Engine exhaust cooler

A cooler and engine technology, which is applied to engine components, machines/engines, exhaust devices, etc., can solve the problems of large changes in heat transfer coefficient, reduction of heat transfer power of coolers, and different heat transfer coefficients of heat exchange tubes. Achieve the effect of increasing heat transfer coefficient, reducing pressure loss and increasing heat transfer power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

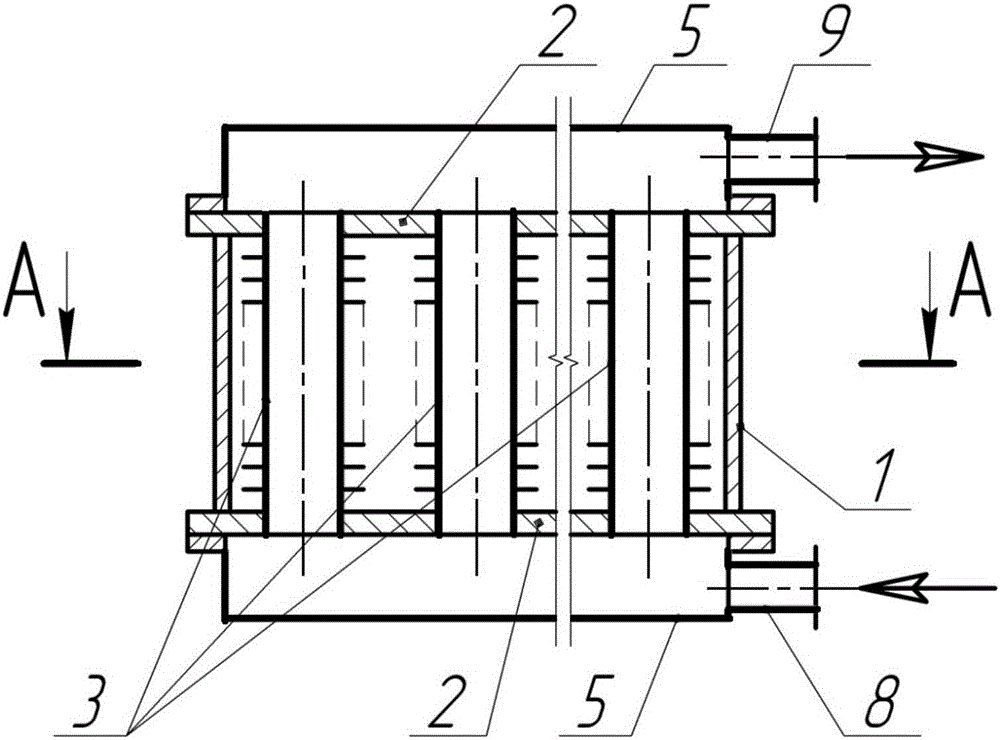

[0017] Embodiment 1, figure 1 , figure 2 Provided is an engine exhaust cooler, including a housing 1, the housing 1 has a built-in cavity, and the cavity is provided with a smoke flow channel and a coolant flow channel, and the smoke flow channel and the coolant flow channel are connected to each other. Intertwining, the flue gas temperature is cooled by cooling liquid.

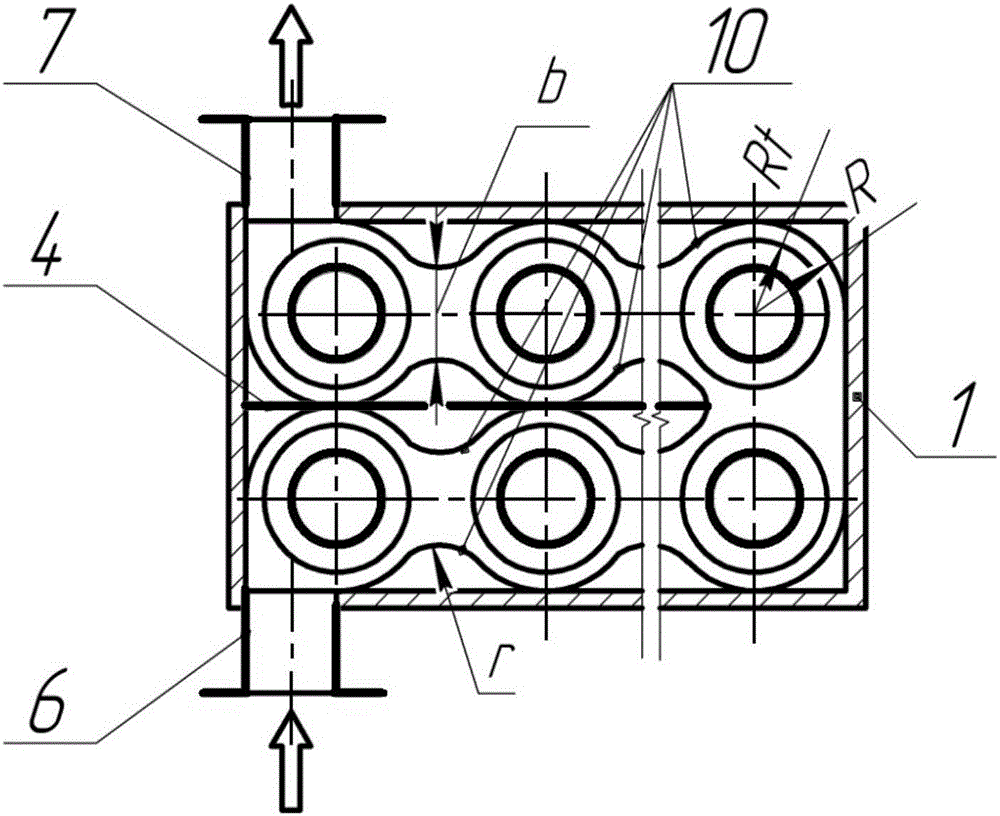

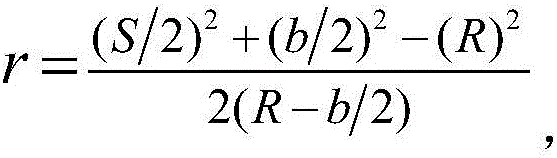

[0018] The flue gas flow channel is a deflector 10, and a partition 4 is vertically arranged on the bottom surface of the housing 1, and the deflector 10 is U-shaped by connecting two sections of circular arcs periodically along the direction of the partition 4. The U-shaped configuration enables the deflector 10 to achieve as long a travel space as possible in as small a space as possible, increasing the cooling effect.

[0019] And this cooling fluid channel is finned tube 3, and this finned tube 3 is inside deflector 10, realizes the supply function of cooling fluid by arranging water chamber housing 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com