Realization circuit and realization method of constant current and constant power

A constant power and circuit technology, applied in the field of control circuits, can solve the problem that the shunt is difficult to meet the requirements of power derating, and achieve the effects of high accuracy, simple circuit structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

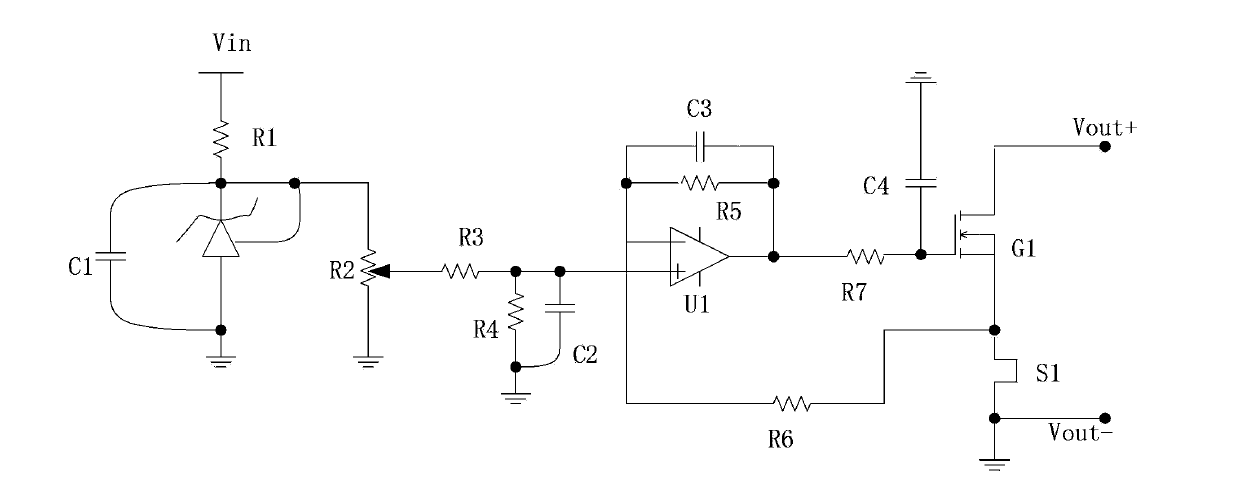

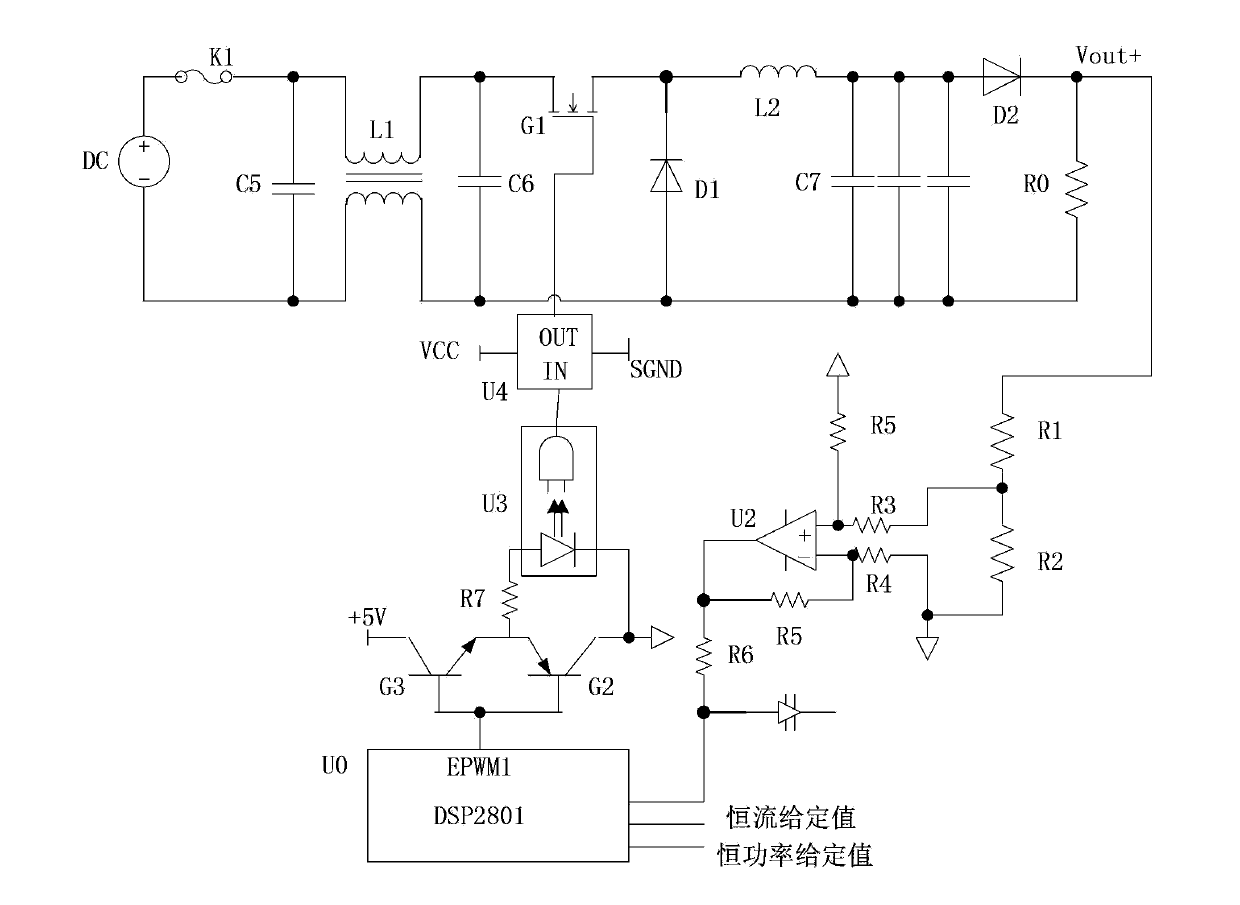

[0032] The invention realizes constant current and constant power output by sampling the voltage on the output resistor, and then utilizes chopping to realize constant current and constant power output without sampling components, and has many advantages such as easy implementation, simple circuit, and low implementation cost.

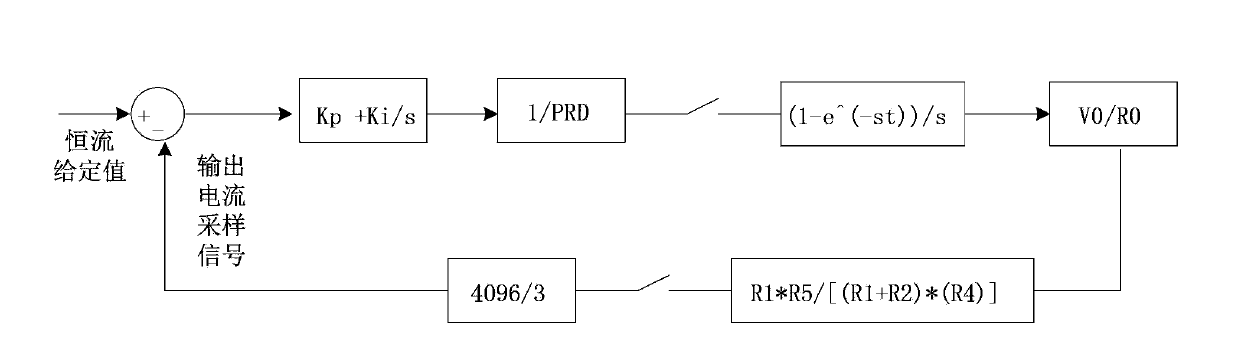

[0033] figure 2 Shown is a schematic circuit diagram of one embodiment of the present invention. The DC power supply reaches the output terminal through the main circuit to supply power for the resistive load R0 (also referred to as the load R0). By detecting the voltage across the resistive load R0 (that is, the output voltage), and then dividing it by the resistance value of the resistive load R0, that is The actual output current can be obtained, therefore, the output current sampling value is obtained by adopting the output current on the load R0; the current sampling circuit connected to the load R0 includes a voltage divider circuit connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com