A long-term passive containment heat extraction system

A passive containment and heat export technology, applied in the field of containment, can solve problems such as failure and increase in impact, and achieve the effects of increasing driving force, reducing consumption and extending operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

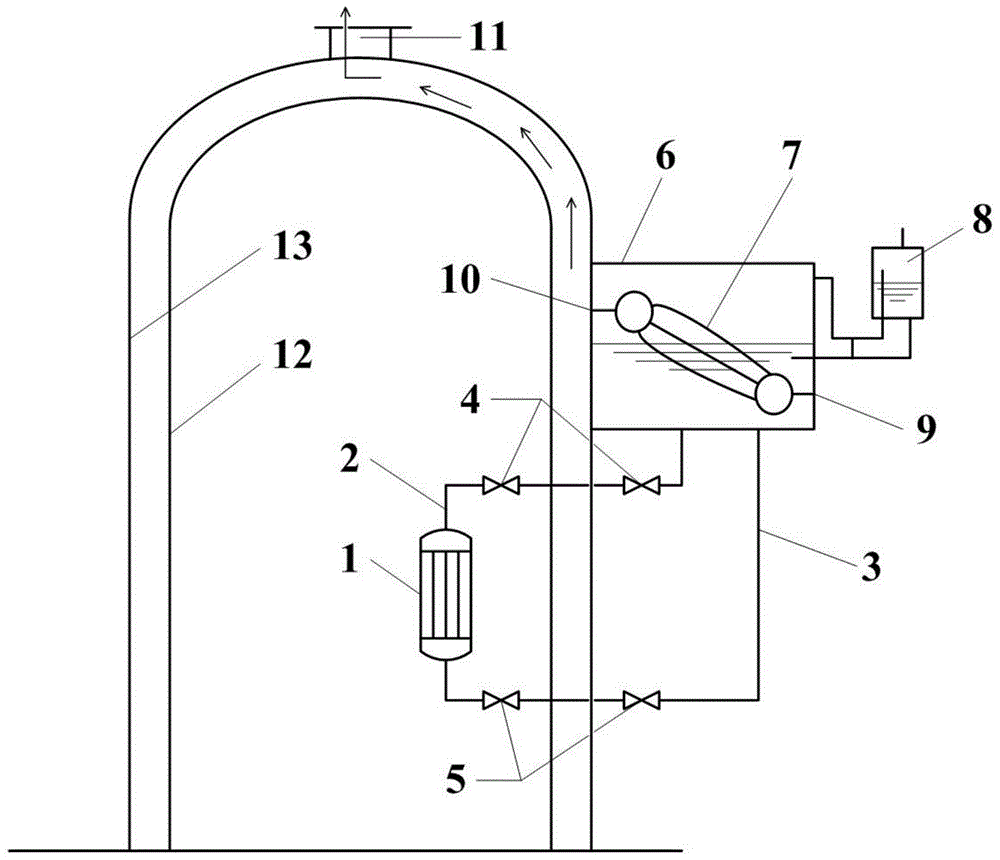

[0016] combine figure 1 , a long-term passive containment heat export system of the present invention, the system mainly includes an internal heat exchanger 1, an ascending pipeline 2, a descending pipeline 3, isolation valves 4, 5, a cooling water tank 6, and an air-cooled condensation-cooler 7 And water sealing device 8. Among them, the internal heat exchanger 1 is located in the upper space of the inner concrete containment 12 close to the side wall; the cooling water tank 6 is located outside the outer concrete containment 13, and its relative position is higher than that of the internal heat exchanger, and the distance between the internal heat exchanger The air-cooled condensing-cooler 7 is a shellless heat exchanger, which is located inside the cooling water tank 6 and is arranged obliquely. A part of the heat transfer tube is placed in the water space. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com