Mixed oil negative-pressure evaporation equipment

A negative pressure evaporation and mixed oil technology, applied in evaporation, evaporator accessories, flash evaporation, etc., can solve the problems of poor stability and large evaporation consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

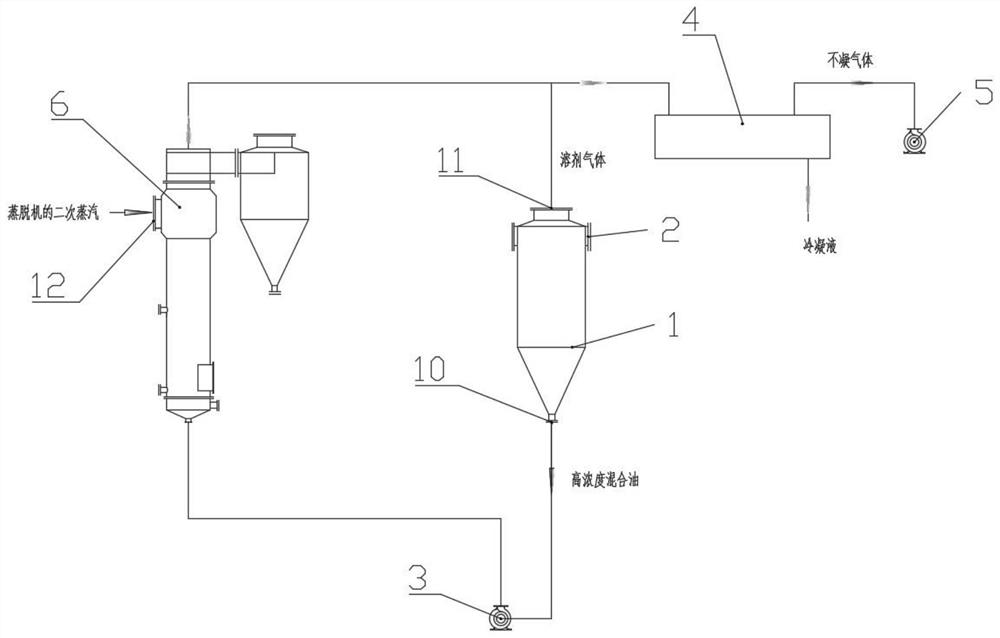

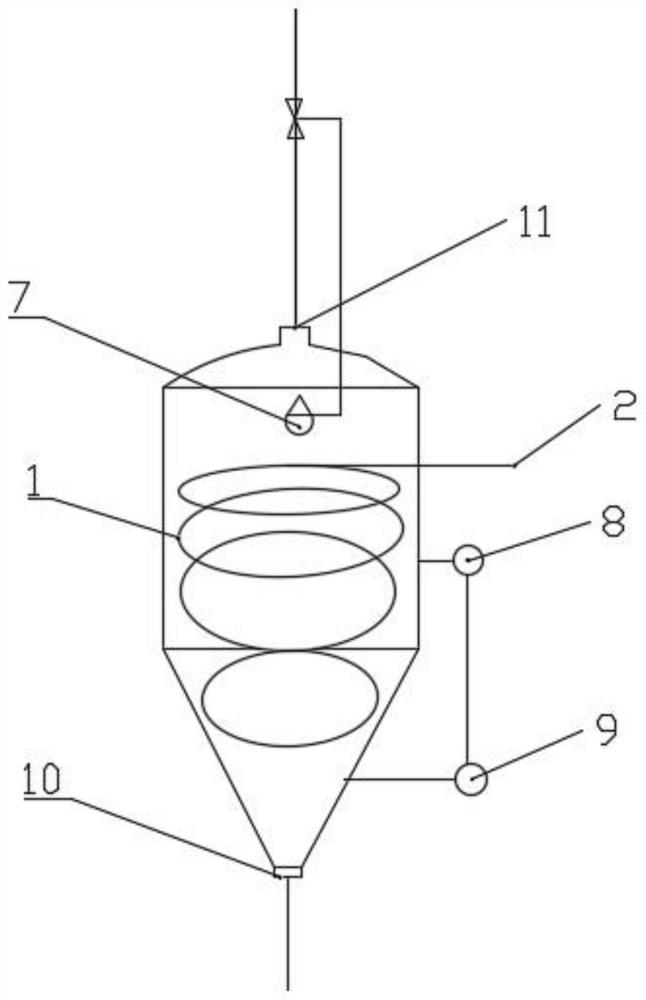

[0024] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, a mixed oil negative pressure evaporator of this embodiment, including a flash tank 1, a mixed oil pump 3, a condenser 4, a negative pressure water ring pump 5 and a first evaporator 6, on the flash tank 1 It is processed with a mixed oil input port 2, a mixed oil output port 10 and a volatile gas output port 11. The mixed oil output port 10 of the flash tank 1 is connected to the mixed oil pump 3, and the volatile gas output port 11 of the flash tank 1 is connected to the condenser 4. Connection, the output end of the mixed oil pump 3 is connected to the input end of the first evaporator 6, the output end of the first evaporator 6 is connected to the input end of the condenser 4, and the output end of the condenser 4 is connected to the negative pressure water ring pump 5 , the mixed oil enters the flash tank 1 from the mixed oil input port 2, and the flash tank 1 is in a negative pr...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, a kind of mixed oil negative pressure evaporation equipment of this embodiment, the bottom of described flash tank 1 is processed with mixed oil output port 10, and the side wall of flash tank 1 is processed with mixed oil input port 2, The top of the flash tank 1 is processed with a volatile gas output port 11; the solvent gas in the flash tank 1 is output from the volatile gas output port 11 on the top of the flash tank 1, and the mixed oil in the flash tank 1 is output from the mixed oil output port. 10 flows out, and the mixed oil to be processed flows in from the mixed oil input port 2.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, a kind of mixed oil negative pressure evaporation equipment of this embodiment, the flash tank 1 is a conical tank, the mixed oil enters the flash tank 1 in a tangential direction on the side of the flash tank 1, the mixed oil The inner wall of the flash tank 1 rotates and descends, and the top of the flash tank 1 is connected to the condenser 4. The solvent gas evaporated in the flash tank 1 enters the condenser 4 through the upper pipe for condensation, and the negative pressure inside the flash tank 1 is maintained. , solvent volatilization is achieved while the mixed oil is rotating down, and the temperature of the mixed oil is lowered while increasing the concentration of the mixed oil.

[0027] Specific implementation mode four: combination Figure 1-Figure 2 Describe this embodiment, a mixed oil negative pressure evaporator of this embodiment, the side wall of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com