Movable random boring lathe

A boring machine and boring shaft technology, applied in the field of boring machines, can solve the problems of difficult maintenance of parts, difficult maintenance, high maintenance costs of enterprises, etc., and achieve the effects of avoiding equipment precision, shortening downtime, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The power source, the control device, and the processing head are arranged separately, and the two are connected by a power and control transmission line, and the power source and the control device provide power and control signals for the processing head.

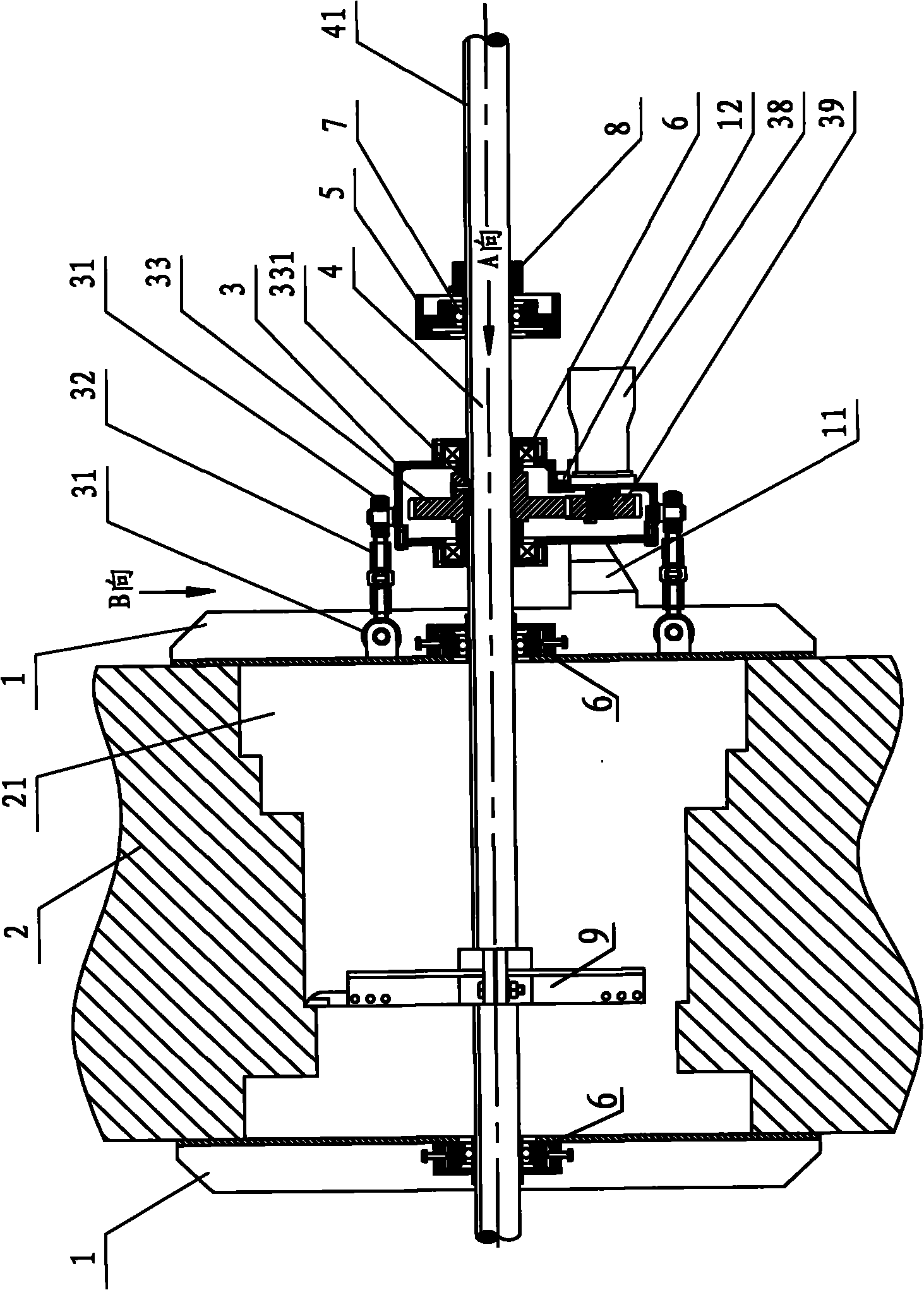

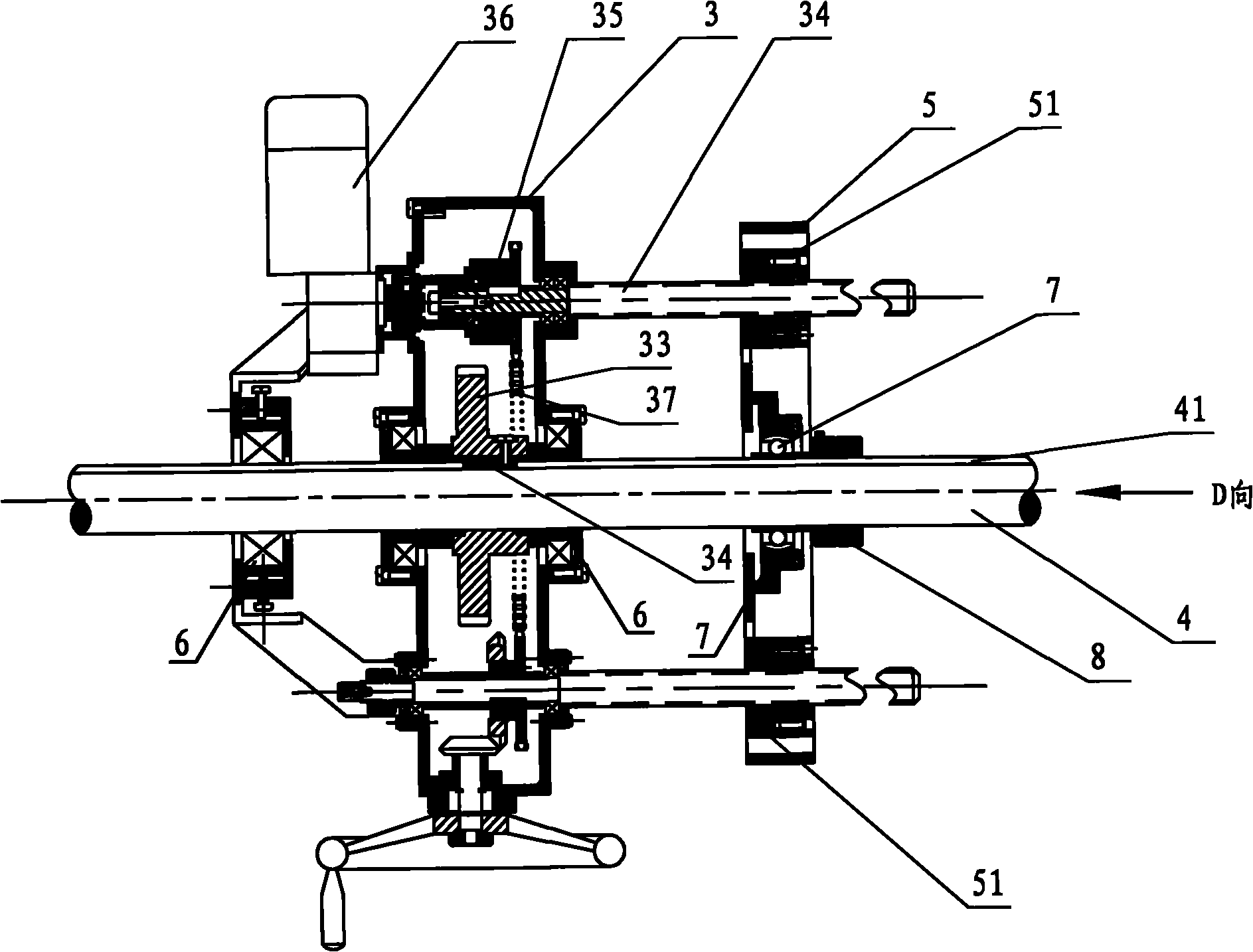

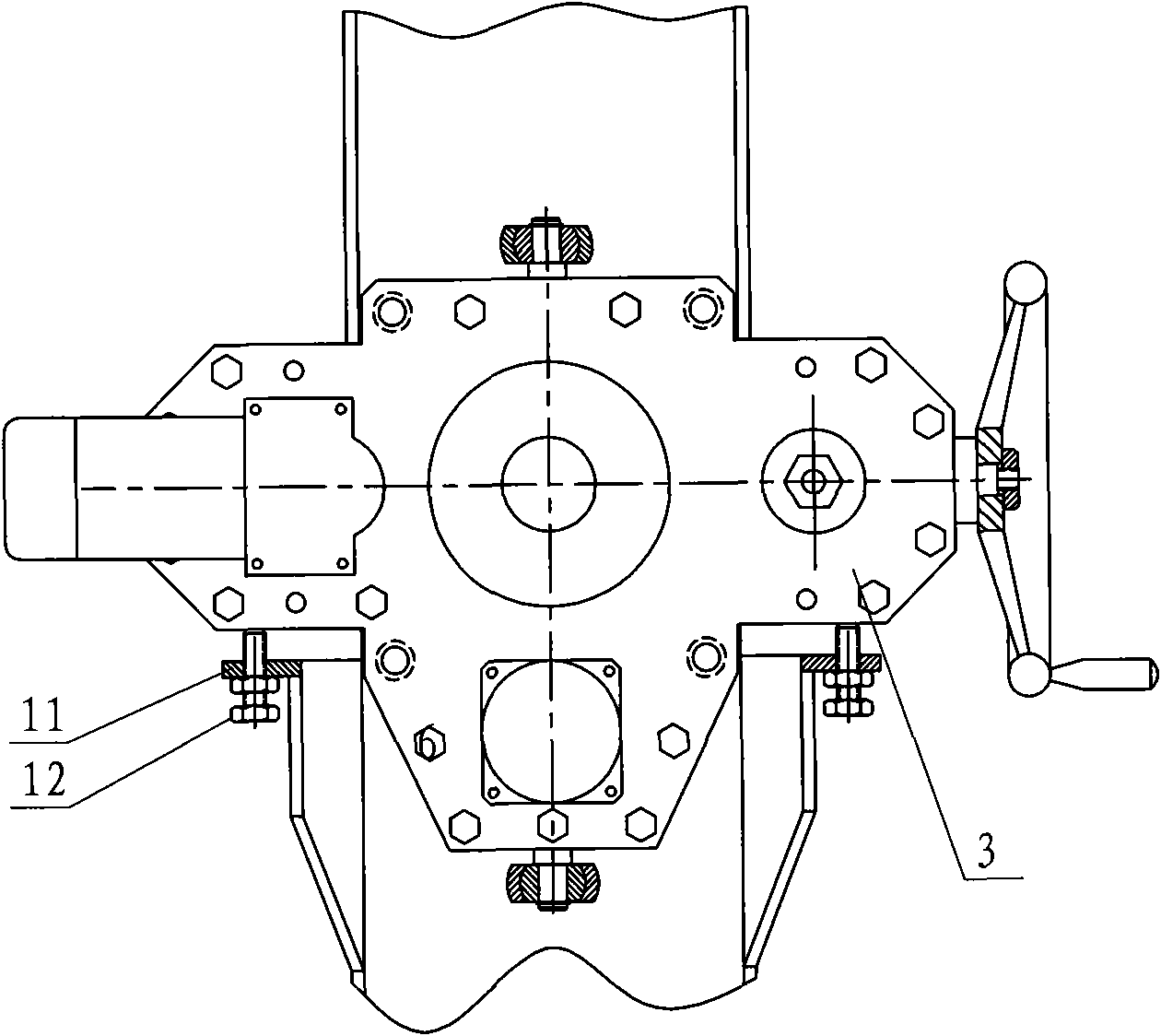

[0012] see figure 1 and 2 , the processing head is that the fixed support outer arm 1, the cutter head 9, the fixed support inner arm 1, the transmission and feed gearbox 3 and the feed screw tailstock 5 are installed on the boring shaft 4 in turn from the outside to the inside, and the cutter The disk 9 is fixed on the boring shaft, and other devices are installed on the boring shaft through the bearing 6. The bearing 6 and the boring shaft 36 slide and fit together, so that the boring shaft can move axially in the inner sleeve of the bearing, and the bearing 7 on the tailstock 5 It is a spherical ball bearing, and the clamping sleeve 8 fixes the inner sleeve of the tailstock 5 bearing 7 on the boring shaft, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com