Boiling water nuclear reactor and emergency core cooling system of the same

a nuclear reactor and core cooling technology, applied in nuclear engineering, nuclear elements, greenhouse gas reduction, etc., can solve the problems of molten core, damage to core, and falling water level in the pressure vessel of the reactor,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

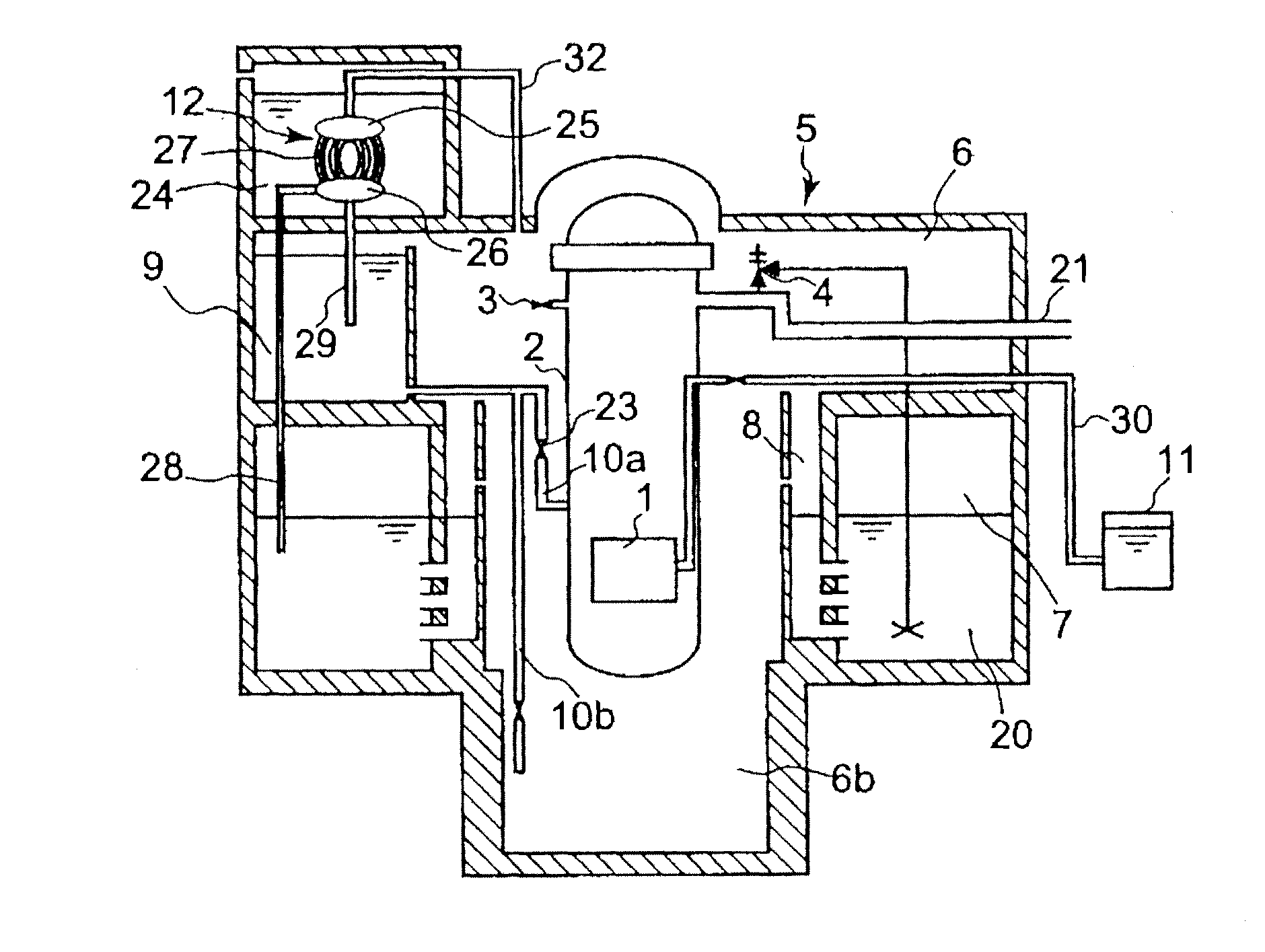

[0024]FIG. 1 is a schematic elevational cross-sectional view of the first embodiment of a boiling water nuclear reactor according to the present invention. The reactor containment vessel 5 of the reactor includes a dry well 6 and a wet well 7, and a reactor pressure vessel 2 of the reactor is contained in the dry well 6. A pressure suppression pool 20 is arranged in the wet well 7. The water in the pressure suppression pool 20 is used to fill the fuel exchange pool with water when the operation of the reactor stopped to replace the core fuel. The reactor pressure vessel 2 contains the core 1, the internal structure and the reactor water (not shown).

[0025]Vent pipes 8 extend from an upper part of the dry well 6 into the pressure suppression pool 20. Main steam pipes 21 are arranged to feed the main steam generated in the reactor pressure vessel 2 to the steam turbine (not shown) outside the reactor containment vessel 5 and main steam safety relief valves 4 are fitted to the main stea...

second embodiment

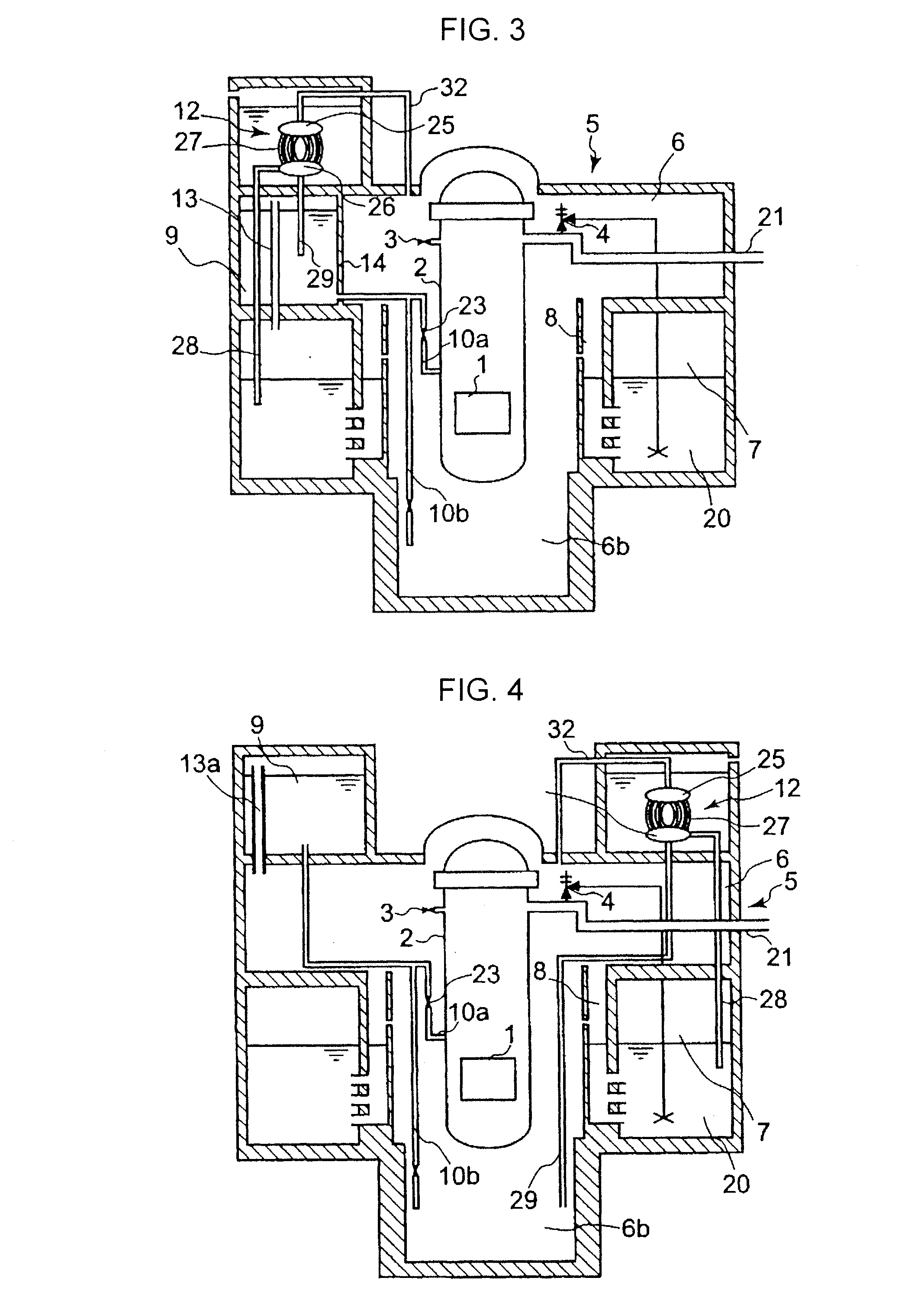

[0045]FIG. 3 is a schematic elevational cross-sectional view of the second embodiment of a boiling water nuclear reactor according to the present invention. In this embodiment, the gravity-driven water injection pool 9 holding boric acid aqueous solution is isolated from the dry well 6 by means of a partition wall 14. The gas phase section above the liquid surface of the gravity-driven water injection pool 9 is held in communication with the upper gas phase section in the wet well 7 by way of a first communication pipe 13.

[0046]The boric acid aqueous solution injection system including a boric acid aqueous solution injection tank 11 and a boric acid aqueous solution injection pipe 30 similar to its counterpart illustrated FIG. 1 are omitted in the embodiment shown in FIG. 3. However, the boric acid aqueous injection system may be arranged in this embodiment as in FIG. 1. This statement also applies to all the succeeding embodiments.

[0047]This embodiment operates like the first embod...

third embodiment

[0048]FIG. 4 is a schematic elevational cross-sectional view of the third embodiment of a boiling water nuclear reactor according to the present invention. In this embodiment, the gravity-driven water injection pool 9 holding boric acid aqueous solution is arranged above the ceiling of the reactor containment vessel 5. The gas phase section above the liquid surface of the gravity-driven water injection pool 9 is held in communication with an upper part of the dry well 6 by way of a second communication pipe 13a. Additionally, the drain pipe 29 connected to the bottom of the lower header 26 of the static containment vessel cooling system heat exchanger 12 extends down into the dry well lower region 6b in this embodiment.

[0049]This embodiment operates like the first embodiment in the sense that it can maintain the core in a subcritical state by holding boric acid aqueous solution in gravity-driven water injection pool 9. Additionally, the design limitations of the inside of the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com