Polyhedral spiral channel heat exchanger for liquid refrigeration

A spiral channel and heat exchanger technology, applied in the field of polyhedral spiral channel liquid refrigeration heat exchangers, can solve the problems of reducing the volume of the heat exchanger, large heat exchanger volume, and low heat exchange density, so as to improve heat exchange efficiency , reduce the volume, prolong the effect of flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

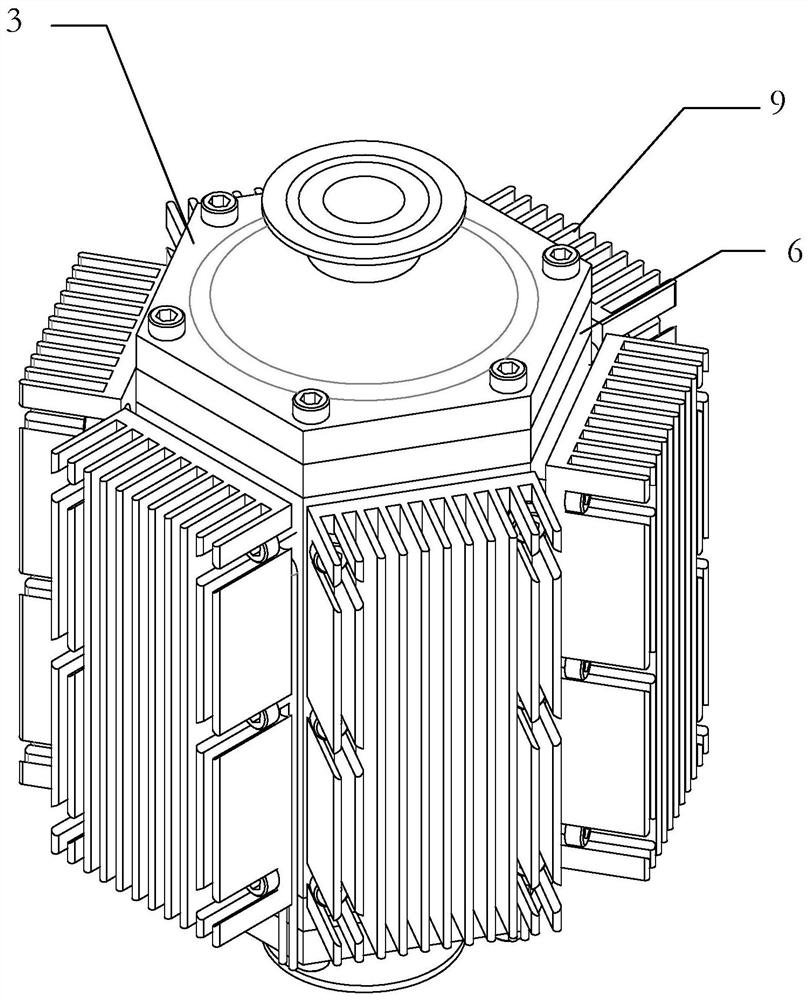

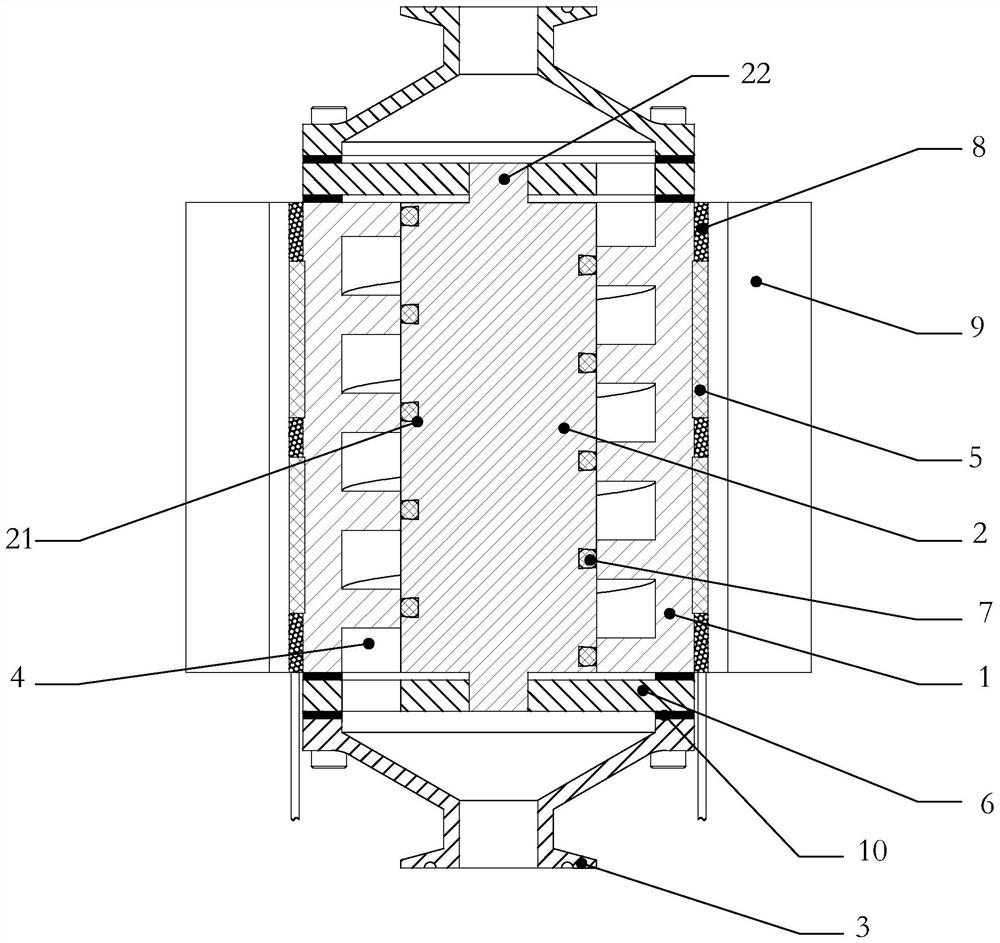

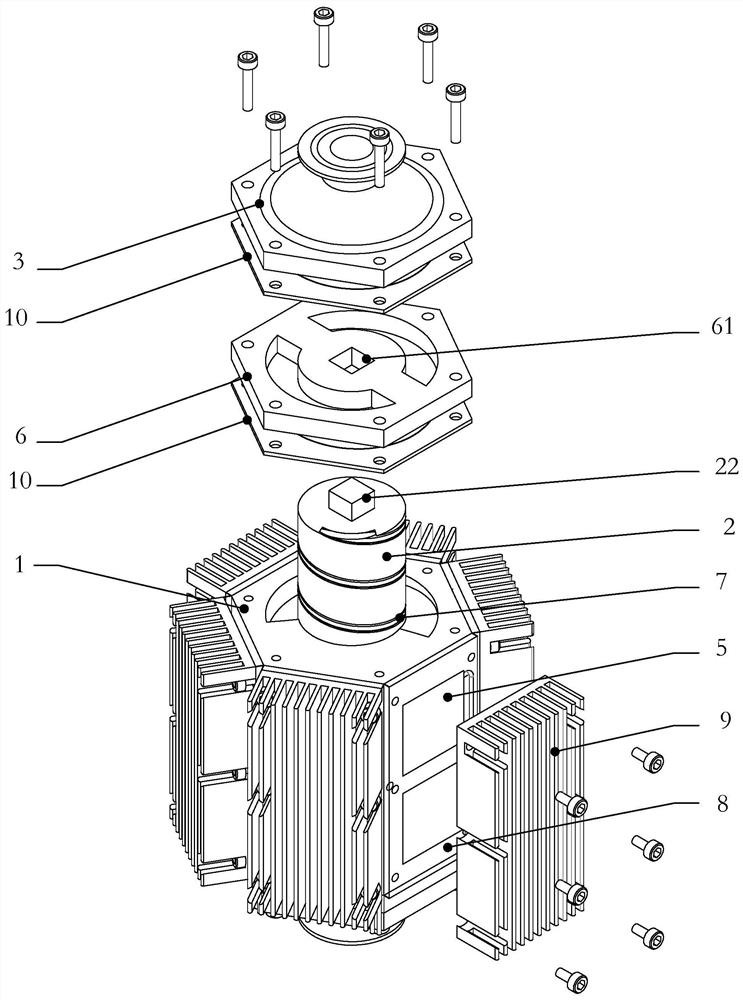

[0031] A heat exchanger for liquid refrigeration of a polyhedral spiral passage of the present embodiment, such as Figure 1-3 As shown, it includes a polyhedral cold block 1 , a mandrel 2 , a connecting flange 3 , a semiconducting cooling sheet 5 and a baffle 6 .

[0032] The polyhedral cold block 1 is a prism with a polygonal cross section. In this embodiment, the polyhedral cold block 1 is a prism with a hexagonal cross section. An inner hole is provided along the axial direction of the center of the prism. The mandrel 2 is sleeved in the inner hole. The connecting flange 3 is respectively fixed on both ends of the prism by screws.

[0033] A spiral groove for circulation of the liquid to be refrigerated is opened along the wall of the inner hole. The groove pitch of the spiral groove is larger than the groove width of the spiral groove. In addition to the spiral groove, the surface of the inner hole wall also has the inner diameter of the spiral groove interval part rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com