A clamping manipulator for capacitor production and processing

A technology of capacitors and manipulators, which is applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of capacitors with different appearances and shapes, capacitors falling, and the stability of capacitor clamping, etc., to achieve the effect of accelerating production efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

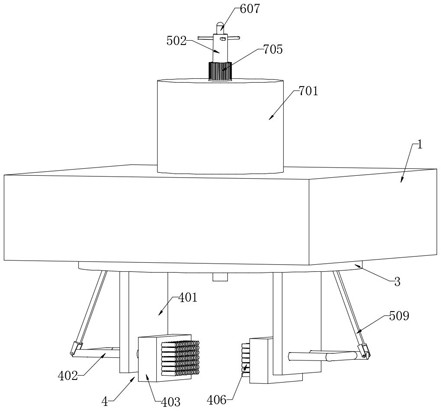

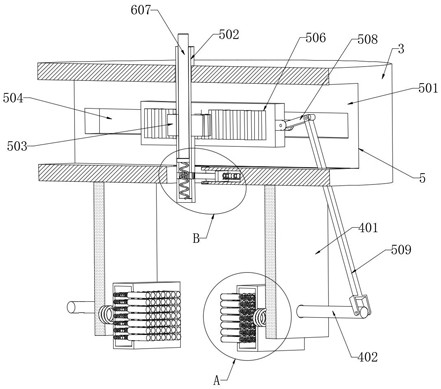

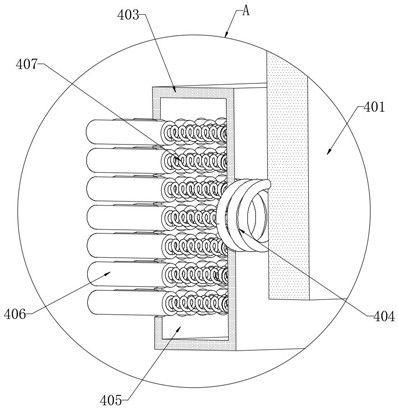

[0027] refer to Figure 1-7 , a clamping manipulator for capacitor production and processing, including a fixed plate 1, a circular groove 2 is opened at the lower end of the fixed plate 1, and a disc 3 is slidably connected to the inner wall of the circular groove 2, and a disc 3 is provided on the disc 3 to clamp the capacitor. The clamping mechanism 4, the clamping mechanism 4 includes two vertical plates 401 fixedly connected to the lower end of the disc 3, the side walls of the vertical plates 401 are slidably connected to the driving rod 402, and one end of the driving rod 402 is fixedly connected to the splint 403, and the side of the splint 403 The wall is elastically connected to the side wall of the vertical plate 401 through the first spring 404. A cavity 405 is opened in the splint 403. The inner wall of the cavity 405 is evenly distributed and slidably connected with a plurality of clamping rods 406. One end of the clamping rod 406 located in the cavity 405 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com