Heat exchanger core and heat exchanger based on bionic stacking three-dimensional configuration

A three-dimensional configuration and heat exchanger technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of medium import and export restrictions, limited flow channel form, fuel medium coking, etc. Installation space, simple structure, and improved heat transfer power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

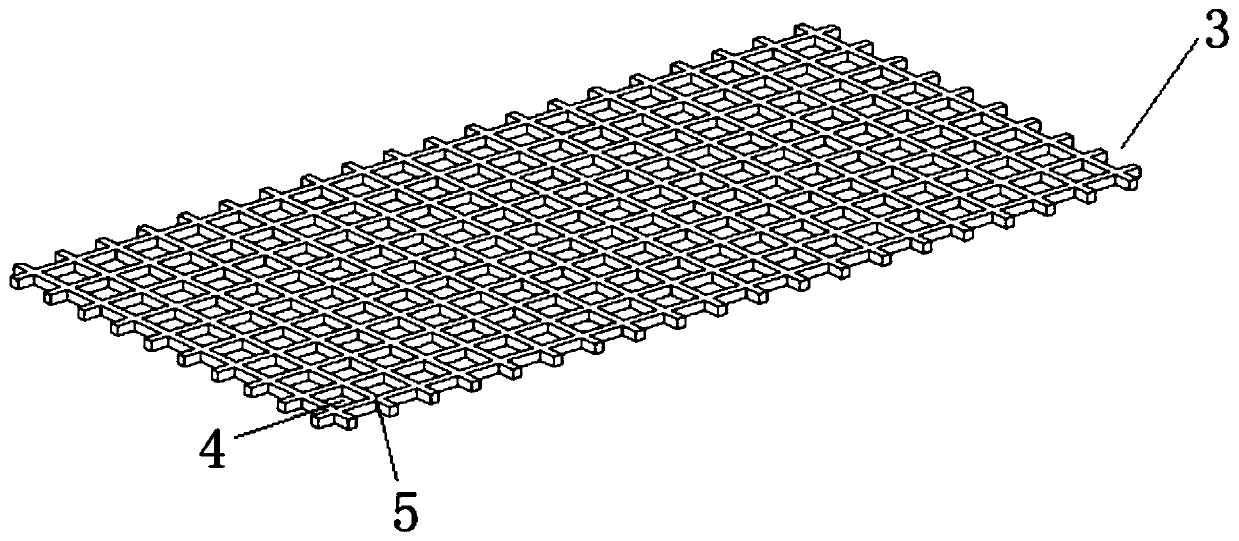

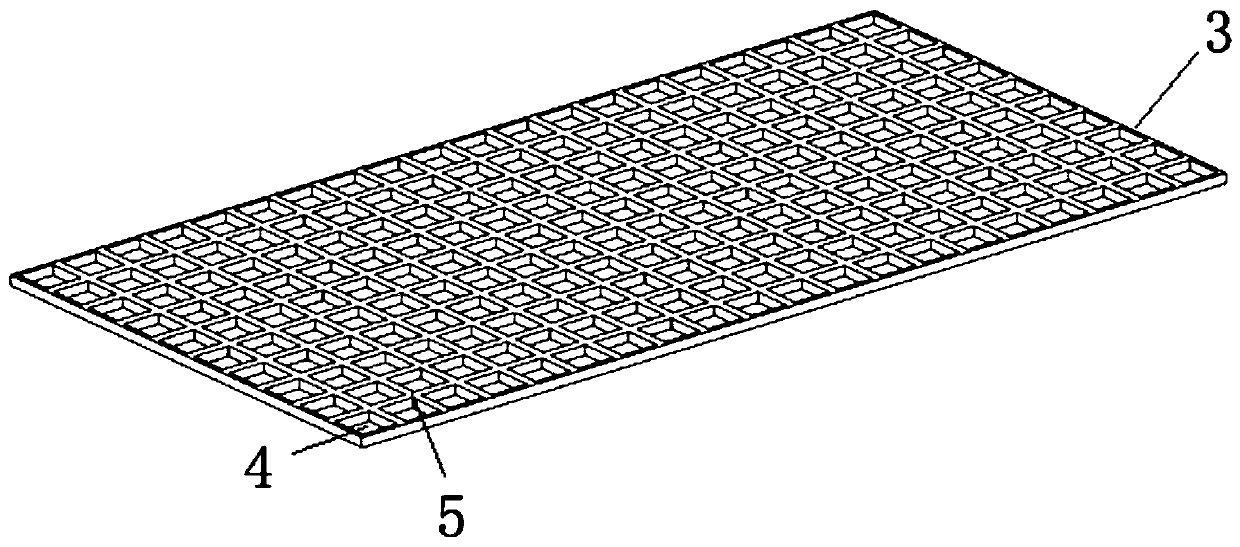

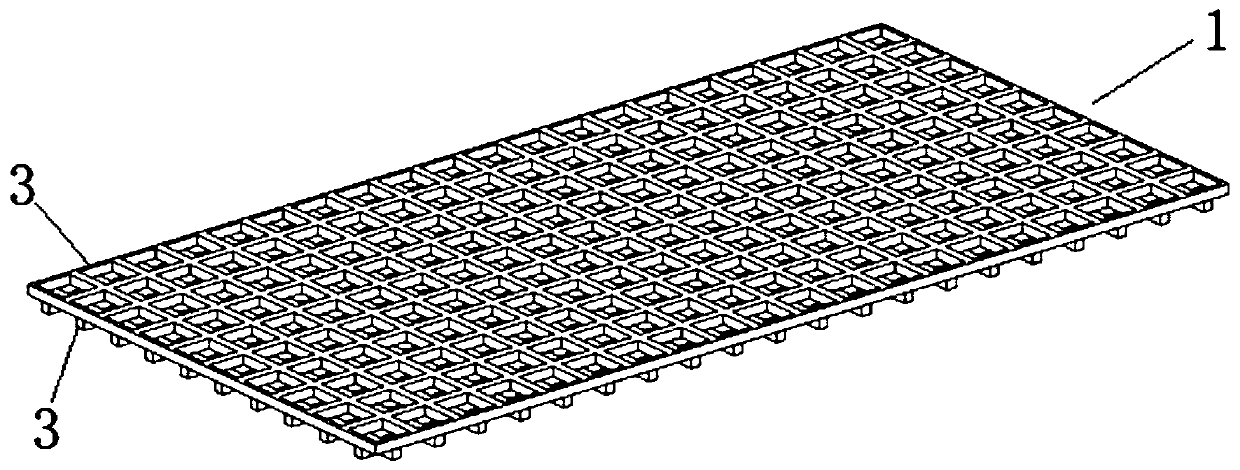

[0046] Heat exchanger core body of the present invention, as Figure 1-5As shown, it consists of multiple heat exchange units 1 stacked, each heat exchange unit 1 includes two layers of mesh plates 3, and a plurality of grids 4 are evenly distributed on the opposite end surfaces of the mesh plates 3, and the two layers of mesh The mesh rib nodes 5 of the plates 3 are interlaced (that is, the mesh rib nodes 5 of one layer of mesh plates 3 cannot overlap with the mesh rib nodes 5 of another layer of mesh plates 3), forming many interconnected flow channels and Chamber; thereby realizing a huge increase in the heat exchange surface and volume ratio, two adjacent heat exchange units 1 respectively constitute a cold-side medium flow chamber 6 and a hot-side medium flow chamber 7 for heat exchange; the mesh plate 3 The edge is provided with a frame 2 for edge sealing to prevent medium leakage. The cold side medium flow chamber 6 communicates with the cold medium through the inlet an...

Embodiment 2

[0049] Another structure of the heat exchanger core of the present invention, such as Figure 6-7 As shown, the bottom of the grid 4 is a through hole, so that both sides of the mesh plate 3 have the grid 4 with the same structure, and two or more layers of mesh plates 3 are stacked to form a single heat exchange unit 1, such as Figure 6-7 As shown, the exterior of a single heat exchange unit 1 is provided with a partition to prevent medium leakage; the stacking of multi-layer mesh plates 3 can further expand the heat exchange area of the heat exchange unit 1 per unit volume and improve heat exchange performance. The thickness of the mesh plates 3 of the same heat exchange unit 1 or different heat exchange units 1 may be equal or different, and the calculation and selection shall be carried out according to actual use requirements.

Embodiment 3

[0051] Alternative structures for the heat exchanger core of the present invention, such as Figure 8-9 As shown, the grid 4 of the mesh plate 3 is hexagonal, two layers of mesh plates 3 are stacked, and the rib nodes 5 of the two layers of mesh plates 3 are interlaced to form a more complex interconnected flow. Roads and chambers; among two adjacent layers of mesh plates 3, the rib node 5 of one layer of mesh plates 3 is located at the centroid of the grid 4 of the other layer of mesh plates 3.

[0052] The alternative scheme of the heat exchanger core based on the bionic stacked three-dimensional configuration of the present invention:

[0053] Grid 4 is a closed shape composed of straight lines and / or curves. Unclosed parts have poor mechanical properties and are difficult to weld and form; grid 4 is any one of triangles, rectangles, pentagons, hexagons or other polygons type; the grid 4 is any one of sector, ellipse, circle or other arc shapes.

[0054] Among the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com