High-precision current sensor detecting circuit and detecting method thereof

A current sensor and detection circuit technology, applied in the direction of using digital measurement technology for measurement, can solve the problems affecting measurement accuracy, small current change, low output voltage resolution, etc., to achieve good linearity and dynamic performance, and wide operating frequency bandwidth. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

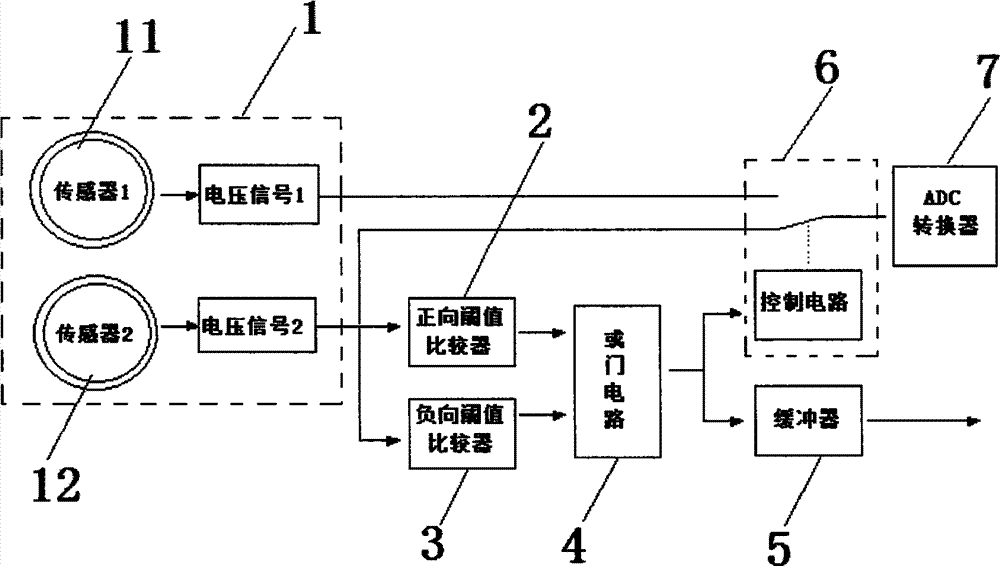

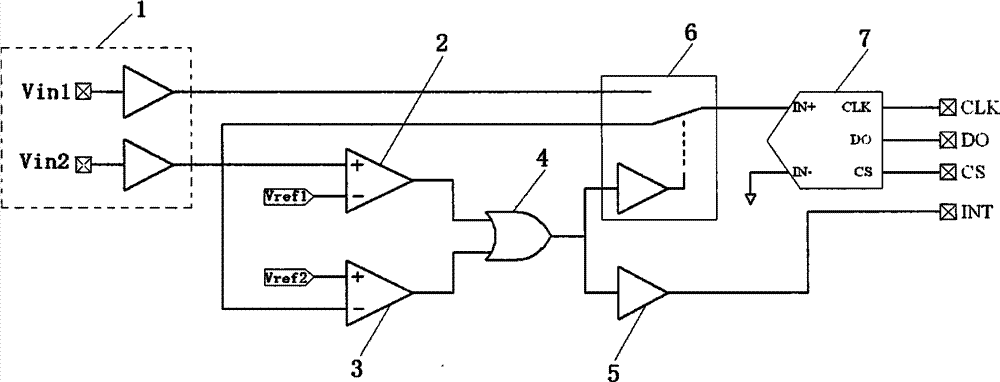

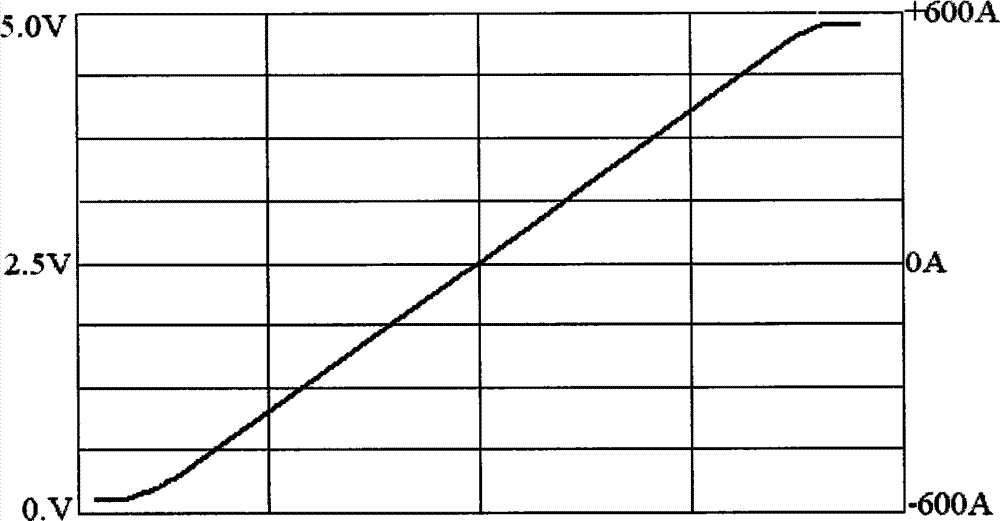

[0022] Such as figure 1 , figure 2 As shown, a high-precision current sensor detection circuit is used to detect the charging and discharging current of the electric vehicle power battery system, including a combined magnetoelectric conversion unit 1, a positive threshold comparator 2, a negative threshold comparator 3, and an OR gate circuit 4. Output buffer 5, SPDT analog switch 6 and ADC converter 7. The combined magnetoelectric conversion unit 1 is composed of a first Hall current sensor 11 with a larger range and a second Hall current sensor 12 with a smaller range. Single pole double throw analog switch 6 selects ADG849 analog switch.

[0023] The output end of the first Hall current sensor 11 is connected to the normally open contact of the SPDT analog switch 6, the output end of the second Hall current sensor 12 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com