Construction machinery, control system and control method thereof

A technology of construction machinery and control systems, applied in the direction of electrical program control, etc., can solve the problems of engine speed control process lag, engine speed lag, hydraulic pump overall distribution, etc., to facilitate operation and control, improve maneuverability, improve The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

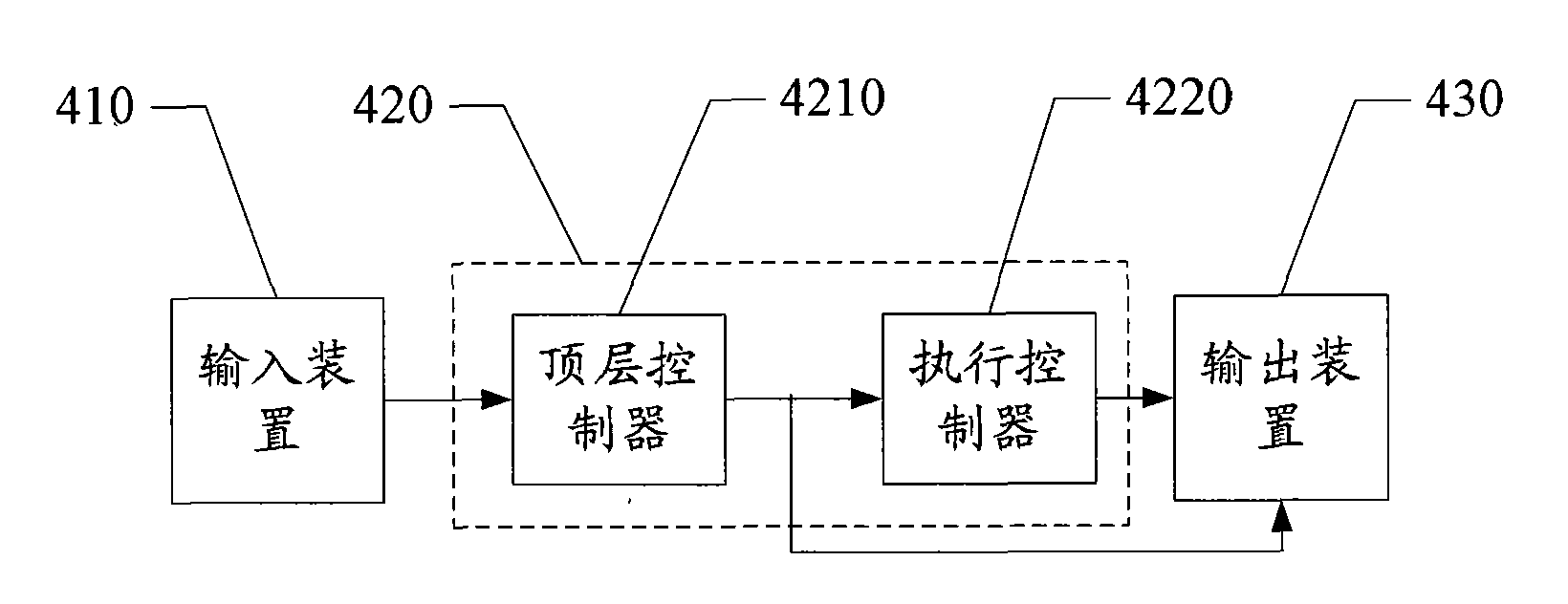

[0072] In the second embodiment, the benefit of the control device 420 including the top-level controller 4210 and the execution controller 4220 is that: the top-level controller 4210 and the execution controller 4220 perform their own duties, and the top-level controller 4210 is responsible for processing the overall power matching and energy of the construction machinery. Optimization, the overall overall optimization of construction machinery can be realized through intelligent technology, for example: it can be realized through fuzzy technology, neural network technology, expert system technology, genetic algorithm technology, quenching algorithm technology, ant colony algorithm technology, chaos optimization technology and other methods Global optimization of construction machinery. Executing controller 4220 actually executes and controls the operation of the hydraulic system. Existing PID or other existing control technologies can be used to obtain two sets of PWM variabl...

Embodiment 4

[0080] Embodiment 4 is an improvement on the basis of Embodiment 3. In addition to the storage unit 4211 and the top-level analysis unit 4212, the top-level controller 4210 also includes a first judgment unit 4213; the first judgment unit 4213 receives the predetermined Operating parameters and actual operating parameters of construction machinery, judge whether the actual operating parameters of construction machinery meet the requirements according to the predetermined operating parameters and actual operating parameters, if yes, then no longer output the obtained predetermined operating parameters, if not, then output the predetermined operating parameters , and deliver predetermined operating parameters to the execution controller 4220 .

[0081] Its specific operation process is as Figure 6 as shown, Figure 6 It is a schematic diagram of the working process of the construction machinery control system provided by Embodiment 4 of the present invention, and is also a flo...

Embodiment 6

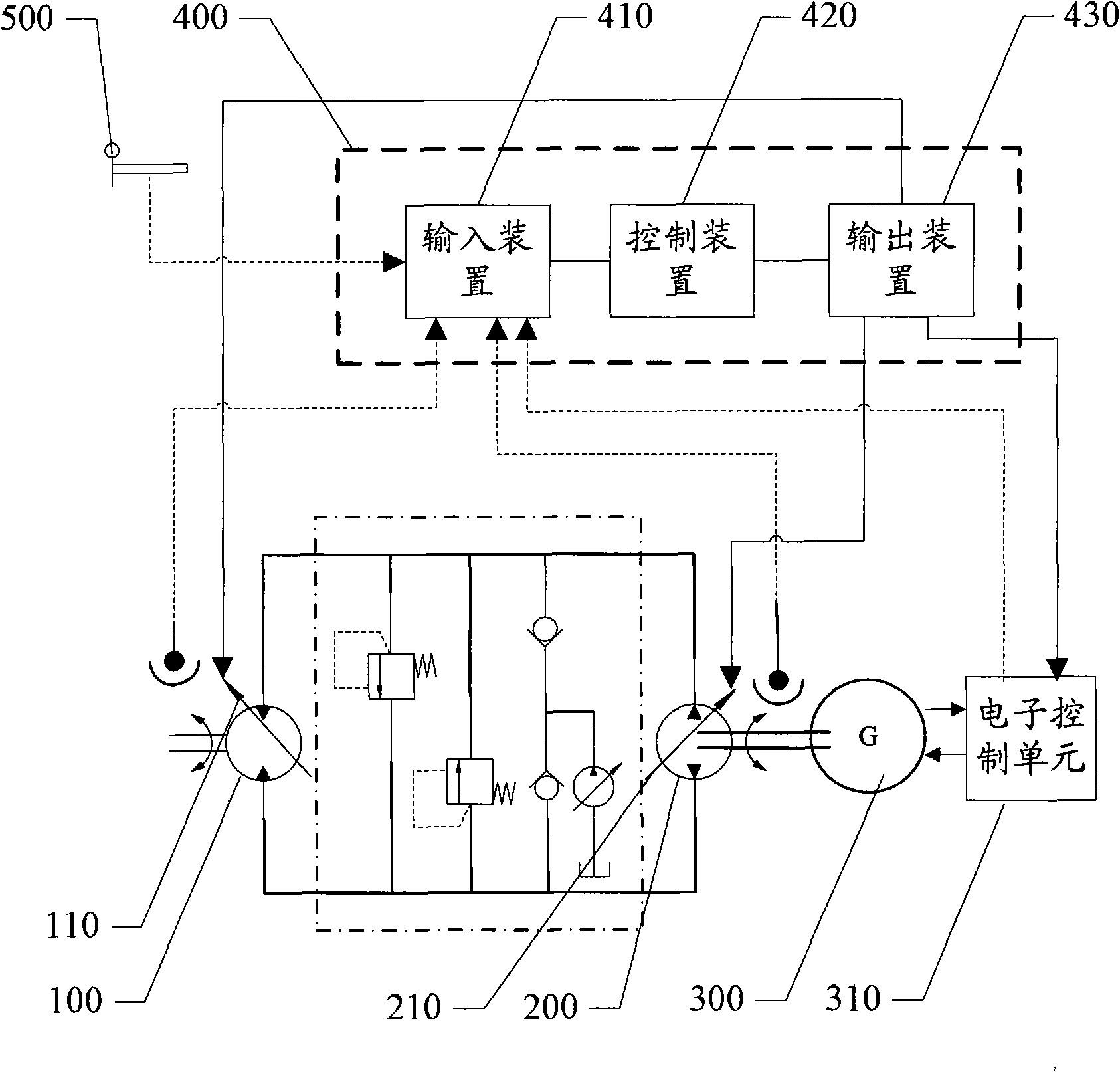

[0090] In the sixth embodiment, the engineering machinery includes a prime mover 300 and a hydraulic system, and the hydraulic system includes a hydraulic pump 200, a hydraulic control element 110, a hydraulic actuator 100, and an operating mechanism 500. In this example, the hydraulic system is an open hydraulic system, and the hydraulic system The actuator 100 is a hydraulic cylinder, and the hydraulic control element 110 is a reversing valve, through which the extension or retraction of the hydraulic cylinder is controlled. The control system also includes an output device 410 , a control device 420 and an output device 430 . The control device 420 may further include a top-level controller 4210 and an execution controller 4220, and the top-level controller 4210 and the execution controller 4220 may have the above-mentioned specific structure.

[0091] The working process of the construction machinery control system provided in Embodiment 6 is basically the same as that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com