Control rod driving mechanism of floating type reactor

A floating reactor and driving mechanism technology, applied in the control of nuclear reactions, reactors, reducing greenhouse gases, etc., can solve problems such as wear, complex contact conditions, and difficulty in re-engaging the roller nut and the lead screw, and achieve precise operation High strength, simple and easy structure, and reliable mechanism transmission action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

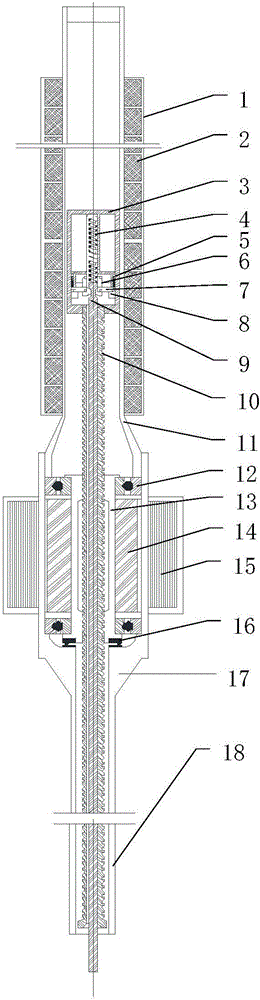

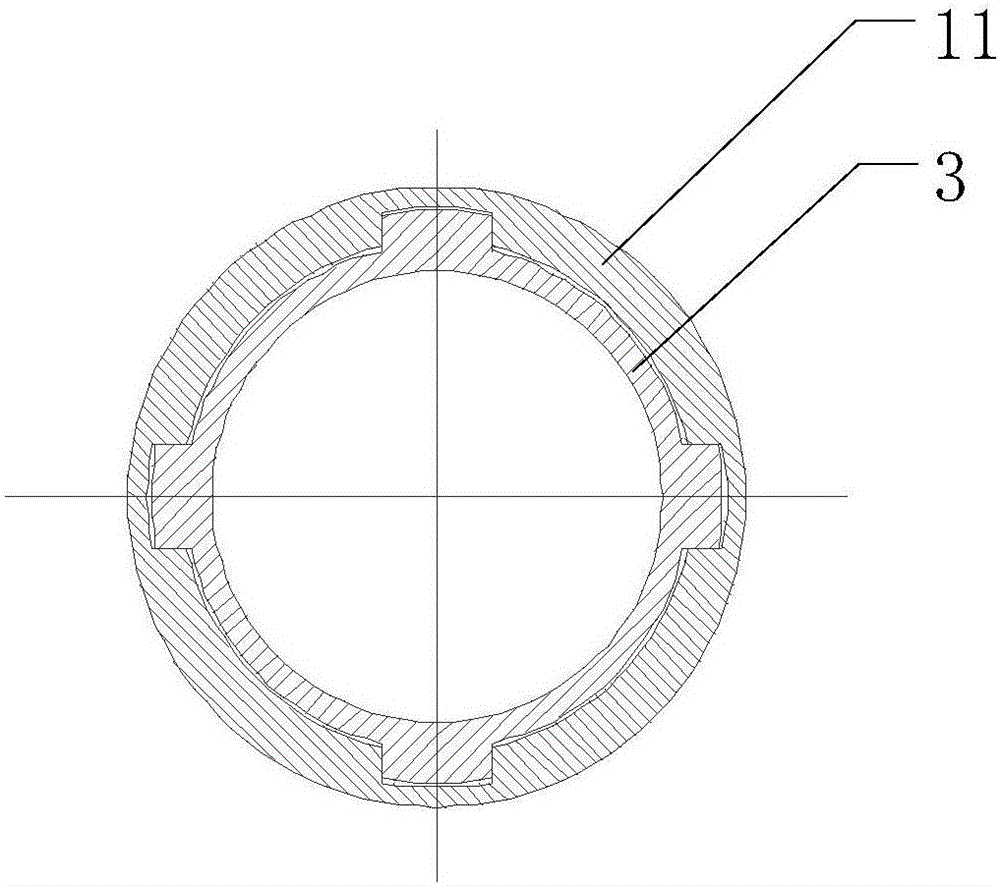

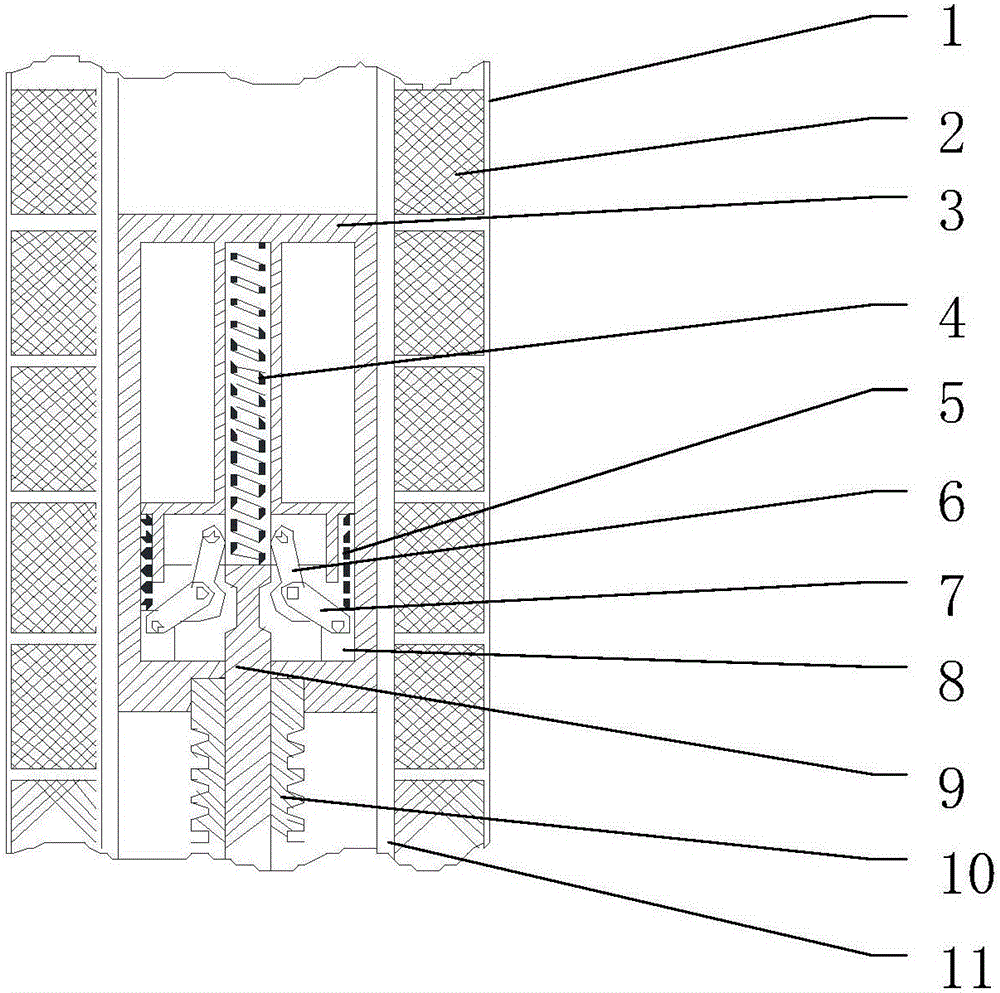

[0027] as attached figure 1 As shown, the floating reactor control rod driving mechanism of the present invention includes a pressure-bearing shell part, a driving motor part, a rod drop release mechanism part, a yoke coil part and a driving screw part. Among them: the pressure-bearing shell components are composed of the screw stroke shell 11, the motor pressure-bearing shell 17 and the guide sleeve 18, which together form the pressure boundary, wherein the motor pressure-bearing shell 17 and the reactor top cover (not shown in the figure) The connection is fixed; the driving motor components are composed of stator windings 15, rotor 14, nuts 13, thrust bearings 16 and radial bearings 12, wherein the stator windings 15 can be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com