Module type pressurized water reactor

A pressurized water reactor and modular technology, applied in the field of nuclear reactors, can solve the problems of difficulty in refueling maintenance, power scale and parameter limitations, and technical difficulties, so as to improve safety and economy, reduce construction costs, and simplify refueling. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

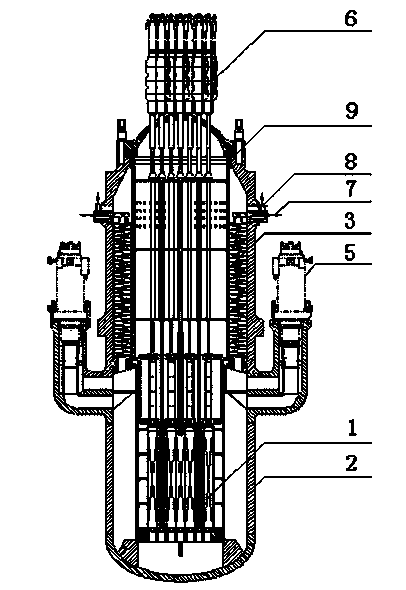

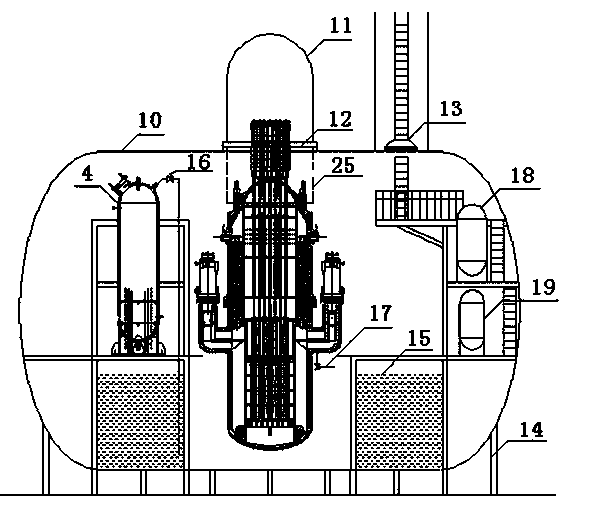

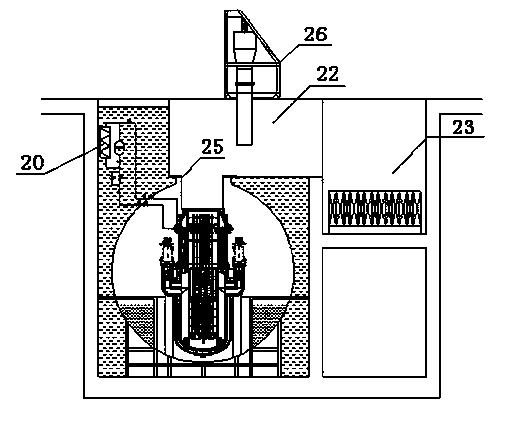

[0043] Such as figure 1 As shown, the modular pressurized water reactor of the present invention includes a reactor body and related safety systems.

[0044] The reactor body is composed of a reactor core 1 , a reactor pressure vessel 2 , a DC steam generator 3 , a shielded motor main pump 5 , and a control rod drive mechanism 6 .

[0045] The reactor core 1 is composed of truncated nuclear power plant fuel assemblies and related components, which are hung on the support steps in the middle of the reactor pressure vessel 2 through hanging baskets, located at the lower part of the reactor pressure vessel 2, and the intermediate chamber on the upper part of the reactor core 1 is for cooling The ascending channel of the agent.

[0046] The control rod drive mechanism 6 is arranged on the top cover of the pressure vessel 2 .

[0047] The once-through steam generator 3 is evenly arranged in the annular cavity between the reactor pressure vessel 2 and the upper internals along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com