Three-phase power factor correcting circuit with AC boosting mode

A technology of three-phase power and correction circuit, which is applied in the field of power electronics, can solve problems such as technical difficulty and difficulty in realizing harmonic suppression of three-phase circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

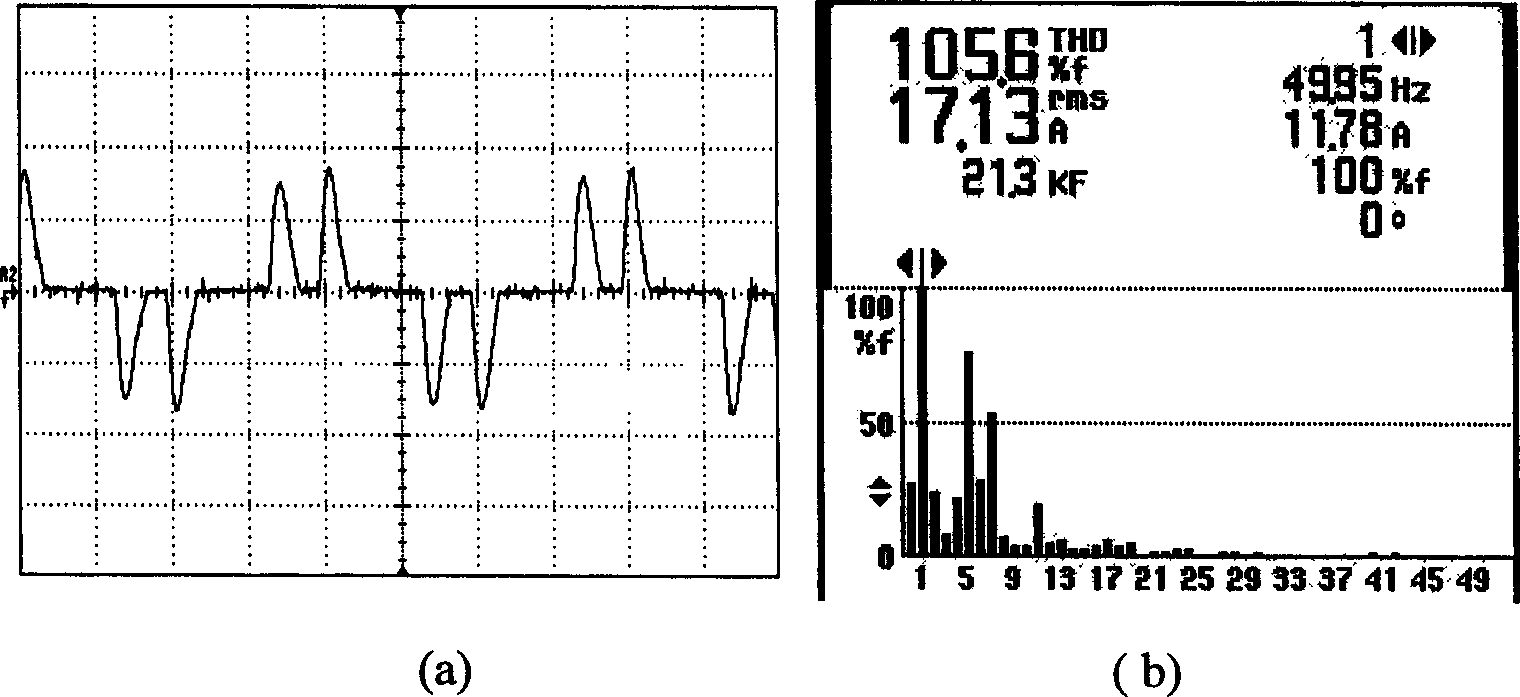

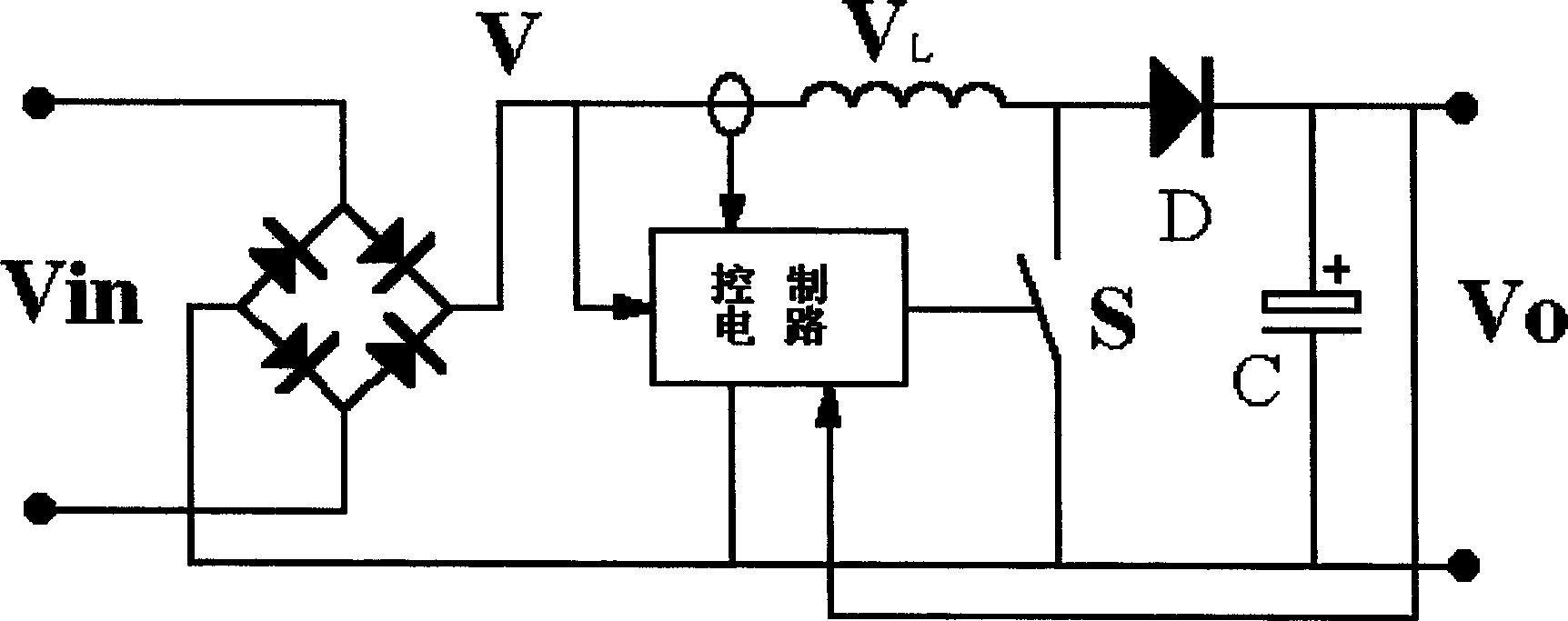

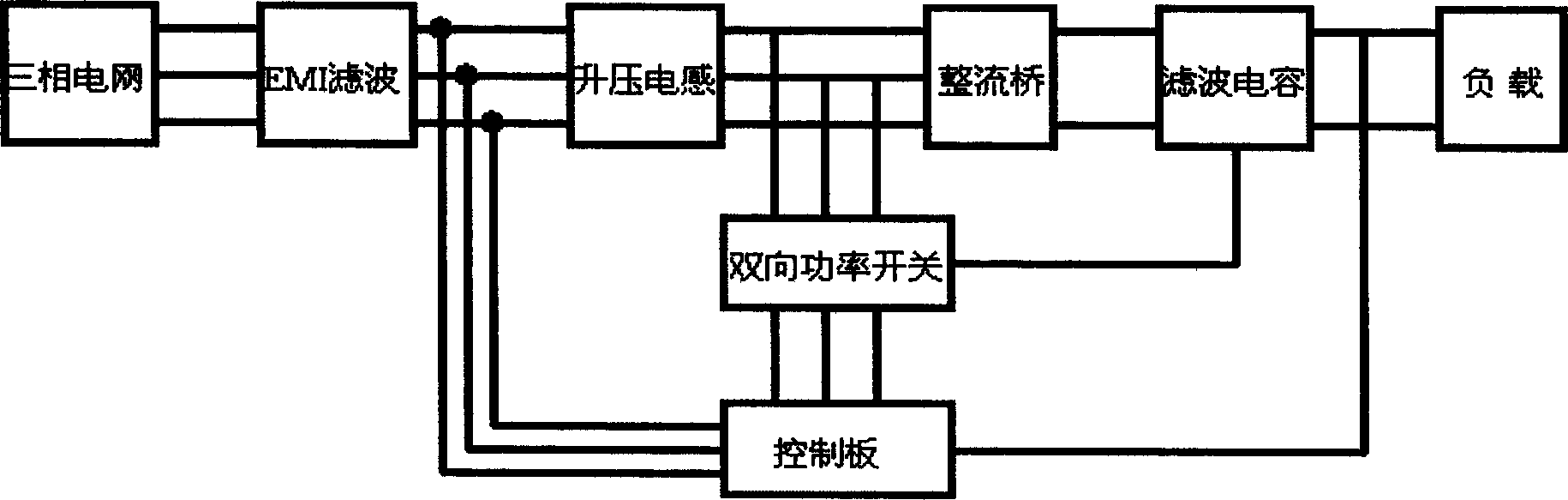

[0026] By adopting the design of the present invention, a 400A arc welding inverter power supply with harmonic suppression function is developed. Its input stage adopts a three-phase power factor correction circuit of AC boost mode (inductance value 3mL, DC side capacitor C1 , C2 is 2200uF, the rectifier bridge adopts diode rectification with fast recovery characteristics, the base part of the bidirectional power switch module is IGBT (BSM150GB120DN2)), the power output range is 10kW-15kW, and the power converter adopts a full-bridge inverter circuit. Arc welding inverter power supply with low harmonic distortion is the development trend of welding power supply. In general, this welding machine includes two parts: one is a harmonic suppressor, which can also be called a voltage pre-regulator or a power factor correction stage, and the other is a power converter, which is a traditional arc welding inverter power supply. Remove the input rectifier filter part. These two parts are ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com