Forming machine for automobile lamp dimming motor mini turbine

A technology of automobile lamps and molding machines, which is applied in the field of molding equipment, can solve the problems of reducing work efficiency and inconvenience of taking and placing products, achieve safety efficiency, and realize the effect of unmanned automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

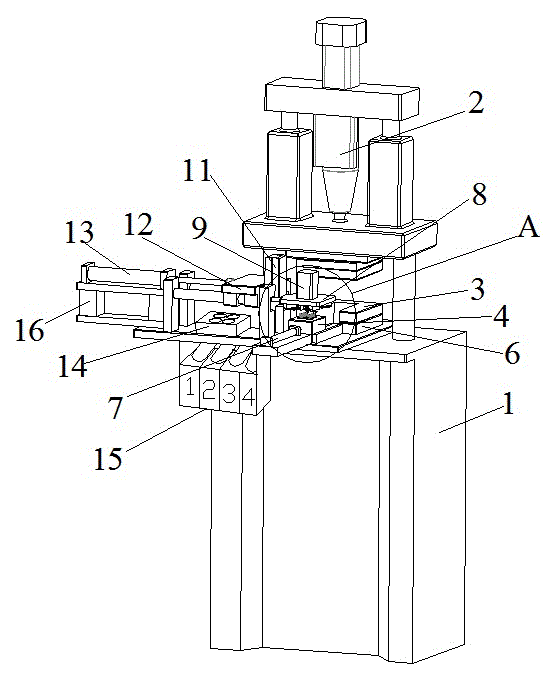

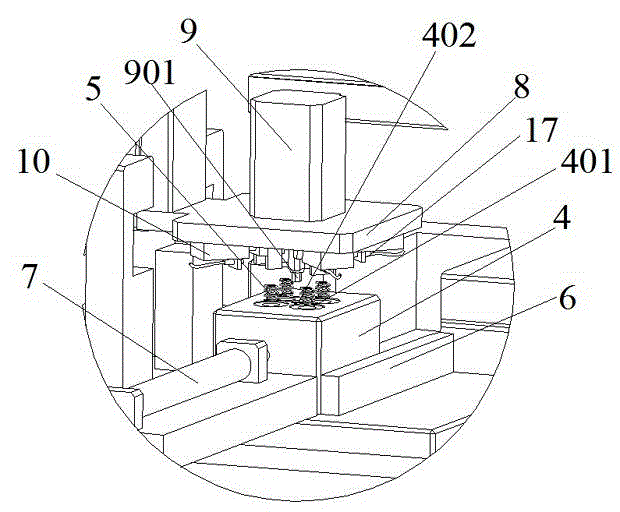

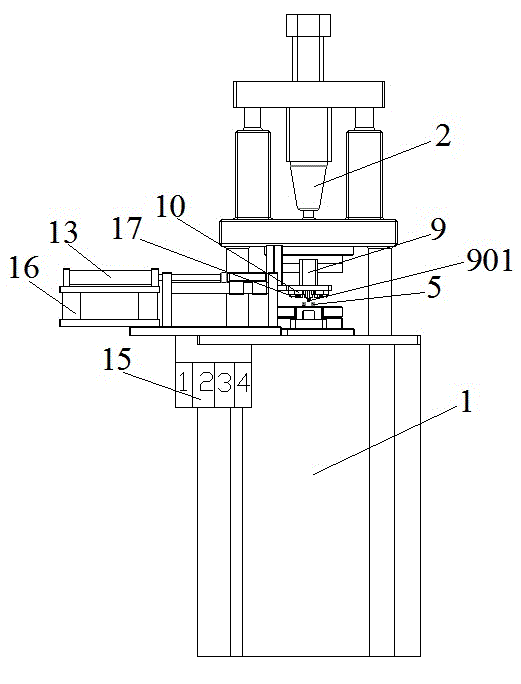

[0017] see Figure 1 to Figure 3 , the molding machine of the present invention suitable for small turbines of automotive lamp dimming motors includes a molding machine main body 1 and an injection molding assembly 2, a mold 3 and a mold core 4 are arranged on the molding machine main body 1, and several mold cores are formed on the mold core 4. Product forming area 401 and a polygonal connection hole 402 .

[0018] In order to realize automatic pick-and-place products (small turbine 5), a pick-and-place assembly is provided between the molding machine main body 1 and the injection molding assembly 2. Specifically, the pick-and-place assembly includes: guide device 6, mold core cylinder 7, bracket 8, Motor 9, jaw cylinder 10, slide rail cylinder 11, connecting plate 12 and moving cylinder 13, wherein the mold core cylinder 7 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com