Toilet lid hanging and conveying system

A conveying system and toilet lid technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of material falling, chain jamming, collision, etc., and achieve the effect of preventing collision and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

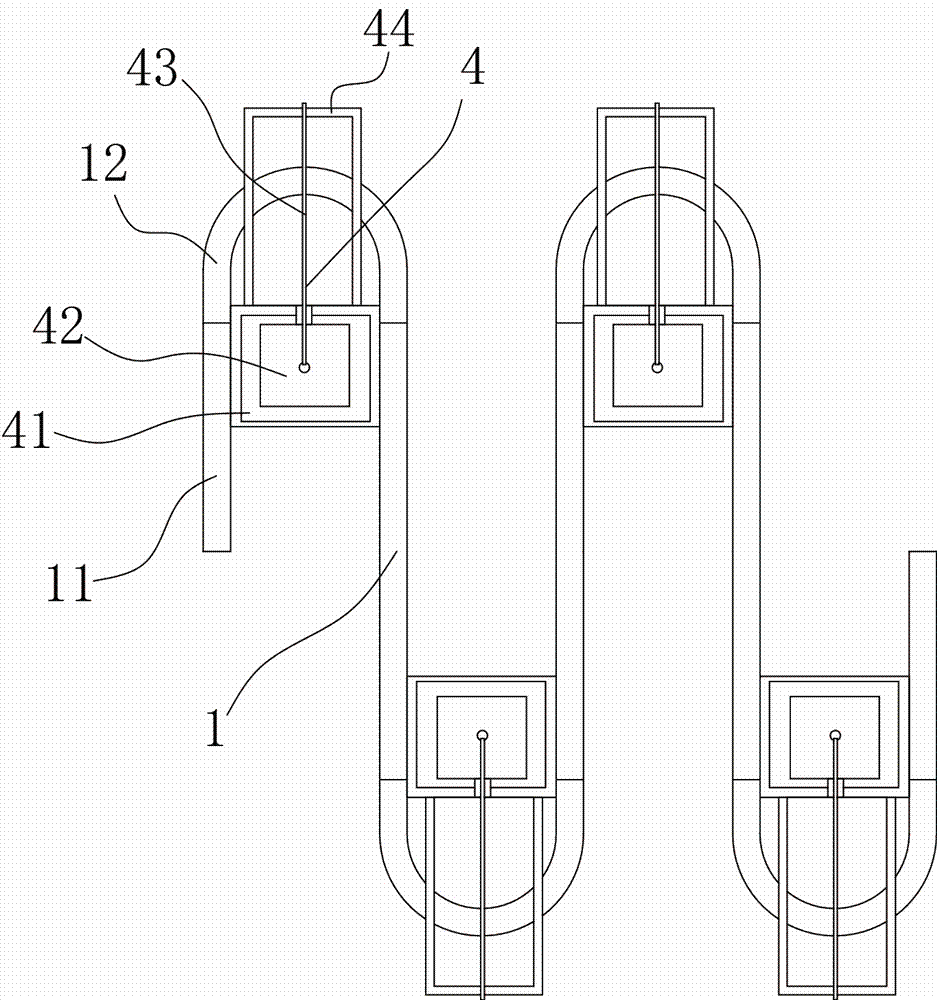

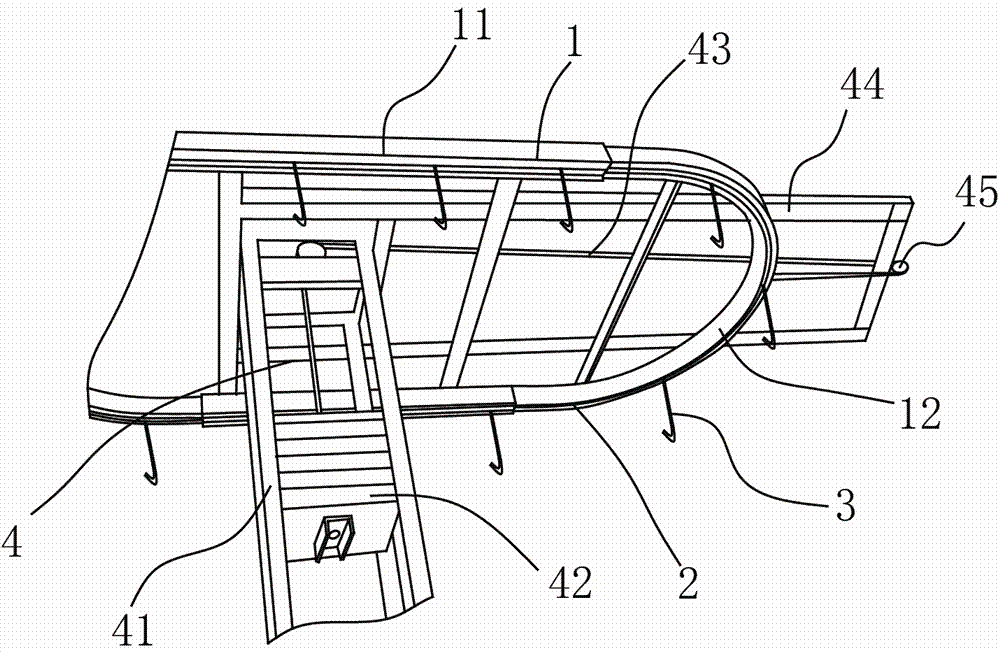

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , a toilet lid suspension conveying system, including a track 1, a chain 2 is arranged in the track 1, a hook 3 for hanging materials is arranged on the chain 2, and a plurality of sprockets are connected to the chain 2 (not shown on the figure) Drawing), the track 1 includes a fixed part 11 and a sliding part 12, the sliding part 12 is located at the bend of the track 2, the sliding part 12 is connected with a tensioning structure 4, and the tensioning structure 4 will The sliding part 12 pulls away from the fixing part 11 . The tensioning structure 4 is used to pull the sliding part 12 outward, so that the chain 2 is always kept in a tensioned state, preventing the material on the hook 3 of the chain 2 from colliding and falling.

[0014] Described tensioning structure 4 comprises a fixed vertical slideway 41, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com