Environment-friendly printing drying device

A printing drying and environmental protection technology, applied in the printing field, can solve the problems of paper surface quality reduction, loss of interception effect, paper wrinkling, etc., and achieve the effect of saving resources and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which presently preferred embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and will fully convey the scope of the invention. communicated to technical staff.

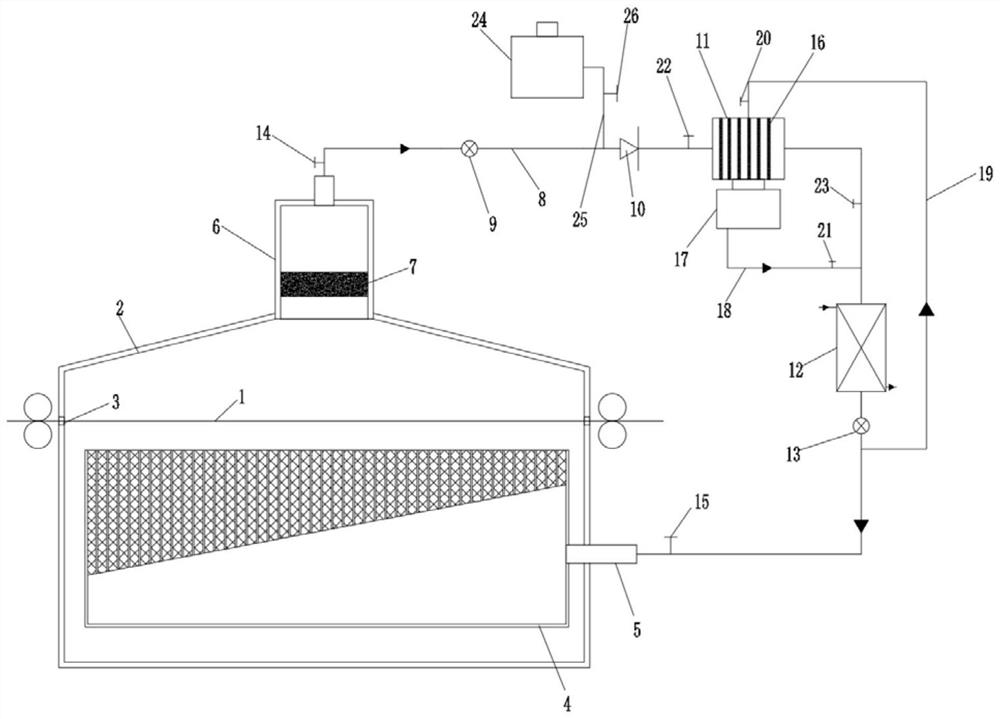

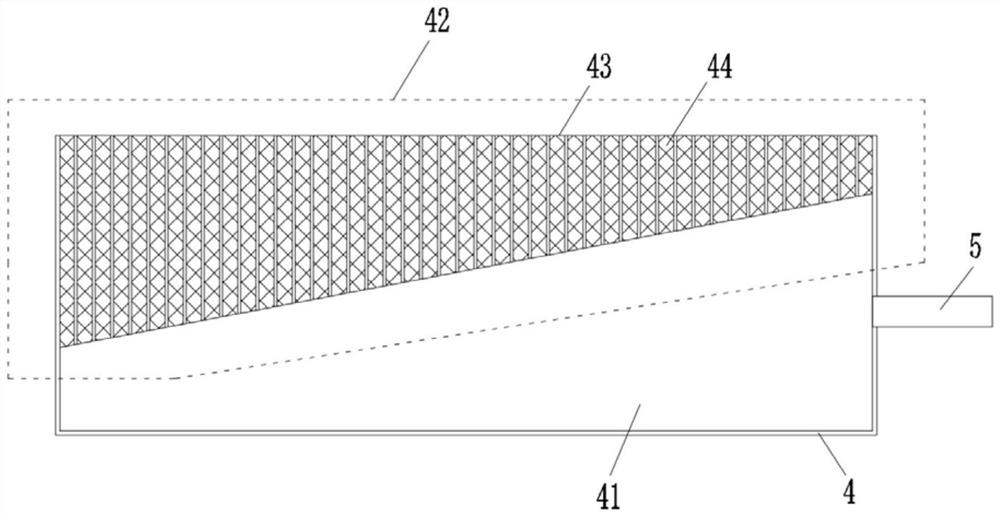

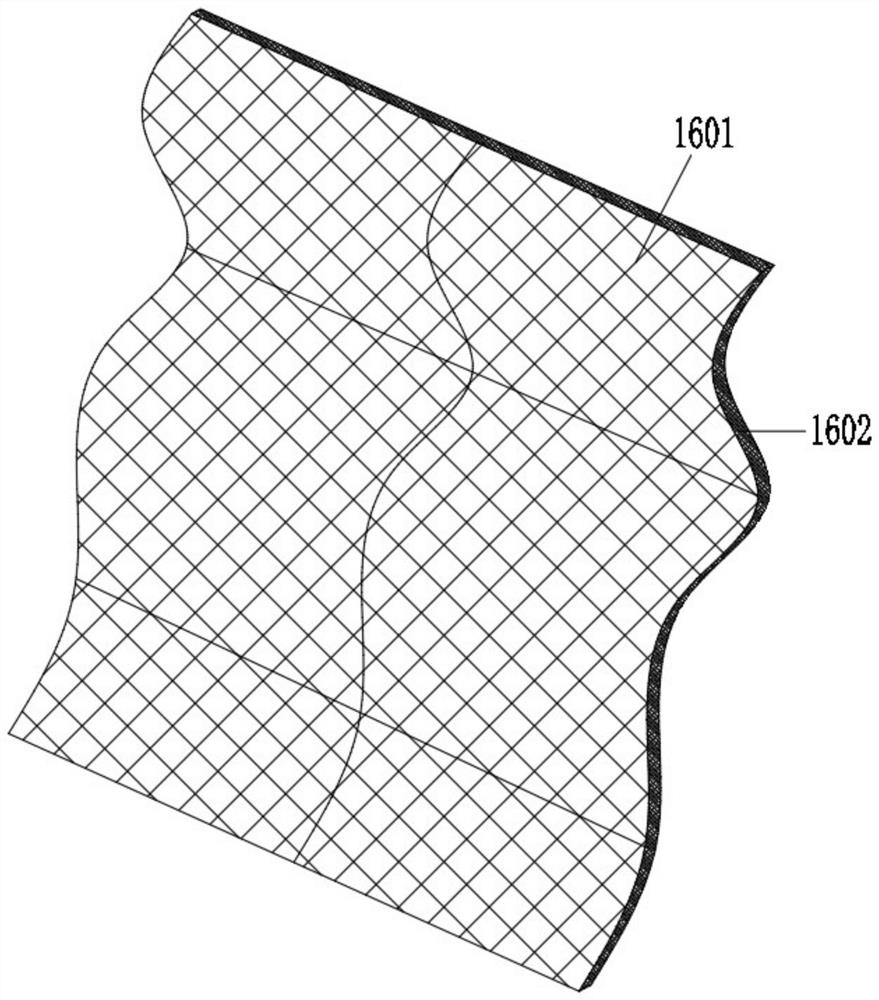

[0052] Such as Figure 1-9 As shown, an environmental protection printing drying device includes a drying chamber 2, a hot air box 4, an air inlet pipe 5, a drying box 6, a condensation water collector 7, a circulation pipeline 8, a first pressure pump 9, a filter box 11, Heat exchanger 12, second pressure pump 13, first shut-off valve 14 and second shut-off valve 15, gaps 3 are opened on both side walls of drying chamber 2, and paper 1 passes through the gaps 3 on both sides of drying chamber 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com