Reactor containment vessel cooling system, reactor containment vessel, and reactor containment vessel cooling method

a technology for containment vessels and reactors, which is applied in the direction of domestic cooling apparatus, greenhouse gas reduction, nuclear elements, etc., can solve the problems of accidental loss of the power supply responsible for the entire nuclear facility, difficult to completely eliminate the possibility of releasing radioactive materials into the atmosphere along with water vapor and other gases, and the cooling method is not acceptable. to achieve the effect of preventing the cooling capability and structural integrity of the reactor containment vessel cooling system from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

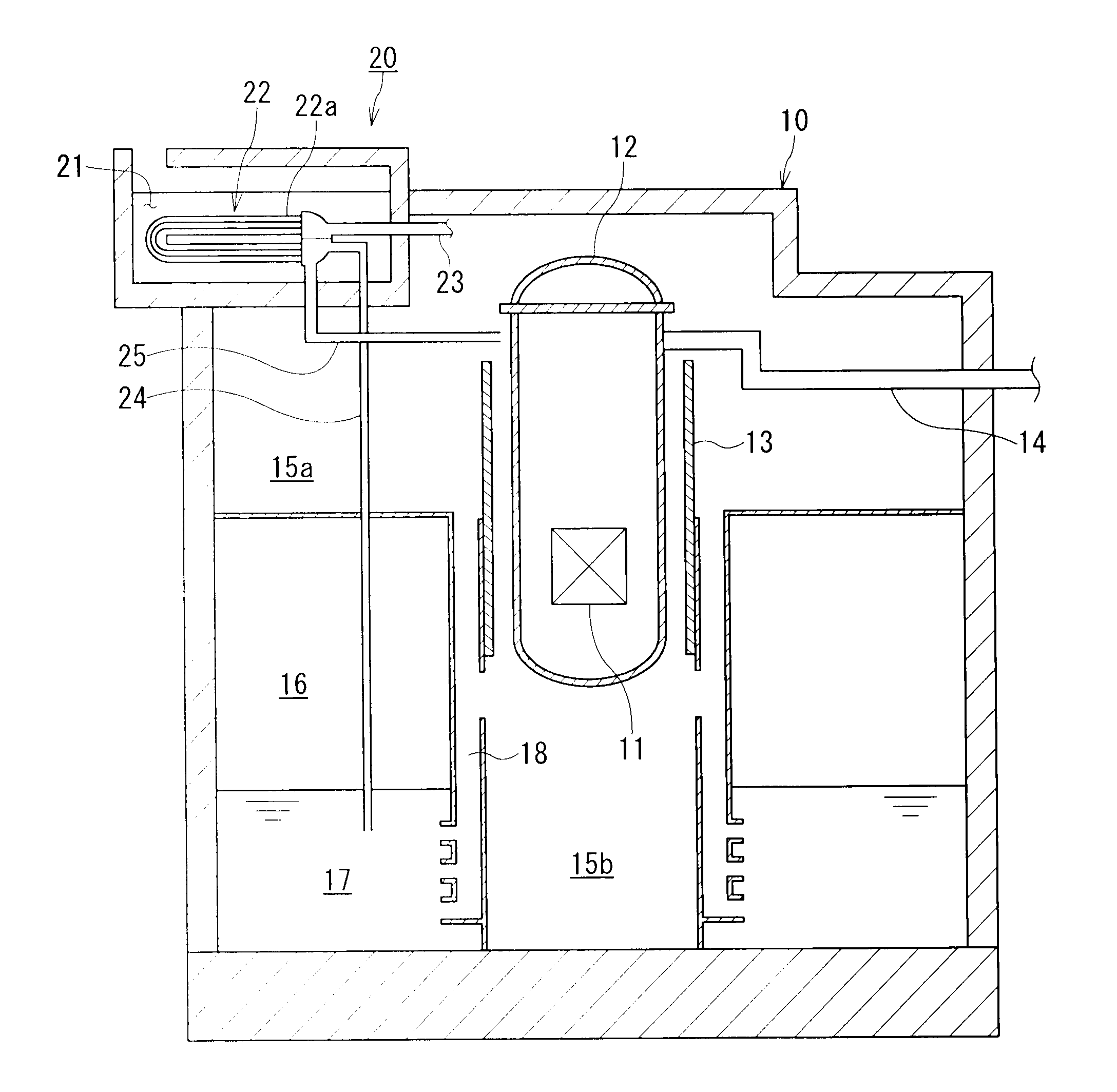

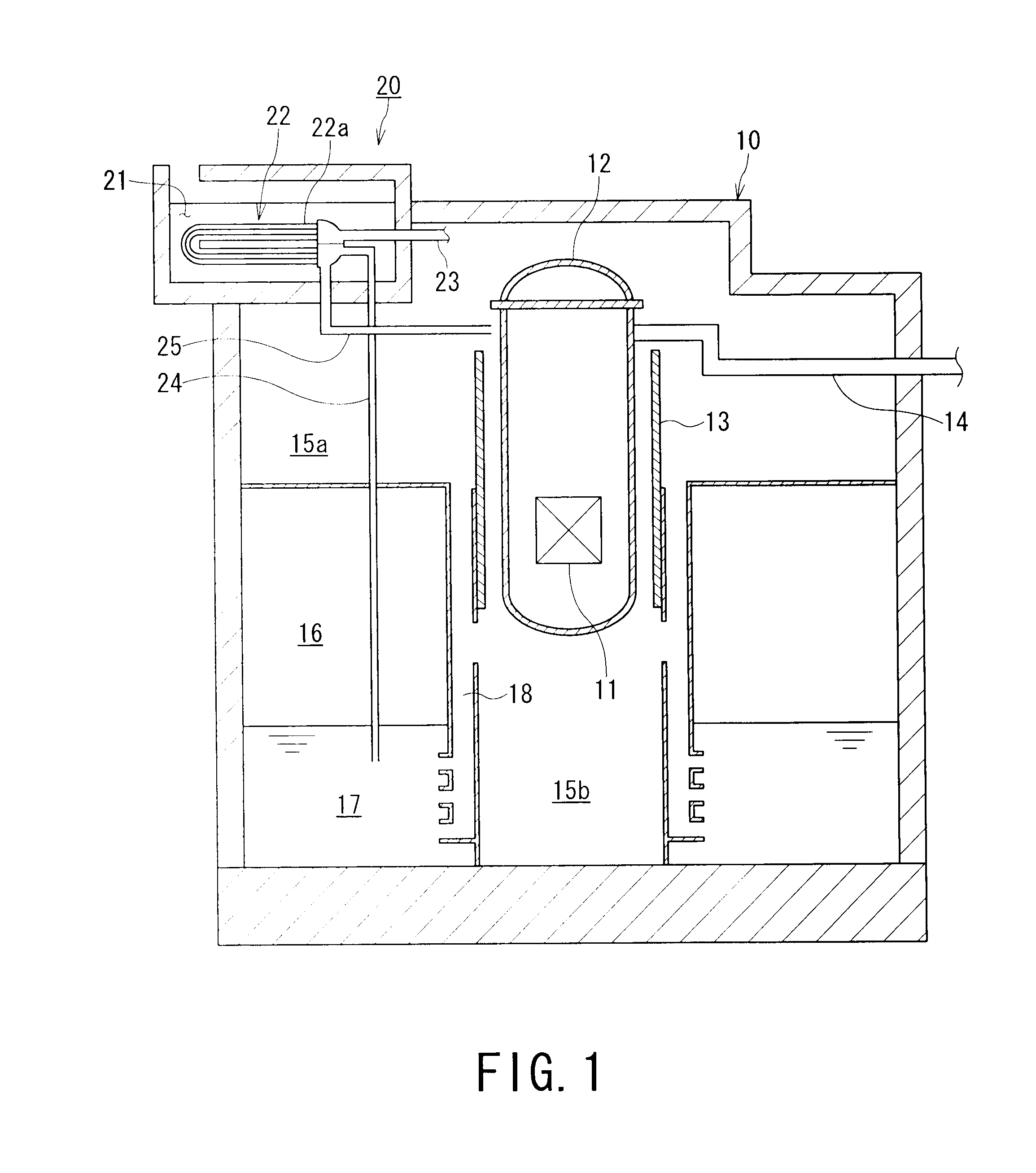

[0034]FIG. 1 is a front sectional view showing a first embodiment of a reactor containment vessel cooling system according to the present invention.

[0035]A reactor containment vessel cooling system 20 according to the first embodiment is provided inside or outside a reactor containment vessel 10.

[0036]The reactor containment vessel 10 is provided so as to surround reactor pressure vessel 12 that accommodates a core 11, a react or shielding wall 13 and other reactor structures or components. The reactor containment vessel 10 has a structure capable of preventing fission products from being released into the atmosphere even in a case where a primary steam tube 14 or any of her component is broken and hence reactor water in the reactor pressure vessel 12 is lost and a fuel is melt or damaged.

[0037]The reactor containment vessel 10 includes a dry well 15 (upper dry well 15a and lower dry well 15b) that forms a space for accommodating the reactor pressure vessel 12 and a suppression cham...

second embodiment

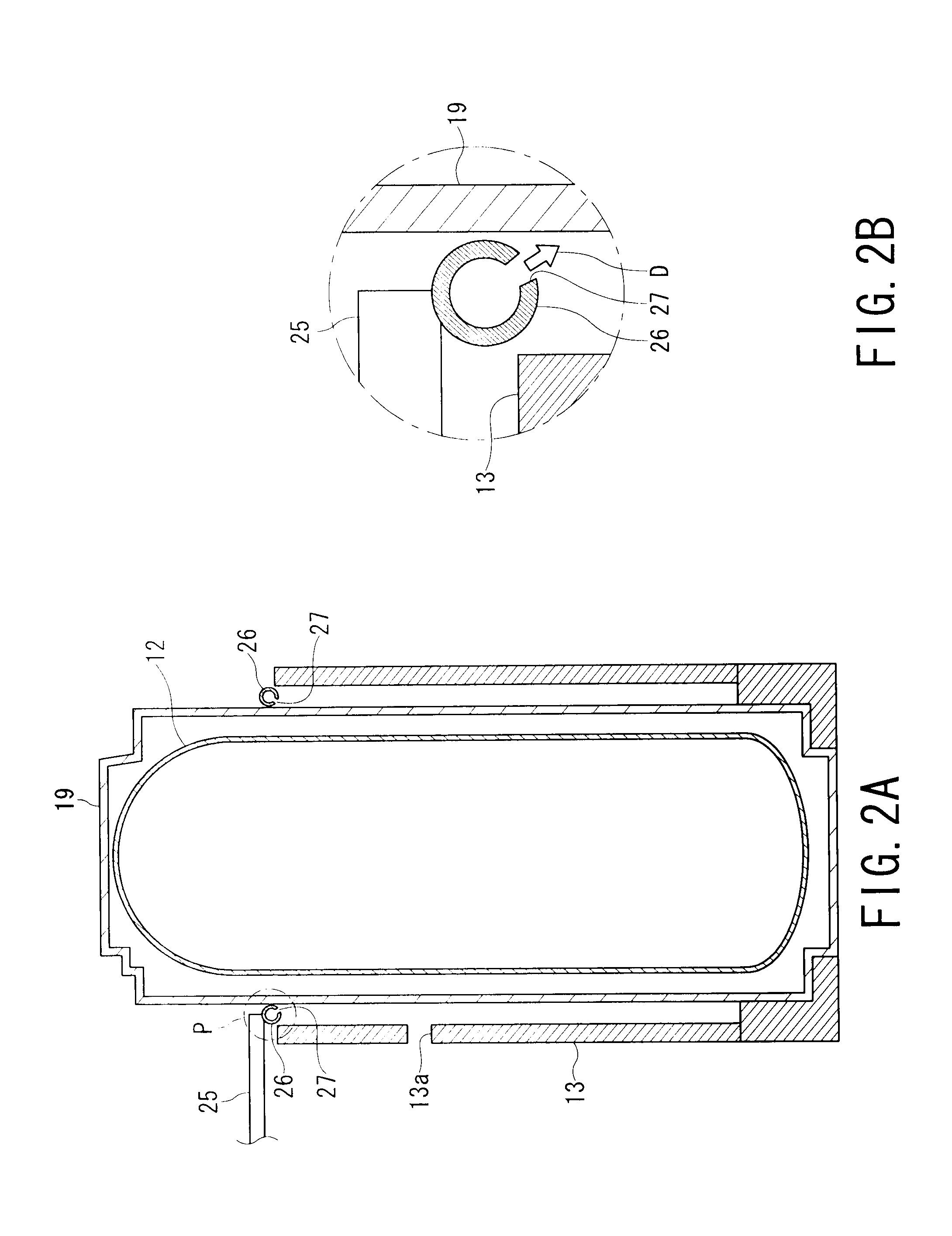

[0058]FIG. 5 is an enlarged sectional view of a key portion showing a second embodiment of the reactor containment vessel cooling system according to the present invention. The present embodiment is an example in which the condensate drain pipe 25 in the reactor containment vessel cooling system 20 in the first embodiment is configured differently. In the following descriptions, components or members similar to those in the first embodiment are added with the same reference numerals, and components different from those in the first embodiment or added thereto are labeled with “A” in the following description.

[0059]A condensate drain pipe 25A in the present embodiment includes a header tube 26A.

[0060]The header tube 26A is formed of a ring-shaped pipe through which condensate extracted from the heat exchanger 22 (see FIG. 1) flows, as in the first embodiment, but is embedded in the thermally insulating member 19 and circumferentially surrounds the reactor pressure vessel 12.

[0061]The...

third embodiment

[0067]FIG. 6 is an enlarged sectional view of an essential portion representing a third embodiment of the reactor containment vessel cooling system 20B according to the present invention. The present embodiment is an example in which the condensate discharge parts 27A in the reactor containment vessel cooling system 20A in the second embodiment are configured differently. In the following descriptions, components or members similar to those in the second embodiment are added with the same reference numerals, and components different from those in the second embodiment or added thereto are labeled with “B” in the following description.

[0068]The reactor containment vessel cooling system 20B includes nozzles 29B, as shown in FIG. 6. Each of the nozzles 29B extends from the edge of the corresponding discharge port 27A (see FIG. 5) in the second embodiment and forms a discharge portion through which the condensate extracted from the heat exchanger 22 (see FIG. 1) is discharged.

[0069]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com