Bionic-based compact honeycomb structure heat exchanger core and heat exchanger

A honeycomb structure and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve problems such as inability to achieve, and achieve the effect of strong adaptability, compact structure, and improved heat exchange power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

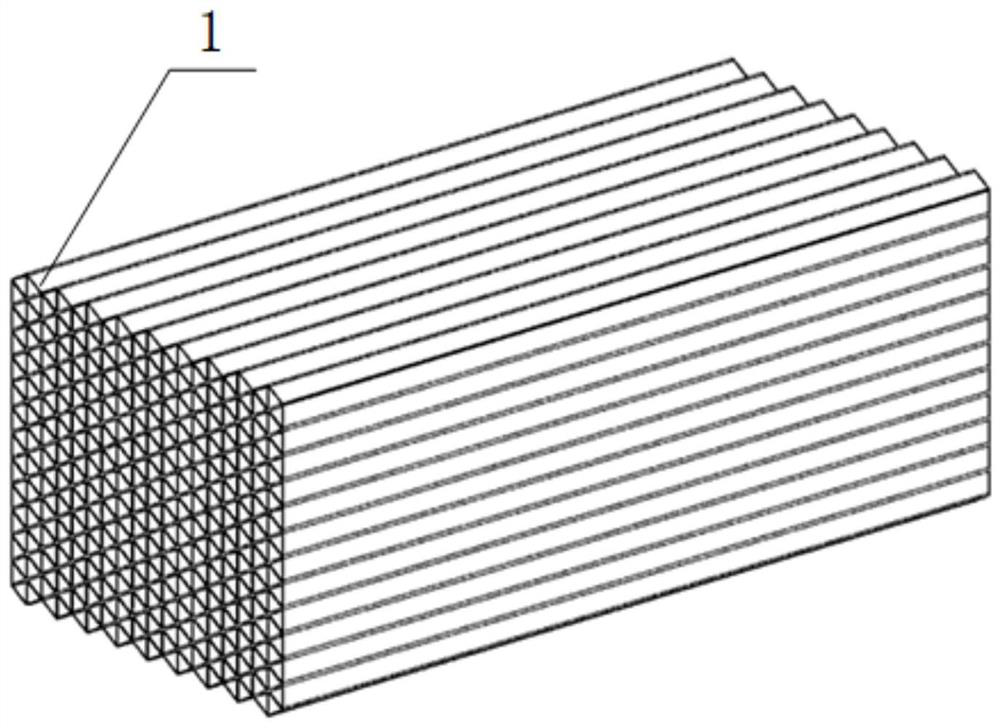

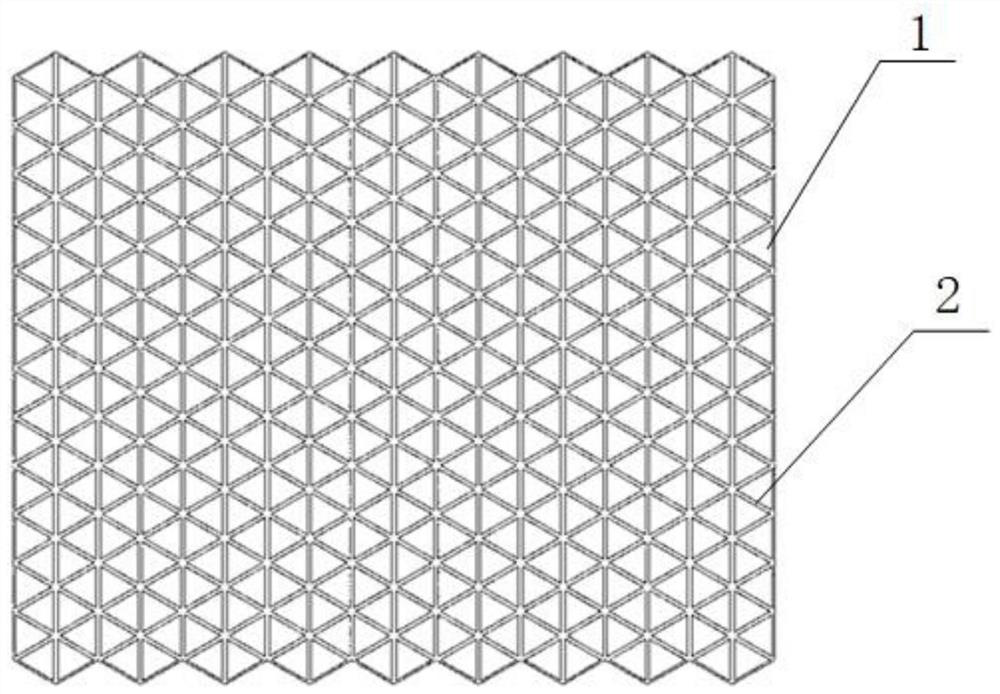

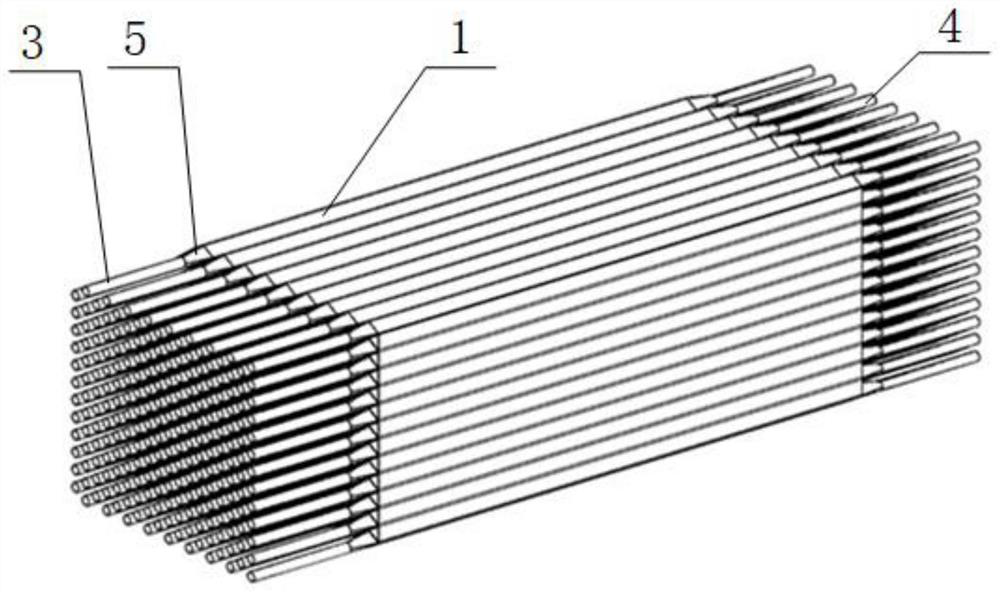

[0044] The embodiment of the present invention is based on a bionic compact honeycomb structure heat exchanger core, such as Figure 1-2 As shown, it includes a plurality of radially spliced straight passages 1, and the outside of the straight passages 1 is provided with a closed shell 8, and the adjacent straight passages 1 respectively pass into the cold medium and the hot medium with opposite flow directions, depending on the medium The straight channel 1 is divided into the first group of straight channels 6 and the second group of straight channels 7, the adjacent first group of straight channels 6 and the second group of straight channels 7 share a wall surface 2, and the first group of straight channels 6 pass through the corresponding The variable diameter adapter pipe 5 communicates with the medium pipeline, and the second set of straight passages 7 communicates with the medium pipeline through the housing 8 . The heat exchange surface between the hot medium and the...

Embodiment 2

[0050] The section of the straight channel 1 is a closed shape composed of straight lines and / or curves. For example, the section of the straight channel 1 is any one of regular triangles, rectangles, regular pentagons, regular hexagons or other polygons, such as Figures 9a-9b As shown, the main body of the cross section of the straight channel 1 is an equilateral triangle, and the three sides are evenly zigzag, which ensures that the flow direction and cross-sectional area of the medium in the core remain unchanged. Compared with the equilateral triangle, the structure increases the unit volume The lower heat exchange area can further increase the heat exchange power per unit mass of the heat exchanger. In addition, in a working environment with a large temperature difference, the heat exchanger will bear a large thermal stress; at this time, the zigzag structure can release the thermal stress through its own elastic deformation, and has better adaptability. The cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com