Electric vehicle driving motor internally provided with differential and reducer assembly

A technology for electric vehicles and driving motors, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of unfavorable driving needs of electric vehicles, low power density of the whole machine, low rated speed, etc., and achieve good chemical stability and thermal oxidation Stability, integrated cooling and lubrication, high insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

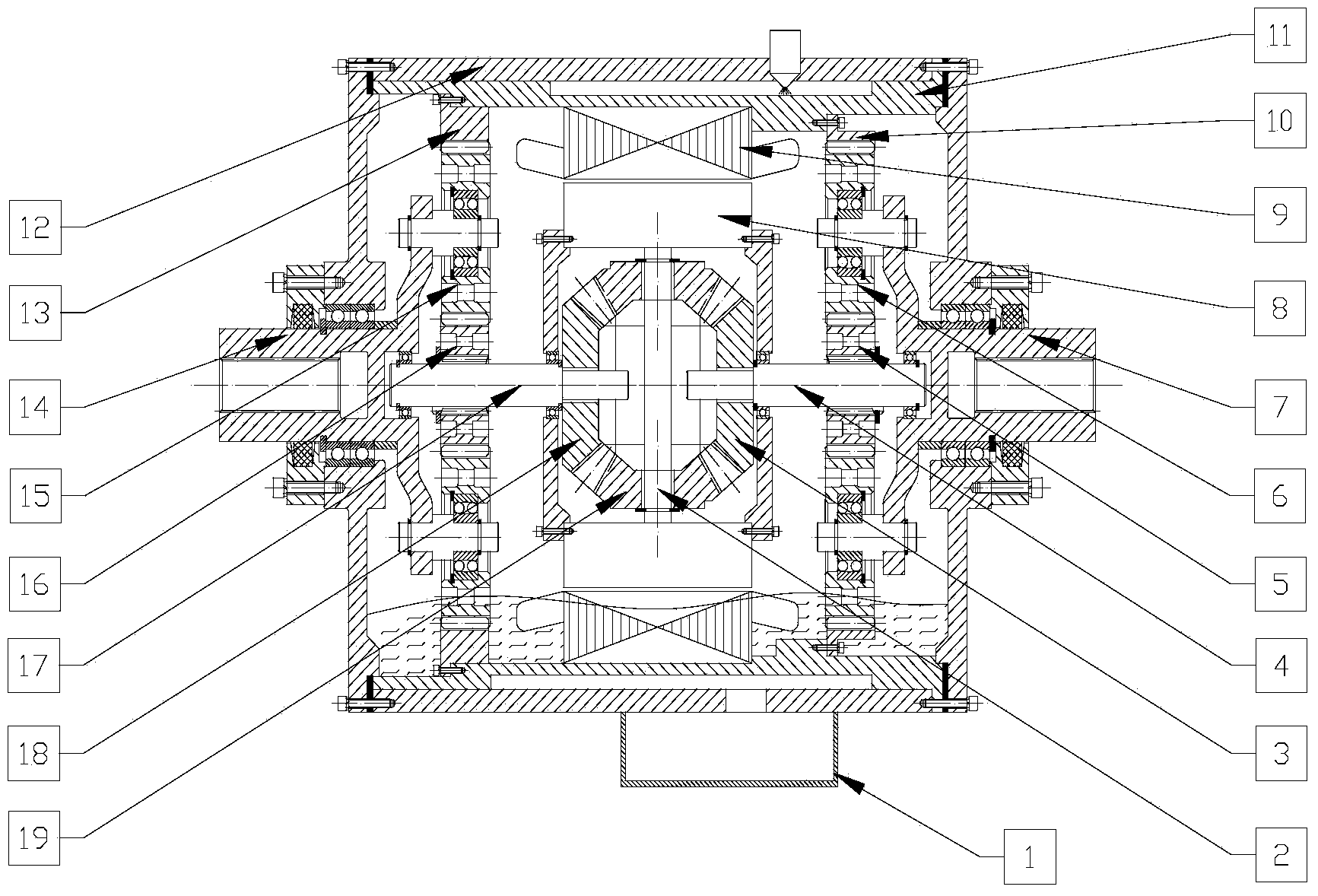

[0027] Such as figure 1 As shown, an electric vehicle drive motor with a built-in differential subtraction assembly includes a casing 12, an oil jacket 11, a motor stator 9, a motor rotor 8, a differential, a planetary reducer and a fuel tank 1; a motor stator 9, a motor rotor 8. The differential gear and the planetary reducer are arranged in the casing 12, and the oil jacket 11 is connected to the casing 12 inside the casing 12. An annular cavity is formed between the casing 12 and the oil jacket 11, and the fuel injection nozzle is set in the On the casing 12, the nozzle faces the annular cavity, and the oil tank 1 is arranged at the bottom of the casing 12; the differential includes a differential planet carrier 2, a first differential driven gear 3, a second differential driven gear Gear 18, the first differential gear output shaft 4, the second differential gear output shaft 17 and the differential drive gear 19; the planetary reducer includes the first planetary reducer ...

Embodiment 2

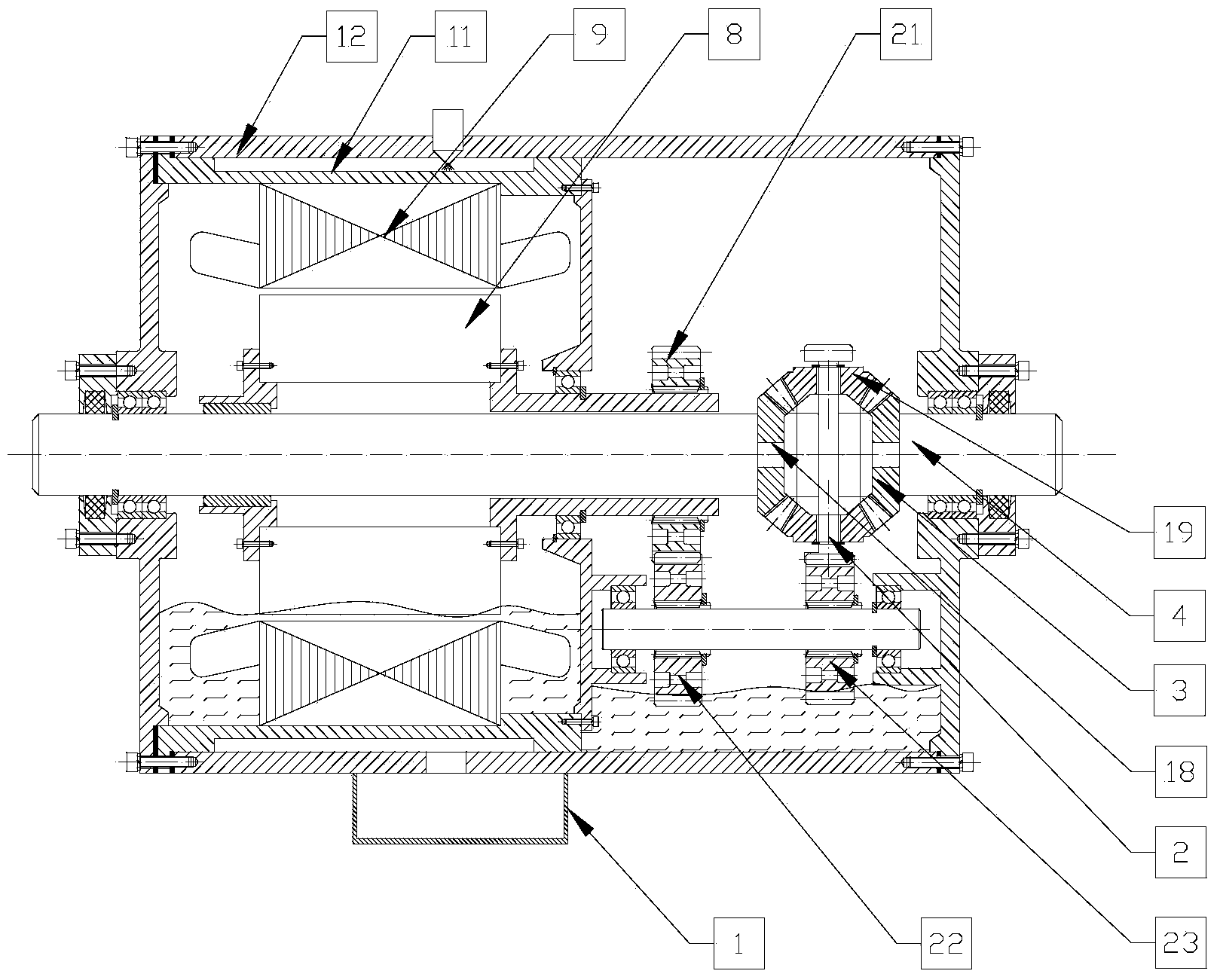

[0034] Such as figure 2 Shown is another embodiment of the invention. This embodiment uses a fixed shaft gear reducer without a planetary reducer. An electric vehicle drive motor with a built-in differential subtraction assembly, including a casing 12, an oil jacket 11, a motor stator 9, a motor rotor 8, a differential, a fixed shaft gear reducer, and an oil tank 1; a motor stator 9, and a motor rotor 8 , differential, and fixed-axis gear reducer are arranged in the casing 12, and the oil jacket 11 is connected with the casing 12 inside the casing 12, and an annular cavity is formed between the casing 12 and the oil jacket 11, and the fuel injection nozzle is set On the casing 12, the nozzle faces the annular cavity, and the oil tank 1 is arranged at the bottom of the casing 12; the motor rotor 8 is connected with the input gear 21 of the fixed shaft gear reducer through a spline, and the input gear 21 is connected with the first intermediate gear 22 meshing, the first inte...

Embodiment 3

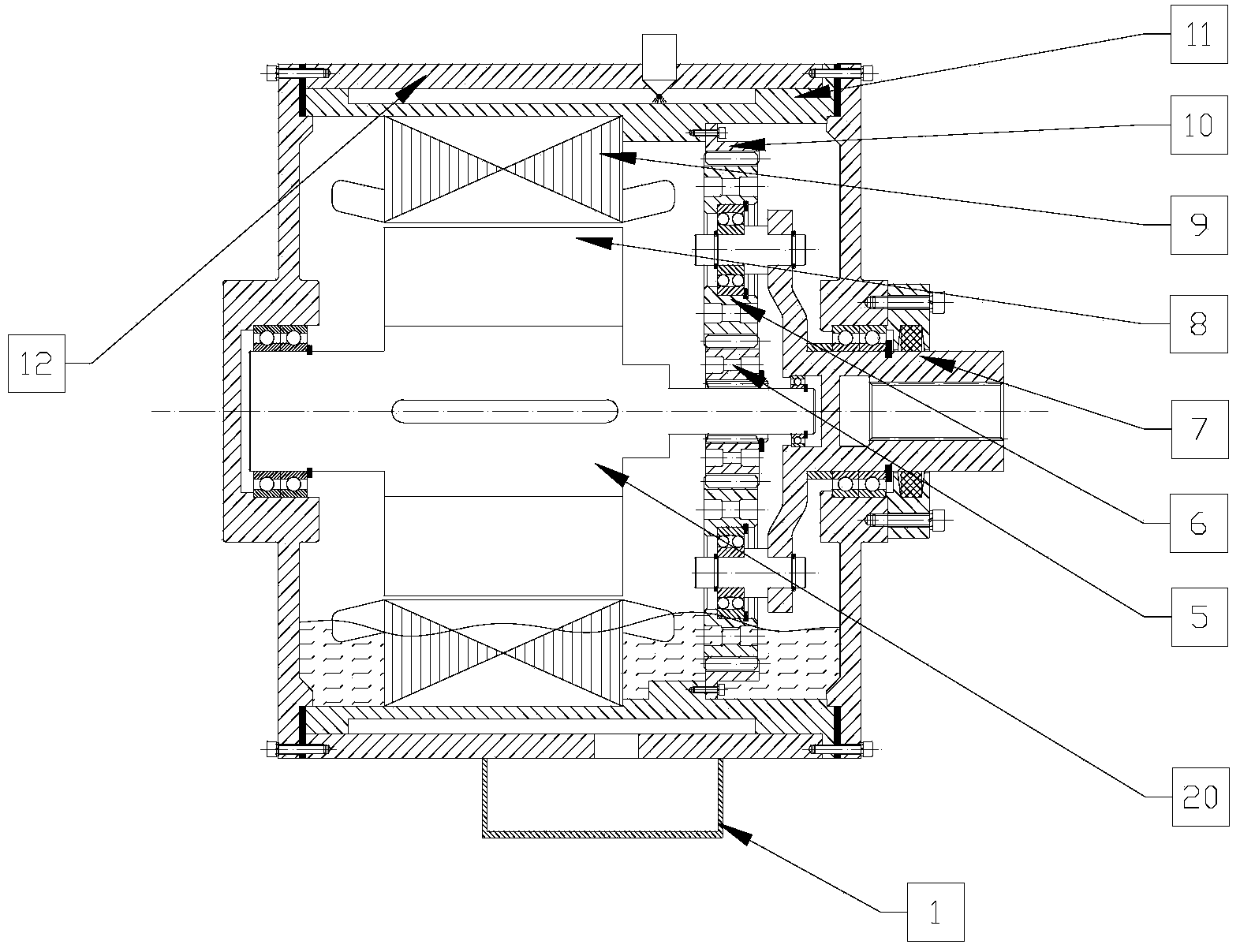

[0038] Such as image 3 Shown is a third embodiment of the invention. This embodiment is a simplification of Embodiment 1. Wherein the driving motor is only integrated with a reducer, so this embodiment only has the functions of driving and deceleration and does not have the function of differential speed. Such as image 3 Shown, a kind of electric vehicle driving motor comprises casing 12, oil jacket 11, motor stator 9, motor rotor 8, speed reducer and oil tank 1; Motor stator 9, motor rotor 8 and speed reducer are arranged in casing 12, The oil jacket 11 is connected to the casing 12 inside the casing 12, and an annular cavity is formed between the casing 12 and the oil casing 11. The fuel injection nozzle is arranged on the casing 12, and the nozzle faces the annular cavity, and the oil tank 1 is arranged on the The bottom of the casing 12; the motor rotor 8 is connected to the inner rotor shaft 20, the inner rotor shaft 20 is connected to the sun gear 5 of the planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com