Electric penetration piece with radiation shielding structure

An electrical penetration and radiation shielding technology, which is applied in the field of electrical penetrations with radiation shielding structures, can solve the problems of limited shielding effect of ordinary stainless steel and reduce the biological shielding performance of containment concrete walls, etc., and achieve good radiation protection ability and radiation dose low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

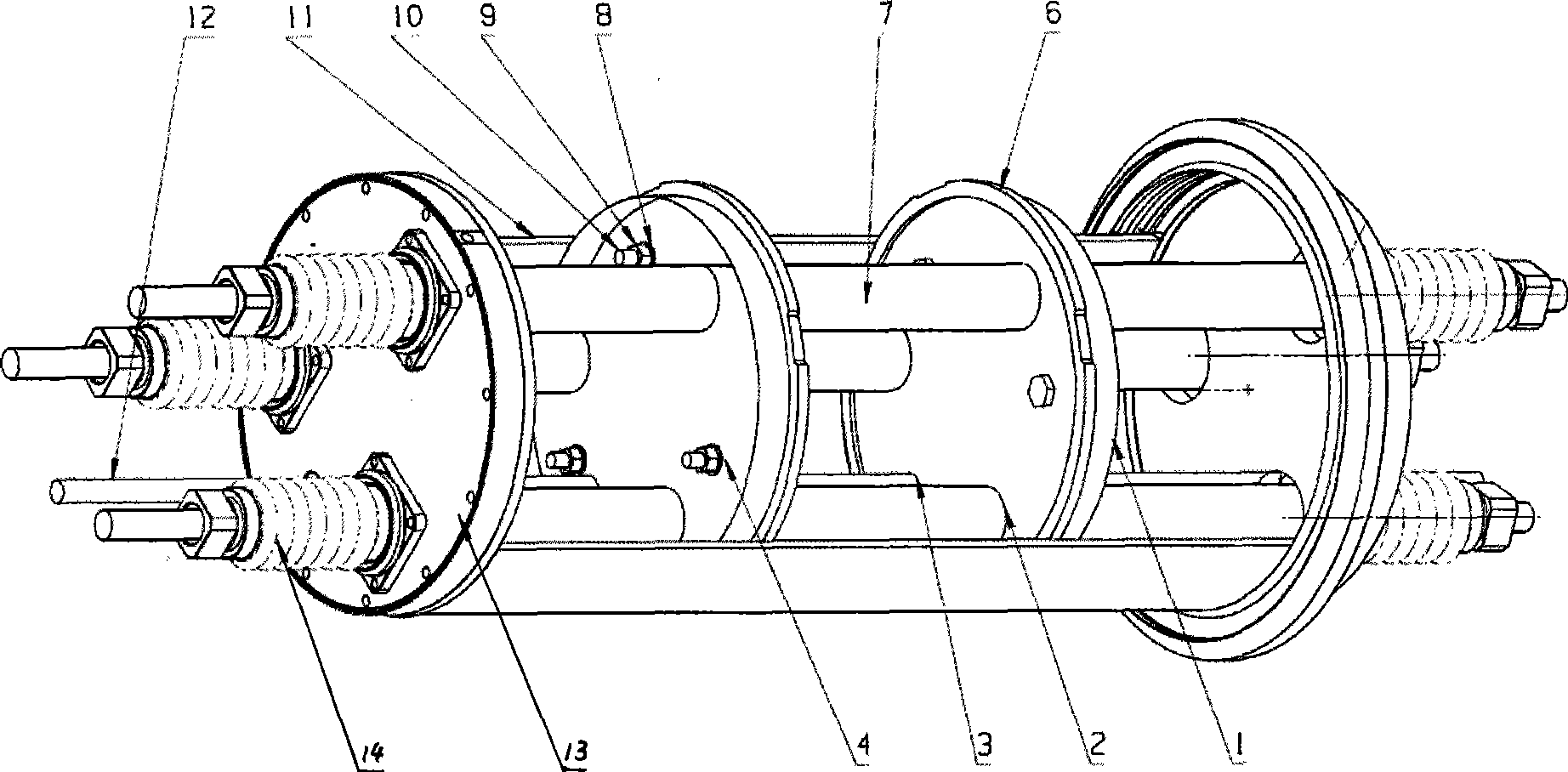

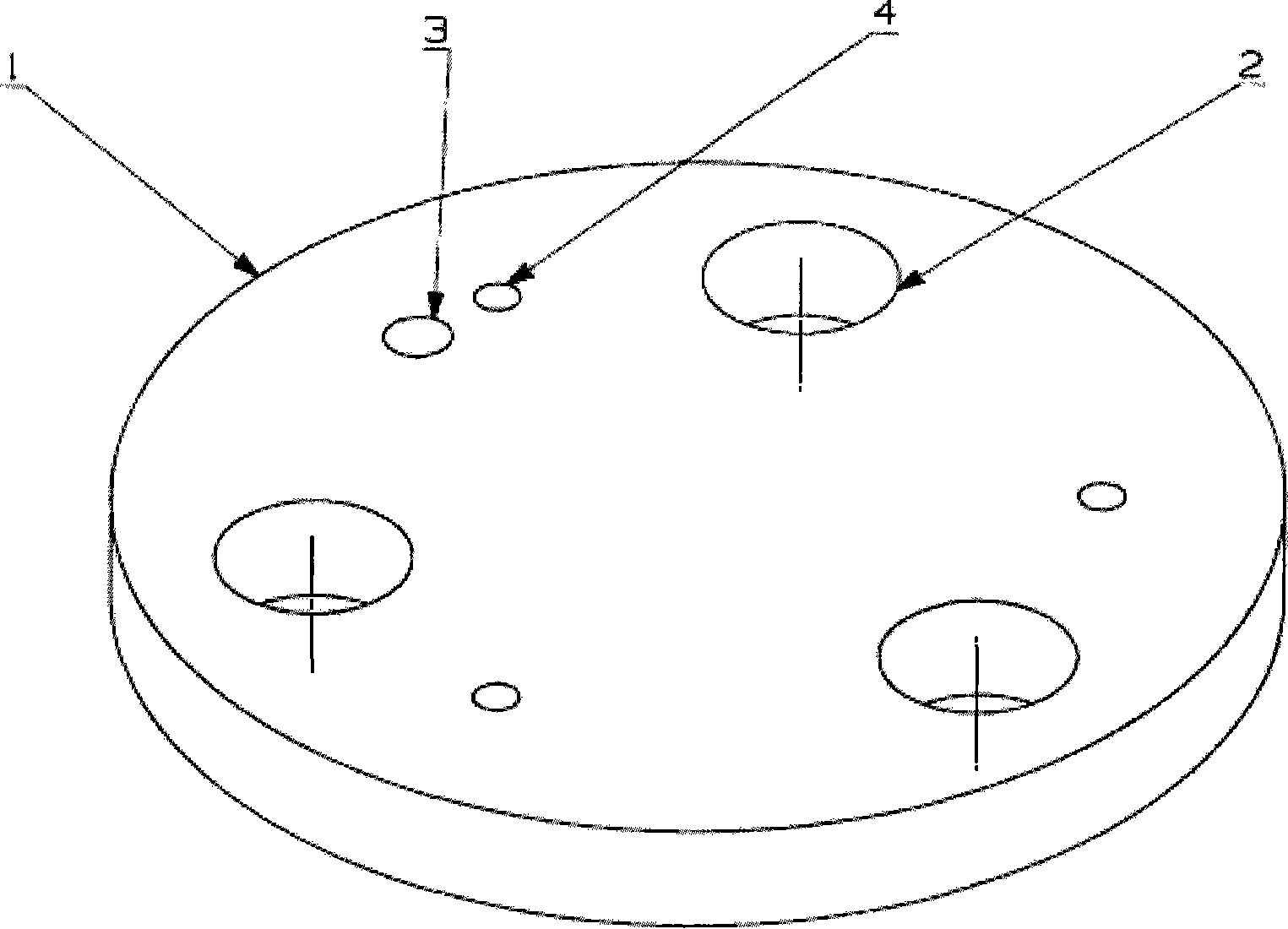

[0025] An electrical penetration with lead plate radiation shielding structure

[0026] Such as figure 1 , image 3 As shown, the electrical penetrating part of the present invention consists of a cylinder body 11, flanges 13 encapsulating the two ends of the cylinder body 11, the conductor assembly 7 and the grounding conductor 12 encapsulated in the cavity of the cylinder body 11 by the flange 13, in the cavity of the cylinder body 11 In the body, the supporting partition 6 is welded vertically on the inner wall of the cylinder along the axial direction of the cylinder and penetrated by the conductor assembly 7 and the grounding conductor 12, and is fixed on the supporting partition 6 and is simultaneously connected by the conductor assembly 7 and the grounding conductor 12. It is composed of the matching lead plate 1 through which the axis extends; wherein, the lead joints 14 at both ends of the conductor assembly 7 are respectively fixed on the disk surface of the flange ...

Embodiment 2

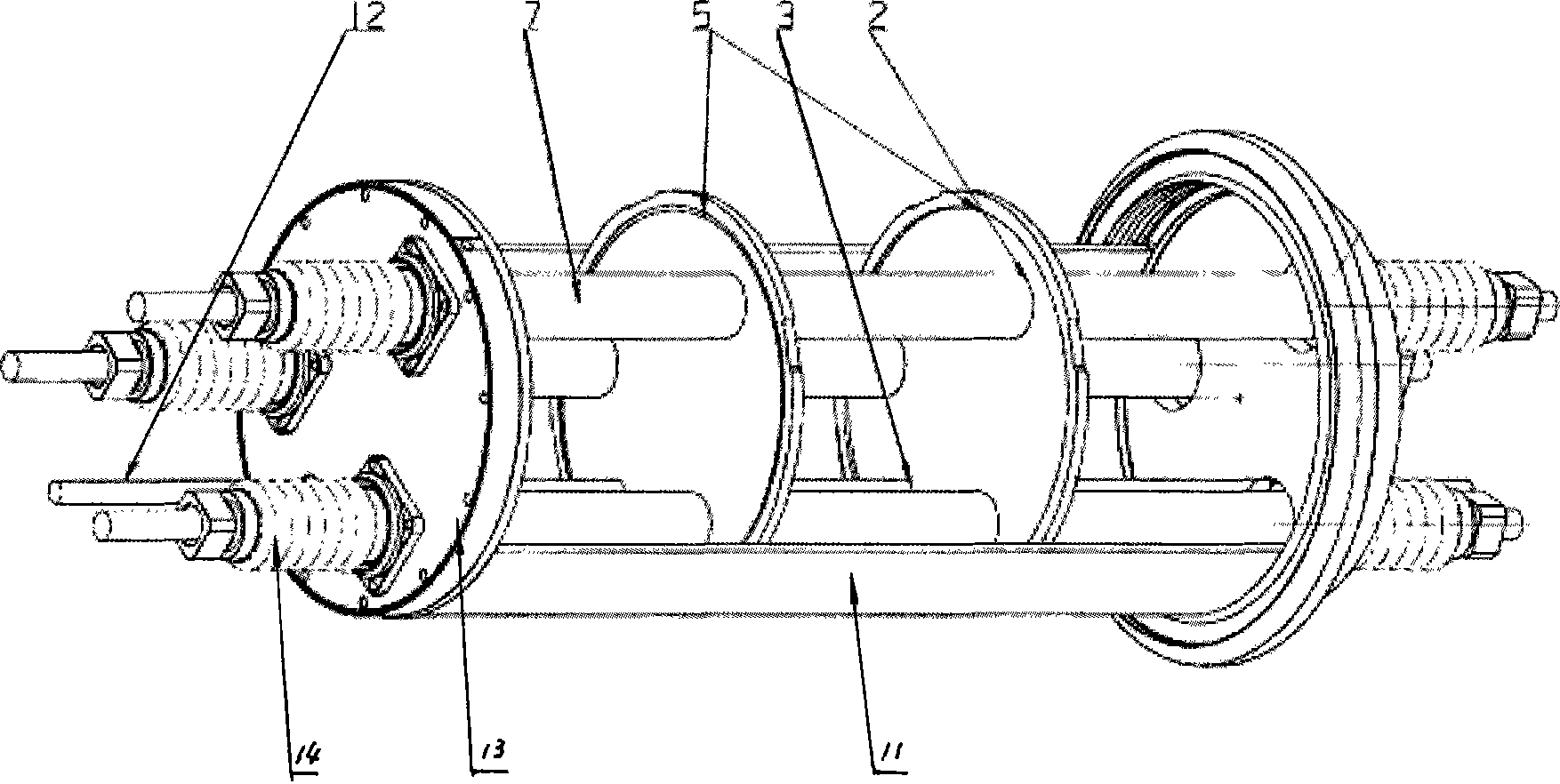

[0031] An electrical penetration with radiation shielding structure of high boron stainless steel plate

[0032] Such as figure 2 , Figure 4 As shown, the electrical penetrating part of the present invention consists of a cylinder body 11, flanges 13 encapsulating the two ends of the cylinder body 11, the conductor assembly 7 and the grounding conductor 12 encapsulated in the cavity of the cylinder body 11 by the flange 13, in the cavity of the cylinder body 11 The body is composed of high-boron stainless steel plates welded vertically on the inner wall of the cylinder along the axial direction of the cylinder and penetrated by the conductor assembly 7 and the grounding conductor 12; wherein, the lead joints 14 at both ends of the conductor assembly 7 are respectively fixed on the flanges at both ends On the disk surface of flange 13, the two ends of the grounding conductor 12 pass through the disk surface of flange 13.

[0033] There is only one piece of high-boron stainles...

Embodiment 3

[0037] A high boron stainless steel plate radiation shielding structural electrical penetration with metal compound coating

[0038] The structure of the electrical penetration part of this embodiment is basically the same as that of Example 2, the difference is that B4C, WC, FeNiB, TiC, iron-nickel, which have the functions of relieving thermal stress and enhancing shielding, are prepared on the surface of high-boron stainless steel by thermal spraying technology. Any coating of aluminum metal compound makes high boron stainless steel have better mechanical properties and radiation shielding properties. The high-boron stainless steel with the sprayed layer is used to process the same structure as the support partition, which replaces the support partition on the traditional penetrating piece, and plays the functions of support and radiation shielding at the same time.

[0039] The radiation shielding structure of the electrical penetrations in the above embodiments can effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com