Pressure suppression and safe injection system

A technology for safe injection and containment, which is used in nuclear power generation, climate sustainability, emergency protection devices, etc. It can solve the problems of complex configuration of safety systems, poor economy, and large containment size, and achieve good economy and containment. Small size, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

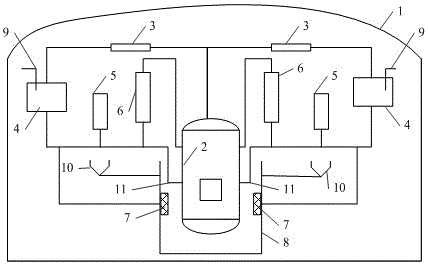

[0027] In Embodiment 1, a suppression and safety injection system is provided, please refer to figure 1 , the system includes:

[0028] Containment vessel 1, the containment vessel 1 is equipped with: suppression pool 4, core water supply tank 6, safety injection tank 5, pressure vessel sump 8, primary circuit pressure relief device 3, and reactor pressure vessel 2; wherein, The decompression water pool 4 is used to absorb the heat released by the reactor system under an accident, and the water in the depressive water pool 4 is injected into the core by gravity to realize the low-pressure injection function; The water source is provided for active high-pressure safety injection; the safety injection tank 5 is used to provide water source for passive medium-pressure safety injection; the pressure vessel sump 8 is used to collect condensed water condensed by the containment cooling system, and is used for long-term recycling Cooling provides a water source and enables retention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com