Drill rod unloading device suitable for submarine drilling rig

A technology for drilling rigs and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve the problem of not being able to connect and unload drill pipes at multiple positions, and achieve the effect of reducing the clamping force and rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

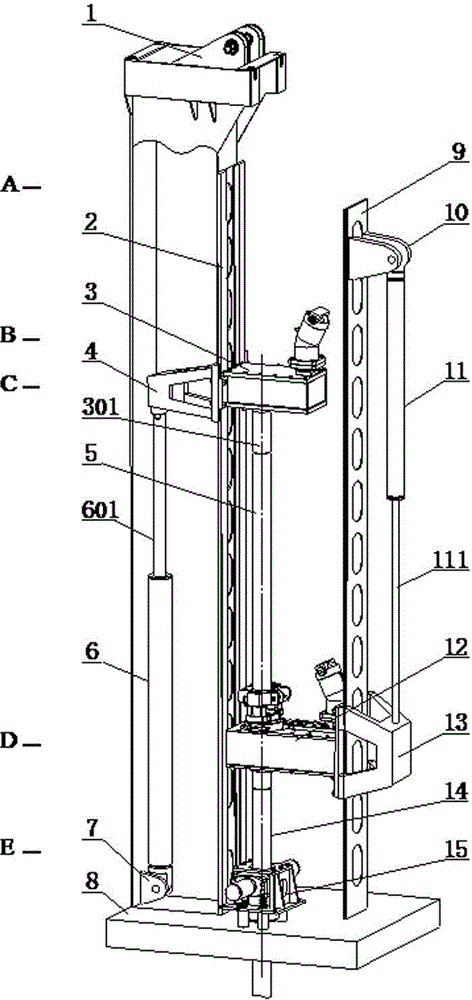

Image

Examples

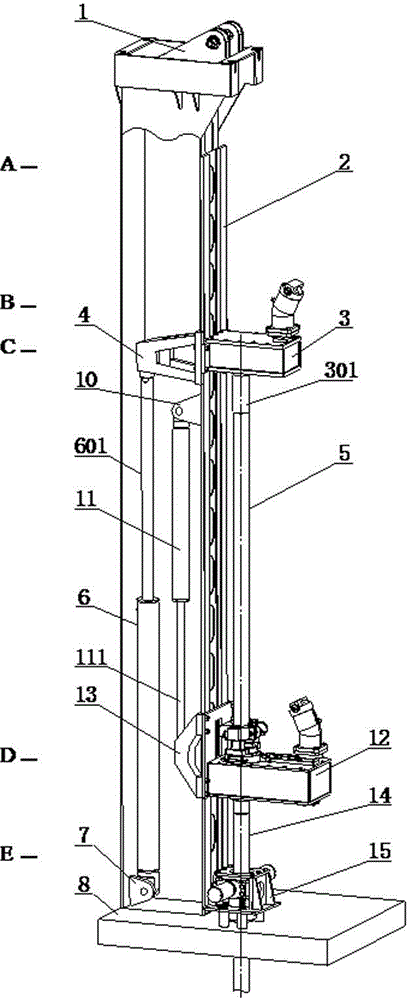

Embodiment 2

[0026] Such as figure 2 As shown, the structure is similar to that of Embodiment 1, except that the power chuck 12 does not have a separate slide rail frame 9, but the drilling power head slide rail 2 of the existing subsea drilling rig mast frame 1 is downward extend, so that the power chuck 12 shares a slideway 2 with the drilling power head of the existing subsea drilling rig. The installation method in the frame 1 should ensure that there is no interference between the propulsion slider 4 and the lifting hydraulic cylinder 11 and the lifting hydraulic cylinder base 10 when the propulsion cylinder 6 drives the drilling power head 3 to descend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com