Hot forging feeding electric-joint manipulator and operating method thereof

A manipulator and hot forging technology, which is applied in the field of hot forging feeding electric joint manipulator, can solve the problems of large impact vibration, slow speed, fast speed, etc., and achieve the effect of reducing impact vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

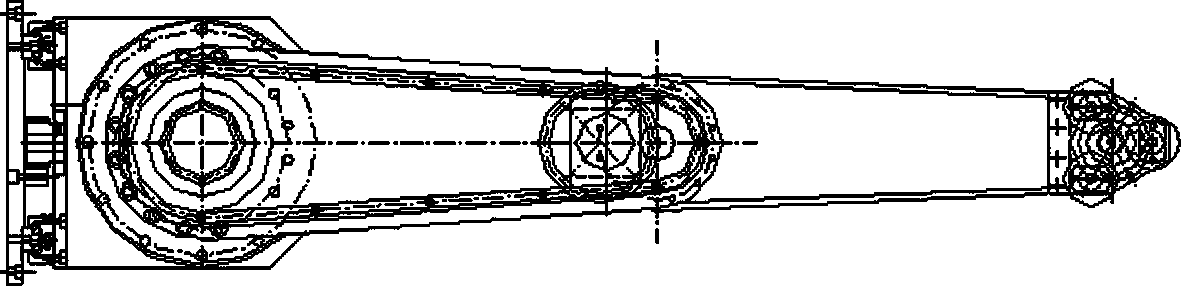

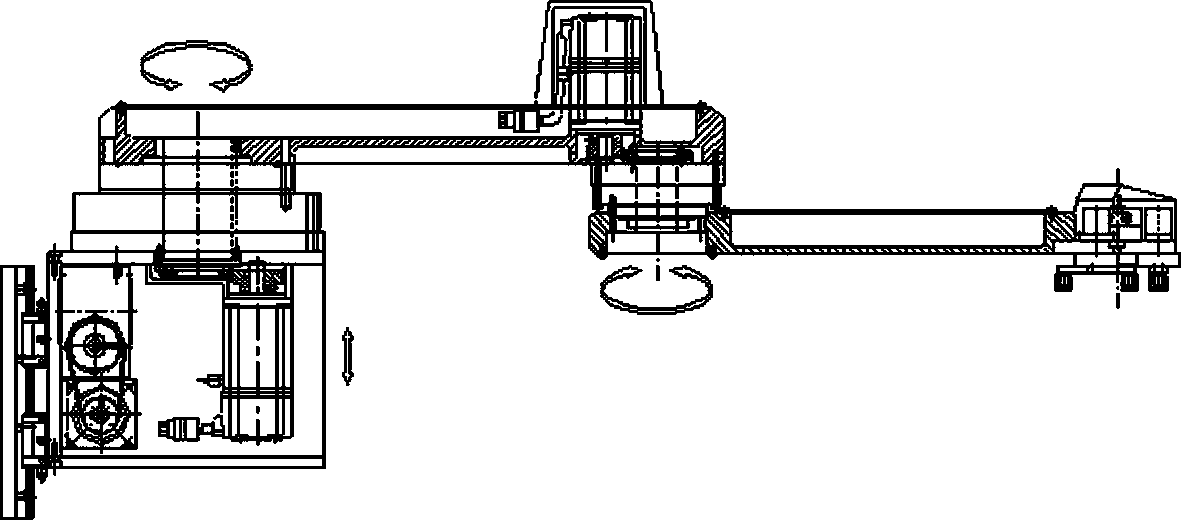

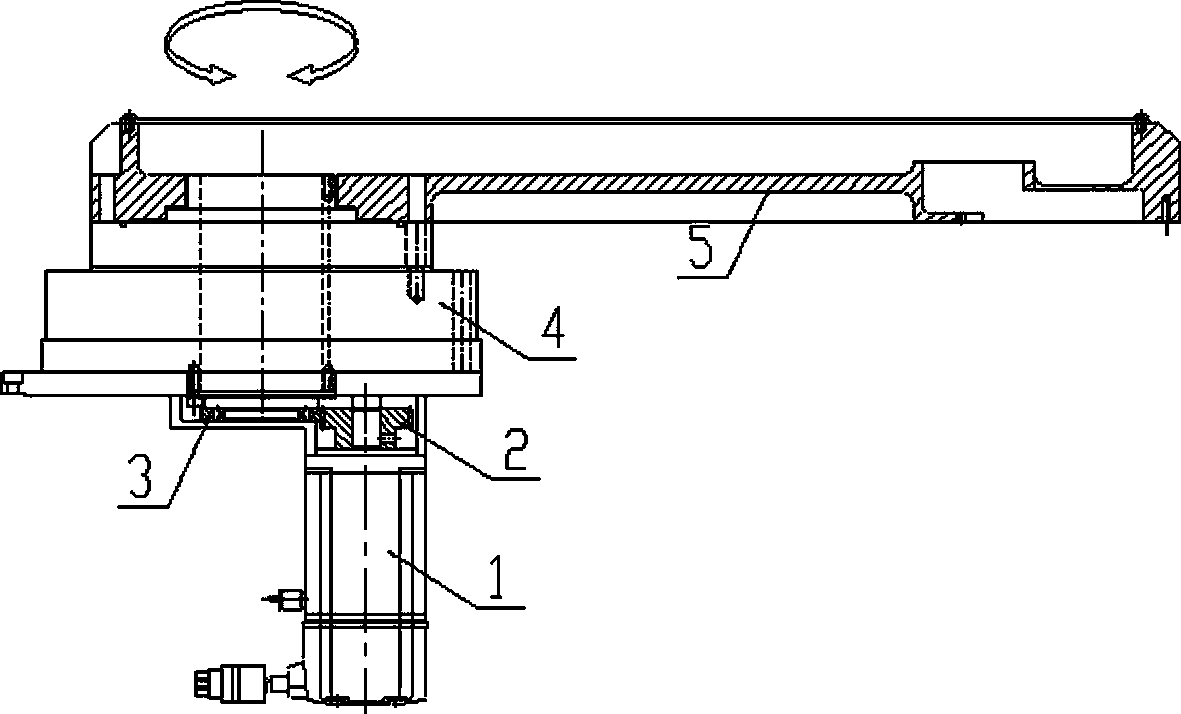

[0027] According to Figure 1 a Figure 4 As shown, a hot-forging electric joint manipulator for feeding materials includes: a large arm rotating component J1, a small arm rotating component J2, and a claw-type vertical up and down movement component J3; On the J1 shaft boom 5 of the component J1, the casing of the driving worm gear reducer 16 of the claw type vertical up and down movement component J3 is contained in the casing below of the driving worm gear reducer 4 of the boom rotating component J1.

[0028] The boom rotating member J1 includes: a servo motor 1 fixed on the upper and lower platforms, a driving gear 2 is installed on the shaft of the servo motor 1, the driving gear 2 and the gear 3 mesh, and a harmonic reducer is installed above the gear 3 4. The harmonic reducer 4 is connected with the boom 5 of the J1 axis.

[0029] The small arm rotating member J2 includes: a servo motor 6 fixed at the end of the boom 5 of the J1 axis, a drive gear 7 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com