A Multiple Heat Exchange System Based on Deep Well Heat Exchange Technology

A heat exchange system and technology, which is applied in the field of multiple heat exchange systems based on deep well heat exchange technology, can solve the problems of poor heating efficiency at the heating end, the system cannot work normally, and cannot achieve long-term continuous heating, etc. Heating efficiency, heat loss reduction, temperature loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

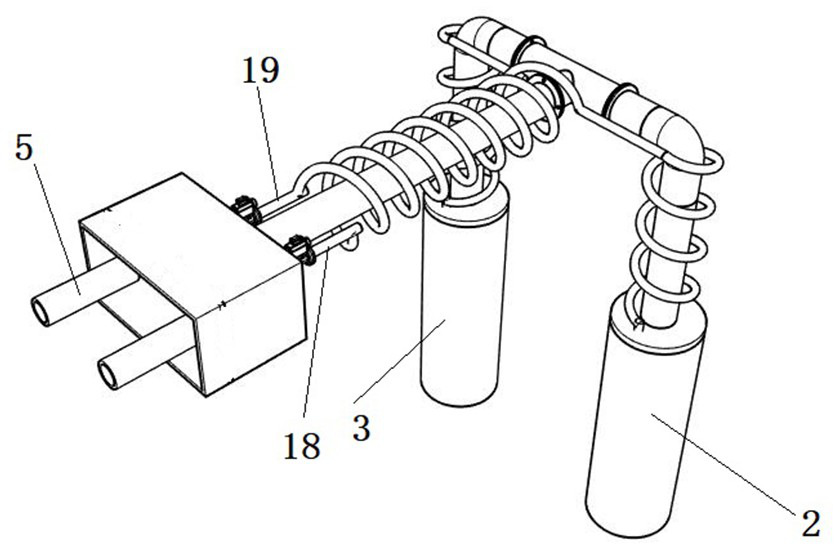

[0029]Embodiment 1, the first water return pipe 18 and the second water return pipe 19 are straight pipes, and the first water return pipe 18 and the second water return pipe 19 are respectively arranged on both sides of the water outlet pipe 16; The outer side of the second water return pipe 19 is evenly provided with heat dissipation fins 22; the heat dissipation fins 22 increase the heat dissipation effect of the first water return pipe 18 and the second water return pipe 19, enhance the heat preservation effect of the water outlet pipe 16, and reduce heat loss.

Embodiment 2

[0030] Embodiment 2, the first return pipe 18 and the second return pipe 19 are spiral pipes, and the first return pipe 18 and the second return pipe 19 are arranged on the periphery of the outlet pipe 16; the heat preservation effect of the outlet pipe 16 is enhanced, Reduced heat loss.

[0031] During the implementation process, the applicant found that turning on and off the first circulation pump 20 and the second circulation pump 21 may cause a large impact on the slider 14; the impact not only causes greater vibration and noise to the system, but also the internal slider 14 The impact in the high-pressure and high-speed system may cause damage to the slider 14 and reduce the reliability of the device. A sliding column 23 is horizontally provided in the reversing cylinder 10, and the slider 14 is provided with a corresponding sliding column. The gap 24; the slider 14 is inlaid with a first magnet 25; the barrier ring 15 is respectively provided with a second magnet 26; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com