Continuous dynamic intelligent metering mechanism

A metering device and intelligent technology, applied in measurement devices, mass flow measurement devices, weighing and other directions, can solve the problems of complex structure, heavy maintenance work, low dynamic measurement accuracy, etc., and achieve a wide measurement range, reasonable structure, and overload. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

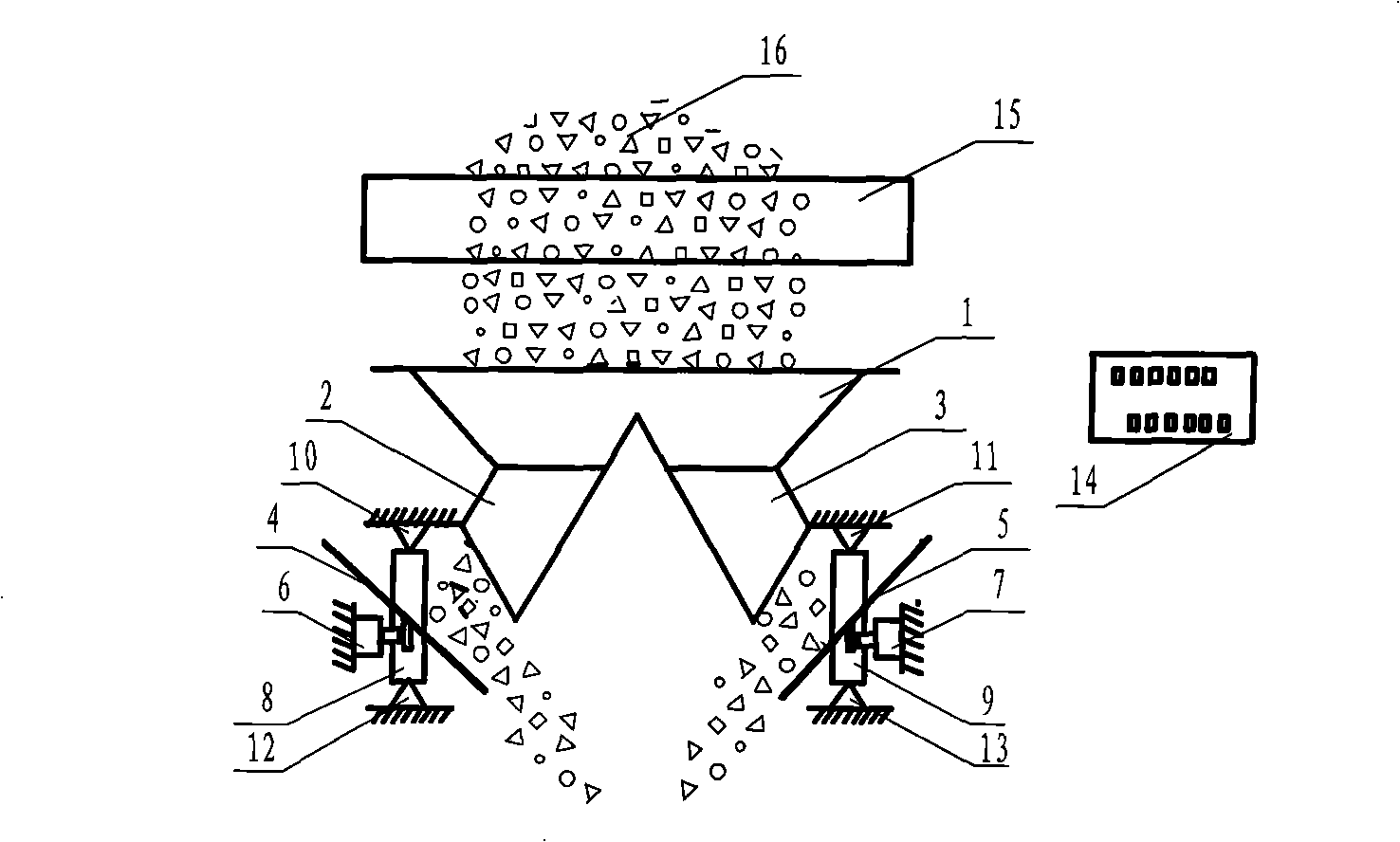

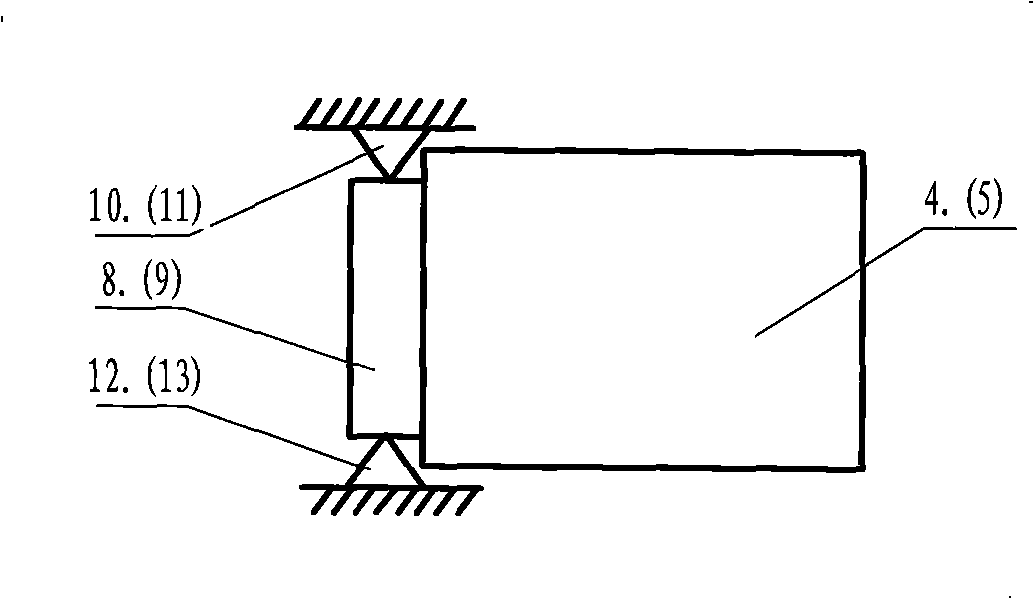

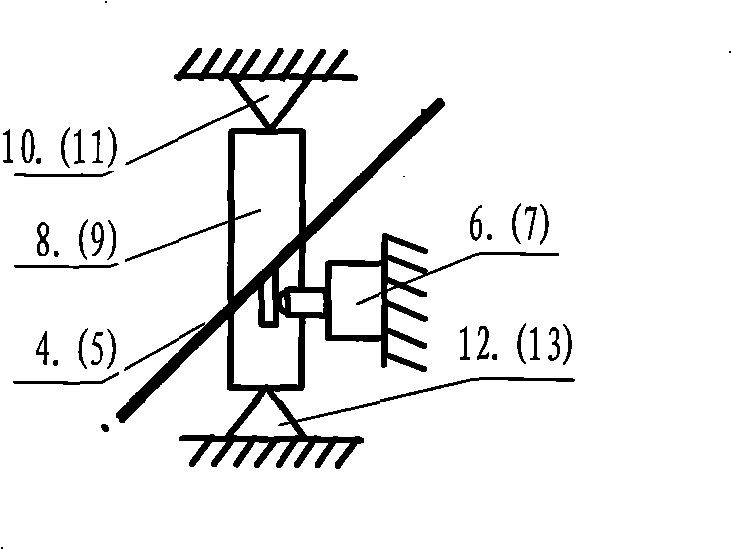

[0020] The application of a new type of bulk solid material intelligent metering device of the present invention on the belt conveyor, such as figure 1 , the metering device is made up of funnel 1, chute 2, 3, punching plate 4, 5, weighing sensor 6, 7, and intelligent measuring and controlling instrument 14, and described funnel 1, chute 2, 3, punching plate 4, 5 form a weighing frame Structure; its described weighing sensor 6,7 and intelligent measurement and control instrument 14 form measuring system, described funnel 1 adopts four pieces of 15mm thick steel plates to be welded into a cone-trapezoidal shape, and chute 2,3 adopts three pieces of 15mm thick steel plates to weld In the shape of a trough, funnel 1, chute 2, 3, welded into one, installed at 0.5m directly below the discharge end of belt conveyor 15, used to collect and concentrate solid material 16, the punching plate 4, 5 adopts 20mm thick The steel plate and the vertical shafts 8 and 9 are welded together and i...

Embodiment approach 2

[0036] The application of a continuous dynamic intelligent metering device of the present invention on a scraper conveyor, wherein the funnel 1, chutes 2, 3, punching plates 4, 5 form a weighing frame structure; the weighing sensors 6, 7 and the intelligent measuring and controlling instrument 14 to form a measuring system, the funnel 1 adopts four 15mm thick steel plates welded into a conical trapezoidal shape, the chutes 2 and 3 adopt three 15mm thick steel plates welded into a trough shape, and the funnel 1, chutes 2 and 3 are welded into one , installed at 0.5m directly below the discharge end of the scraper conveyor, used to collect and concentrate solid materials 16, the punching plates 4, 5 are welded into one by 20mm thick steel plates and vertical shafts 8, 9, and installed in the chute 2 , The two sides of 0.5m place below 3, others are the same as embodiment 1.

Embodiment approach 3

[0038]The application of a continuous dynamic intelligent metering device of the present invention on a screw conveyor, the funnel 1 adopts four 15mm thick steel plates welded into a cone-trapezoidal shape, and the chutes 2 and 3 adopt three 15mm thick steel plates welded into a trough shape, The funnel 1, the chute 2, 3 are welded together and installed at 0.5m directly below the discharge end of the screw conveyor to collect and concentrate the solid material 16. The punching plates 4, 5 are made of 20mm thick steel plates and vertical shafts 8 and 9 are welded into one body, installed on both sides of the 0.5m place below the chutes 2 and 3, and the others are the same as the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com