High speed safety shockproof turnout for railway

A high-speed and railway technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of restricting the running speed of high-speed trains, reducing operating efficiency, increasing train energy consumption, etc., and achieving the effect of shortening running time, significant economic benefits, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

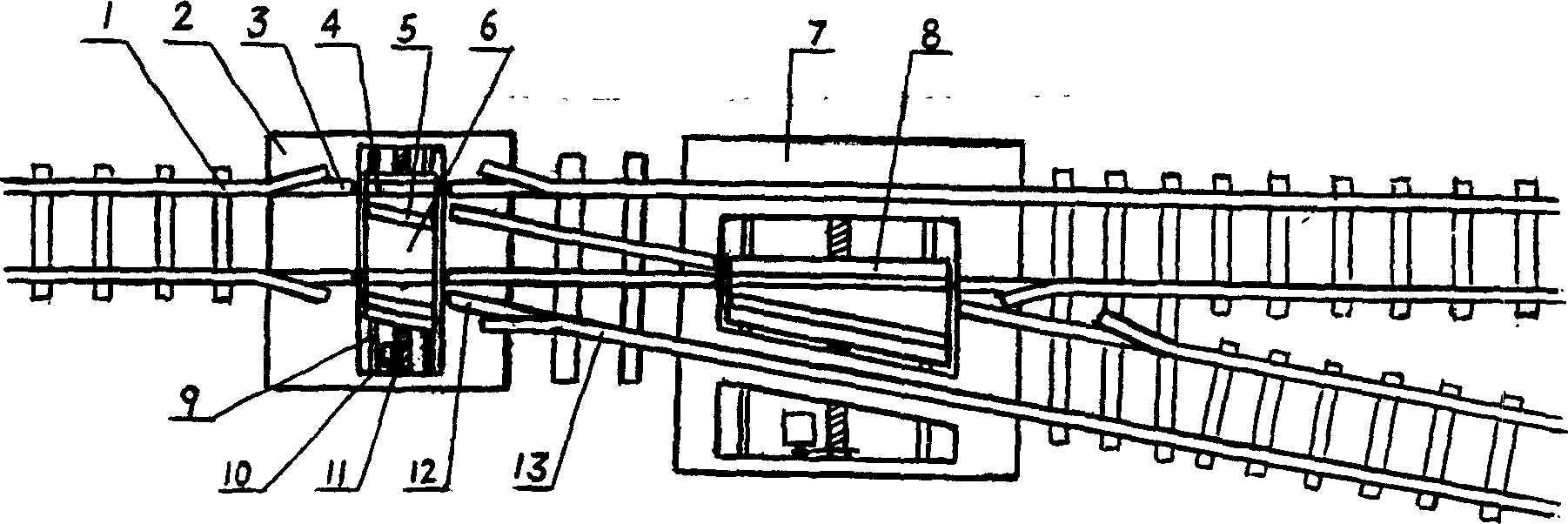

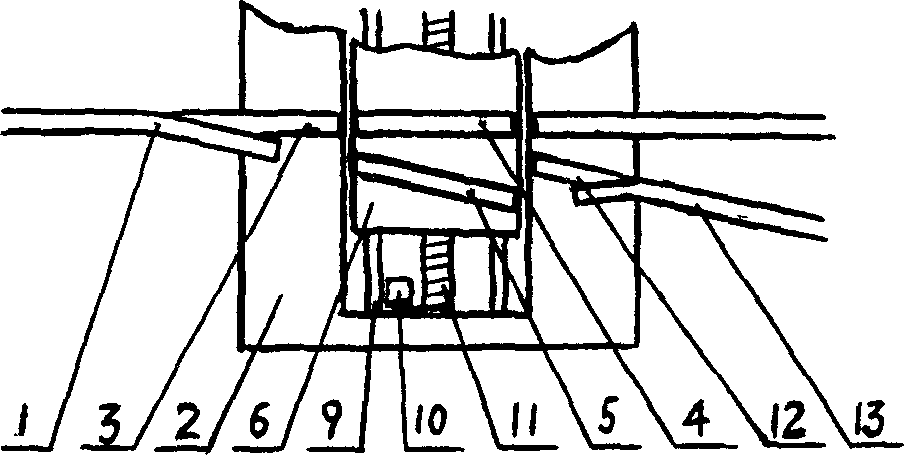

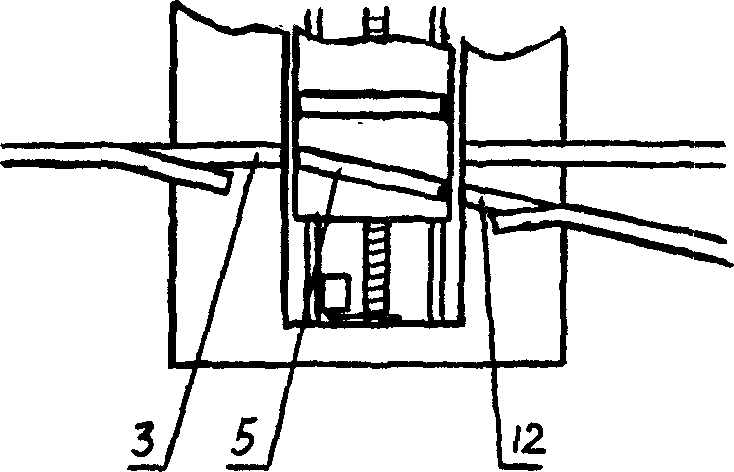

[0013] see figure 1 , as shown in the figure, a turnout sleeper 2 is set under the turnout part in the railway track line, and a turnout sleeper 7 is set under the place where the turnout track on one side crosses the straight track on the other side, and the turnout sleeper 2 and the turnout sleeper 7 A ram 6 and a ram 8 are respectively provided in the chute, and two straight transition rails 4 and two branch transition rails 5 are provided on the ram 6; a straight transition rail and a On the turnout transition rail, the rams 6 and 8 are respectively installed in the chute of the turnout sleeper through the guide rod 9 and the screw rod 11. One end of the screw rod 11 is connected with the motor 10 through the gear set, and the motor 10 drives the screw rod through the gear set to drive the internal gear in the ram. Threads to allow the ram to move in the chute.

[0014] The rail joint fixedly installed on the top of the turnout sleeper adopts a seamless telescopic connect...

Embodiment 2

[0018] see image 3 and Figure 3-1 , in the three-track line with the top rail erected by the door frame 22, a switch is installed in the rail below the door frame 22 and in the top rail above the door frame at the same time, wherein the switch in the rail is the same as in Embodiment 1, and the top rail switch The working principle of the structure is also the same as that of the switch in embodiment 1, and the top track switch and the road track switch work synchronously to complete the conversion between the straight line and the branch line.

[0019] As shown in the figure, the top track switch is composed of a top rail sleeper 19 and a ram 23 located in the chute of the top rail sleeper. The ram 23 is also provided with a straight transition top rail 20 and a branch transition top rail 21. The straight transition top rail Or the branch transition top rail is located between the straight top rail joints 18 set on the top rail sleeper, or between the straight transition t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com