Non-contact measuring method for leaf apex radial clearance of engine rotor

A technology of radial clearance and measurement method, applied in the field of mechanical processing, can solve the problems affecting the assembly accuracy and performance of the engine, the measurement range cannot reach the entire circumference, and the accuracy is poor, so as to improve the assembly quality, reduce the failure rate, and improve the measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

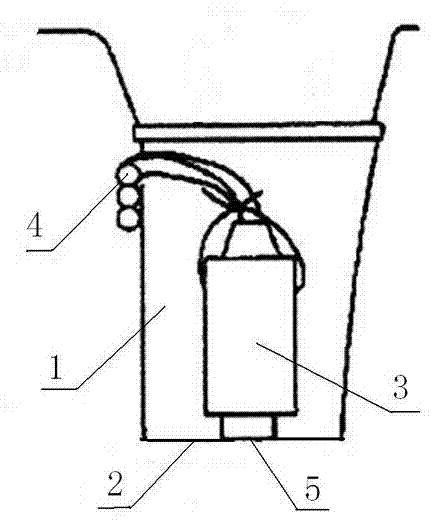

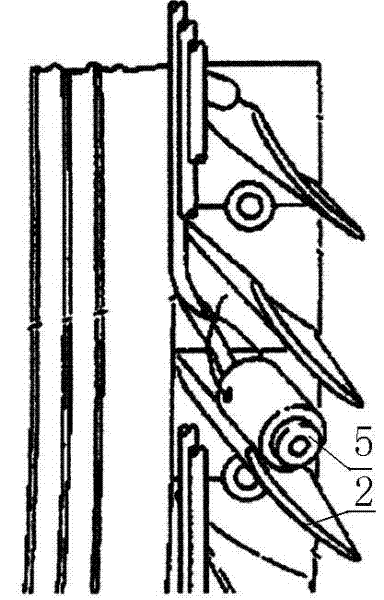

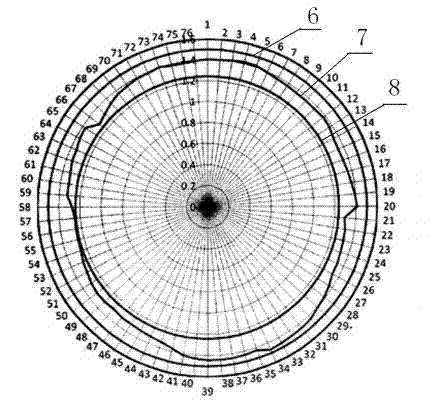

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

[0024] The model of the sensor 3 used in this embodiment is 9001 / C-P, the model of the measuring instrument is CS-1000, and the sensor wire 4 adopts a flexible triaxial cable;

[0025] 1) Assemble the measurement system, calibrate the sensor 3, and determine the relationship between the blade tip radial clearance and the voltage;

[0026] First connect the measuring instrument and the sensor 3 through a flexible triaxial cable, then contact the front end 5 of the sensor probe with the end face of the micrometer, then adjust the voltage of the measuring instrument to 0V, and then adjust the front end 5 of the sensor probe and the micrometer at a certain interval The end face gap (that is, the distance) is adjusted from 0mm to 2mm, and the relationship between the gap and the voltage is established as voltage (U)=5*gap (L).

[0027] 2) Preparation be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com