Copper-magnesium alloy strand production process thereof

A copper-magnesium alloy and production process technology, used in metal/alloy conductors, conductors, electrical components, etc., can solve the problems of small overload capacity, poor corrosion resistance, poor thermal stability, etc., and achieve stable and reliable work and good corrosion resistance. , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

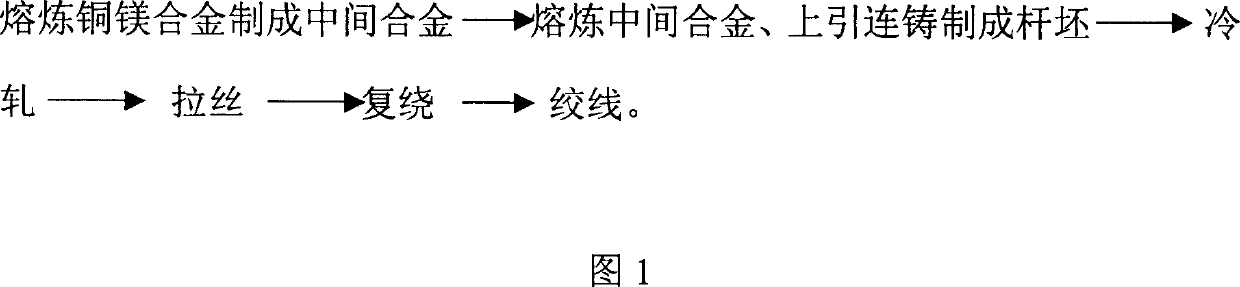

Method used

Image

Examples

Embodiment 1

[0027] 1. Take 24.75Kg of copper ingots and 0.1125Kg of magnesium ingots, put them into a vacuum furnace, heat to 1050-1200°C, cool and crystallize to form a copper-magnesium alloy solid solution as an intermediate alloy for use.

[0028] 2. According to the feeding amount, take the above-mentioned copper-magnesium alloy solid solution and continuously add it to the intermediate frequency furnace, heat it to 1050°C, melt it into a copper-magnesium alloy melt, and then use the method of upward continuous casting to make a copper-magnesium alloy rod.

[0029] 3. Put the above-mentioned copper-magnesium alloy rod on a rolling mill for multi-pass rolling.

[0030] 4. Place the rolled alloy rod on the wire drawing machine for continuous multi-pass wire drawing.

[0031] 5. Twisted into a coil. The single wire is pre-twisted and deformed under force before being twisted, and then it is made into a twisted wire. Copper alloy stranded wire is a concentric stranded wire, the twist di...

Embodiment 2

[0033] 1. Take 24.75Kg of copper ingots and 0.1375Kg of magnesium ingots, put them into a vacuum furnace, heat to 1200°C, cool and crystallize to form a copper-magnesium alloy solid solution as an intermediate alloy for use.

[0034] 2. According to the feeding amount, take the above-mentioned copper-magnesium alloy solid solution and continuously add it to the intermediate frequency furnace, heat it to 1100°C, melt it into a copper-magnesium alloy solution, and then use the upward continuous casting method to make a copper-magnesium alloy rod.

[0035] All the other are with embodiment 1.

Embodiment 3

[0037] 1. Take 24.75Kg of copper ingots and 0.125Kg of magnesium ingots, put them into a vacuum furnace, heat to 1150°C, cool and crystallize to form a copper-magnesium alloy solid solution as an intermediate alloy for later use.

[0038] 2. Take the above-mentioned copper-magnesium alloy solid solution according to the feeding amount and continuously add it to the intermediate frequency furnace, heat it to 1150°C, melt it into a copper-magnesium alloy melt, and then use the upward continuous casting method to make a copper-magnesium alloy rod.

[0039] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com