Energy-feedback tractive power supply system with high power factor and high cost performance

A traction power supply system, high power factor technology, applied in the direction of reactive power adjustment/elimination/compensation, power lines, reactive power compensation, etc., can solve problems such as large fluctuation range, energy waste, poor overload capacity, etc., to achieve power improvement factor, reducing current harmonics, and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is an example of a traction power supply system with a subway line length of 20 kilometers and 8 energy-feedback substations.

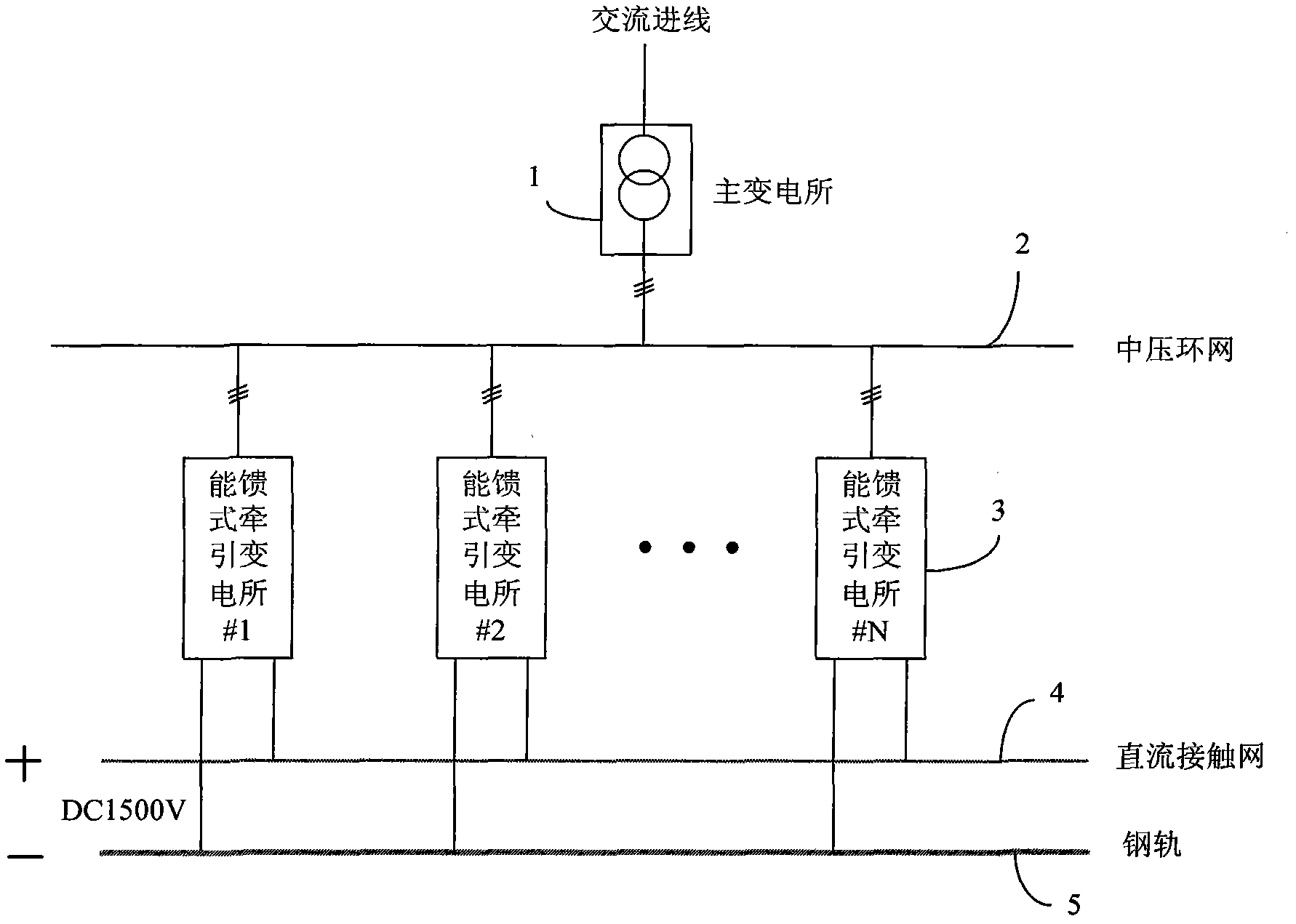

[0026] The whole traction power supply system adopts such as figure 1 The main circuit topology shown. in:

[0027] The main equipment in the main substation is a large-capacity oil-immersed transformer, which is used to convert the input 110kV high voltage into the medium-voltage ring network 35kV voltage, which is used by the energy-fed traction substations on the line. The transformer capacity is 60MVA.

[0028] The medium-voltage ring network adopts 35kV XLPE insulated power cables, which are laid along the subway lines, and are used to transmit and distribute electric energy from the main substation to various energy-fed traction substations. With the adoption of regenerative traction substations, excess train braking energy can also be fed back to the medium-voltage ring network and reused by other substations to achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com