Clamping support with double driving rods

A drive rod and double drive technology, applied in the direction of machine/support, supporting machine, vehicle parts, etc., can solve the problems of complicated operation and inconvenient use, and reduce the locking and unlocking operations of clamping and unclamping , the effect of quick pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

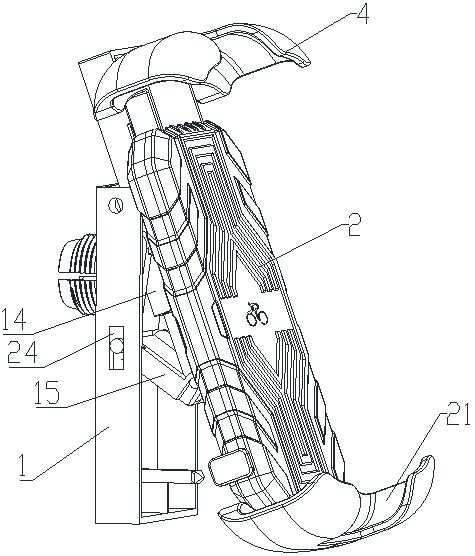

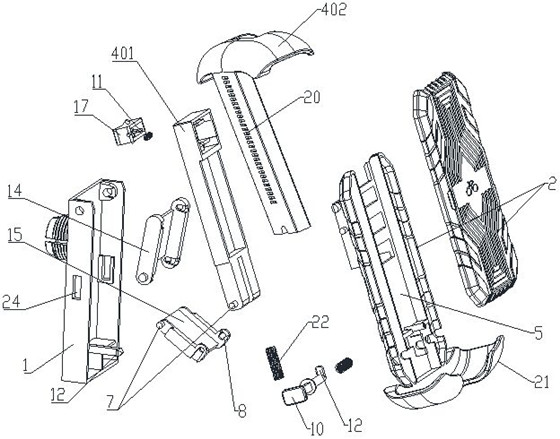

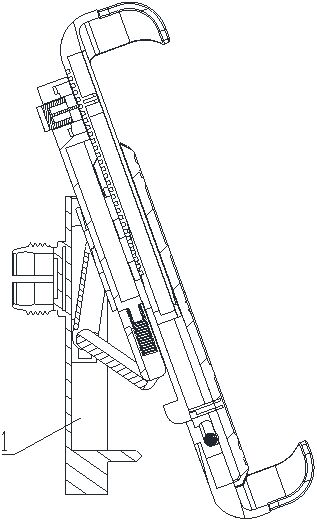

[0030] A double driving rod clamping bracket includes a base 1, a bracket housing 2, a movable clamping arm 4, a first driving rod 14, and a second driving rod 15, and the bracket housing 2 is provided with a slide rail 5. The movable clamp arm 4 slides in the slide rail 5, one end of the first driving rod 14 is rotatably connected with the bracket housing 2, the other end of the first driving rod 14 is rotatably connected with the second driving rod 15, and the first driving rod 14 is rotatably connected with the second driving rod 15. The other end of the two driving rods 15 drives the movable clamp arm 4 to move. The first driving rod 14 and the second driving rod 15 press against the base 1 when the rotating connecting ends of the first driving rod 14 and the second driving rod 15 are pressed. One end of the base 1 is connected to the bracket shell One end of 2 is rotatably connected, and there is a space between the other end of the base 1 and the other end of the bracket ...

Embodiment 2

[0037] A double driving rod clamping bracket includes a base 1, a bracket housing 2, a movable clamping arm 4, a first driving rod 14, and a second driving rod 15, and the bracket housing 2 is provided with a slide rail 5. The movable clamp arm 4 slides in the slide rail 5, one end of the first driving rod 14 is rotatably connected with the bracket housing 2, the other end of the first driving rod 14 is rotatably connected with the second driving rod 15, and the first driving rod 14 is rotatably connected with the second driving rod 15. The other end of the two driving rods 15 drives the movable clamp arm 4 to move. The first driving rod 14 and the second driving rod 15 press against the base 1 when the rotating connecting ends of the first driving rod 14 and the second driving rod 15 are pressed. One end of the base 1 is connected to the bracket shell One end of 2 is rotatably connected, and there is a space between the other end of the base 1 and the other end of the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com