Integrated device of high-frequency PWM rectification and inversion as well as control method thereof

A technology of rectification, inversion and control method, which is applied in the field of power electronics and can solve the problems of wasting energy, resistance heating, and low system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

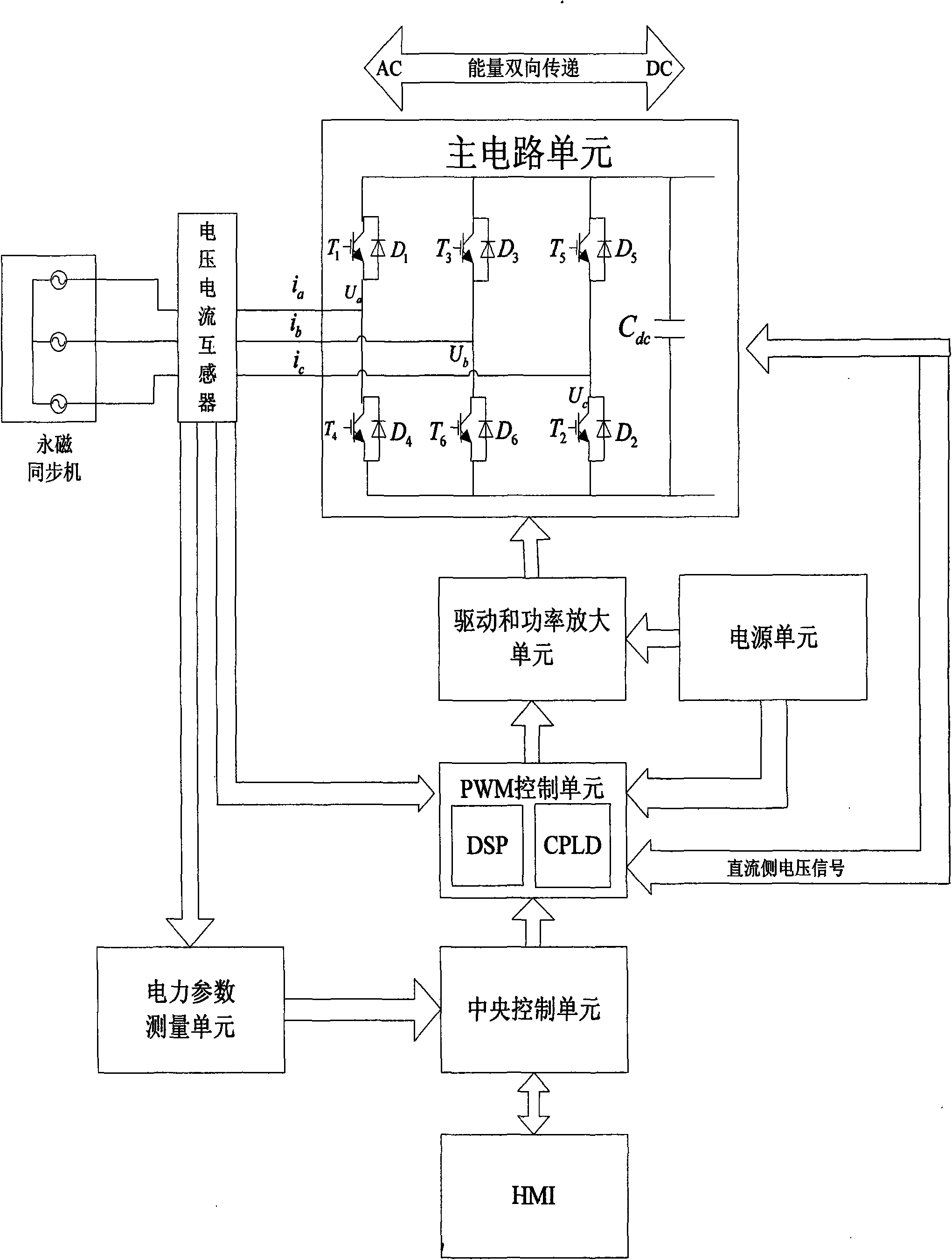

[0154] The block diagram of the device system structure of the present invention is as attached figure 1 shown. It consists of a main circuit unit, a drive and power amplification unit, a pulse modulation unit (PWM), a central control unit, a human-machine interface unit (HMI), a voltage and current transformer, a power parameter measurement unit, and a power supply unit. Among them, the main circuit unit includes power switching device IGBT, anti-parallel diode, absorber and DC filter capacitor; PWM control unit includes digital signal processor (DSP), programmable logic device CPLD, RS485 interface circuit; central control unit includes programmable Logic controllers (PLCs).

[0155] The main circuit unit is connected to the voltage and current transformer, drive and power amplification unit; the drive and power amplification unit are connected to the power supply unit and PWM control unit respectively; the PWM control unit is connected to the power supply unit and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com