Glass or ceramic sintered electric through piece for reactor safety shell

A technology of electrical penetrations and containment, which is applied in the direction of reactors, nuclear power generation, and reduction of greenhouse gases, etc. It can solve the problems of reactor radiation resistance, high temperature resistance, creep resistance, long life, complex production process, low yield, etc. problems, to achieve the effect of mature and reliable production process, low gas leakage rate and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

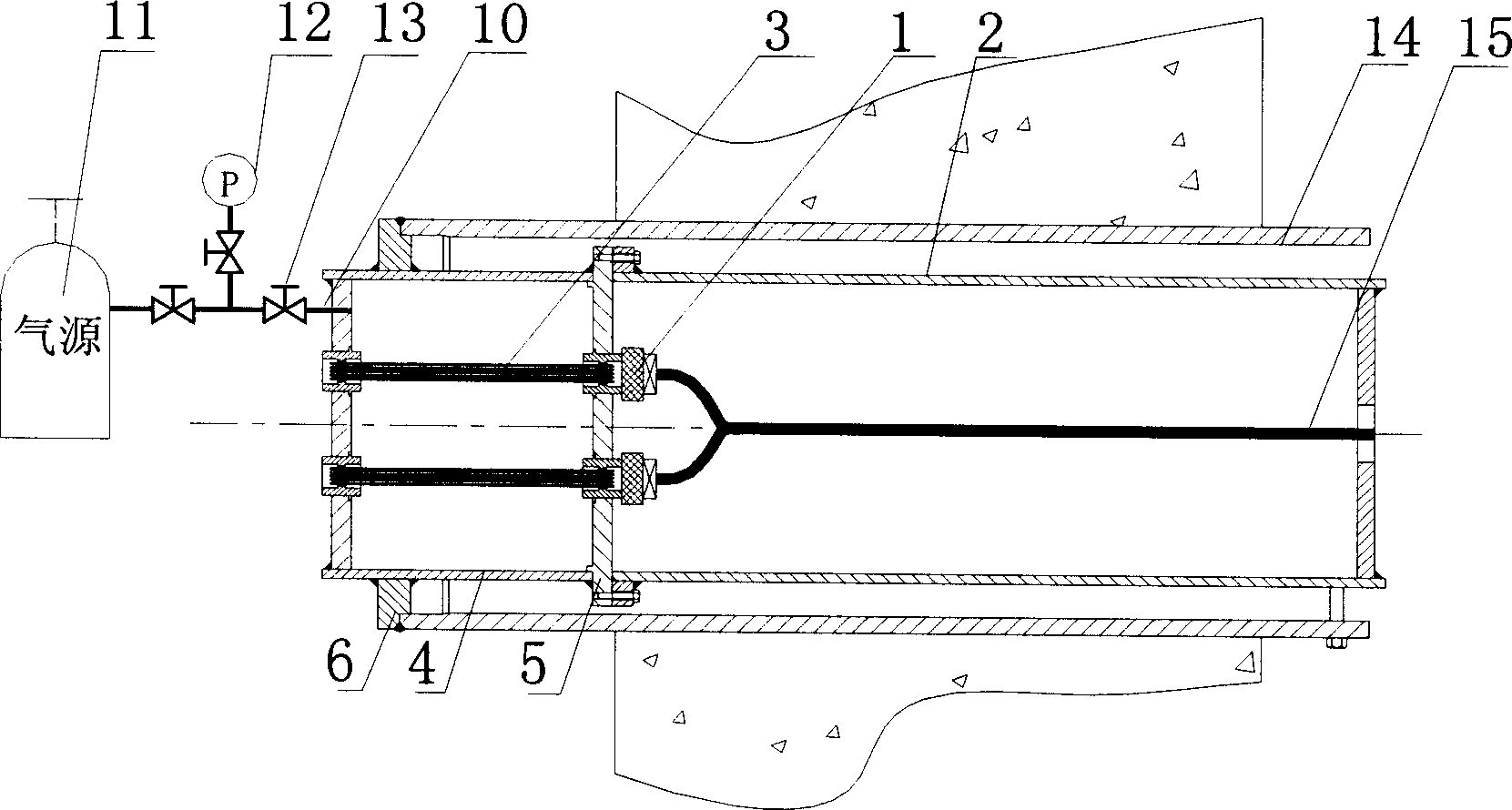

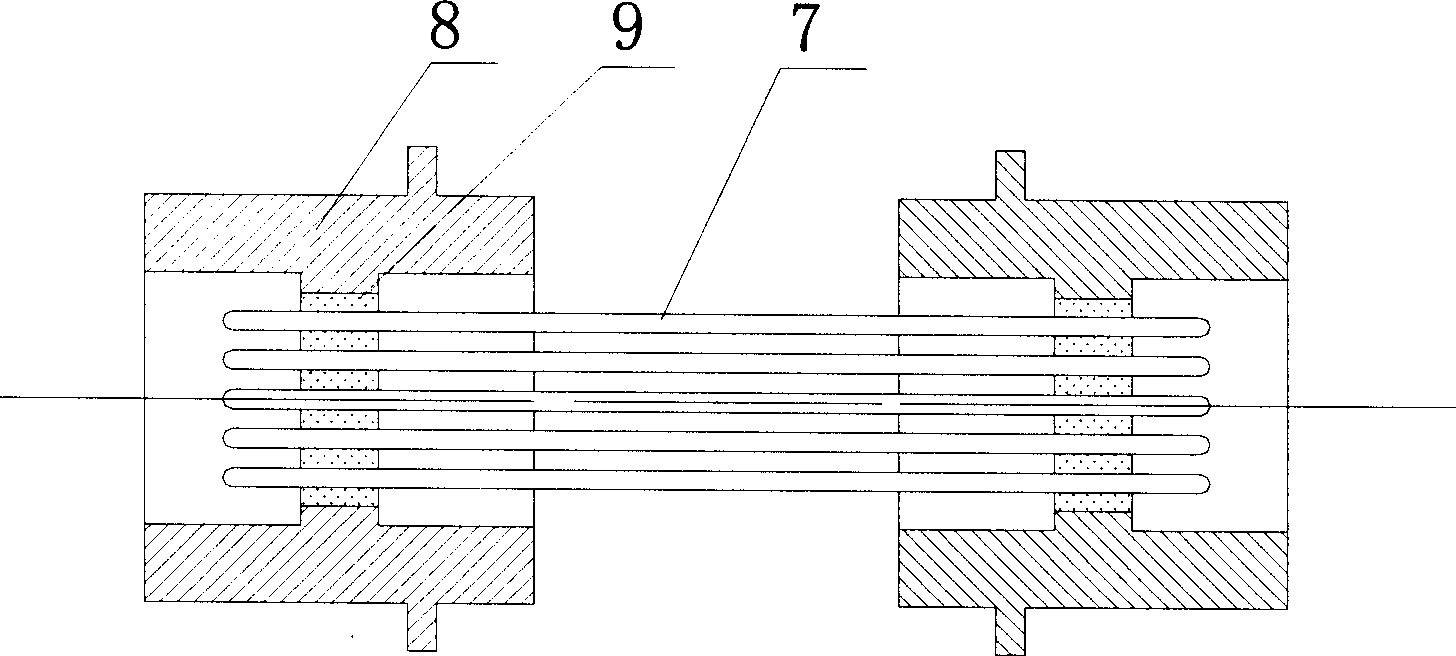

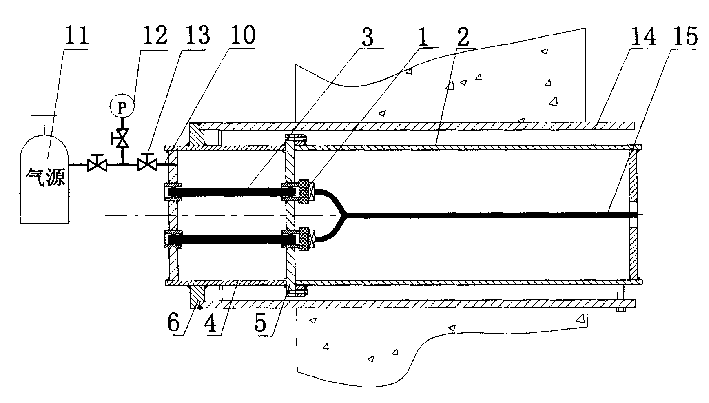

[0010] The electrical penetration of the present invention includes a penetration body, a leak detection device, a cable plug 1 , a protective cover 2 and a connecting flange 6 . The body of the penetration includes an "H"-shaped conductor assembly 3, an assembly housing 4 and two end plates 5, and the connecting flange 6 and the body of the penetration must be designed according to the pressure vessel standard. Each "H"-shaped conductor assembly 3 is composed of one or more electrical conductors 7 and connector sockets 8 at both ends, and the electrical conductors 7 and connector sockets 8 are sintered with glass or ceramics 9 for insulation and sealing. The connector holder 8 is preferably made of a valveable material to ensure that the connector holder 8, the glass or ceramics 9, and the electrical conductor 7 have similar thermal expansion coefficients to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com