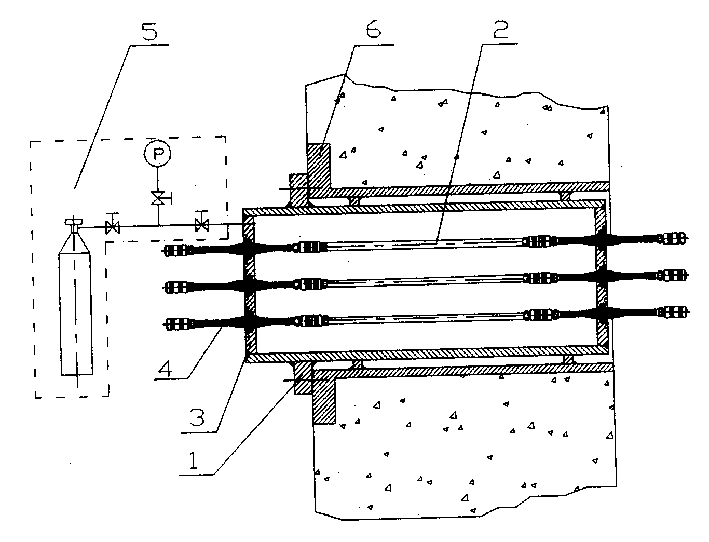

[0014] Such as figure 1 , figure 2 As shown, the reactor containment thermocouple penetrating piece of the present invention includes a pre-embedded pipe 6, a leak detection device 5, a connecting flange 1, a penetrating piece body 3, and a thermocouple penetrating assembly 4 connected by a thermocouple cable 2. It is characterized in that the end plates at both ends of the penetrating member body 3 are welded to the thermocouple penetrating assembly 4 to form an airtight cavity, and are connected to the leak detection device 5 outside the airtight cavity through a connecting tube, so The connecting flange 1 is welded to the penetration body 3, and is connected to the embedded pipe 6 by screwing or welding; the thermocouple penetration assembly 4 includes a connection through a sealing connection material 8 and a mechanical socket The integrated thermocoupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com