Water tank feeding and discharging clamp and method for machining water tank with same

A water tank and material clip technology, applied in metal processing equipment, manufacturing tools, grinding feed motion, etc., can solve the problems of low loading and unloading efficiency and product quality, easy deformation, and weak clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

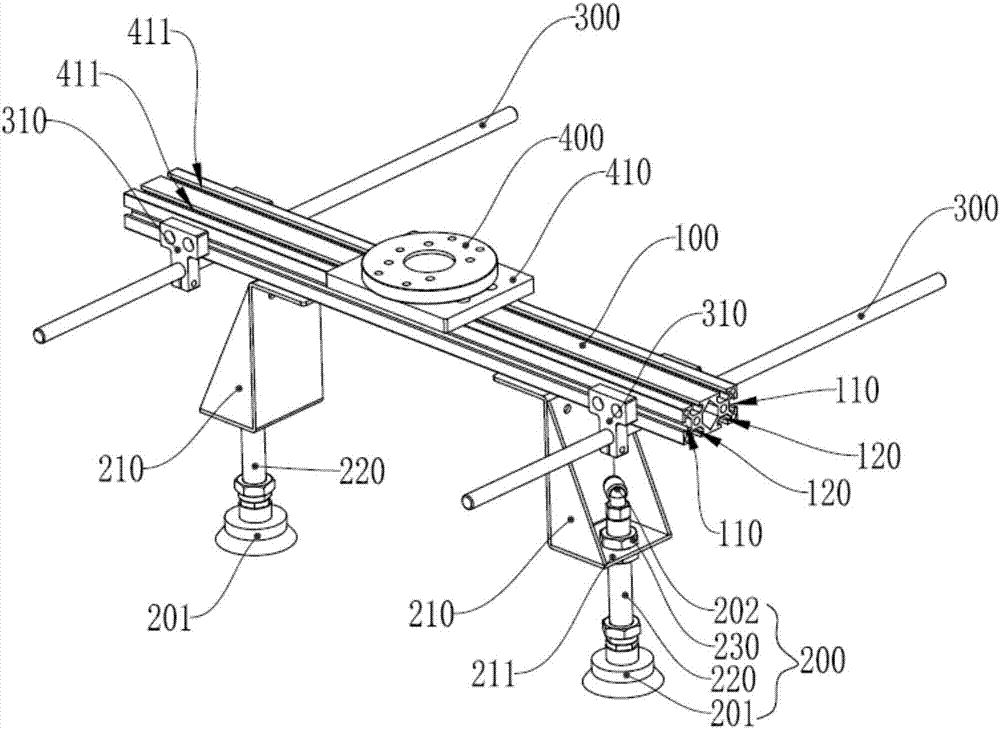

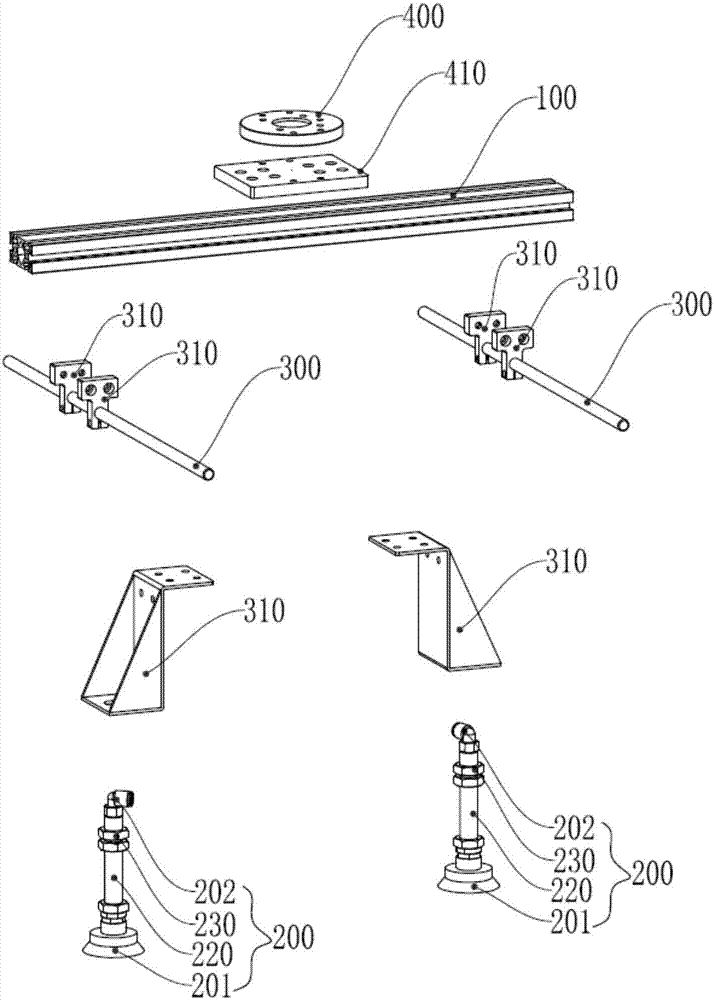

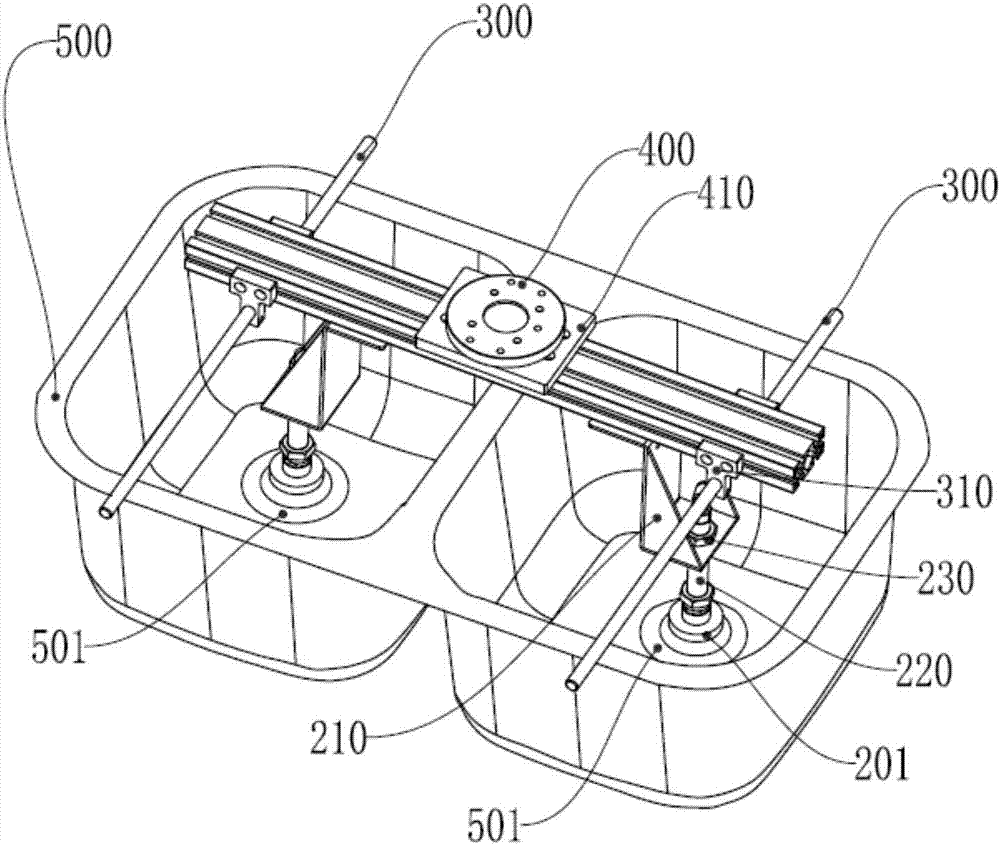

[0044] Such as Figure 1-3 As shown, a sink loading and unloading jig includes a main body beam 100, an adsorption device 200 and a balance correction rod 300; Some suction ends are located below the main body beam 100 and are set vertically downward to the main body beam 100; the balance correction rods 300 pass through both ends of the main body beam 100 vertically and horizontally respectively, and the balance correction rods 300 are arranged on Below the two ends of the main beam 100 and above the adsorption end of the adsorption device 200, so that the two ends of the balance correction rod 300 protrude from both sides of the adsorption device 200 respectively, when the When the adsorption end of the adsorption device 200 is adsorbed to the inner bottom surface of the water tank, the balance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com