Patents

Literature

30results about How to "Increase heat transfer power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

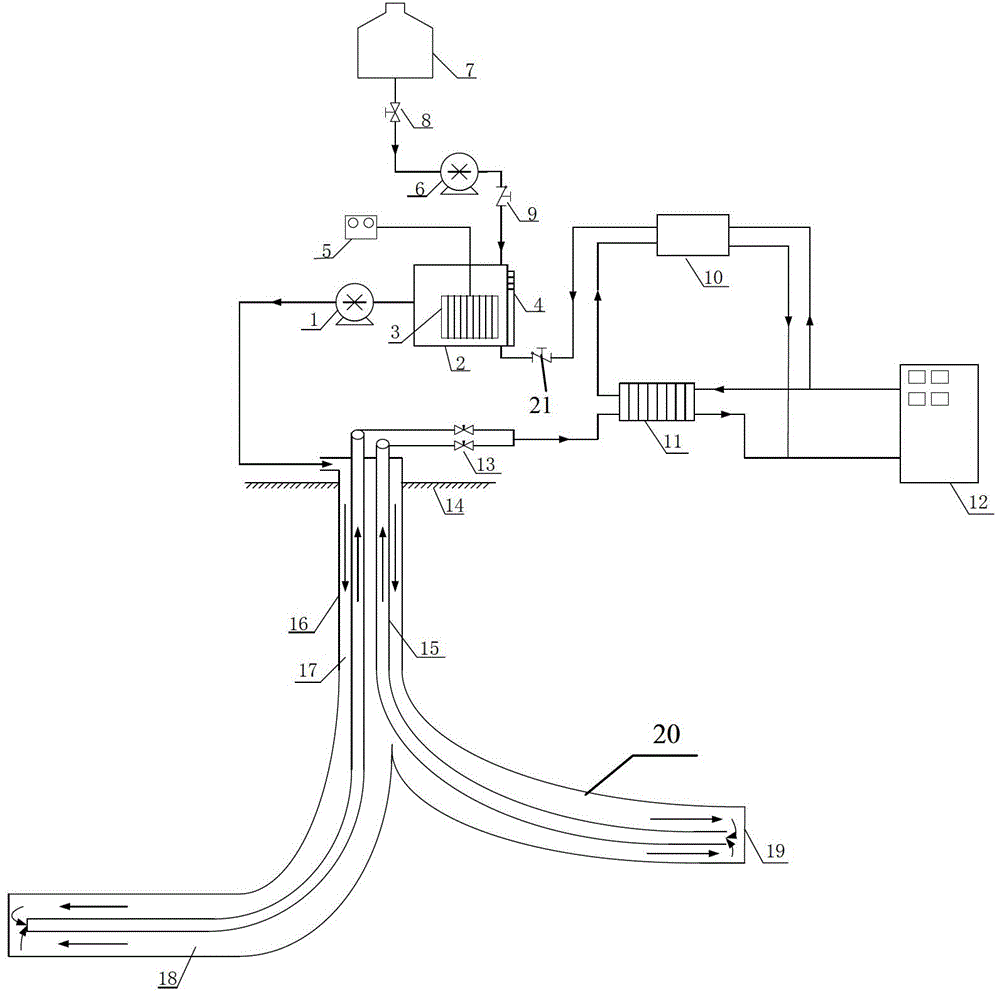

Double-well re-injection geothermal exploitation system based on fracturing technology

ActiveCN103983035AGuaranteed sustainable developmentReduce adverse effectsOther heat production devicesGeothermal energy generationWater flowInjection well

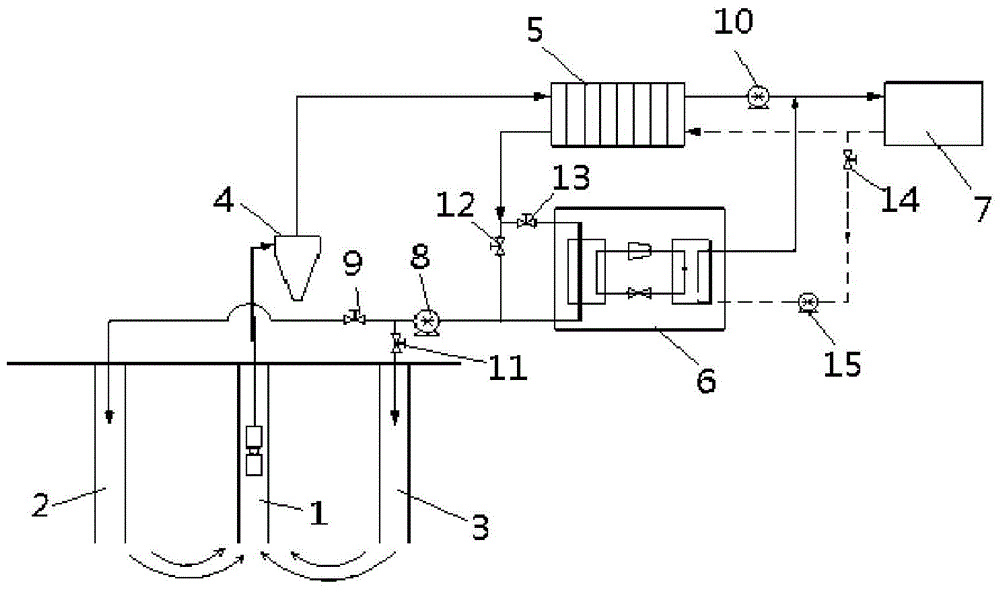

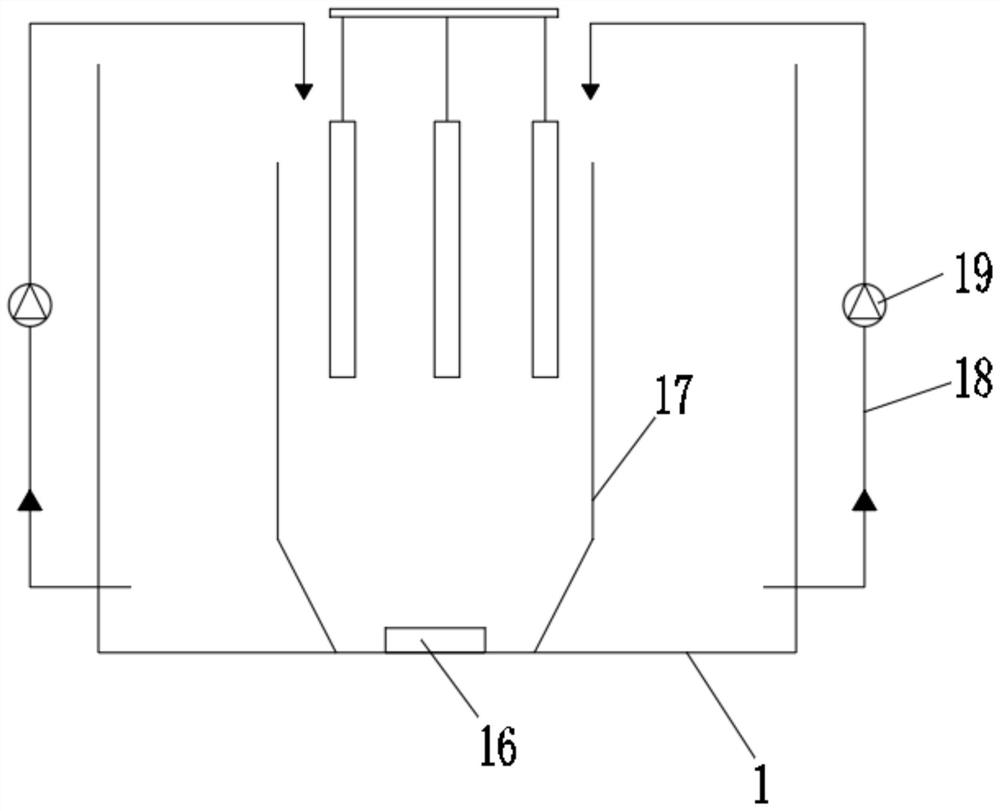

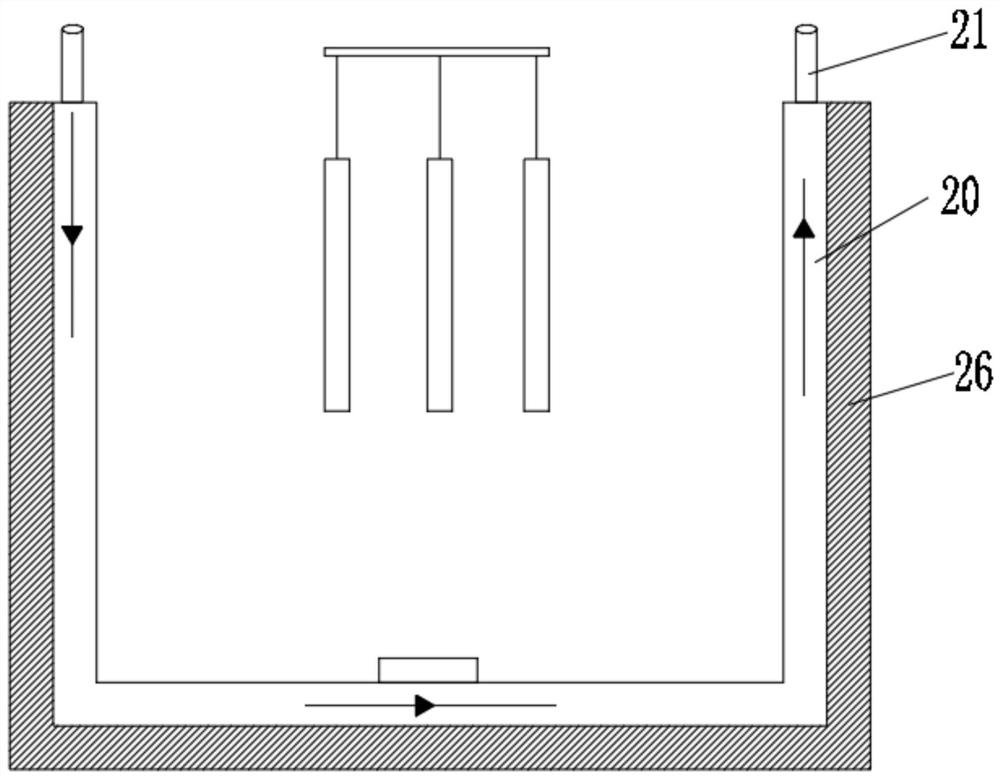

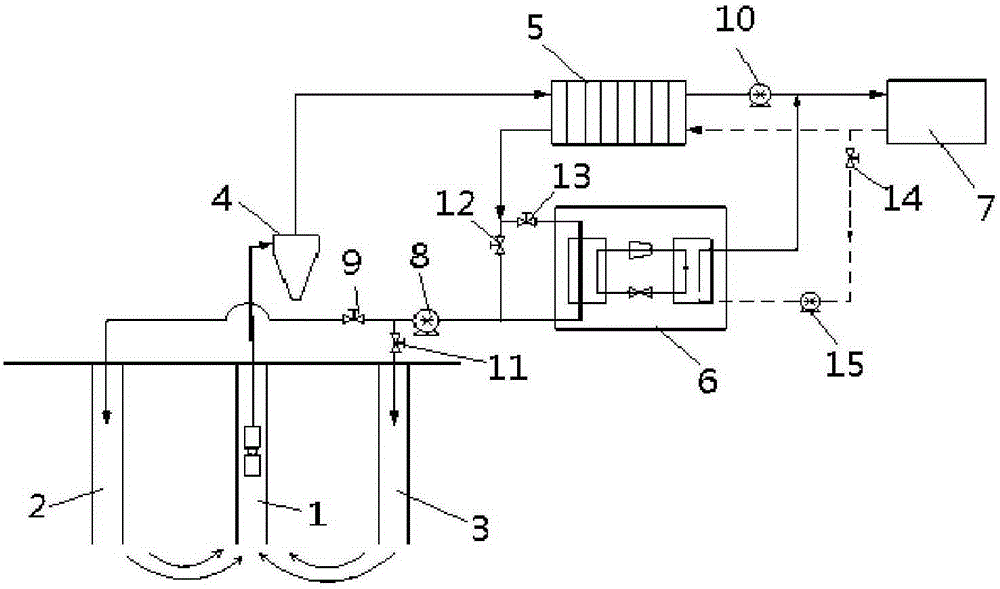

The invention discloses a double-well re-injection geothermal exploitation system based on a fracturing technology. The double-well re-injection geothermal exploitation system based on the fracturing technology comprises a first re-injection well, a second re-injection well and a water taking well arranged between the first re-injection well and the second re-injection well, wherein the water taking well is communicated with the first re-injection well and the second re-injection well through cracks in a heat storage layer respectively; the water taking well is connected with the heat release side inlet of a heat exchanger via a sand remover, the heat release side outlet of the heat exchanger is connected with the first re-injection well and the second re-injection well respectively, and the heat absorption side of the heat exchanger is communicated with the heating pipe network of a user. Because the water taking well is communicated with the first re-injection well and the second re-injection well by virtue of the cracks in the heat storage layer respectively, and the cracks are arranged in the heat storage layer, according to the double-well re-injection geothermal exploitation system based on the fracturing technology disclosed by the invention, geothermal tail water can be completely re-injected in the heat storage layer through the cracks to ensure the sustainable development of geothermal resources, thus reducing the adverse effects of the geothermal tail water on environment and ecology; meanwhile, when the geothermal tail water flows through the cracks, the heat exchange area of a fluid and the heat storage layer is greatly increased, and the heat exchange power is increased.

Owner:陕西圣昊朗道科技有限公司

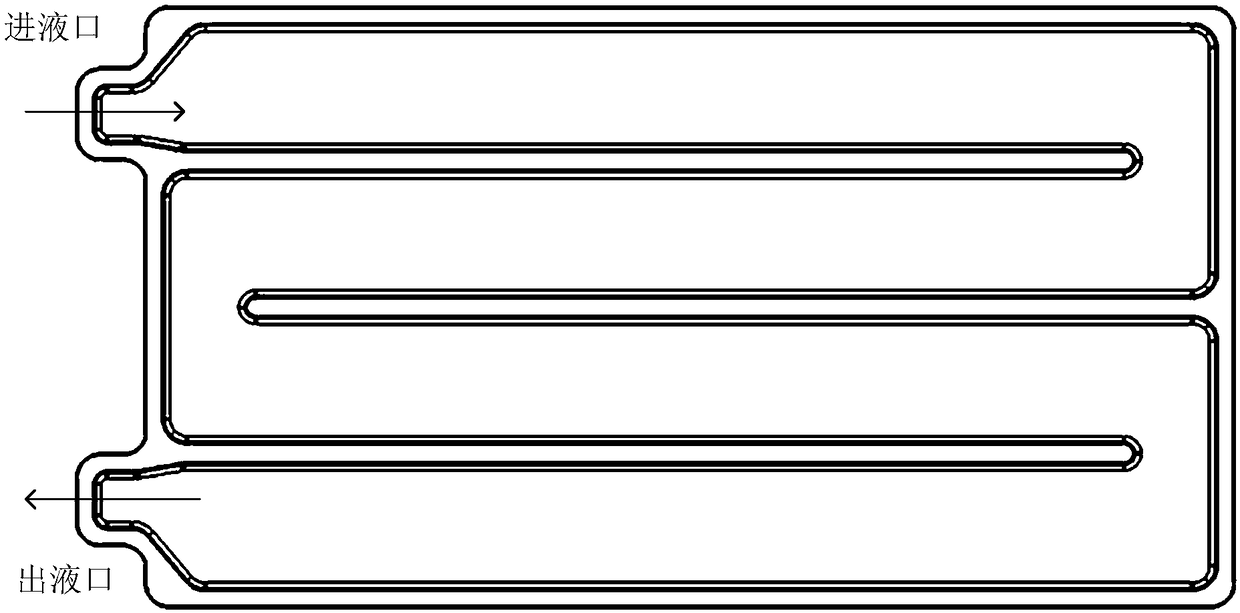

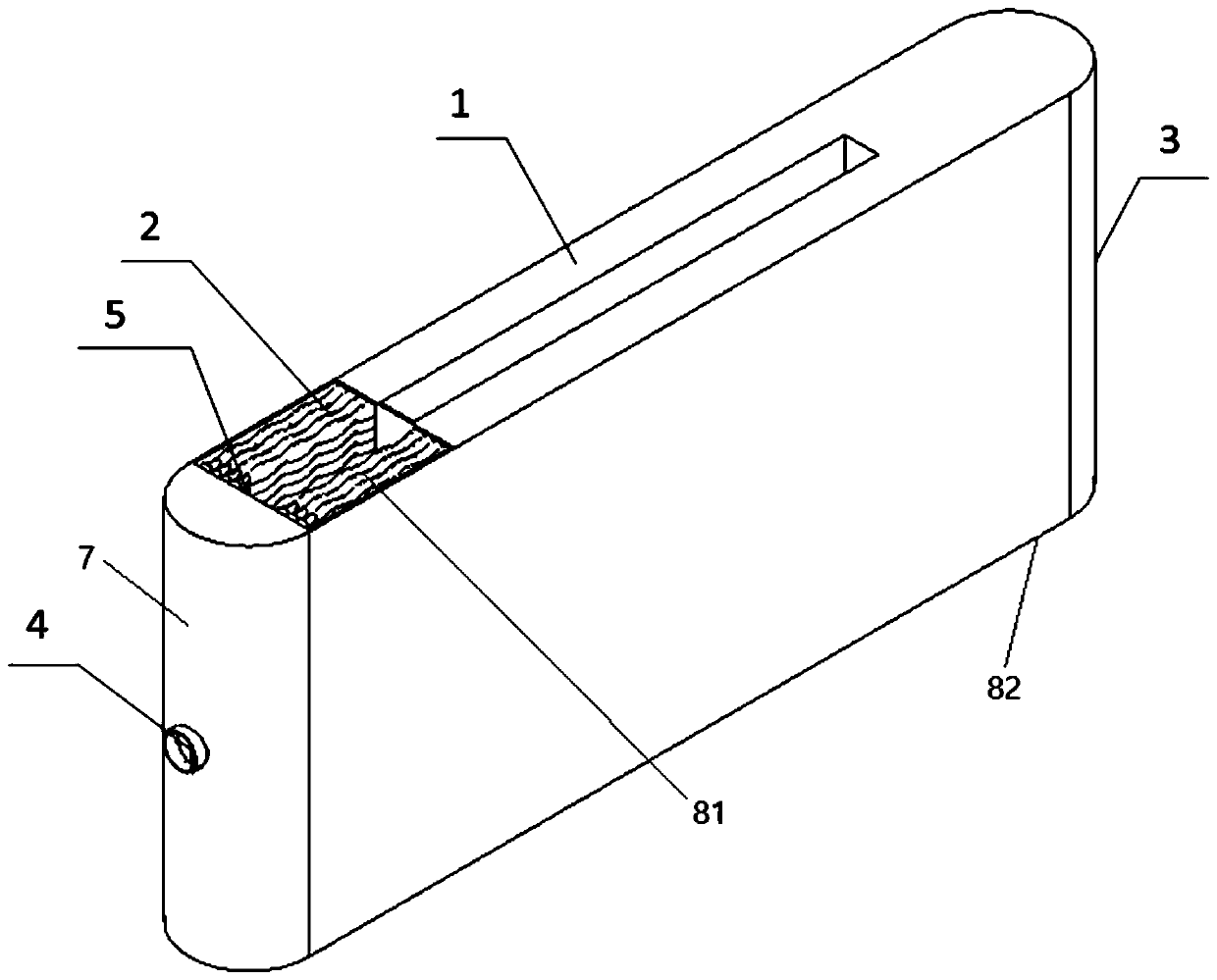

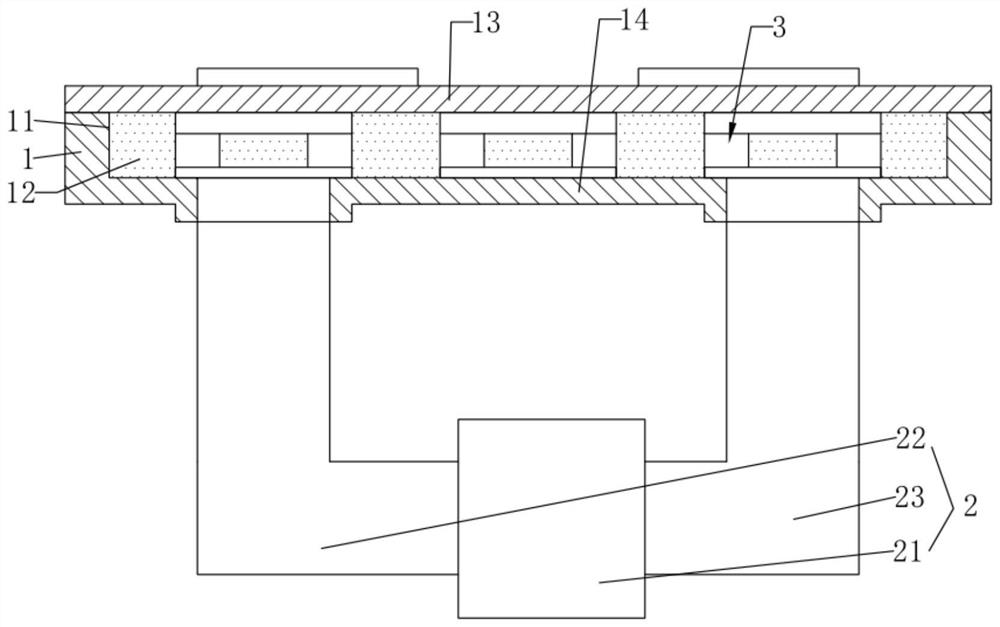

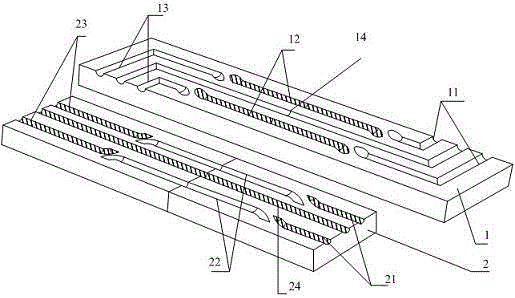

Heat exchange device

The invention provides a heat exchange device. The heat exchange device is used for exchanging heat with a battery and comprises a first flat plate and a second flat plate, wherein the second flat plate is connected to the first flat plate in a butt joint mode; the second flat plate comprises a concave part so as to form a cavity with the first flat plate and further comprises a plurality of firstfinger-shaped partitions extending from a first side end to a second side end and a plurality of second finger-shaped partitions extending from the second side end to the first side end; the multiplefirst finger-shaped partitions and the second finger-shaped partitions are arranged in a staggered mode so as to enable the cavity to form a circuitous flow channel; and turbulent flow pits which aresunken towards the outside of the flow channel are arranged on the flow channel.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

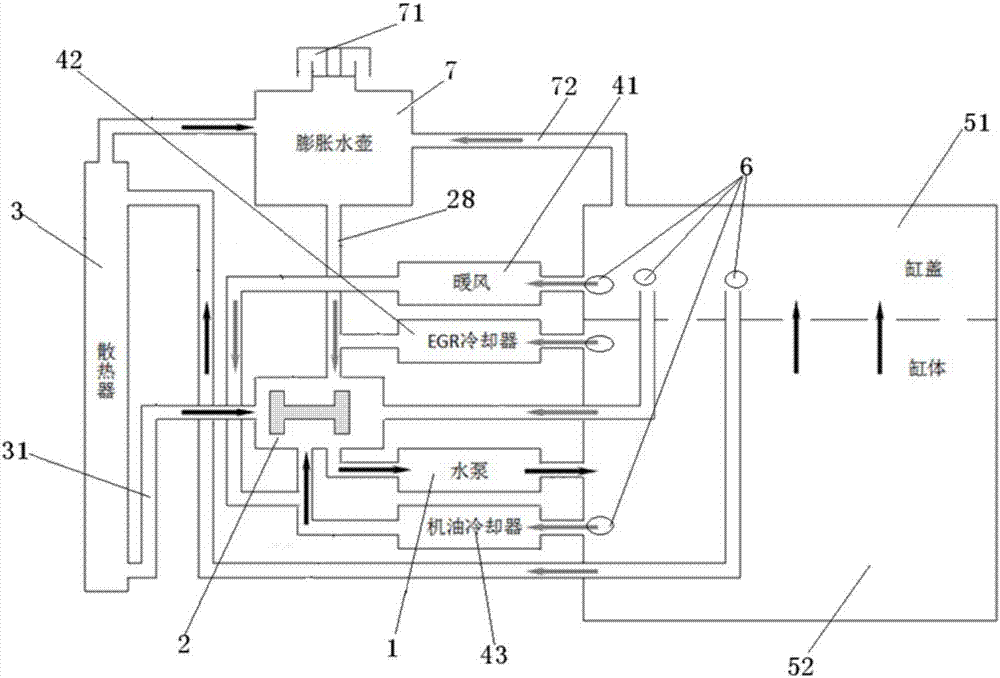

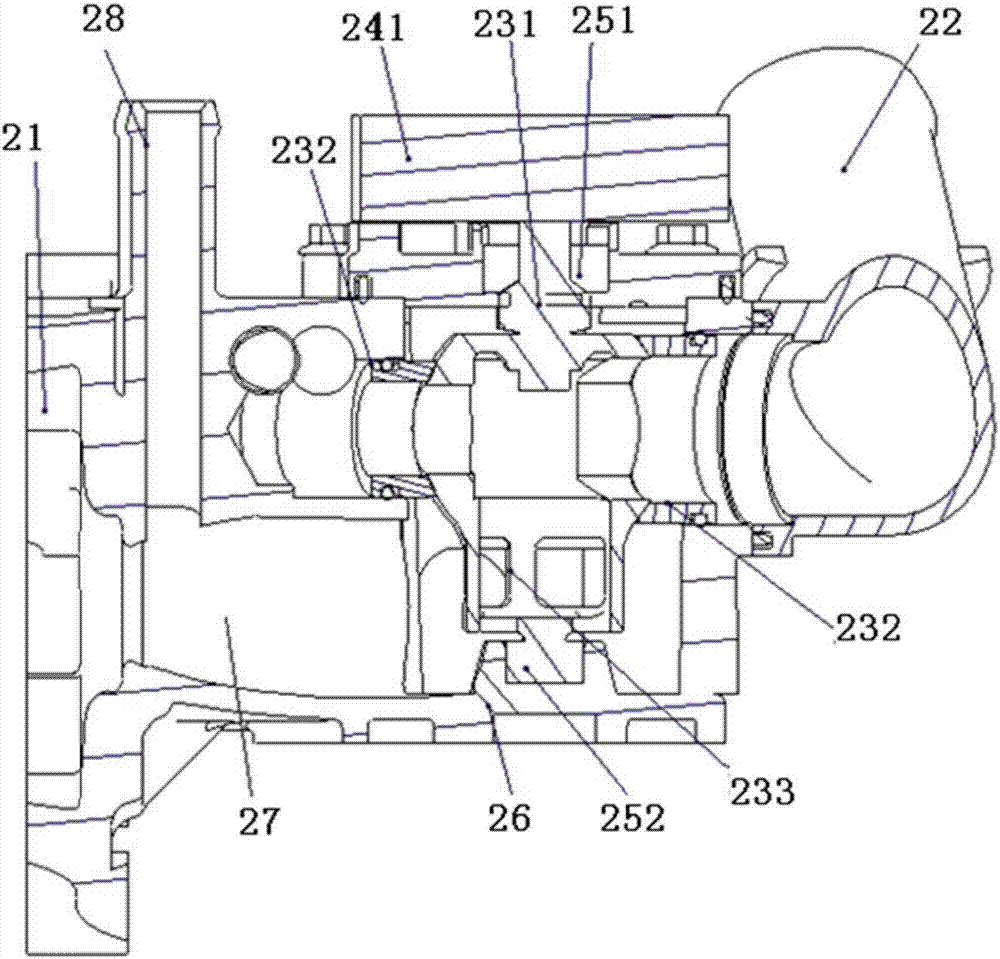

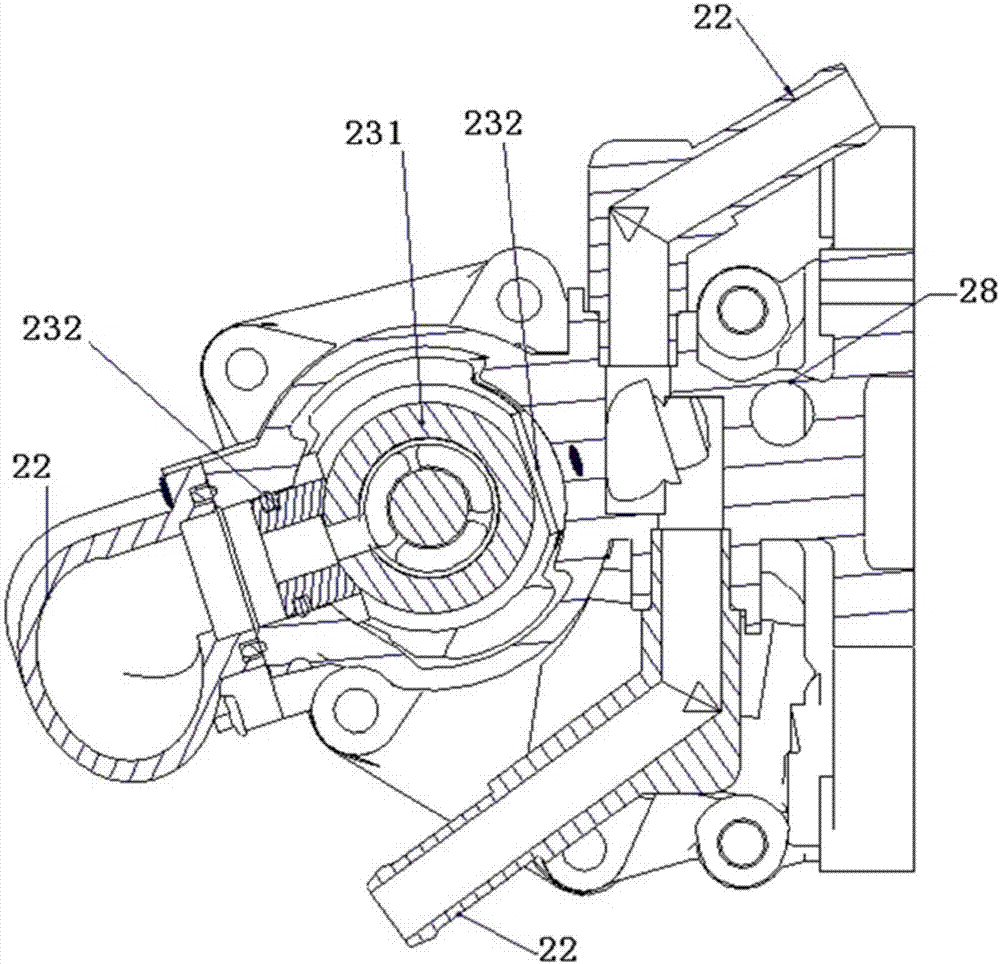

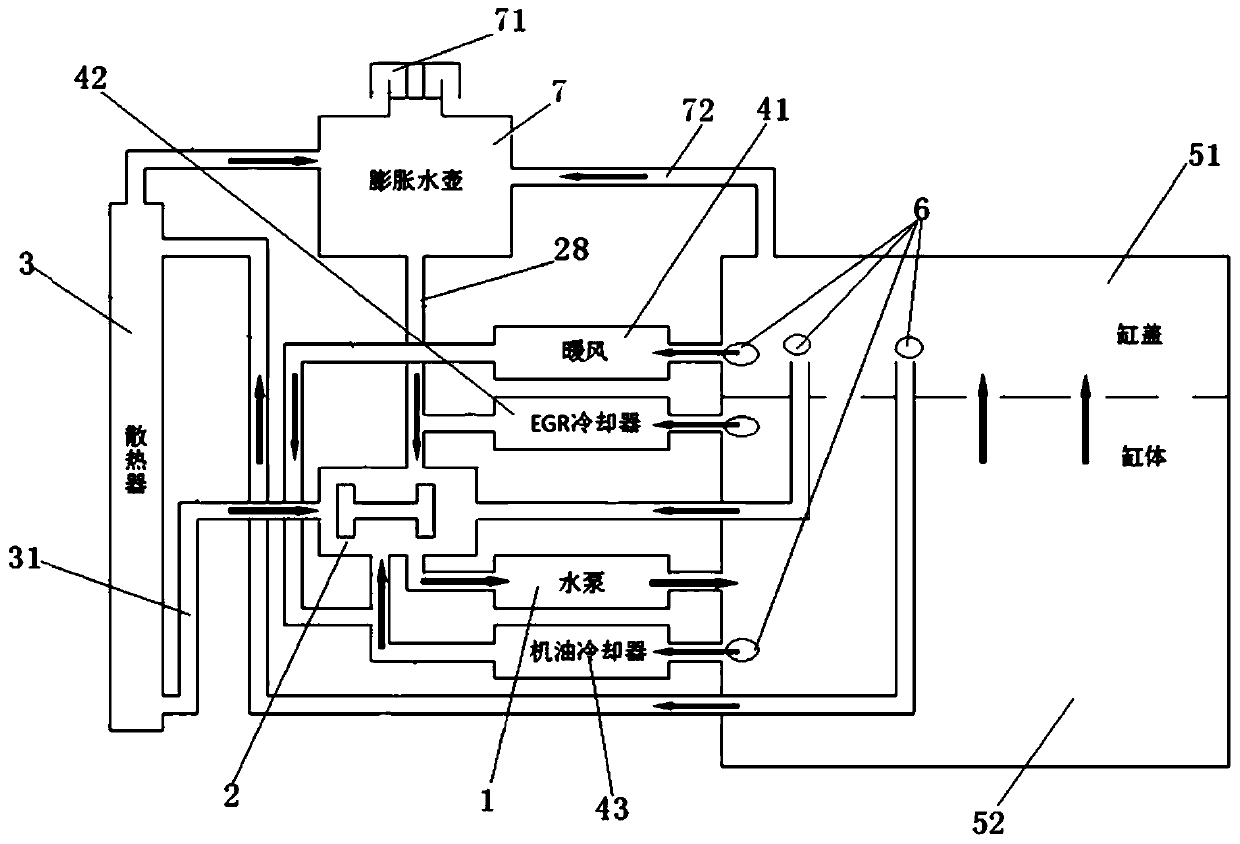

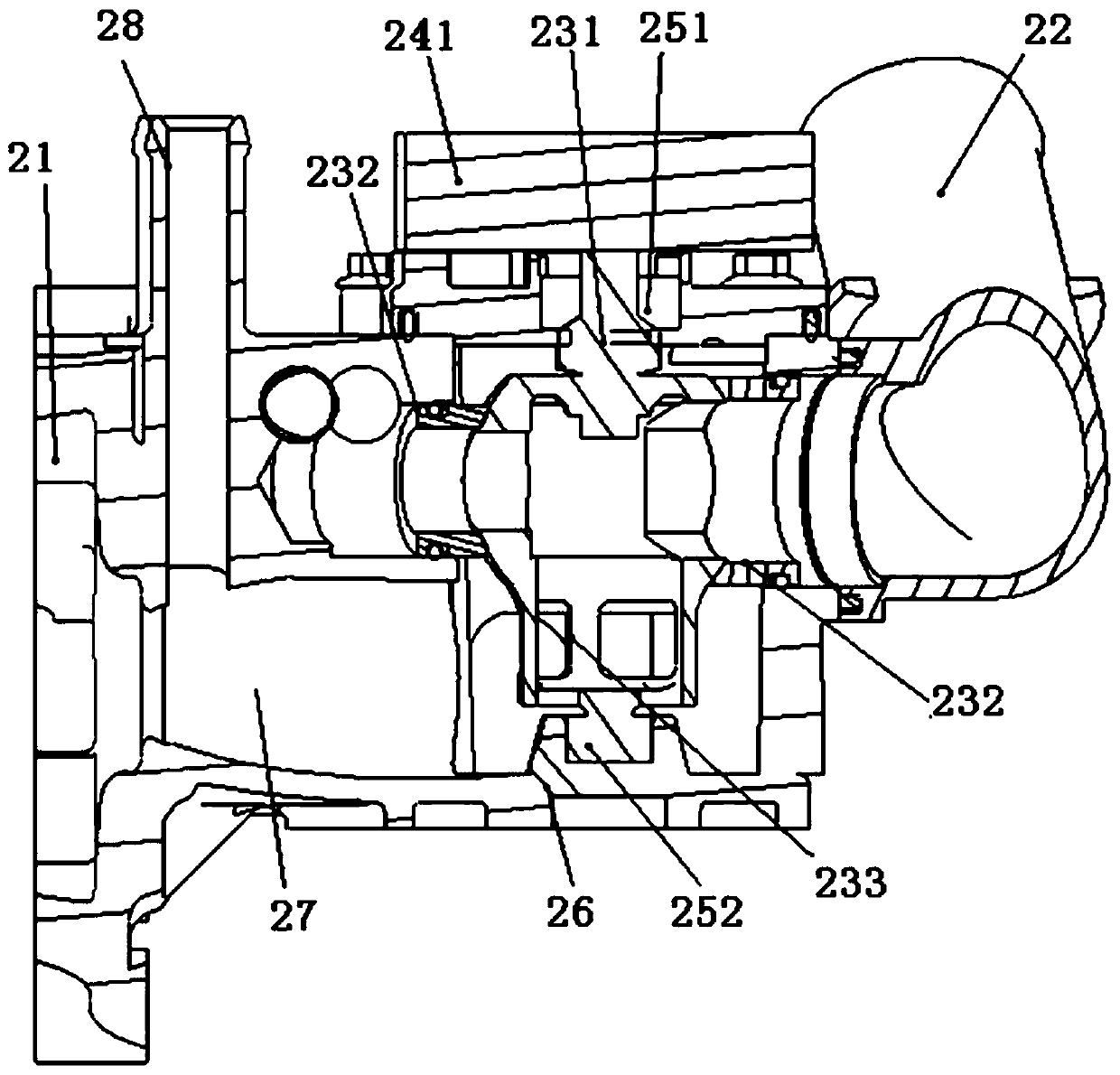

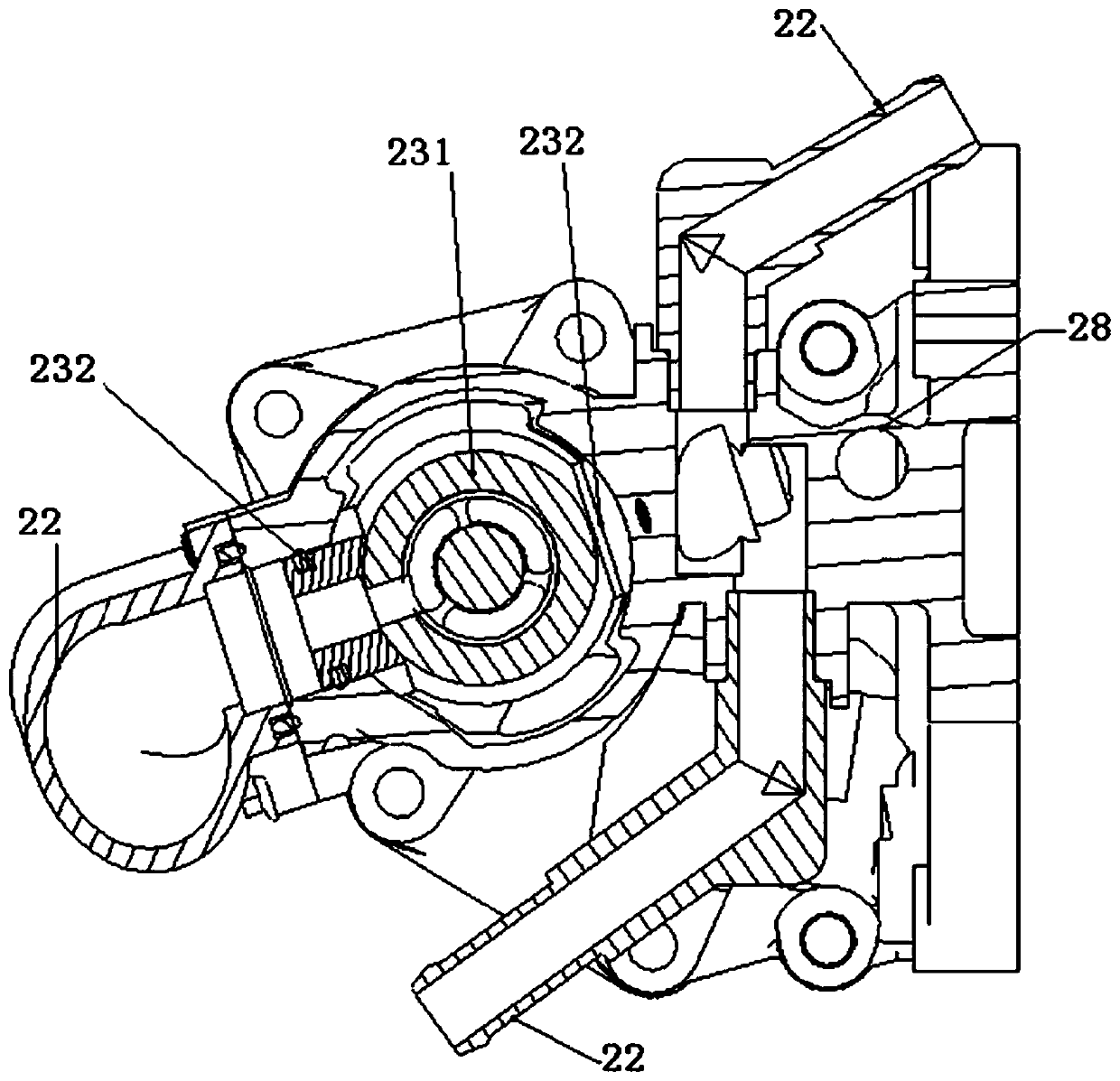

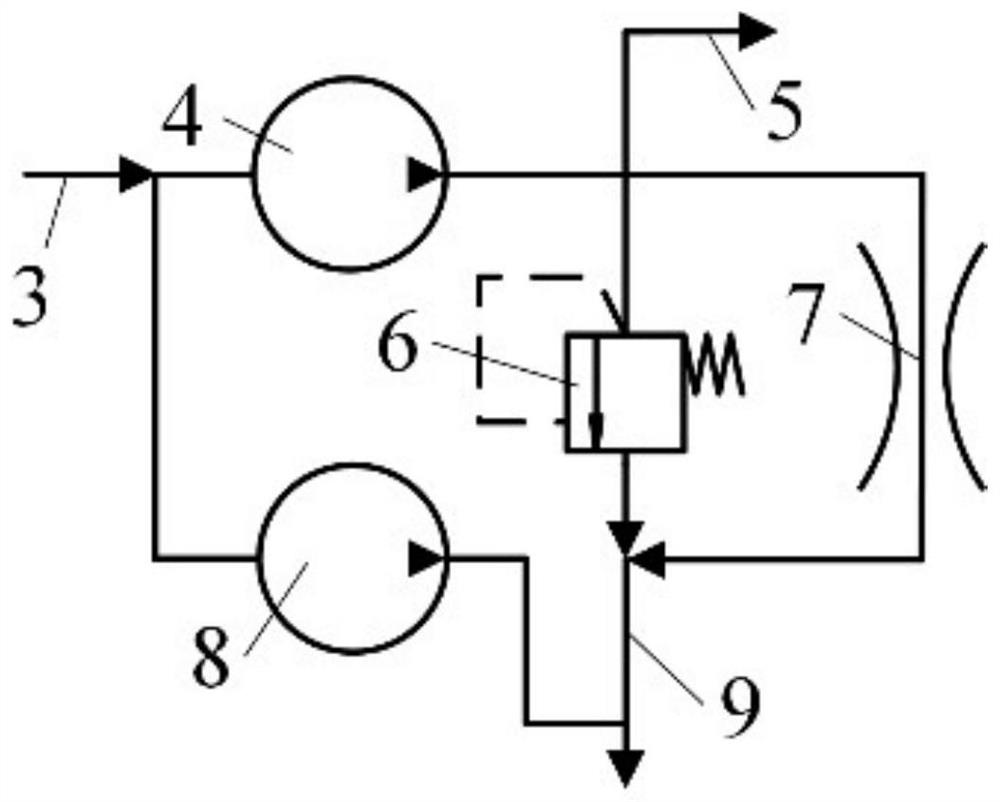

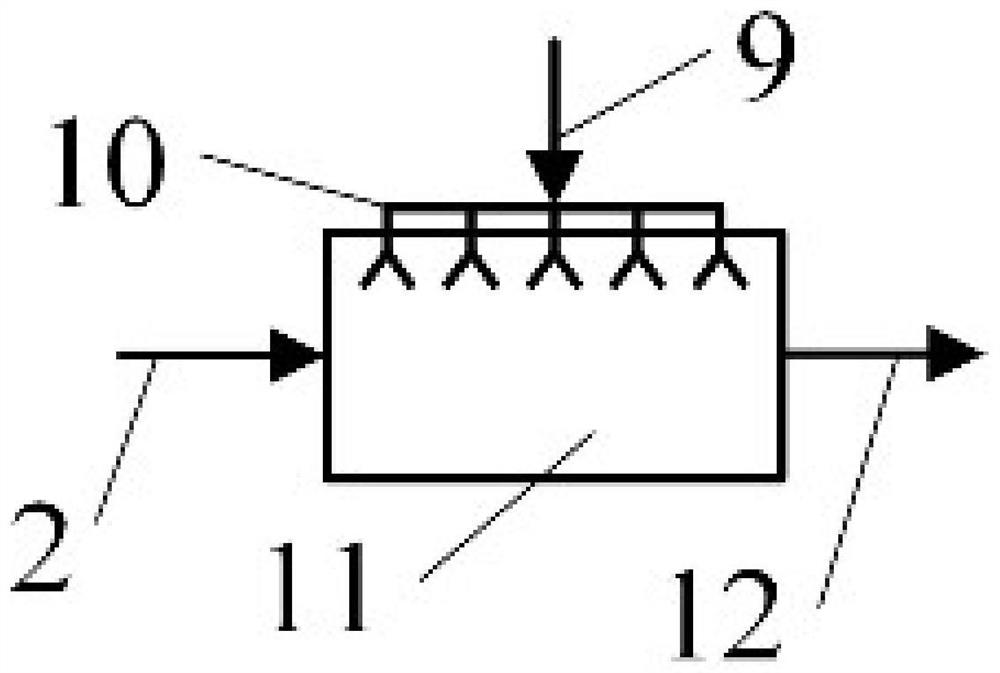

Vehicle cooling system

ActiveCN107165715AImprove boot performanceHigh trafficCoolant flow controlMachines/enginesWater flowEngineering

The invention discloses a vehicle cooling system which comprises a radiator, a cylinder body, a cylinder cover, a flow control structure, a heater water return pipeline, an oil cooler water return pipeline, a cooler water return pipeline and a water pump. The flow control structure comprises a water temperature sensor, a control structure body and a main valve structure. According to the vehicle cooling system, the water temperature sensor sends water temperature signals of the heater water return pipeline, the oil cooler water return pipeline, the cooler water return pipeline and a water inlet pipeline of the radiator to the control structure body in time, and according to the water temperature signals, the control structure body flexibly controls the main valve structure to open or close all the pipelines, so that the situation that water flow branch flows in all the pipelines are flexibly controlled is realized, overall on-demand deployment is realized, and unnecessary energy consumption losses are avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

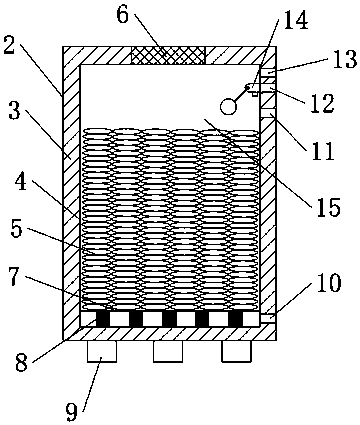

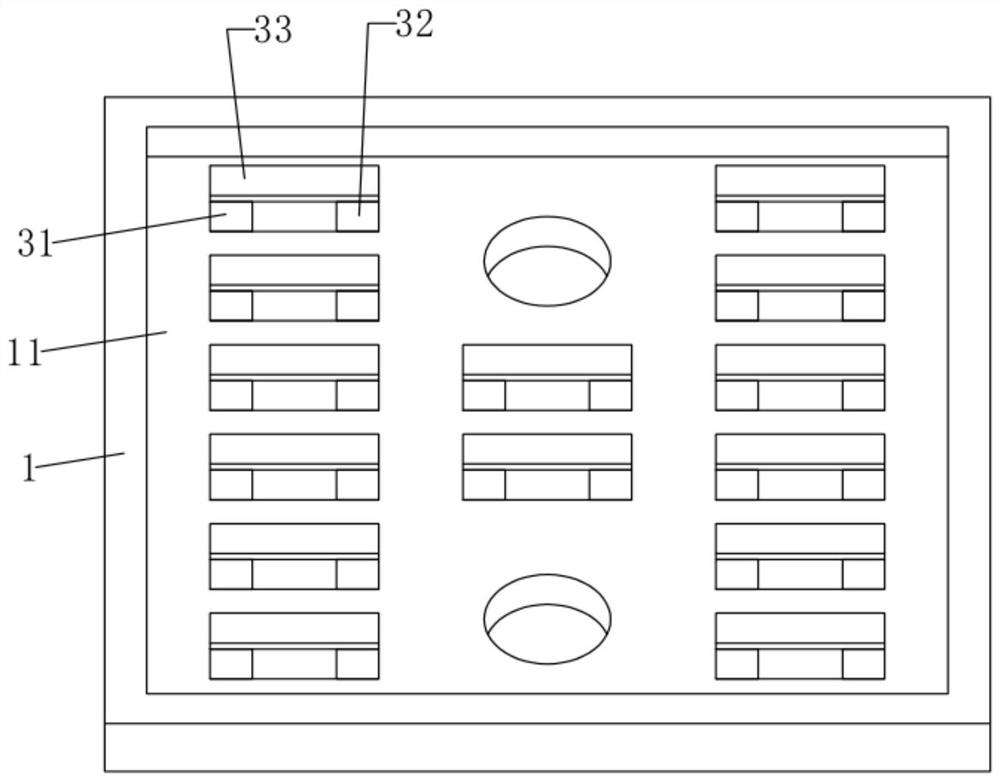

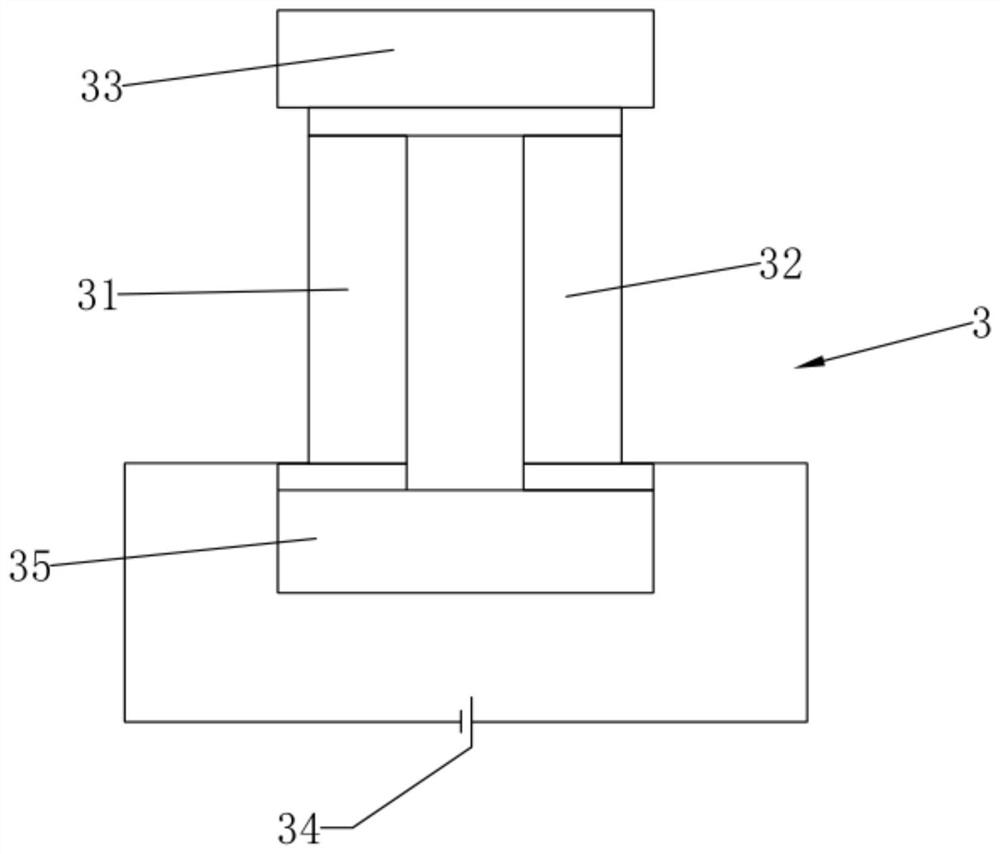

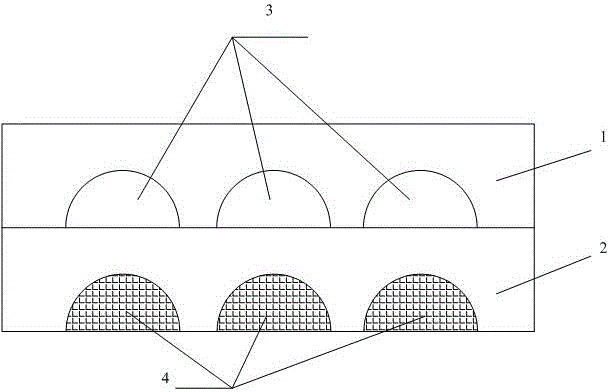

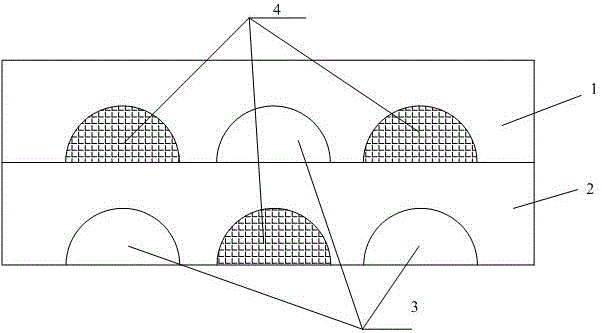

Phase-change energy storage device and system

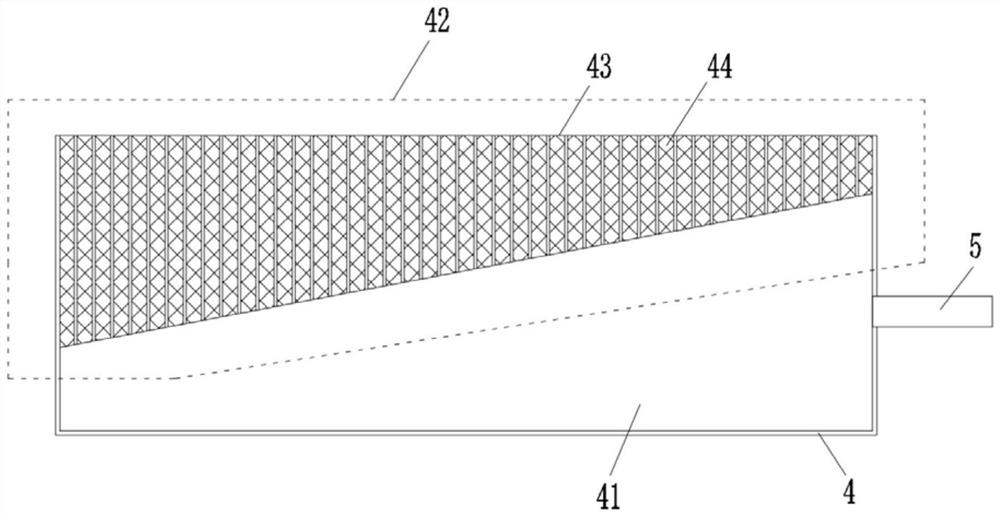

InactiveCN109297336AIncrease contact areaGood dimensional stabilityHeat storage plantsAir conditioning systemsPhase changePhase-change material

The invention discloses a phase change energy storage device and system. The phase change energy storage device comprises a shell, an inner container, a plurality of phase-change energy storage elements, a circulating medium inlet, a circulating medium outlet and circulation medium, wherein an inner container used for containing the phase-change energy storage elements is arranged in the shell, acirculating medium inlet and a circulating medium outlet are formed in the side surface of the inner container, the circulating medium is filled in the inner container, and the phase-change energy storage elements comprises a phase-change material and a plastic package body used for containing the phase-change material. The phase-change energy storage device solves the problem of leakage of the phase-change material from the phase-change energy storage elements, so that the energy is rapidly stored and released, the heat exchange power is large, is safe and reliable, and can continuously and stably output energy.

Owner:谦茂节能科技(上海)有限公司

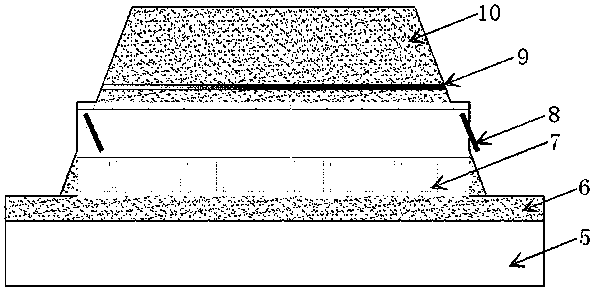

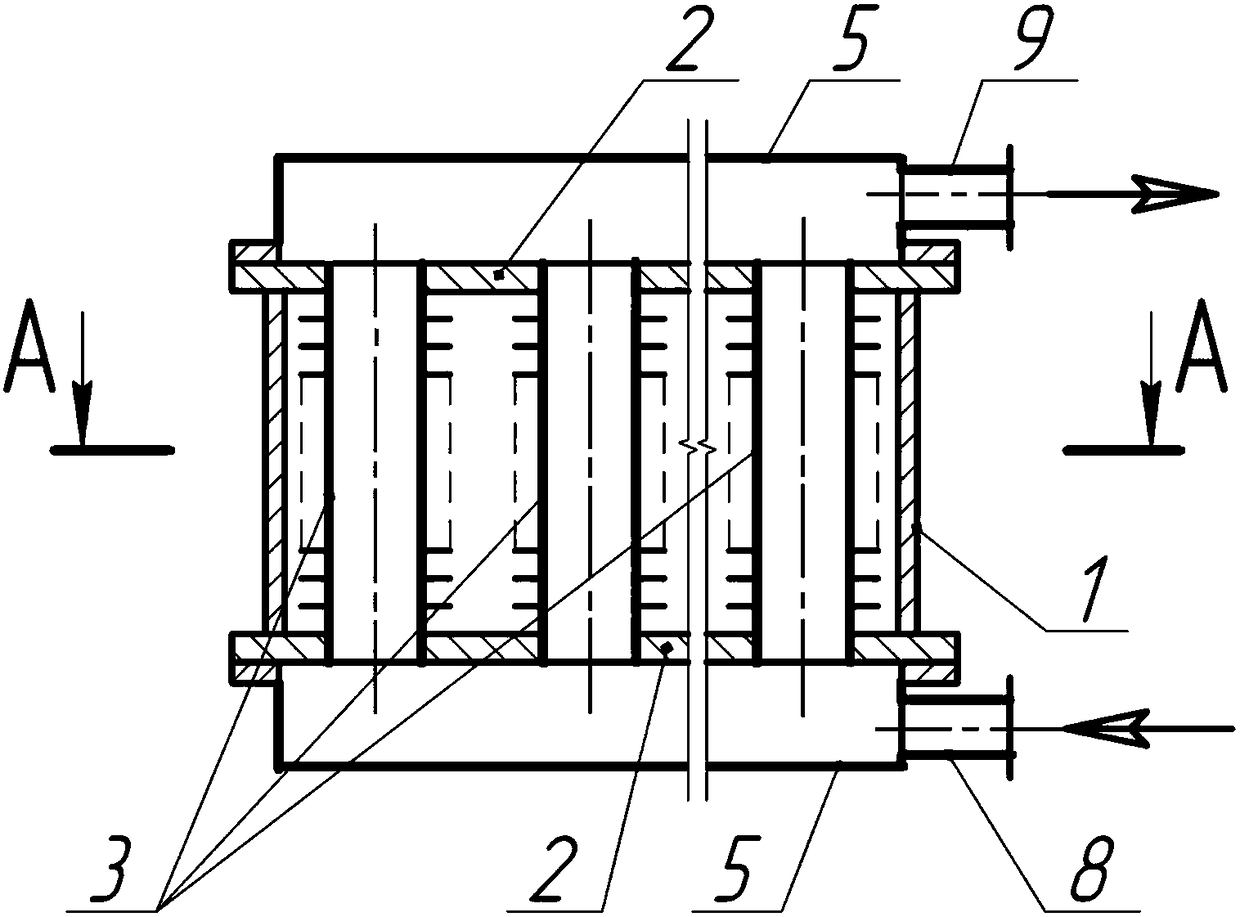

Engine exhaust cooler

InactiveCN105971695AEnsure normal flowConsistent heat transfer coefficientExhaust apparatusSilencing apparatusCooling effectEngineering

The invention discloses an engine exhaust cooler which comprises a shell (1), wherein the shell (1) is internally provided with a fume runner and a coolant runner which intersect with each other; the fume runner comprises guide plates (10); the coolant runner comprises finned tubes (3); the guide plates (10) are internally provided with the finned tubes (3); the finned tubes (3) and the guide plates (10) are correspondingly arranged so as to achieve an optimal cooling effect.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

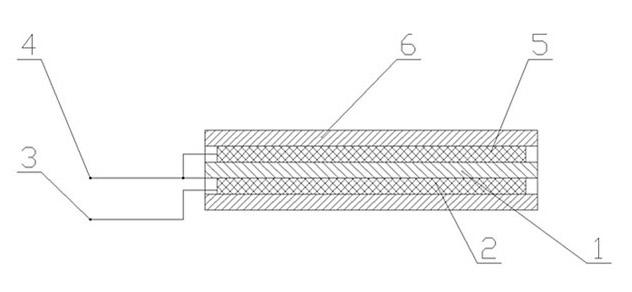

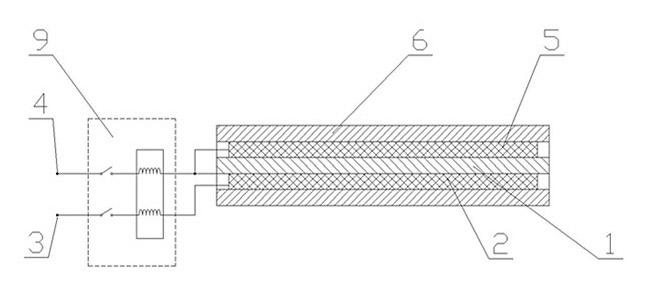

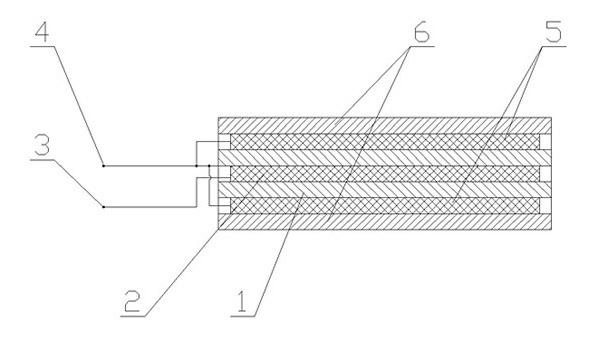

Electric heating film having anti-leakage function

InactiveCN102164428AProblems affecting normal workCause radiationOhmic-resistance heating detailsInsulation layerDrain current

The invention discloses an electric heating film having an anti-leakage function, which comprises upper and lower two layers of insulation films, wherein a conductive heating layer is clamped between the two layers of insulation films; the conductive heating layer is connected to a power line electrode and a null line electrode; second conductive layers connected to the null line electrode are covered outside of the insulation films; and second insulation layers are covered outside of the second conductive layers. A loop can be formed between the generated leaked current and the null line electrode, namely the leaked current can be utilized for generating heat, thereby increasing the heat conversion power and saving electric energy as well as avoiding the problem of influence on the normal work of the electric heating film caused by frequently driving a leakage protector to act by the leaked current. The electric heating film can be assembled according to an assembling operation specification for the electric heating film and the potential safety hazard caused by the leakage of the conductive layers can be eliminated, thereby increasing the assembling efficiency in unit area and improving the warming effect.

Owner:DALIAN FUTE TECH DEV

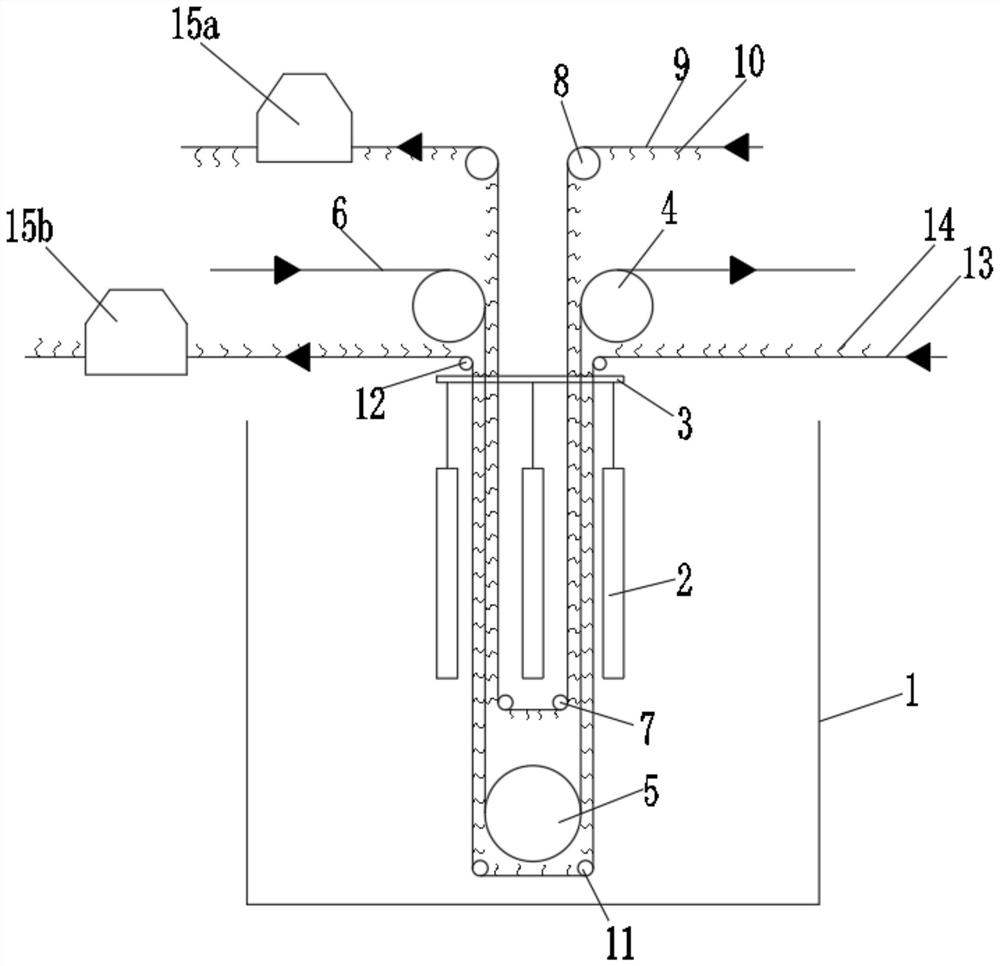

Corrosion device for improving corrosion performance of corrosive aluminum foil

ActiveCN112941612AIncrease specific volumeImprove continuityElectrolysis componentsAluminum foilAdsorption effect

The invention relates to the technical field of corrosive aluminum foil processing, in particular to a corrosion device for improving the corrosion performance of a corrosive aluminum foil. The corrosion device for improving the corrosion performance of the corrosive aluminum foil comprises a corrosion tank and the aluminum foil, wherein hydrogen collecting belts are arranged on the inner side and the outer side of the aluminum foil respectively, and metal palladium wires or metal platinum wires are arranged on the hydrogen collecting belts respectively. For the corrosion device disclosed by the invention, hydrogen on the surface of the aluminum foil and in corrosion holes is taken away through the adsorption effect of the metal palladium wires or the metal platinum wires on the hydrogen, and then the metal palladium wires or the metal platinum wires are heated to a certain degree, so that the hydrogen is separated from the metal palladium wires or the metal platinum wires and then is recycled.

Owner:JIANGXI WANNIAN QUNXING ELECTRONICS

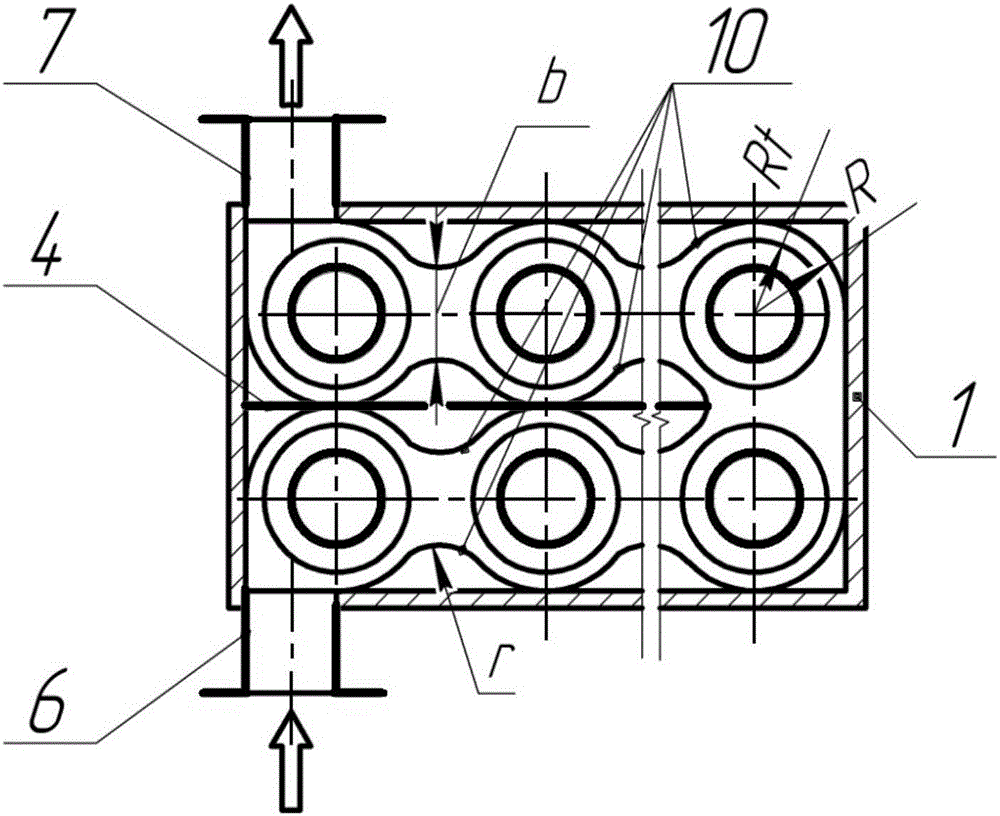

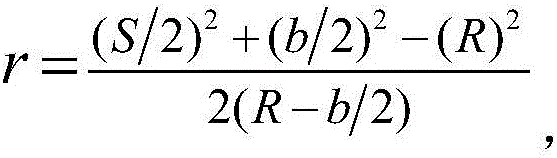

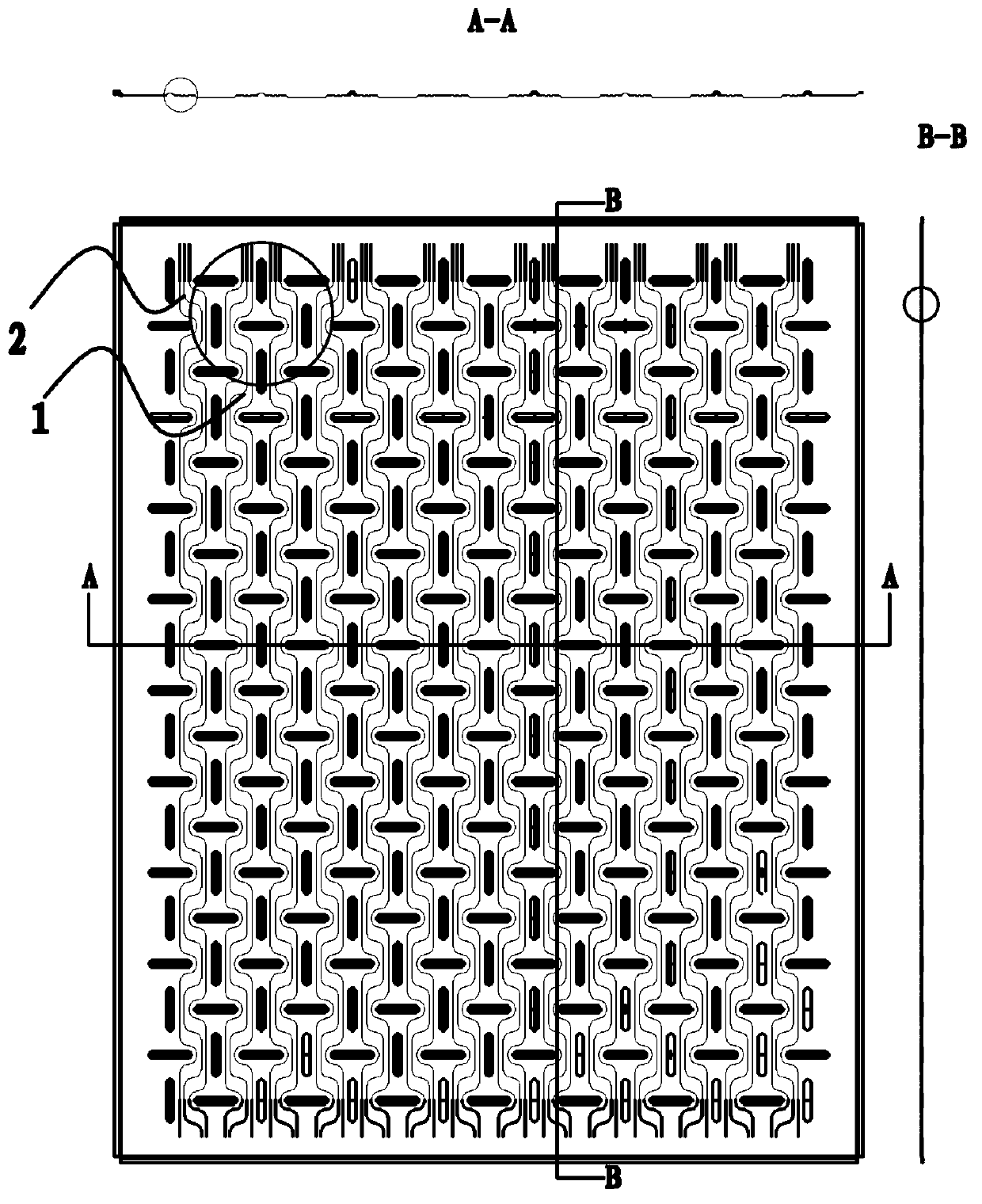

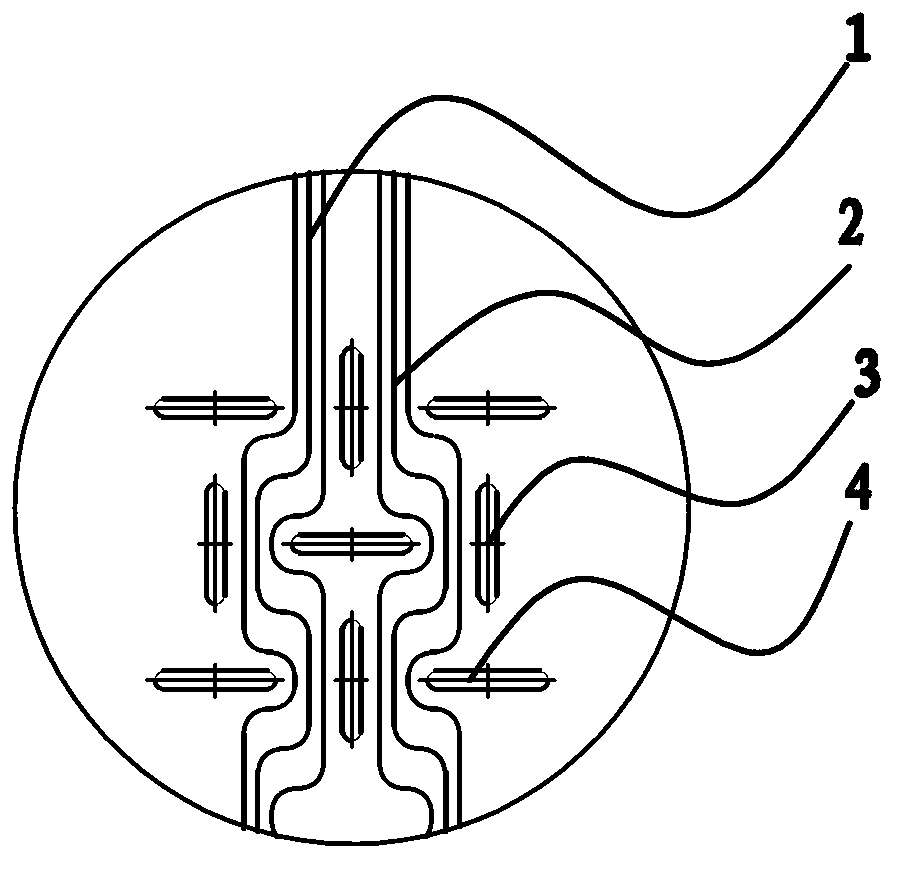

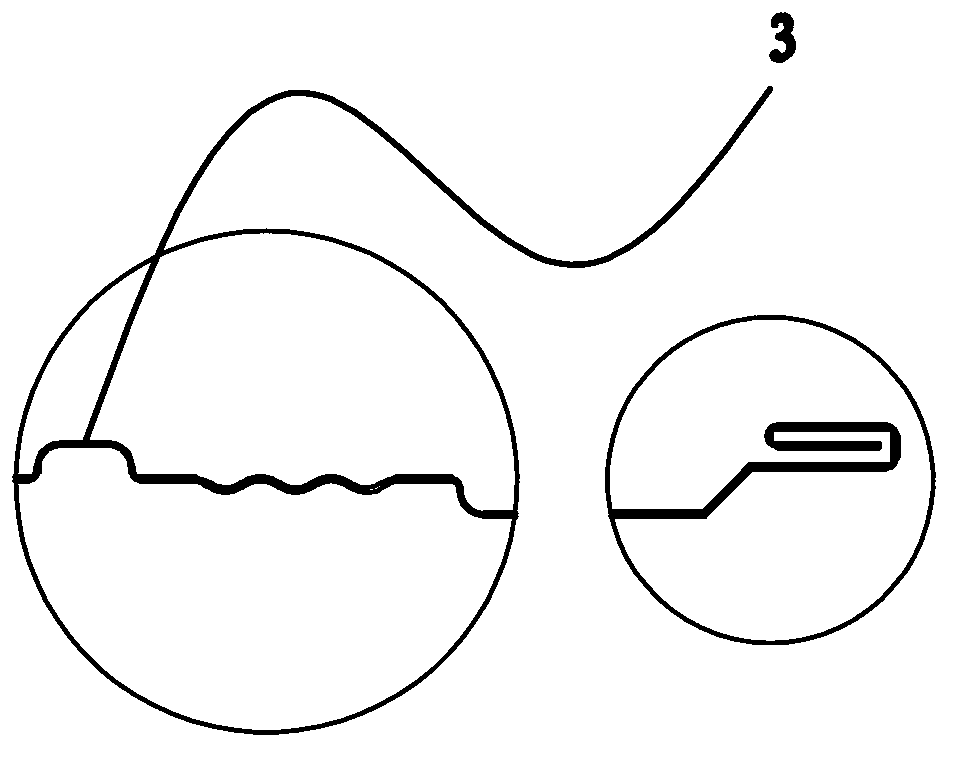

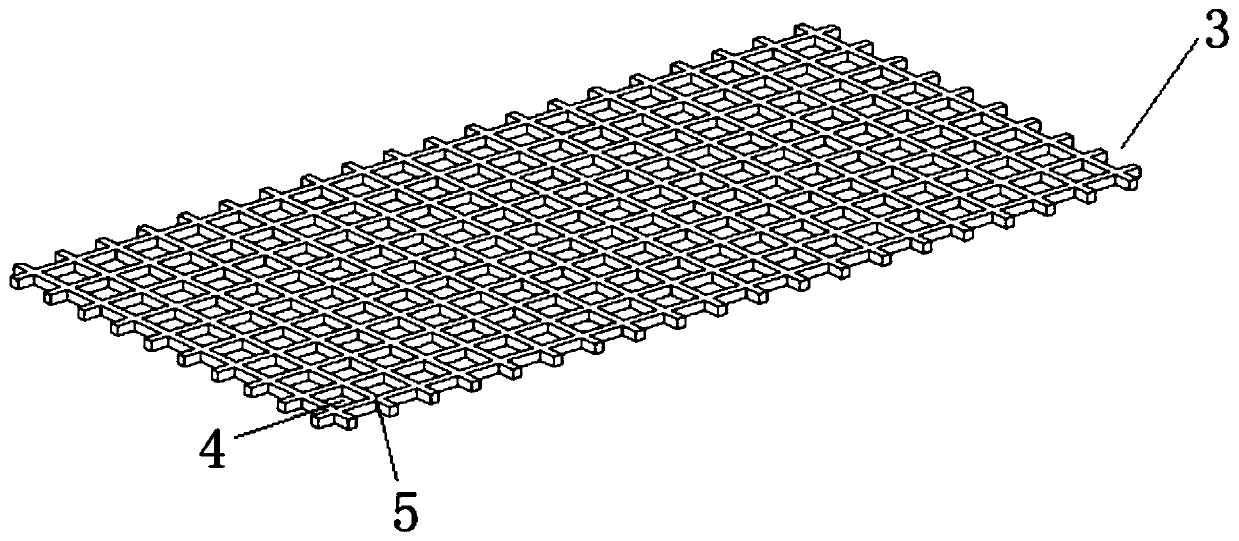

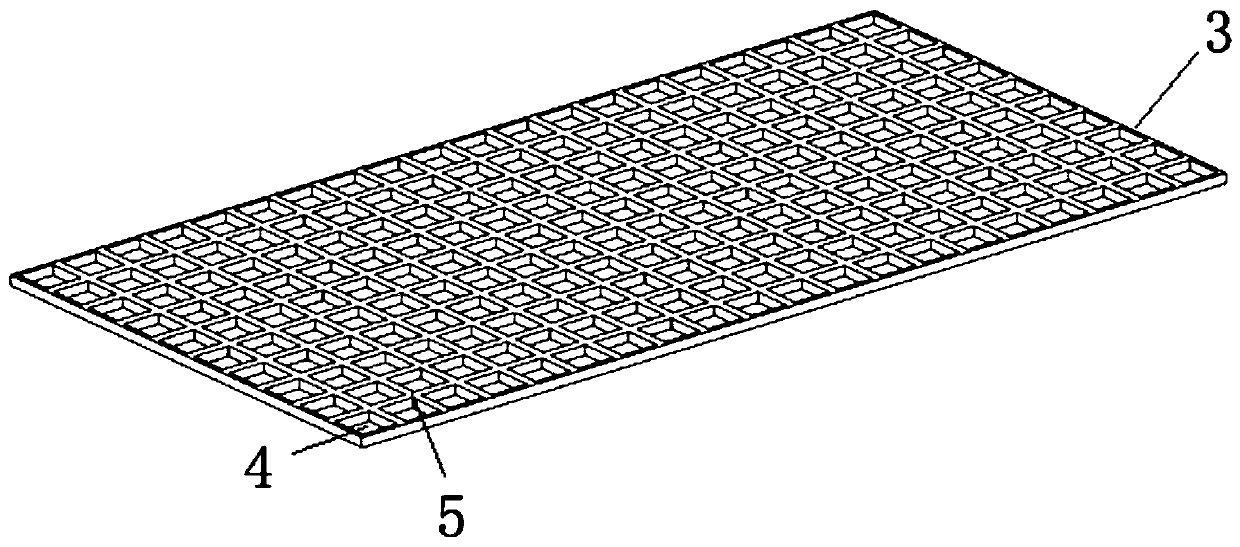

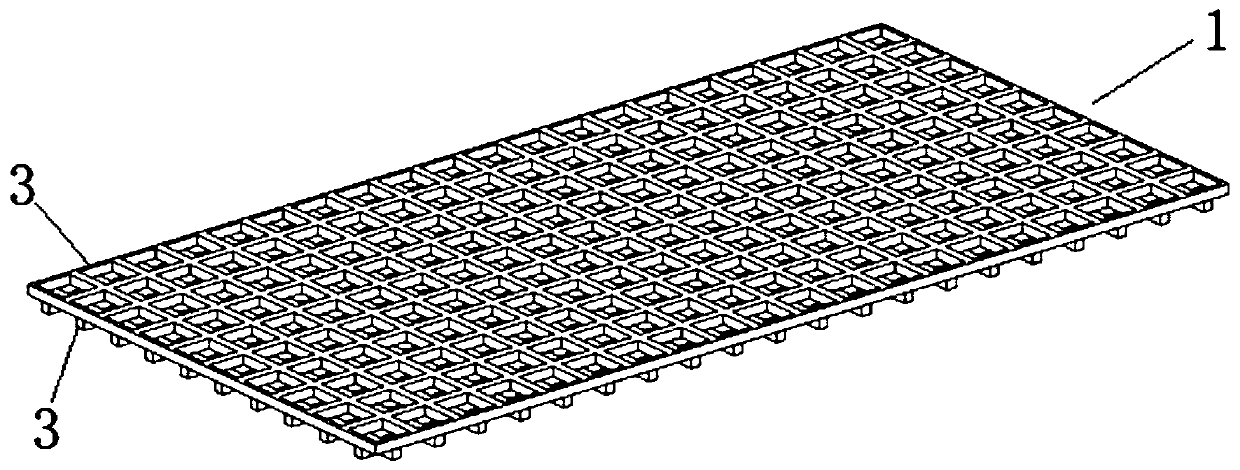

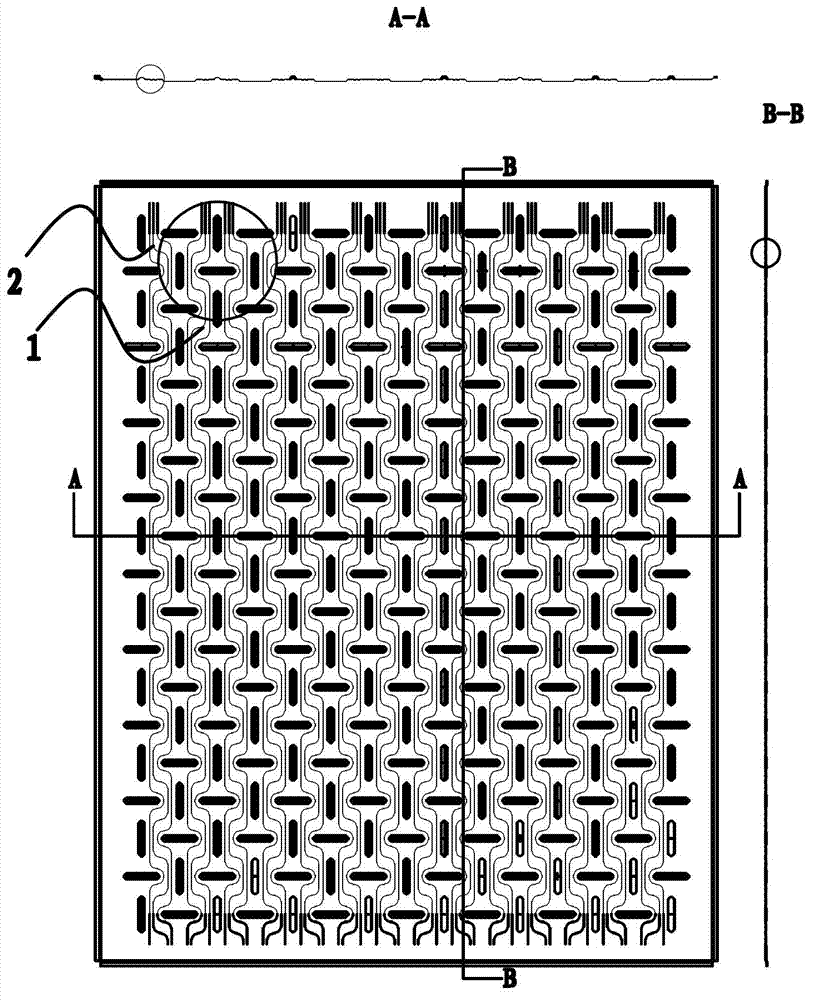

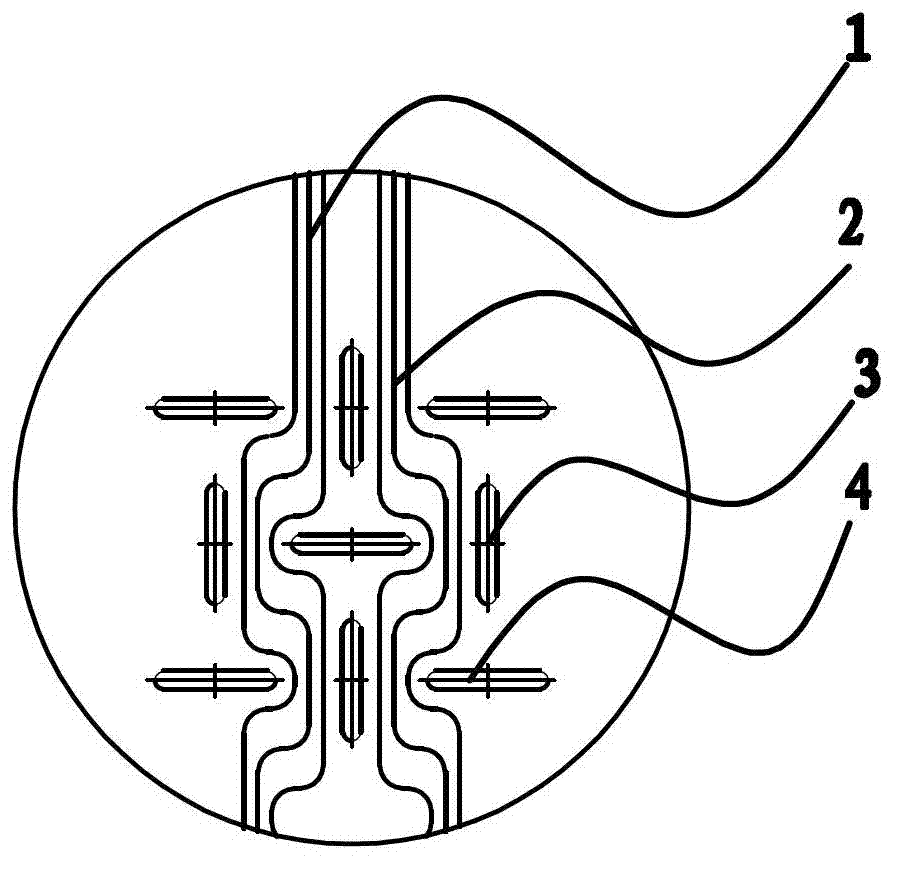

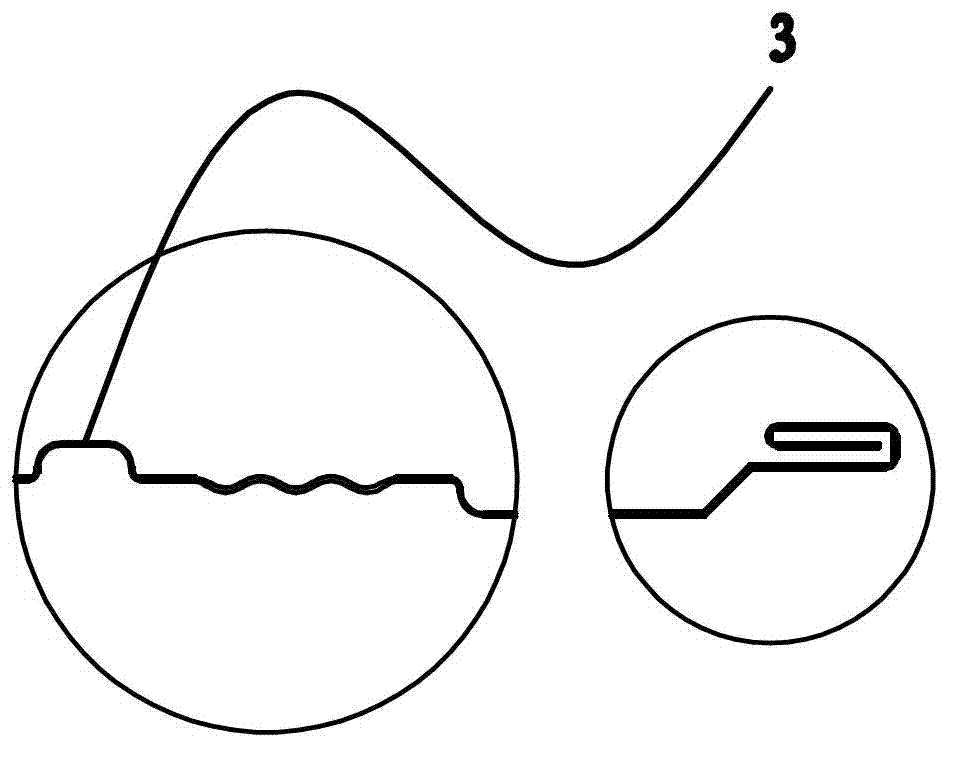

Heat exchange plate

ActiveCN103278035AImprove structural strengthImprove structural rigidityLaminated elementsEngineering

Owner:ZHEJIANG ERG TECH

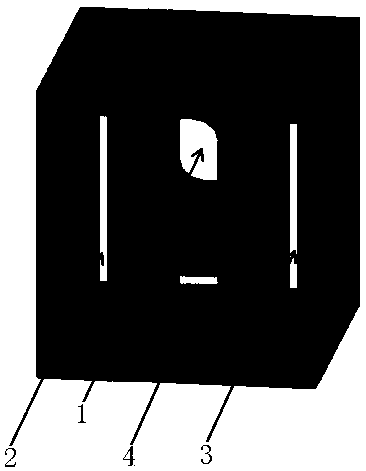

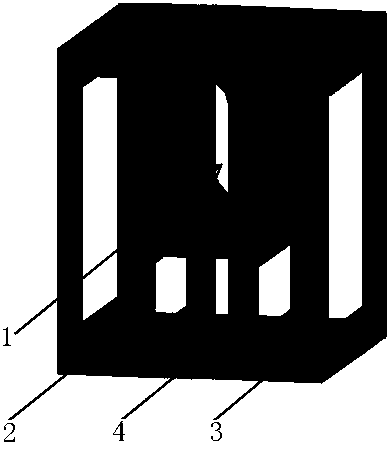

Prefabricated block for frozen soil roadbed temperature reduction and frozen soil roadbed composite structure

ActiveCN109505208ASolve the key problems of control measuresSolve the problem that is difficult to combine stablyRoadwaysClimate change adaptationControl layerNatural convection

The invention relates to a prefabricated block for frozen soil roadbed temperature reduction and a frozen soil roadbed composite structure. The prefabricated block is of an integral structure, and comprises a ventilation passage (1) positioned at the upper part or the middle upper part and three convection heat exchange spaces respectively positioned at left and right lower sides and lower side ofthe ventilation passage (1). The prefabricated block uses the integral design; a plurality of prefabricated blocks are sequentially spliced; then, an integral ventilation passage of an embankment temperature regulation and control layer and an integral convection heat exchange space are formed by one step; convenience and high speed are realized; meanwhile, through the integral combination of theventilation passage and the convection heat exchange spaces, the composite temperature lowering effect of the forced convection of the ventilation pipe and the natural convection of the convection heat exchange space is reinforced, so that the one-way heat conduction effect of the temperature regulation and control layer is achieved to the maximum degree; the power and the temperature lowering effect of the heat exchange layer are exponentially improved; the engineering regulation and control effects are obviously improved; the frozen soil roadbed stability is greatly improved; meanwhile, thedifficult problem of frozen soil highway building is predominantly solved; the long-time safety and stability of the frozen soil engineering are ensured.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

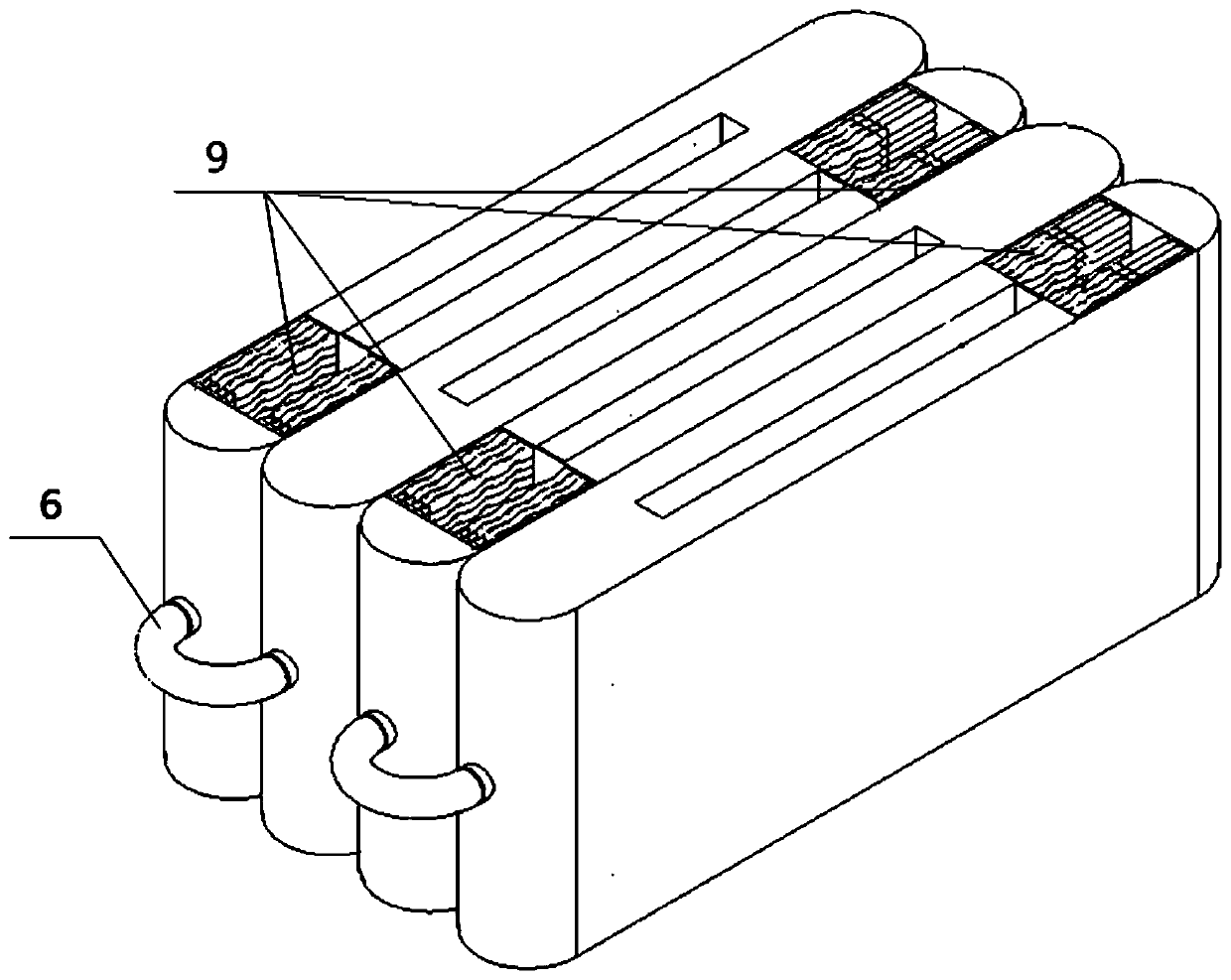

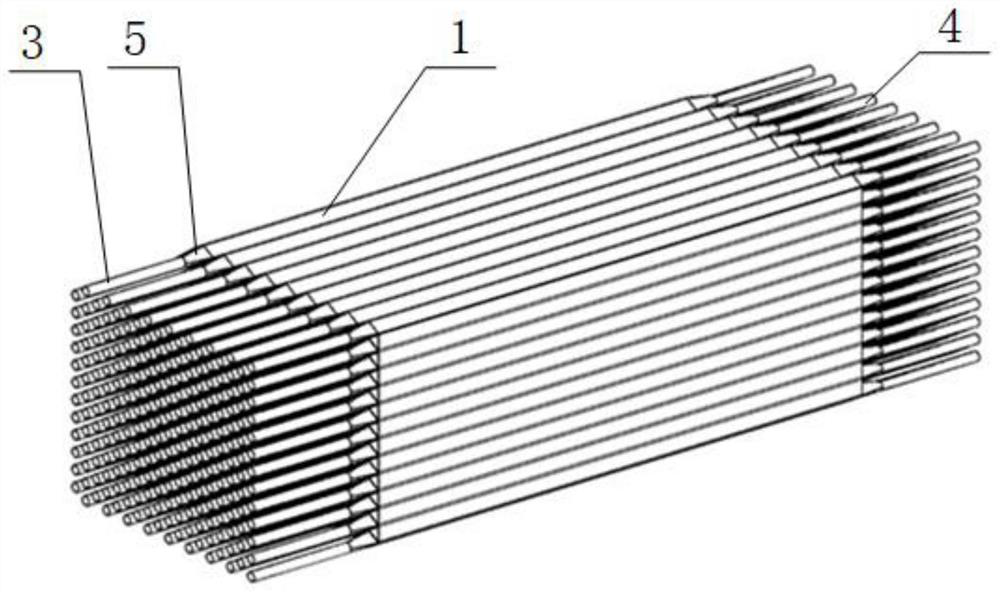

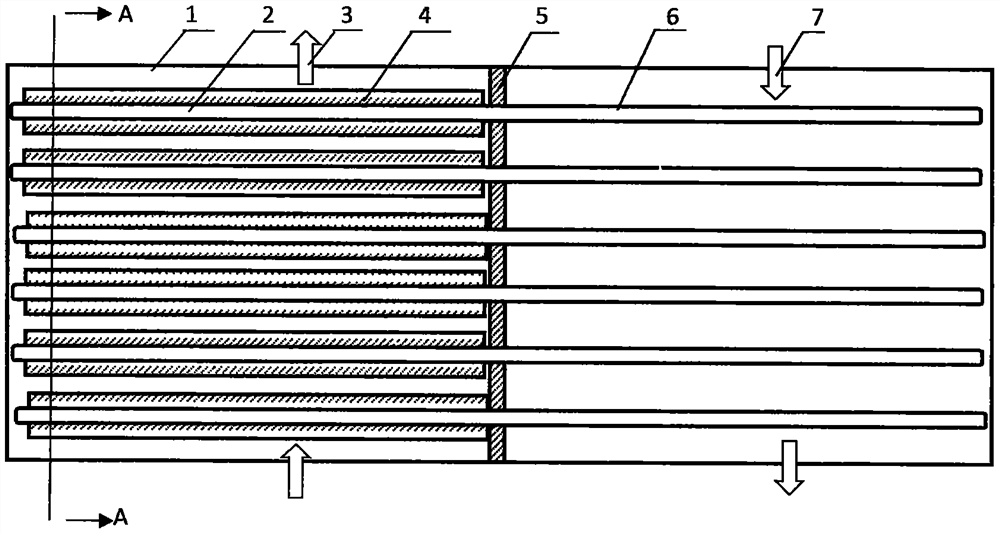

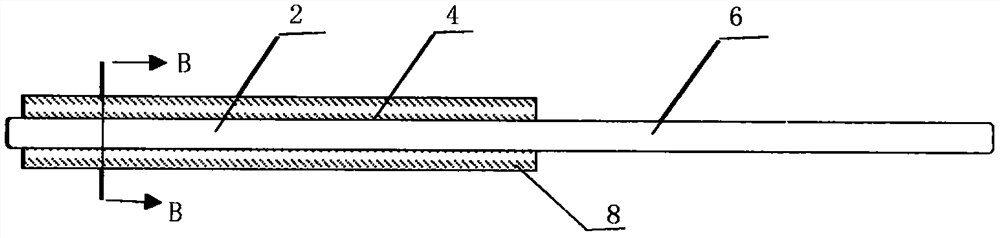

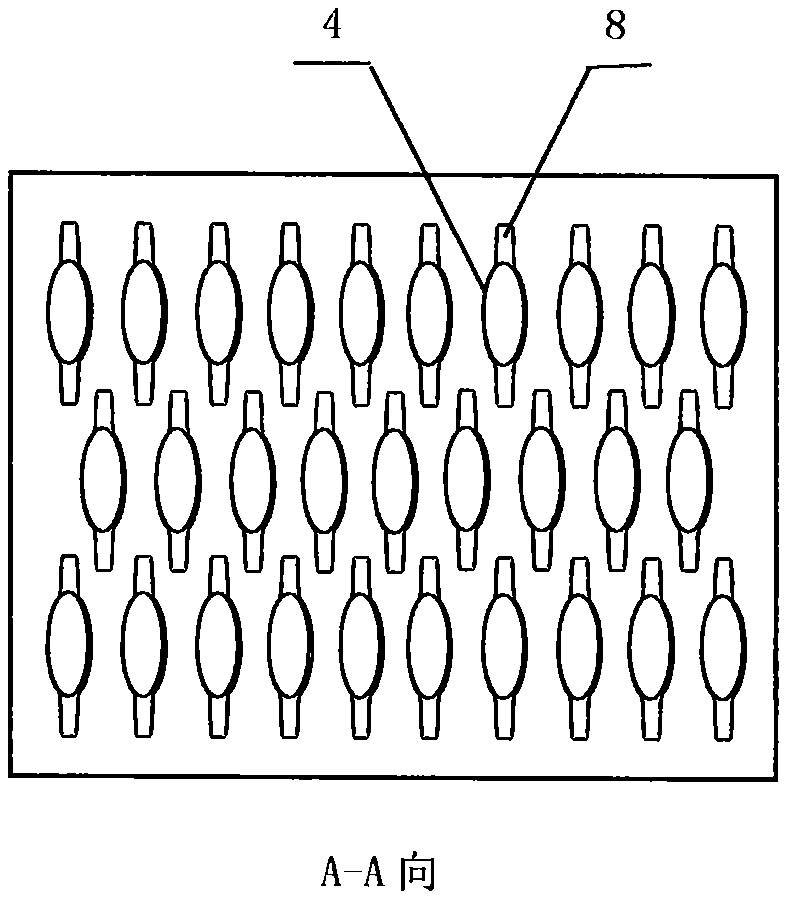

Modular efficient heat exchange structure

InactiveCN110906759AReduce the consumption of manpower and material resourcesReduce economic lossStationary conduit assembliesHeat exchanger casingsProcess engineeringMechanical engineering

The invention relates to a modular efficient heat exchange structure. The modular efficient heat exchange structure comprises a plurality of radiator modules; each radiator module comprises a pipe bundle formed by arranging a plurality of three-dimensional deformation pipes in parallel; a radiator shell covers the outer side of the pipe bundle; an inlet water pipe is arranged at one end of the radiator shell; an outlet water pipe is arranged at the other end of the radiator shell; a communicating elbow is detachably connected between the inlet water pipe and the outlet water pipe of the adjacent radiator modules; the inlet water pipe and the outlet water pipe are respectively communicated with two ends of the pipe bundle; an air inlet is formed in the upper end surface of one end, far awayfrom the inlet water pipe, of the radiator shell; an air outlet is formed in one end, close to the inlet water pipe, of the radiator shell; and a draught fan with an air opening facing vertically anddownwards is installed at the air inlet. With the above technical schemes adopted, corresponding economic losses are reduced; heat exchange under different power requirement can be realized; heat transfer temperature difference is effectively increased, so that the heat exchange power of the equipment is increased; and equipment manufacturing materials can be saved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

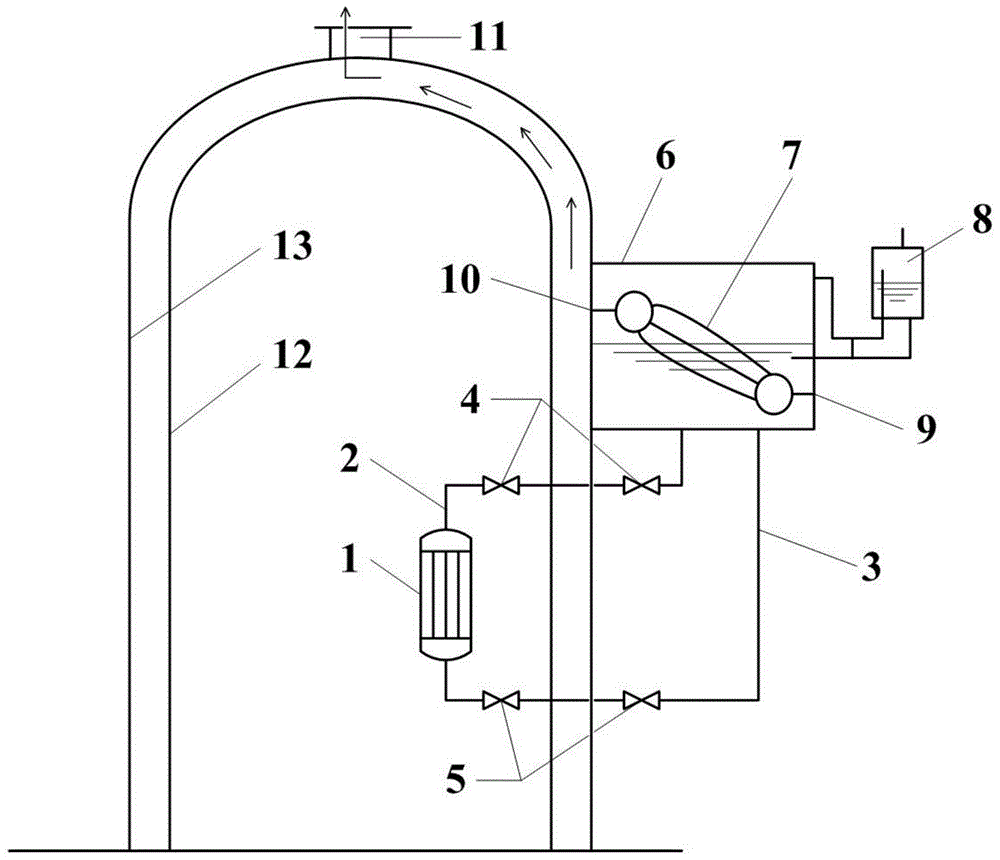

A long-term passive containment heat extraction system

ActiveCN104103325BIntegrity guaranteedIncrease heat transfer powerNuclear energy generationCooling arrangementIsolation valveEnhanced heat transfer

Owner:HARBIN ENG UNIV

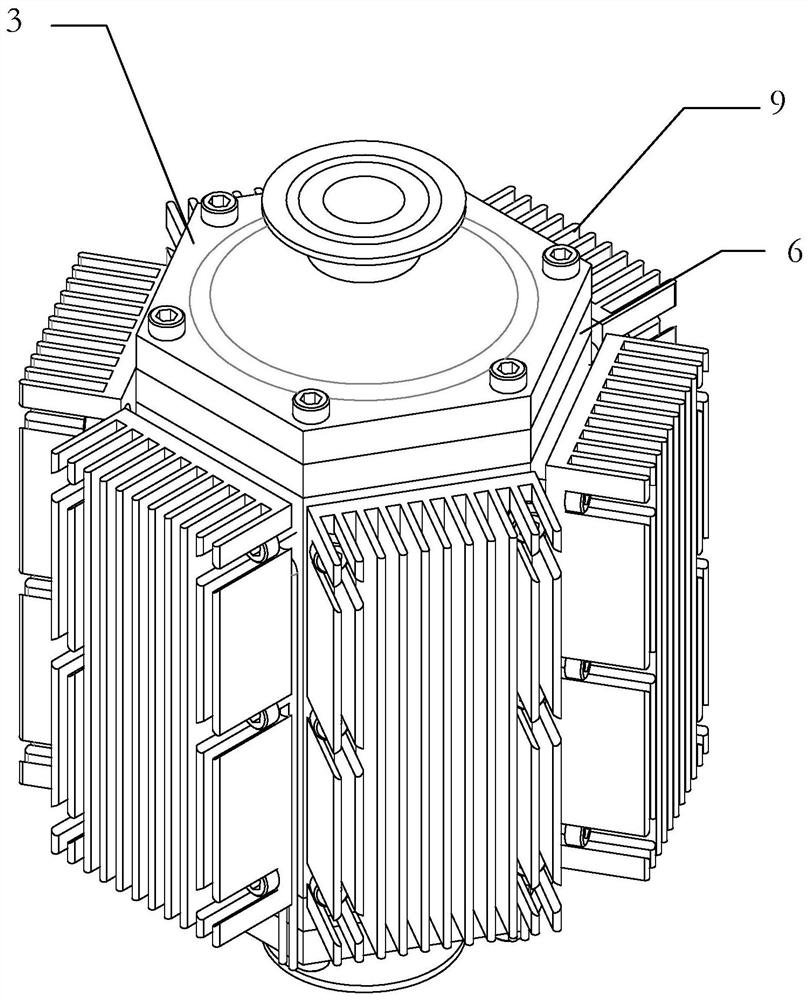

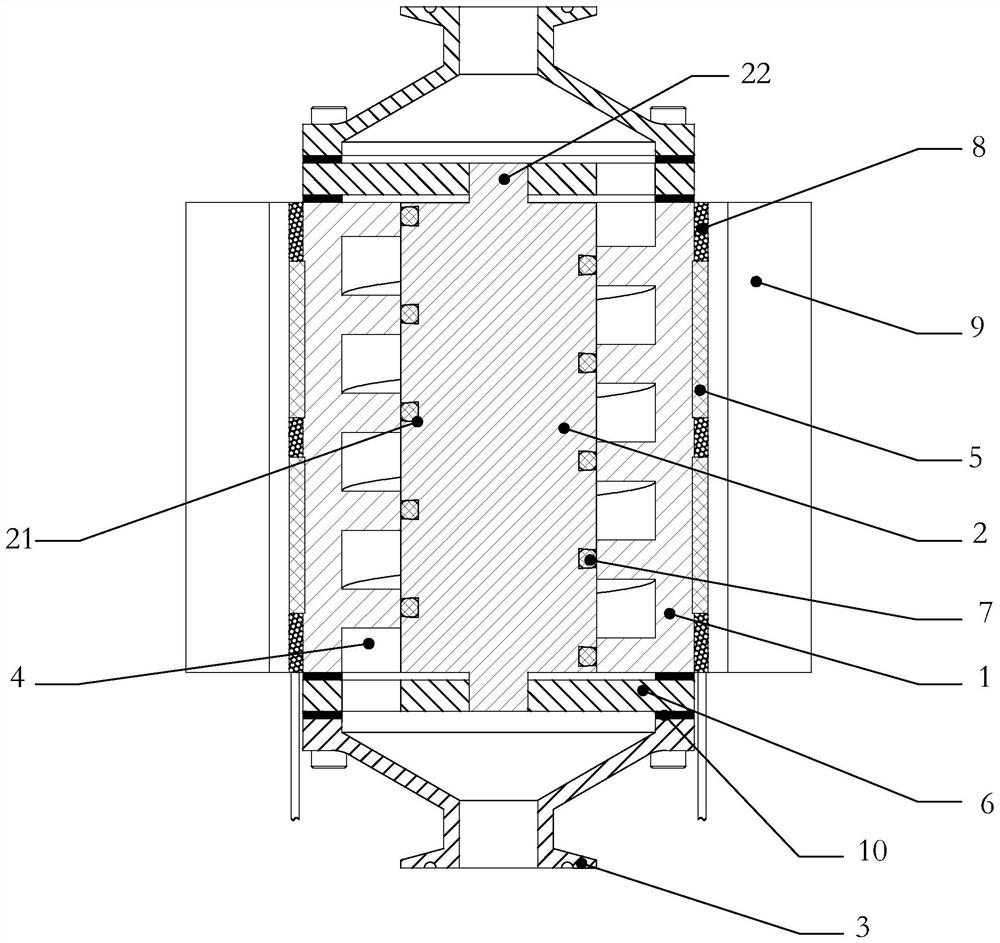

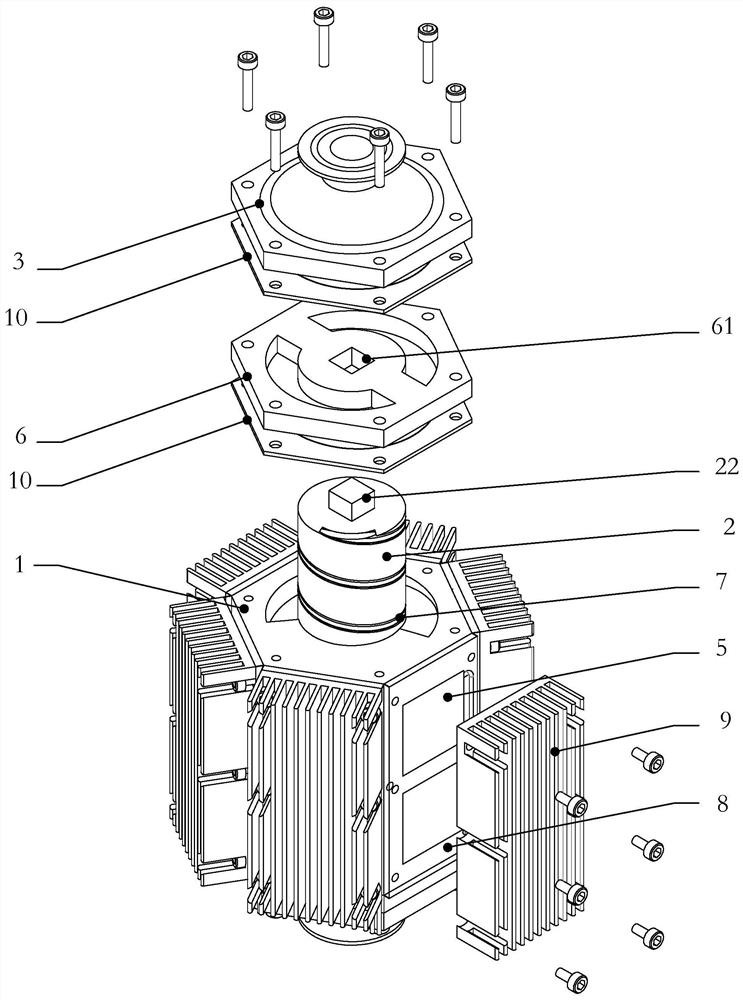

Polyhedral spiral channel heat exchanger for liquid refrigeration

ActiveCN112629064AReduce volumeIncrease energy exchange densityMachines using electric/magnetic effectsEnergy exchangeMechanical engineering

The invention discloses a polyhedral spiral channel heat exchanger for liquid refrigeration. The problems that a heat exchanger in the prior art is of a plate-type structure, large in size, small in heat energy exchange density and low in efficiency in the aspect of high-power refrigeration are solved. The polyhedral spiral channel heat exchanger for liquid refrigeration comprises a polyhedral cold block, a mandrel, connecting flanges and semiconductor chilling plates, wherein the polyhedral cold block is a prism with a polygonal section; an inner hole is formed in the axial direction of the center of the prism; a spiral groove for liquid to be refrigerated to circulate is formed in the wall of the inner hole; the connecting flanges are fixedly connected with two ends of the polyhedral cold block; the semiconductor chilling plates are installed on the side faces of the polyhedral cold block; the diameter of the mandrel is matched with the inner hole; and the mandrel is inserted into the inner hole to form a sealed spiral channel with the spiral groove. The polyhedral cold block is refrigerated together from all positions, so that the energy exchange density is improved, the size of the heat exchanger is reduced, and refrigeration is more uniform. Through the spiral channel, the flowing time of liquid is prolonged, and the heat exchange efficiency is improved.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

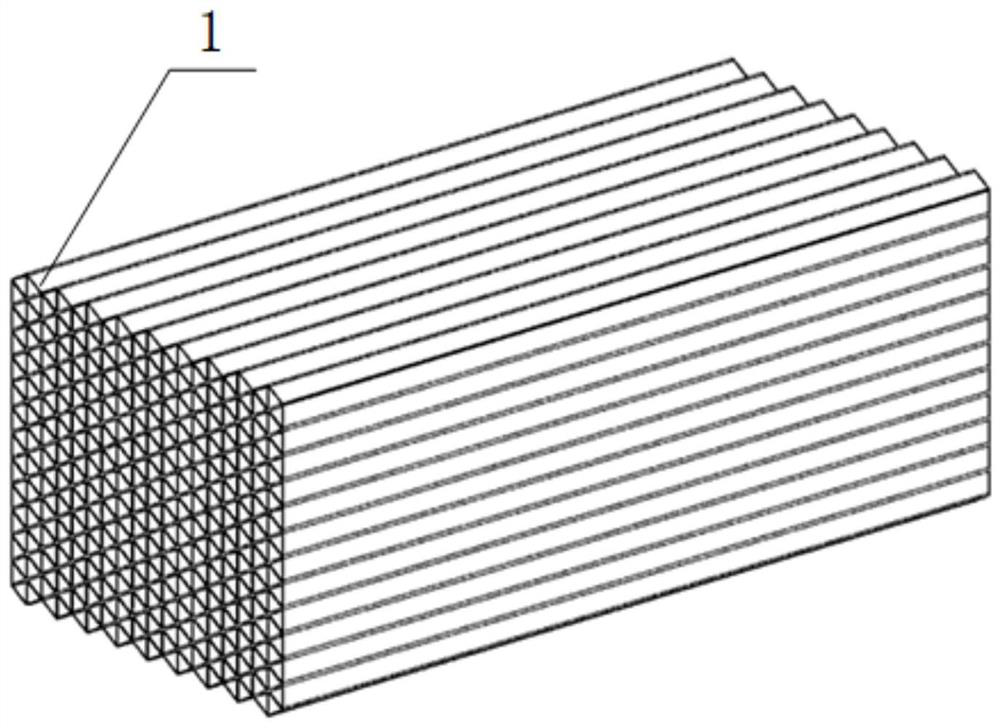

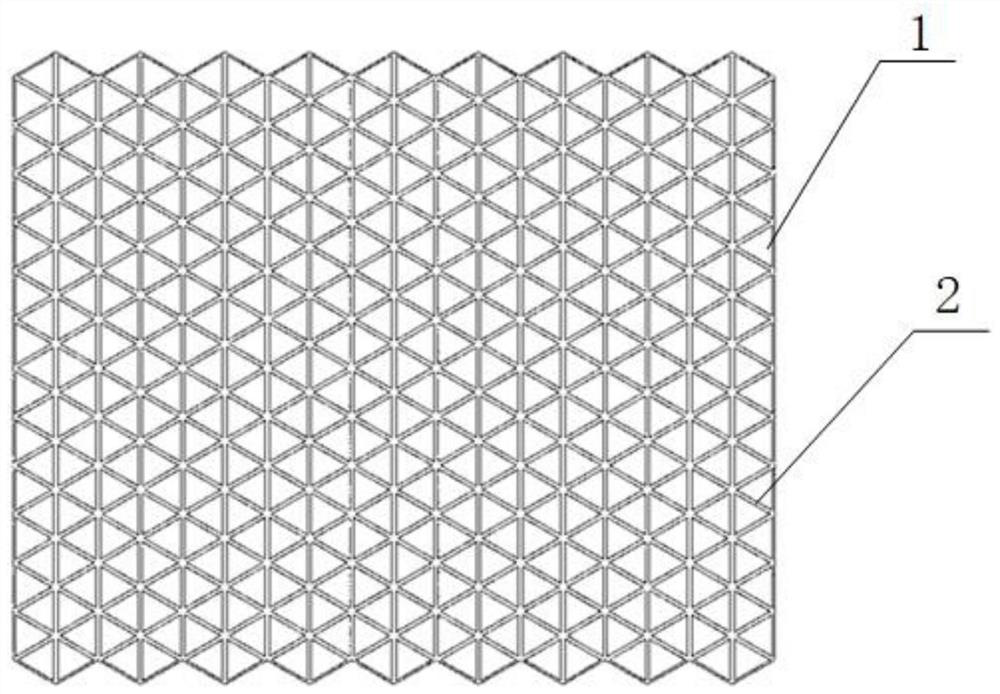

Bionic-based compact honeycomb structure heat exchanger core and heat exchanger

ActiveCN111207609BAdaptableMaximize heat transferStationary tubular conduit assembliesTubular elementsHoneycombEngineering

The invention discloses a bionic-based compact honeycomb structure heat exchanger core and a heat exchanger, comprising a plurality of radially spliced straight passages, a closed shell is arranged outside the straight passages, and adjacent straight passages are The cold medium and the hot medium with opposite flow directions are respectively introduced, and the straight passages are divided into the first group of straight passages and the second group of straight passages according to the different media, and the adjacent first group of straight passages and the second group of straight passages share a wall , the first group of straight passages communicates with the medium pipeline through the corresponding reducing adapter pipes, and the second group of straight passages communicates with the medium pipeline through the housing. The invention has strong adaptability to special-shaped structures, compact structure, and the heat exchange surfaces are all primary heat exchange surfaces, realizing countercurrent heat exchange, good heat exchange performance, high heat exchange per unit weight, and high compressive strength.

Owner:陕西益信伟创智能科技有限公司

A vehicle cooling system

ActiveCN107165715BImprove boot performanceHigh trafficCoolant flow controlMachines/enginesWater flowEngineering

The invention discloses a vehicle cooling system which comprises a radiator, a cylinder body, a cylinder cover, a flow control structure, a heater water return pipeline, an oil cooler water return pipeline, a cooler water return pipeline and a water pump. The flow control structure comprises a water temperature sensor, a control structure body and a main valve structure. According to the vehicle cooling system, the water temperature sensor sends water temperature signals of the heater water return pipeline, the oil cooler water return pipeline, the cooler water return pipeline and a water inlet pipeline of the radiator to the control structure body in time, and according to the water temperature signals, the control structure body flexibly controls the main valve structure to open or close all the pipelines, so that the situation that water flow branch flows in all the pipelines are flexibly controlled is realized, overall on-demand deployment is realized, and unnecessary energy consumption losses are avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

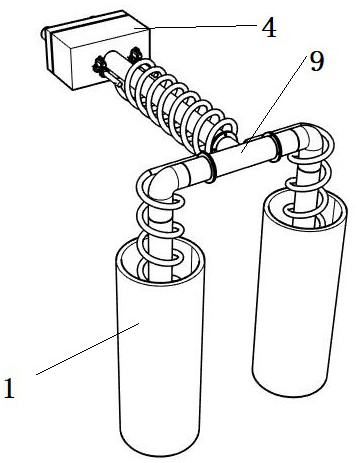

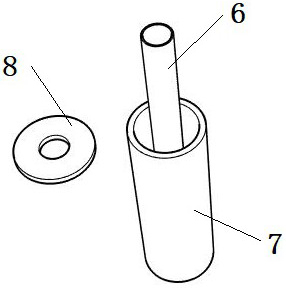

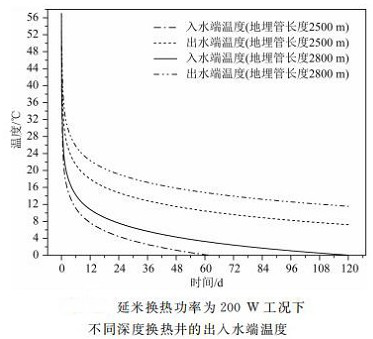

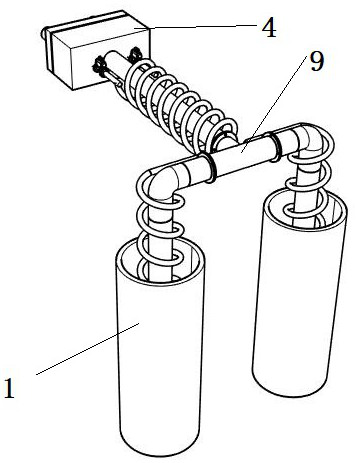

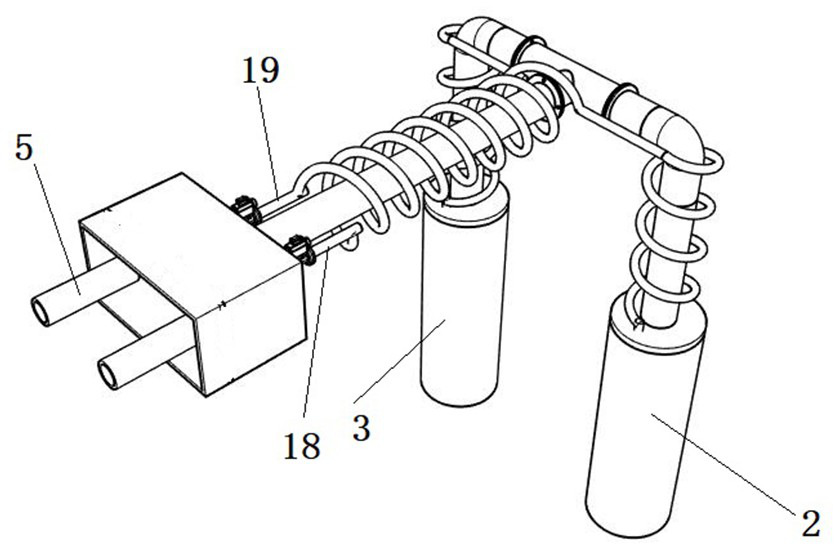

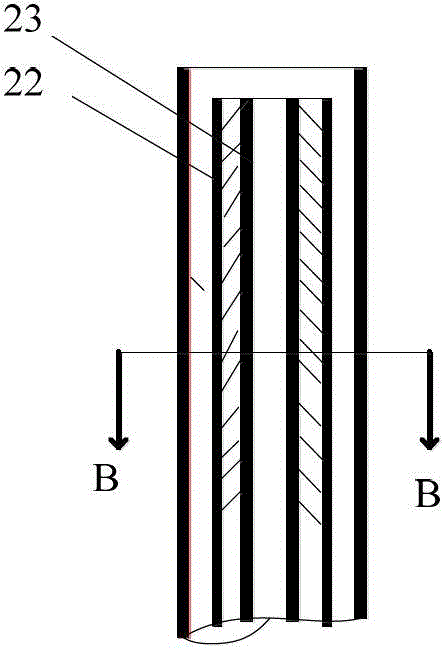

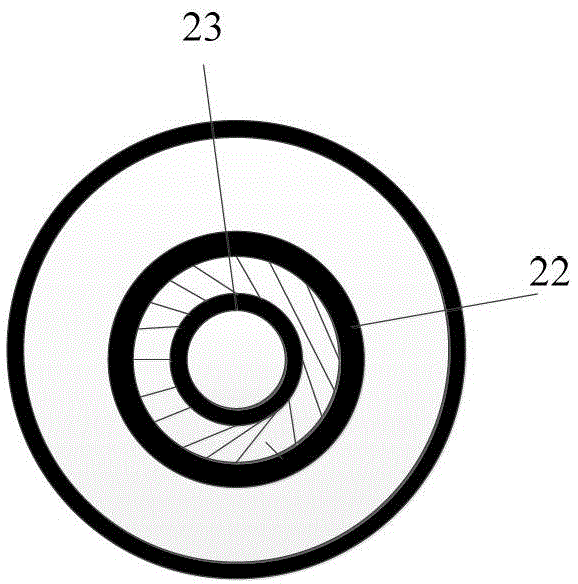

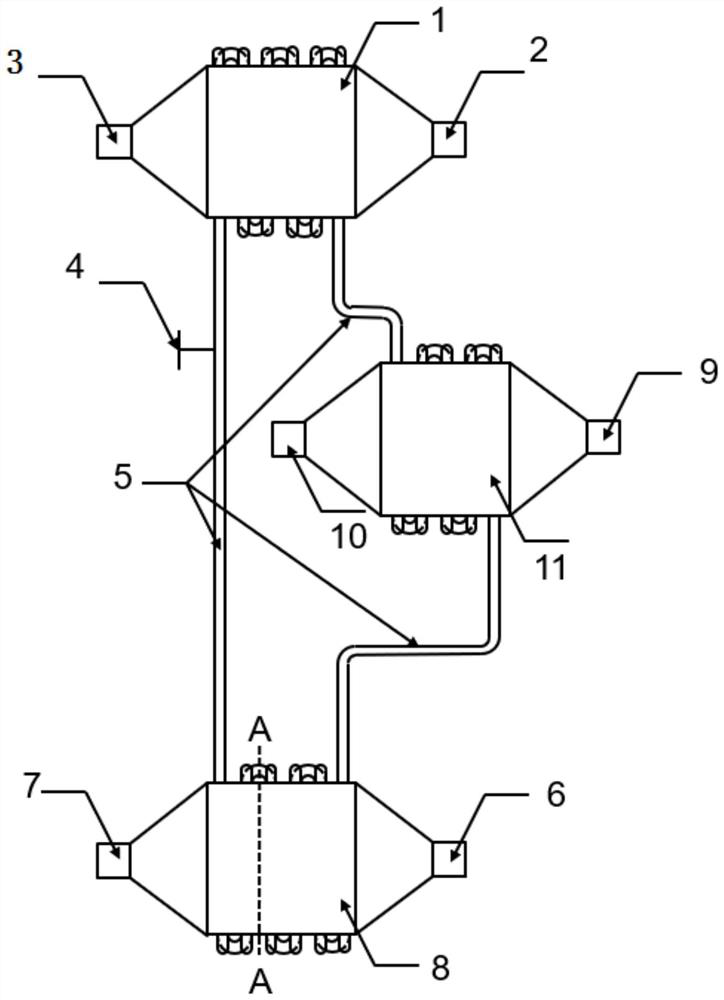

Multiple heat exchange system based on deep well heat exchange technology

ActiveCN112628837AImprove heating efficiencyReduce temperature lossHeat storage plantsGeothermal energy generationSelf adaptiveThermal techniques

The invention discloses a multiple heat exchange system based on a deep well heat exchange technology. The multiple heat exchange system comprises a well body, a first heat collecting pipe, a second heat collecting pipe and a heat exchange box body; the first heat collecting pipe and the second heat collecting pipe are completely the same in structure, the first heat collecting pipe and the second heat collecting pipe are vertically arranged in the well body, the first heat collecting pipe comprises an outer sleeve and an inner sleeve, and a sealing plate is arranged at the upper ends of the outer sleeve and the inner sleeve; and the upper side of the inner sleeve penetrates out of the sealing plate and is connected with a self-adaptive reversing device. According to the system, a double-heat-collection mode is adopted, stable and continuous heat supply is conducted on the heat collection end, continuous heat supply of the heat supply end is guaranteed, and certain heat supply efficiency is improved.

Owner:北方瑞能(内蒙古)集团有限公司

A Multiple Heat Exchange System Based on Deep Well Heat Exchange Technology

ActiveCN112628837BStable and continuous heatingGuaranteed continuous heatingHeat storage plantsGeothermal energy generationEngineeringThermal efficiency

Owner:北方瑞能(内蒙古)集团有限公司

Environment-friendly printing drying device

InactiveCN113291051AAvoid wrinklesImprove surface qualityCombination devicesInking apparatusPhysicsPaper sheet

The invention relates to the technical field of printing, in particular to an environment-friendly printing drying device. The environment-friendly printing drying device comprises a drying chamber, a hot air box, an air inlet pipe, a drying box, a condensation water collector, a circulating pipeline, a first pressure pump, a filter box, a heat exchanger, a second pressure pump, a first stop valve and a second stop valve. The drying force is gradually increased in the paper moving direction, so that wrinkles on the surface of the paper caused by shrinkage of the paper inside and outside the drying chamber due to the too large dry-wet difference are avoided, and then the surface quality of paper finished products is further improved.

Owner:赣州惠彩印刷有限公司

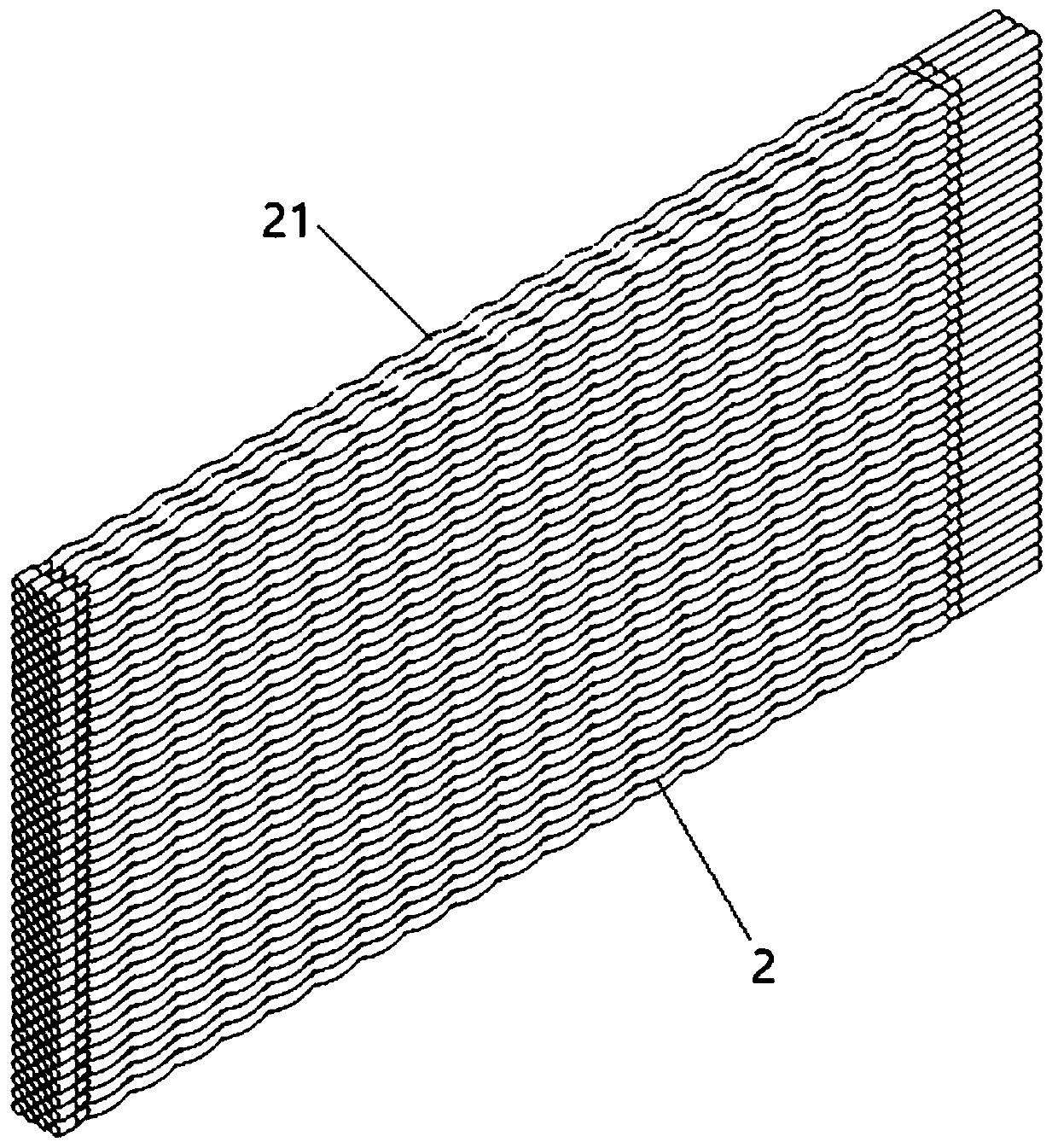

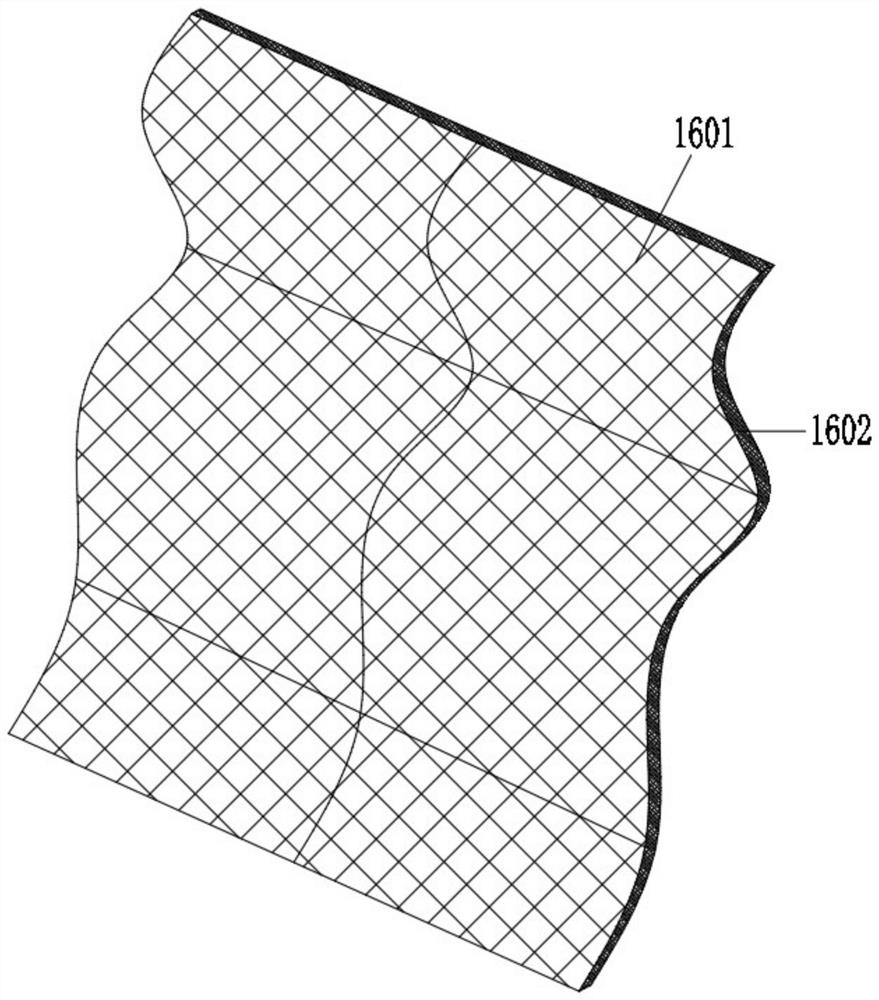

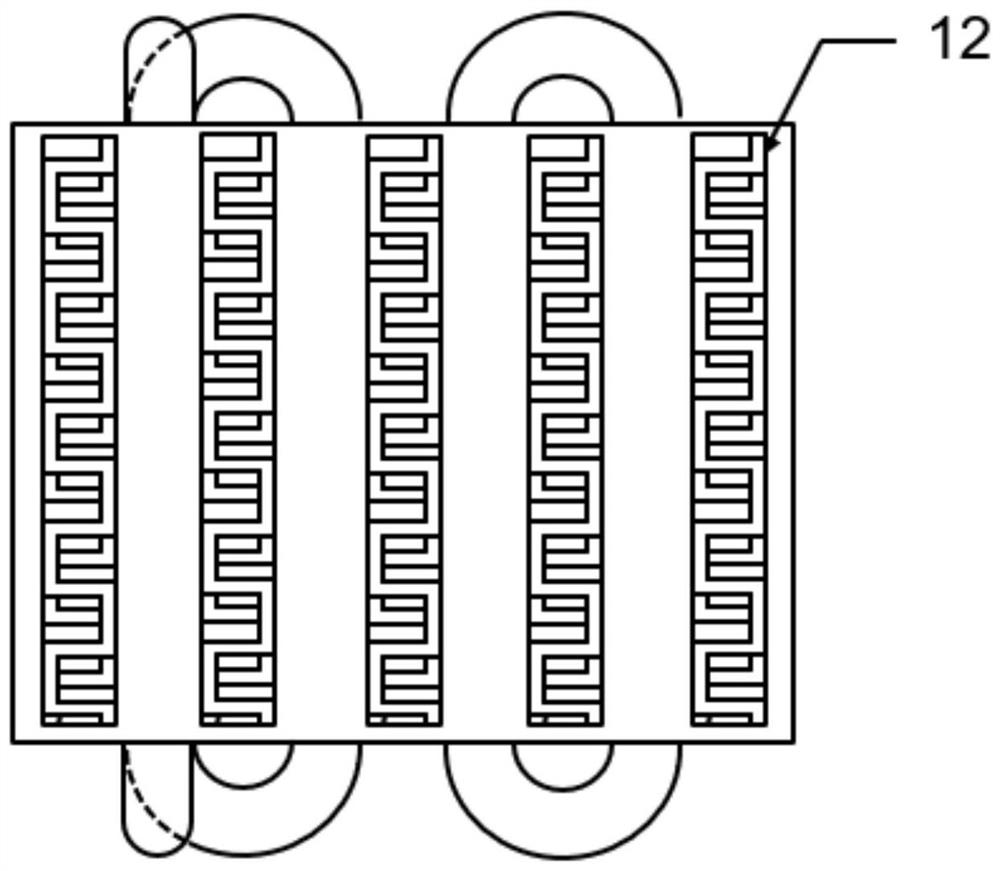

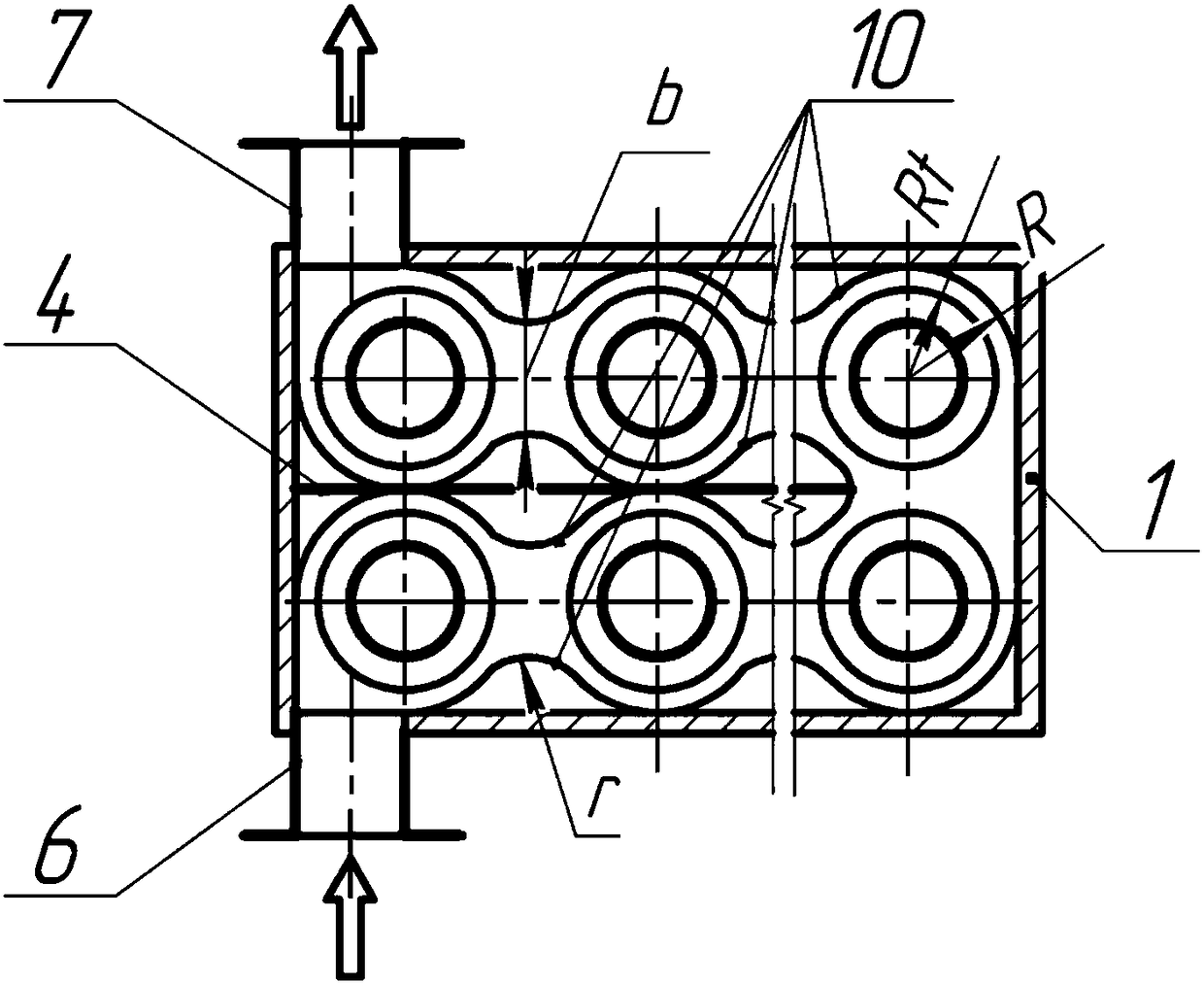

Heat exchanger core and heat exchanger based on bionic stacking three-dimensional configuration

ActiveCN110319729BReduce volumeImprove compactnessLaminated elementsStationary plate conduit assembliesCold sideThermodynamics

The invention discloses a heat exchanger core body based on bionic stacking three-dimensional configuration and a heat exchanger. The heat exchanger core body is formed by stacking a plurality of heatexchange units, each heat exchange unit comprises two layers of net-shaped plates, a plurality of grids are uniformly distributed on the opposite end faces of the net-shaped plate pieces, net rib nodes of the two layers of net-shaped plates are staggered with each other, and a plurality of flow passages and chambers communicating with each other are formed; and every two adjacent heat exchange units forms a cold side medium flow cavity and a hot side medium flow cavity. According to the heat exchanger core body, a plurality of micro cavities communicating with each other are formed in the medium flowing cavities to form a bionic bone marrow structure, and the bionic bone marrow structure has relatively large ratio surface area to volume, compared with a heat exchanger with an internal straight flow channel, the heat exchange power can be improved by 20% or more, and the weight of the heat exchanger is reduced by 20% or more; and the compactness of the heat exchanger is improved to be6 times or more of the compactness of a tube-shell heat exchanger, the heat exchanger can bear high pressure of about 20 MPa, has relatively high heat exchange efficiency under the condition that thehydraulic diameter is large, and is suitable for large heat flux density application scenes.

Owner:陕西益信伟创智能科技有限公司

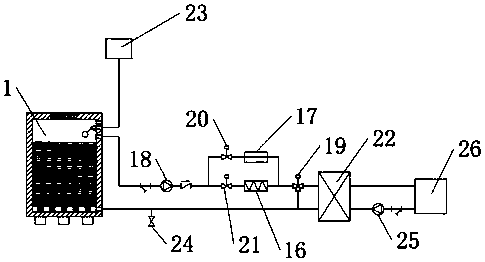

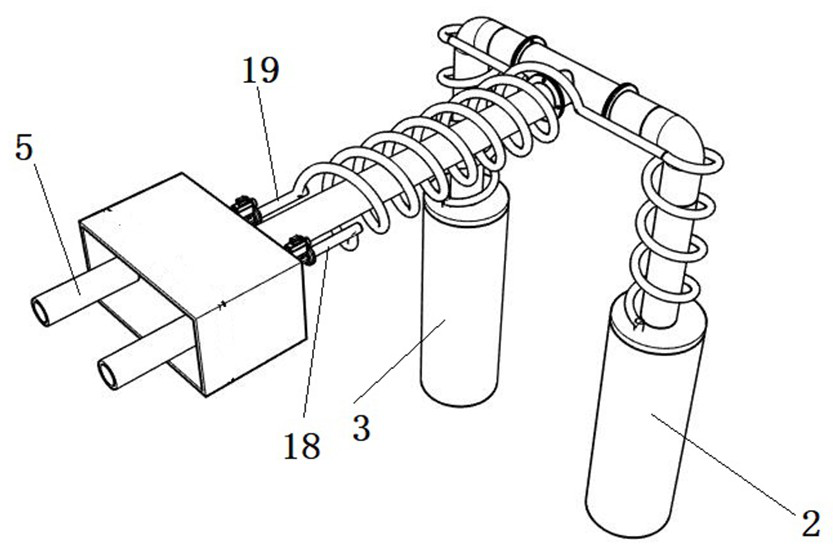

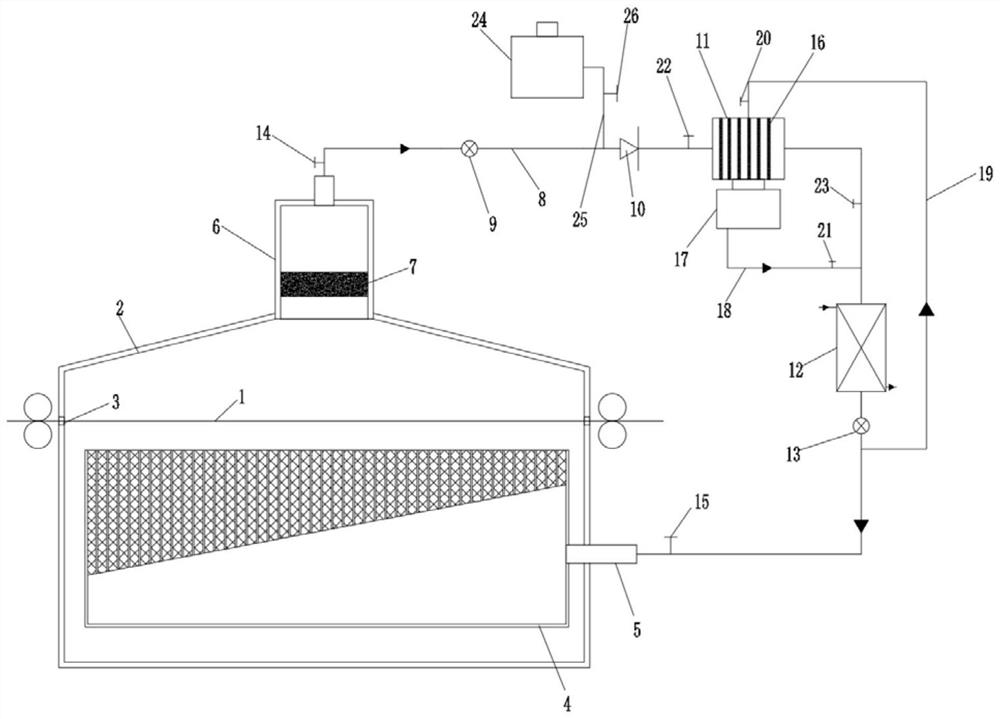

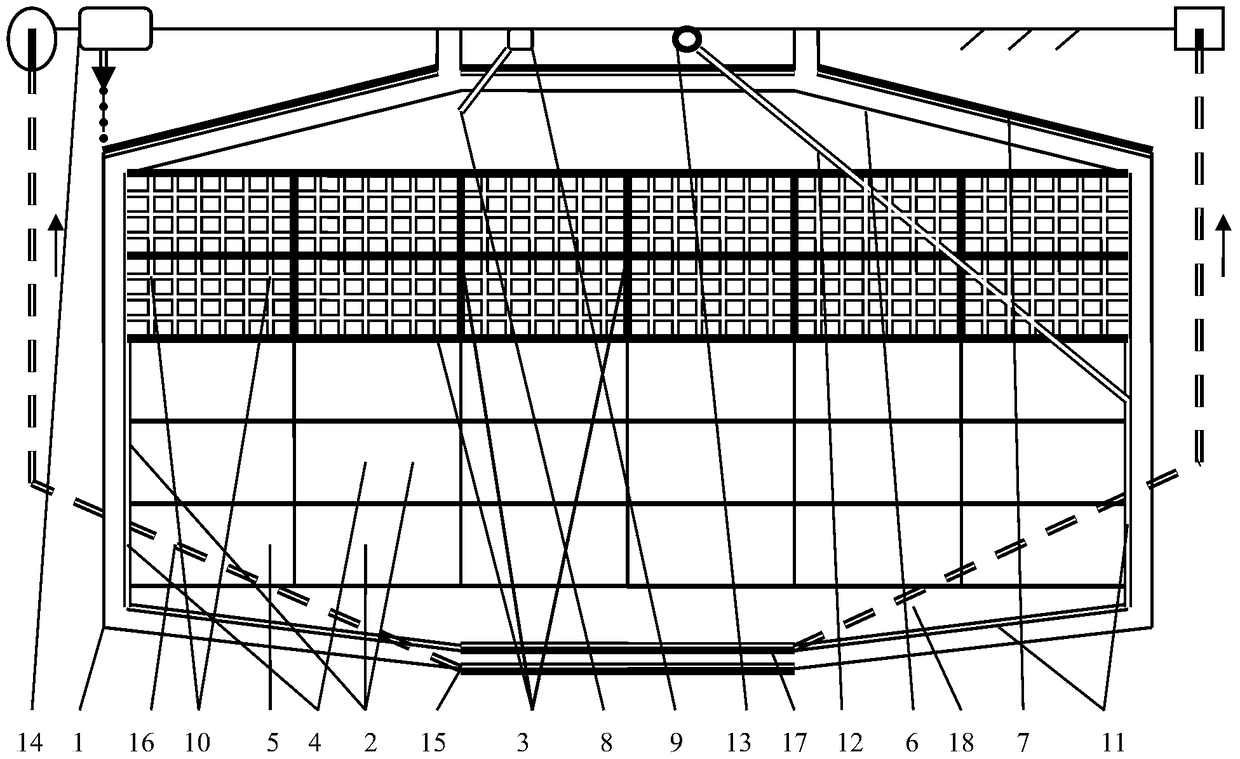

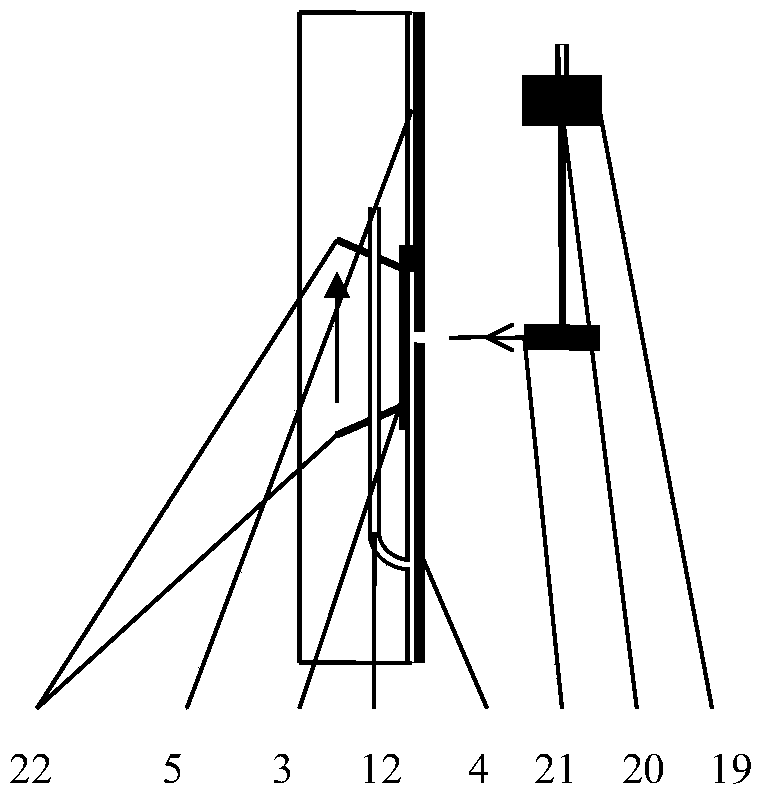

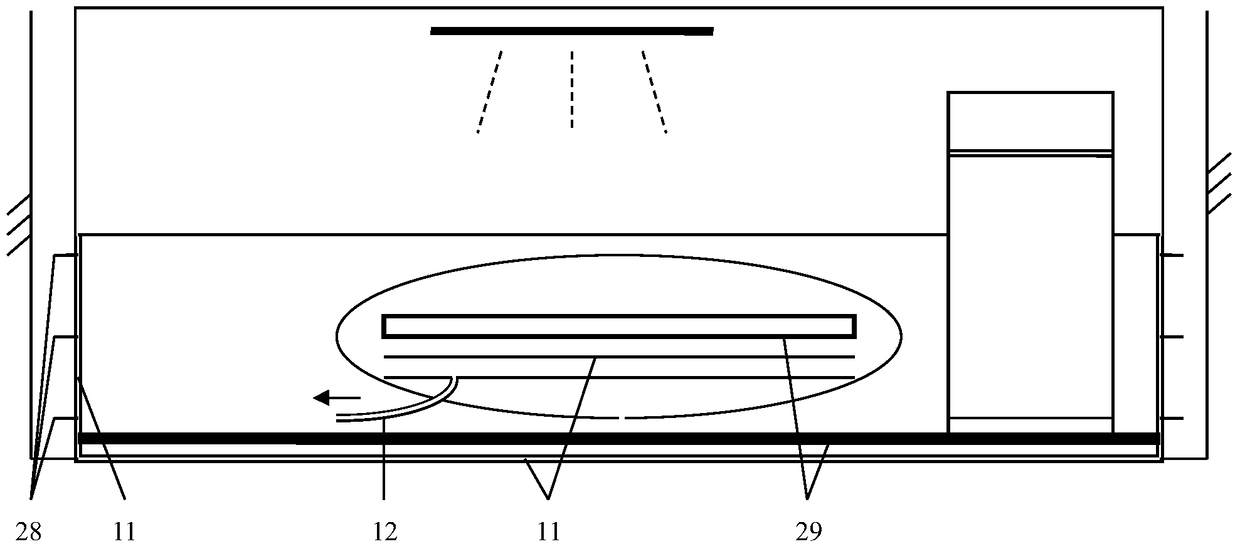

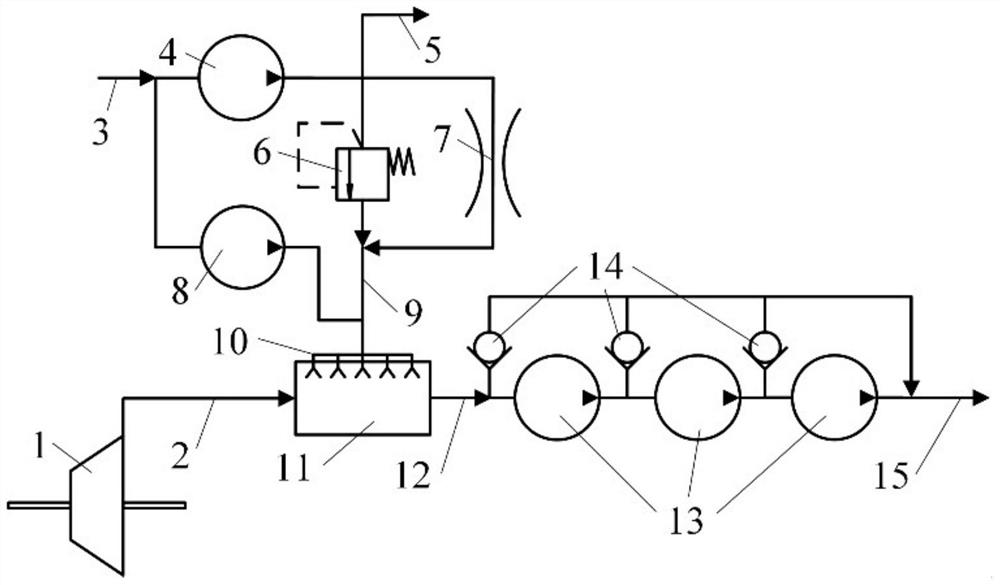

A closed circulation heating system

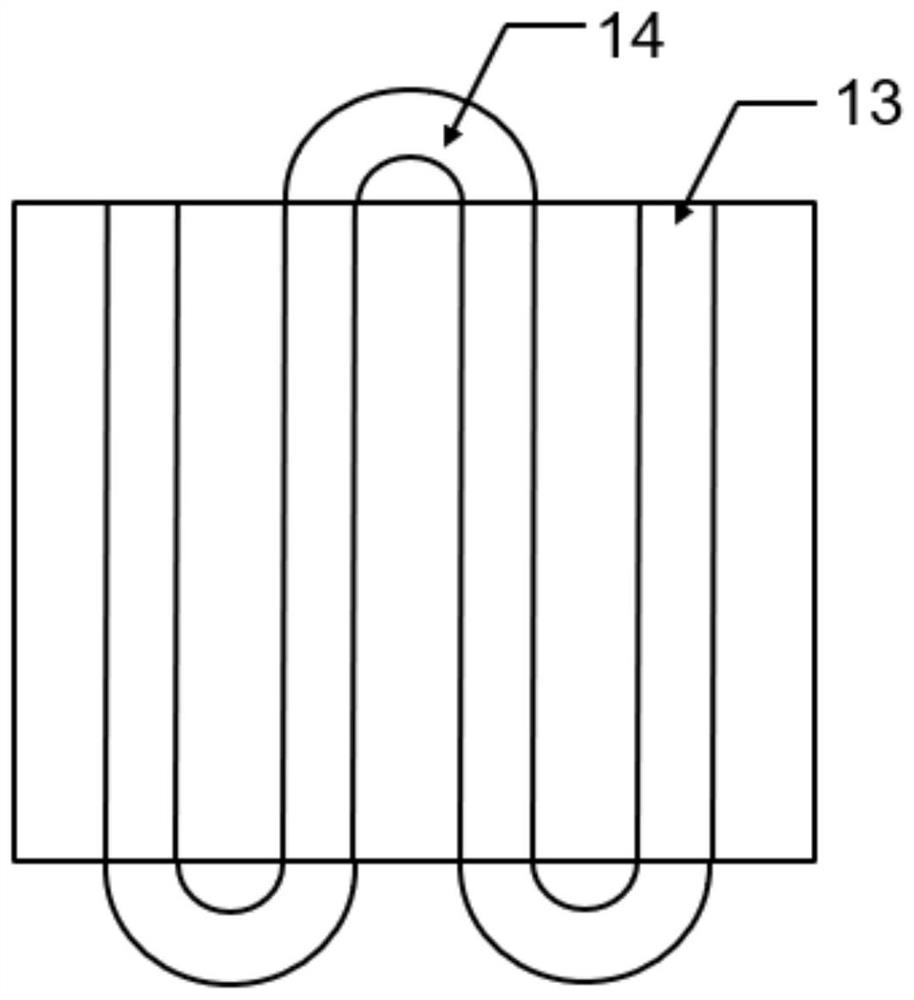

ActiveCN103453571BIncrease the heat exchange areaLower Drilling CostsOther heat production devicesGeothermal energy generationWell drillingClosed loop

A closed circulation heating system comprises a liquid storage tank and a circulation water tank communicated with the liquid storage tank. An electric heating pipe is arranged in the circulation water tank, the circulation water tank is communicated with a plurality of horizontal branched boreholes through a central main borehole, a heat insulating pipe going down from the central main borehole is arranged in each horizontal branched borehole, inlets of the heat insulating pipes are communicated with the horizontal branched boreholes, outlets of the heat insulating pipes are connected with a heat exchanger and then go back to the circulation water tank, and the heat exchanger and a heating pipe network of users form a circulation loop. Well drilling cost is lowered, heat exchange power is increased, pollution to strata during operating of the system is avoided, the closed circulation heating system belongs to an environmental-friendly system, and the problems of poor stability in system operating and relatively short equipment service life caused by adoption of geothermal water are solved. In addition, the closed circulation heating system is high in applicability, free of limitation of geographical positions and geothermal resources, capable of being established at any place and low in operating expense.

Owner:陕西圣昊朗道科技有限公司

Heat exchange plate

ActiveCN103278035BImprove structural strengthImprove structural rigidityLaminated elementsEngineeringUltimate tensile strength

Owner:ZHEJIANG ERG TECH

A kind of embedded micro-pump driven heat dissipation structure and heat dissipation method

ActiveCN111132517BImprove heat transfer efficiencyRealize comprehensive utilizationElectric powerModifications by conduction heat transferThermodynamicsEngineering

Owner:PEKING UNIV

Stainless steel plate pre-embedded steel plate connection interface wall panel underground granary

ActiveCN105133886BReduce humidityAvoid temperature riseArtificial islandsAgricultural buildingsSheet steelPre embedding

Stainless steel plate pre-embedded steel plate connection interface clapboard underground granary, set a parapet interface on the inner surface of the granary, the parapet interface includes a steel plate connection interface and a stainless steel clapboard; the connection interface is continuous, and the clapboard is continuous with the welding interface Welding achieves a sealed connection with the welding interface, and there is a gap between two adjacent stainless steel parapets; or the connection interface is discontinuous, and the welding connection between the clapboard and the connection interface plays a fixed role and two adjacent stainless steel parapets The panel splicing connection includes welding connection, adhesive connection and undercut connection; the stainless steel wall panel and the inner surface of the structure form a closed space; the closed spaces are respectively communicated with negative pressure sources. Negative pressure vacuum also has the functions of drying, killing and slowing down the metabolism of grains. The energy consumption of underground cooling granaries in the Yangtze River Delta region is negligible in the first summer when the storage temperature does not exceed 8°C. Rice stocks are expected to be extended to eight years from the current two years.

Owner:济宁高新科达科技项目服务有限公司

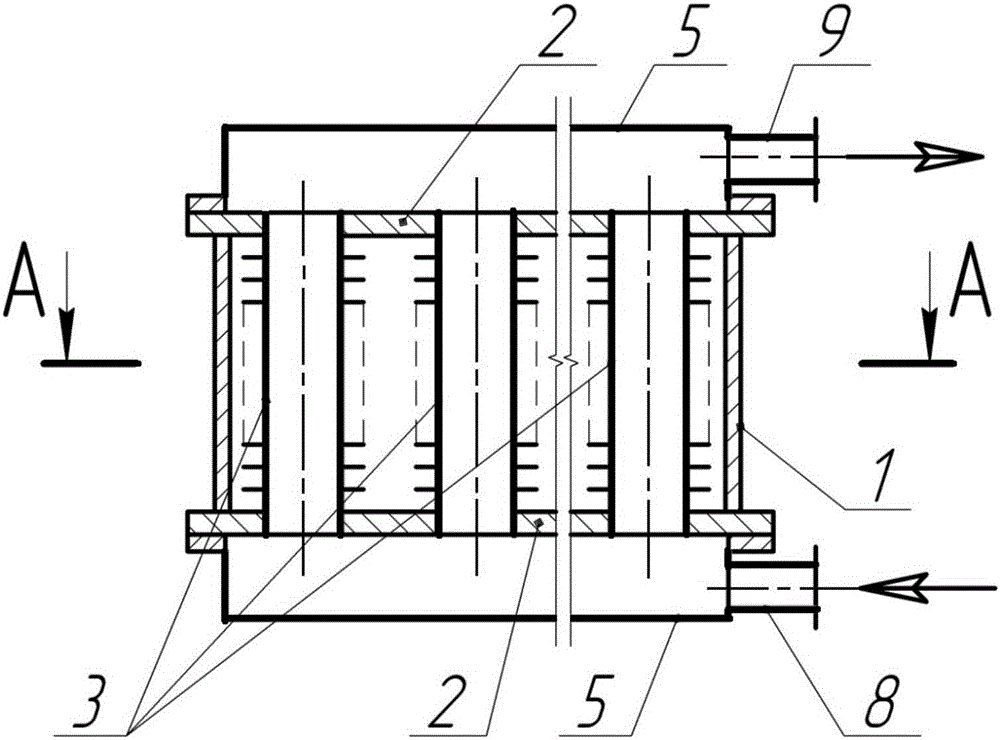

Diversion type low-flow-resistance heat pipe heat exchanger

PendingCN114543107AIncrease heat transfer powerUniform flow fieldIndirect heat exchangersCombustion technology mitigationEngineeringMechanical engineering

A flow guide type low-flow-resistance heat pipe heat exchanger comprises a heat pipe heat exchanger box body, a pipe plate and a flow guide type low-flow-resistance heat pipe bundle.

Owner:王剑

A twin-well recharge geothermal development system based on fracturing technology

ActiveCN103983035BGuaranteed sustainable developmentReduce adverse effectsOther heat production devicesGeothermal energy generationWater flowInjection well

The invention discloses a double-well re-injection geothermal exploitation system based on a fracturing technology. The double-well re-injection geothermal exploitation system based on the fracturing technology comprises a first re-injection well, a second re-injection well and a water taking well arranged between the first re-injection well and the second re-injection well, wherein the water taking well is communicated with the first re-injection well and the second re-injection well through cracks in a heat storage layer respectively; the water taking well is connected with the heat release side inlet of a heat exchanger via a sand remover, the heat release side outlet of the heat exchanger is connected with the first re-injection well and the second re-injection well respectively, and the heat absorption side of the heat exchanger is communicated with the heating pipe network of a user. Because the water taking well is communicated with the first re-injection well and the second re-injection well by virtue of the cracks in the heat storage layer respectively, and the cracks are arranged in the heat storage layer, according to the double-well re-injection geothermal exploitation system based on the fracturing technology disclosed by the invention, geothermal tail water can be completely re-injected in the heat storage layer through the cracks to ensure the sustainable development of geothermal resources, thus reducing the adverse effects of the geothermal tail water on environment and ecology; meanwhile, when the geothermal tail water flows through the cracks, the heat exchange area of a fluid and the heat storage layer is greatly increased, and the heat exchange power is increased.

Owner:陕西圣昊朗道科技有限公司

Separated type three-flow heat exchanger

InactiveCN111964497AFlexible settingsIncrease heat transfer powerLaminated elementsStationary plate conduit assembliesHeat transmissionEngineering

The invention discloses a separated type three-flow heat exchanger which comprises a hot-end heat exchange core body, a medium-temperature-end heat exchange core body, a cold-end heat exchange core body, a core body connecting pipeline and a heat transfer working medium. The hot-end heat exchange core body, the medium-temperature-end heat exchange core body and the cold-end heat exchange core bodyare arranged in a spacing way in a space; fluid courses in the hot-end heat exchange core body, the medium-temperature-end heat exchange core body and the cold-end heat exchange core body and the core body connecting pipeline form a sealed splitless loop with a single path; and the heat transfer working medium is filled in the loop. The separated type three-flow heat exchanger provided by the invention has the performances such as good heat exchange effect, compact structure, light mass and the like, heat can be transmitted over long distances at the same time, and higher and further heat transfer can be realized compared with a heat exchanger with a common heat pipe.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY +1

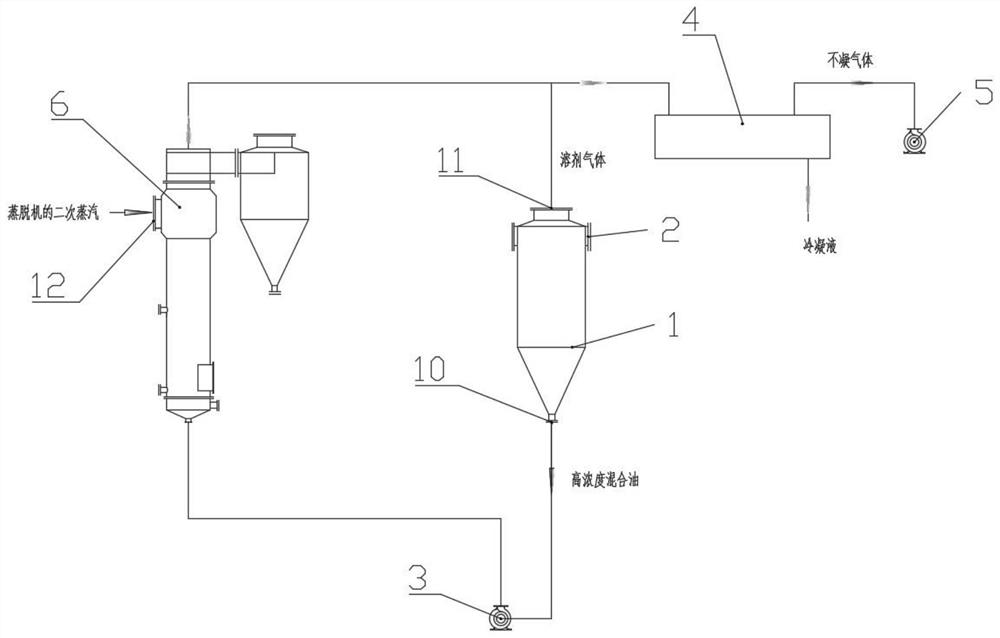

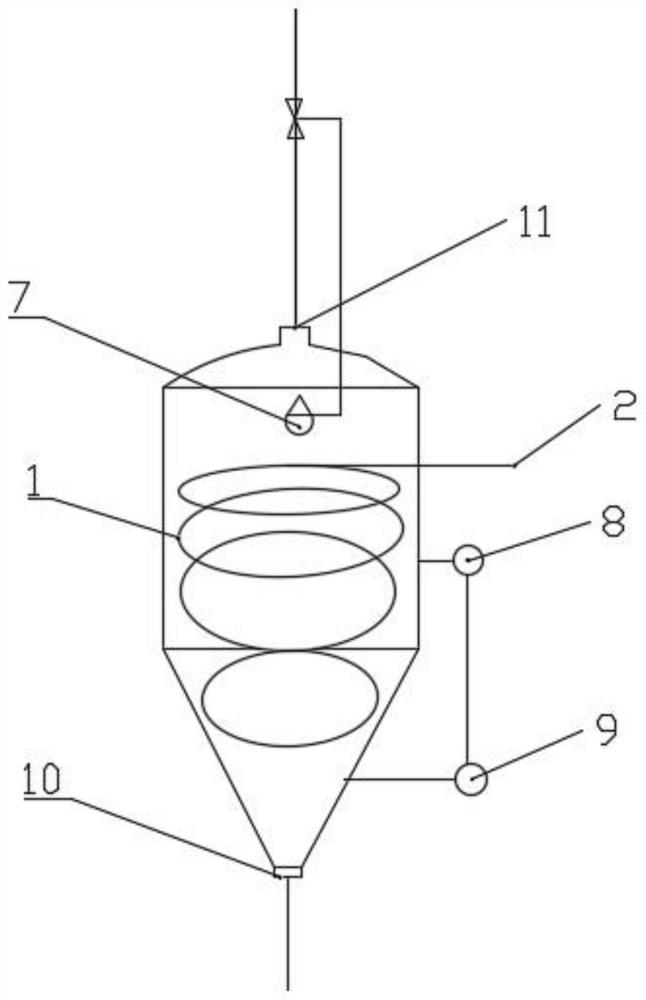

Mixed oil negative-pressure evaporation equipment

PendingCN112717444AIncrease concentrationSave heatEvaporator accessoriesFatty-oils/fats refiningPhysicsEvaporator

The invention discloses mixed oil negative-pressure evaporation equipment, and belongs to the field of evaporation equipment. The problems that existing mixed oil evaporation equipment is large in evaporation consumption and poor in stability are solved. The equipment comprises a flash tank, a mixed oil pump, a condenser, a negative pressure water ring pump and a first evaporator, a mixed oil input port, a mixed oil output port and a volatile gas output port are machined in the flash tank, the mixed oil output port of the flash tank is connected with the mixed oil pump, and the volatile gas output port of the flash tank is connected with the condenser; the output end of the mixed oil pump is connected with the input end of the first evaporator, the output end of the first evaporator is connected with the input end of the condenser, and the output end of the condenser is connected with the negative-pressure water ring pump. By means of the mixed oil negative pressure evaporation equipment, the effect of steam in the mixed oil evaporation process is effectively reduced, and the negative pressure in the evapo-separated machine and the vacuum stability of the whole system are guaranteed.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD

engine exhaust cooler

InactiveCN105971695BEnsure normal flowConsistent heat transfer coefficientExhaust apparatusSilencing apparatusEngineeringCooling fluid

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

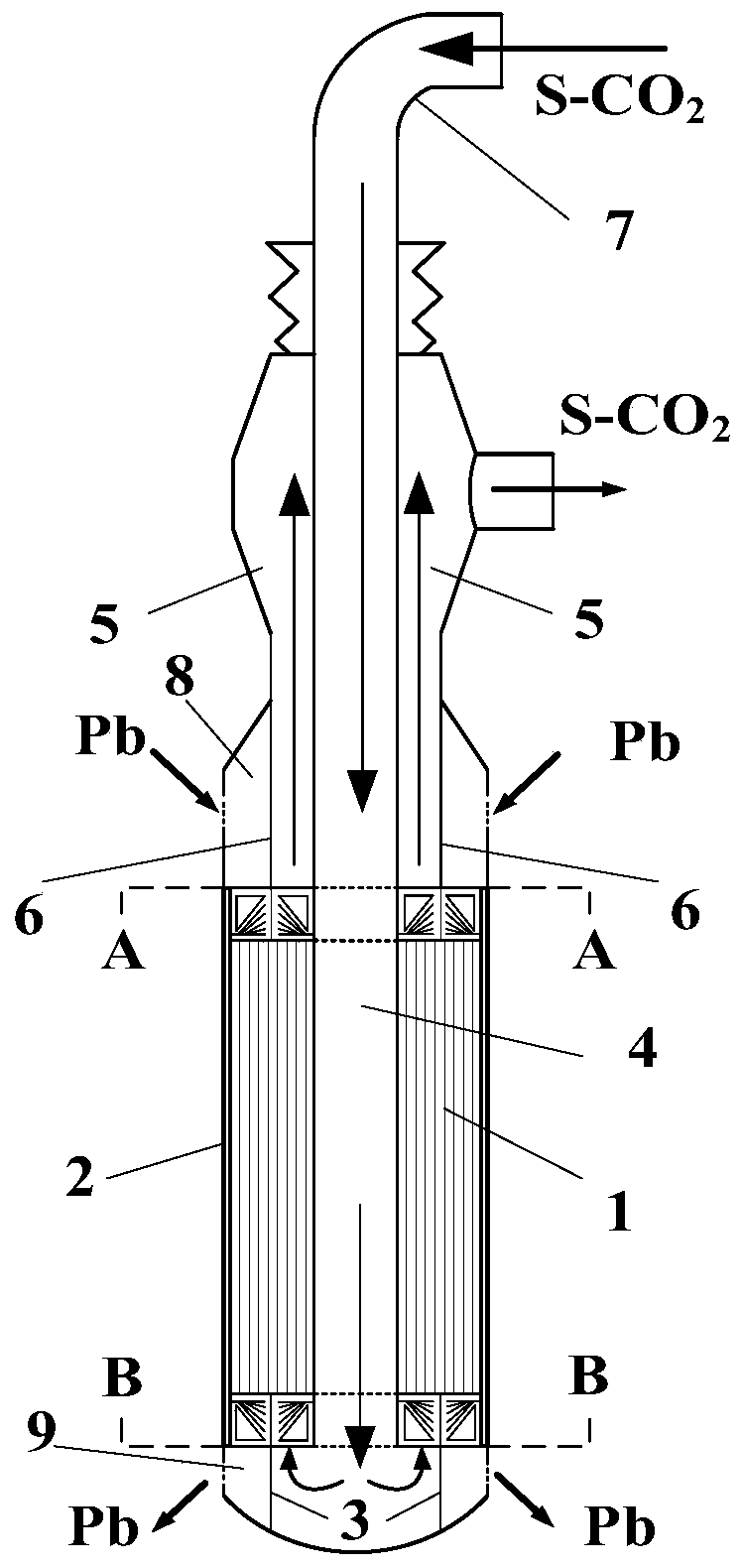

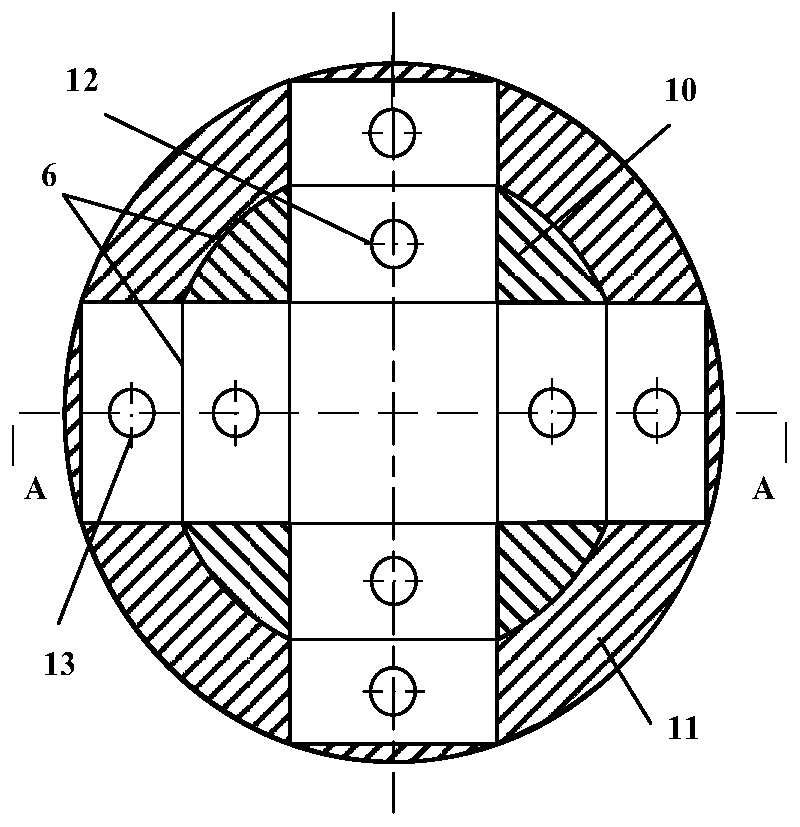

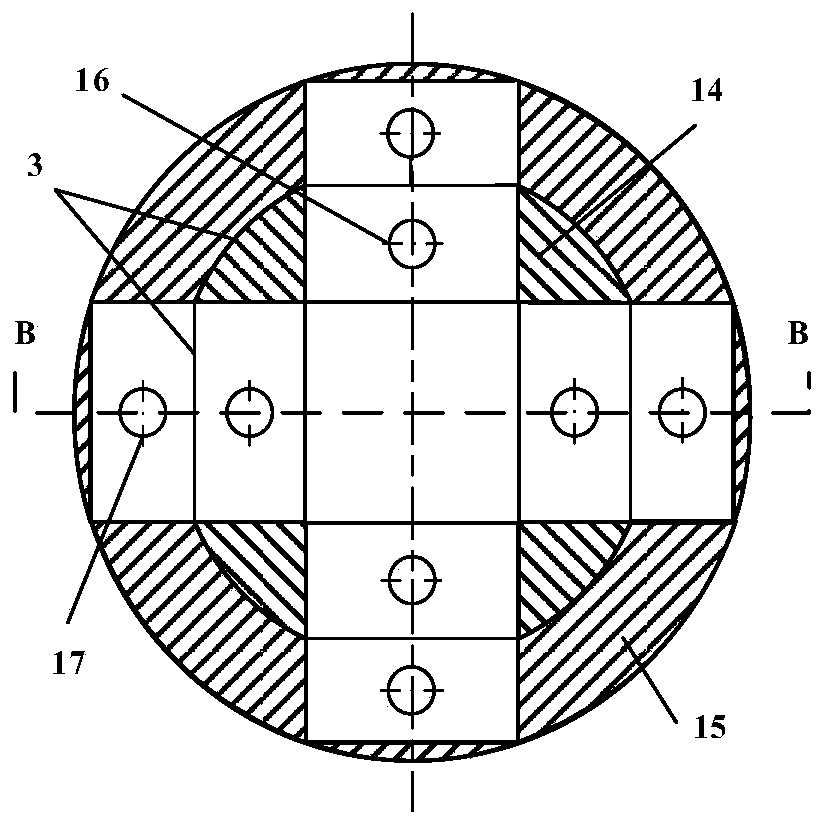

A lead-supercritical carbon dioxide intermediate heat exchanger

ActiveCN109443043BImprove heat transfer efficiencyImprove compactnessNuclear energy generationStationary tubular conduit assembliesCold sideBrayton cycle

The present disclosure discloses a lead-supercritical carbon dioxide intermediate heat exchanger, including four modular printed circuit board heat exchangers (modular PCHEs), a cylinder, vertical partition boards, horizontal partition boards and heat exchange fluid channels. S-CO2 fluid flows upward along microchannels in PCHE cold side heat exchange plates after reaching the bottom of the cylinder along a square central down tube formed by the four PCHEs to absorb heat from hot side heat exchange plates. S-CO2 leaves the intermediate heat exchanger upward after being collected by a current collector at the other end of each PCHE. Liquid lead enters microchannels in the PCHE hot side heat exchange plates from a duct at the upper end of the cylinder to transfer heat to S-CO2 on the other side, and then flows out of the intermediate heat exchanger from a duct at the lower end of the cylinder to complete heat exchange.

Owner:XI AN JIAOTONG UNIV

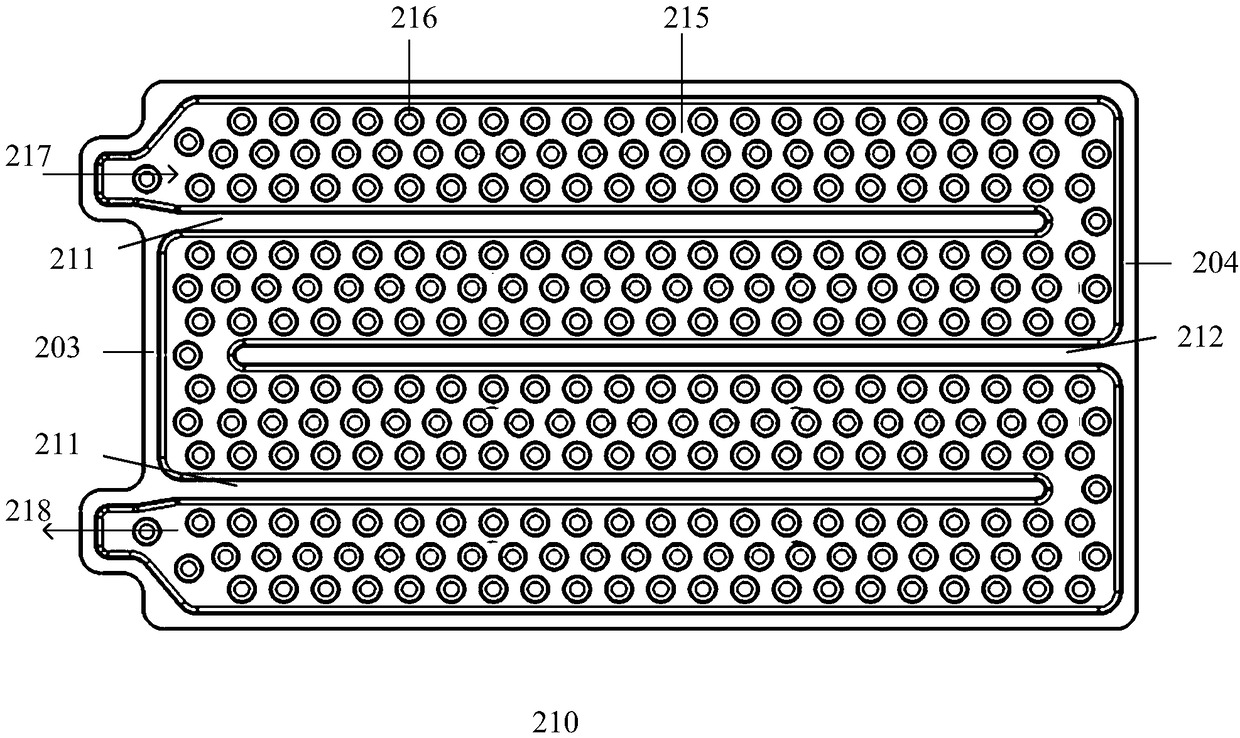

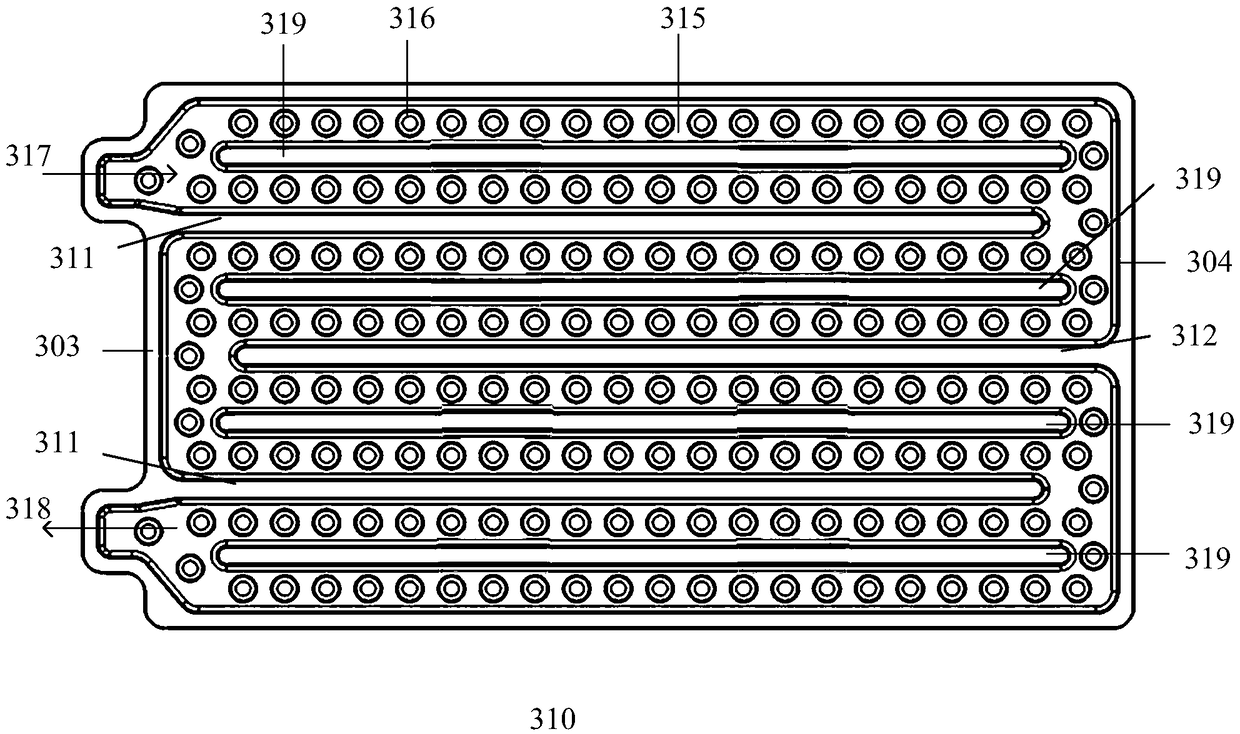

High-efficiency compact heat exchanger with vertical cross microchannel

ActiveCN106123656BIncrease heat transfer powerReduce volumeLaminated elementsStationary plate conduit assembliesEngineeringInlet flow

The invention discloses a high-efficiency and compact heat exchanger with vertical crossing microchannels, which comprises at least two flow plates stacked together, and the two adjacent flow plates are respectively an upper flow plate and a lower flow plate, and at least two fluid channels, the upper flow plate and the lower flow plate Heat exchange channels are arranged in the downstream plate, and the heat exchange channel of the upper plate includes at least one first-type flow channel, the first-type flow channel includes the inlet section of the first-type flow channel, the middle section of the first-type flow channel, The outlet section of the first type of flow channel, the heat exchange flow channel of the down flow plate includes at least one second type of flow channel, the second type of flow channel includes the inlet section of the second type of flow channel, the middle section of the second type of flow channel, the second type of flow channel The outlet section of the flow channel, the inlet section of the first type of flow channel communicates with the outlet section of the first type of flow channel through the middle section of the second type of flow channel, and the inlet section of the second type of flow channel connects with the second type of flow channel through the middle section of the first type of flow channel The exit section of the road is connected. Through the design of the inlet and outlet flow channels of the heat exchanger, part of the flow channels of the upper and lower boards is opened to achieve the purpose of realizing the three-dimensional fluid arrangement of the hot and cold runners in the printed circuit board.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Exhaust gas pressurizing and discharging device for underwater semi-closed cycle power system

ActiveCN112594066AImprove depth adaptabilityReduce boost powerRotary/oscillating piston combinations for elastic fluidsGas turbine plantsMarine engineeringTurbine

The invention discloses an exhaust gas pressurizing and discharging device for an underwater semi-closed cycle power system. The exhaust gas pressurizing and discharging device comprises a seawater inlet system and a turbine main engine, wherein a seawater nozzle is connected with the end part of the seawater inlet system; a gas-liquid mixing cavity is connected with the seawater nozzle; the turbine main engine is connected with an input end of the gas-liquid mixing cavity through a main engine exhaust gas pipeline; and an output end of the gas-liquid mixing cavity is sequentially connected with a gas-liquid mixed working medium pipeline, a two-phase booster pump set and a discharge pipeline. Excessive seawater is introduced to mix and condense an exhaust gas of the main engine to form a gas-liquid mixed working medium, and then the working medium is pressurized through a gas-liquid two-phase pump and discharged overboard, so that it is guaranteed that the thermal power main engine canefficiently operate under various waterway depth conditions, and the depth flexibility of an underwater thermal power system is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com