Compound accident residual heat removal system for accelerator-driven sub-critical reactor

A waste heat removal system, accelerator-driven technology, applied in reactors, greenhouse gas reduction, nuclear engineering and other directions, can solve problems such as poor passive performance and poor effectiveness, and achieve the effect of meeting safety design requirements and improving passive safety characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

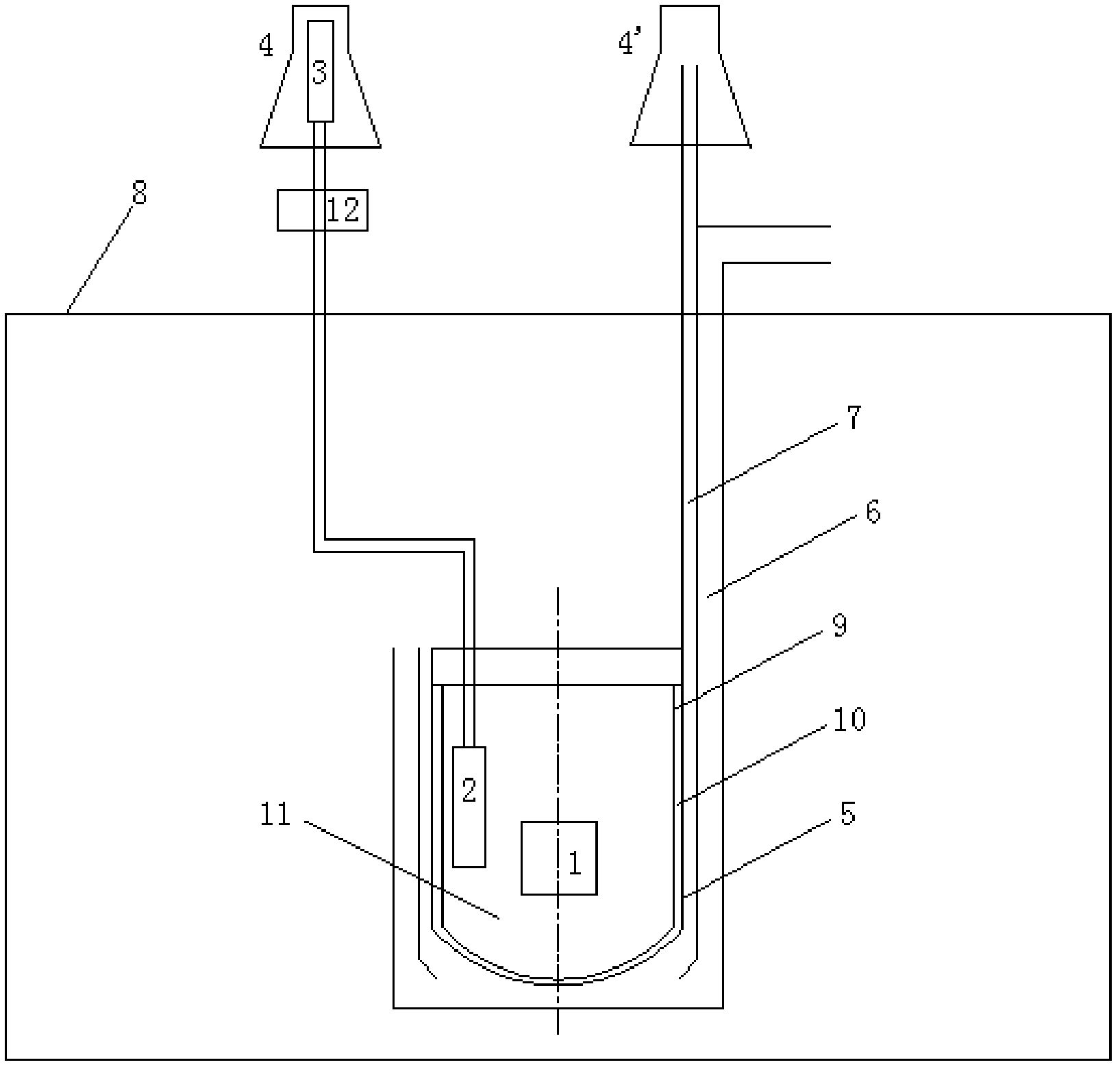

[0017] Such as figure 1 As shown, the present invention consists of two sets of passive and independent cooling systems, each of which relies on natural circulation for cooling without the need for an AC power supply, including a reactor core direct cooling system and a reactor safety vessel auxiliary cooling system.

[0018] The reactor core direct cooling system is composed of two mutually independent loops with the same structure. The two independent loops with the same structure belong to the same system, but they are independent of each other during operation and have redundancy Sexual characteristics, in order to improve the reliability and effectiveness of the system. Each loop includes an independent heat exchanger 2 installed in the lead-bismuth pool, an air heat exchanger 3 outside the containment, a first exhaust chimney 4 and measuring and controlling instruments 12 . Among them, the measurement and control instrument 12 belongs to a part of the reactor measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com