Composite pressing clamp of panel-type electrode bracket for COMMB-LED (chip on mirror metal board-light emitting diode)

A COMMB-LED, electrode support technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of not meeting the processing requirements of the COMMB-LED surface electrode support, the wear of the pressing steel ball of the rotary handle self-locking mechanism, Problems such as low clamping force and clamping accuracy, to achieve the effect of light weight, reduced processing procedures, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

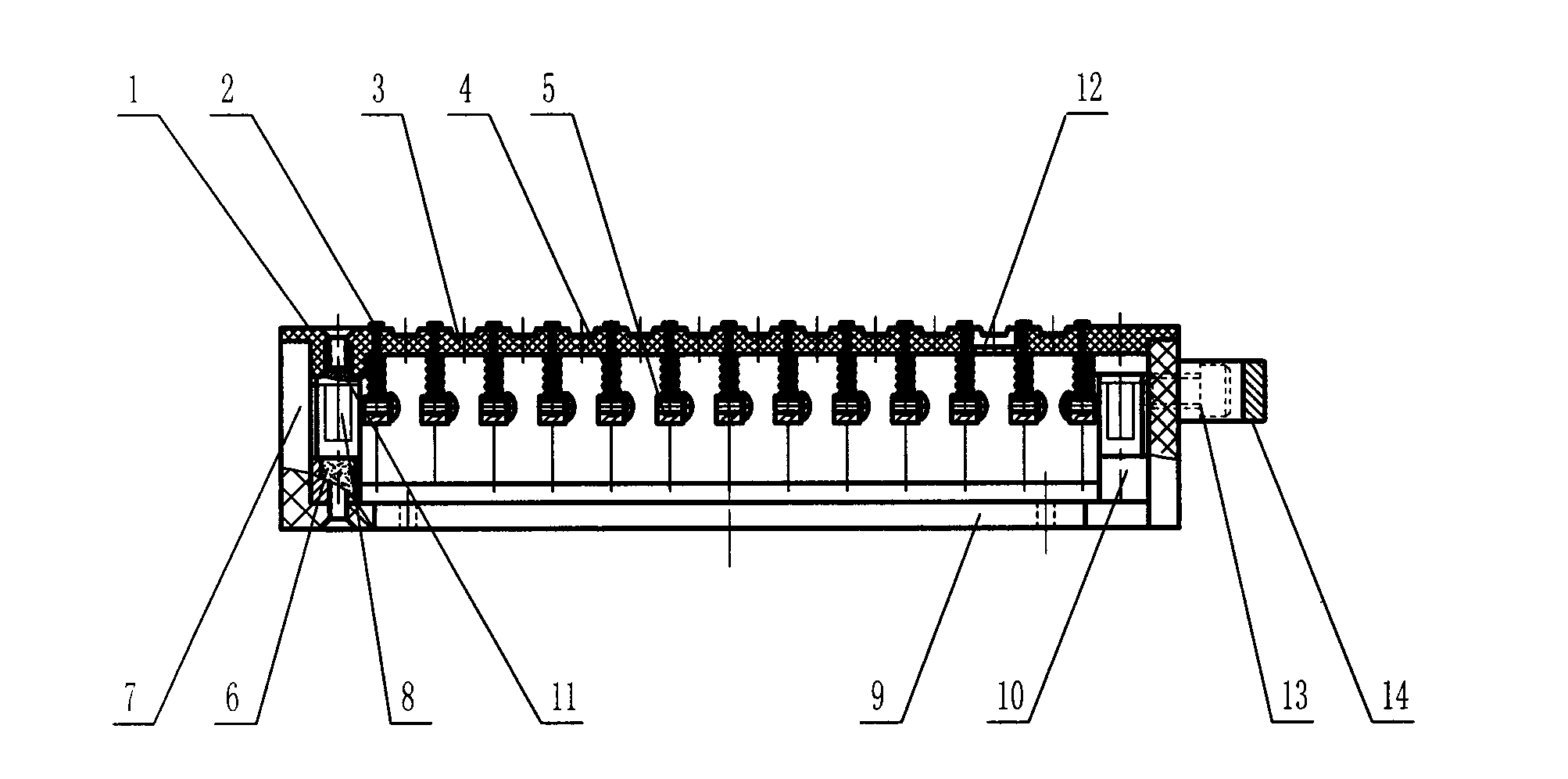

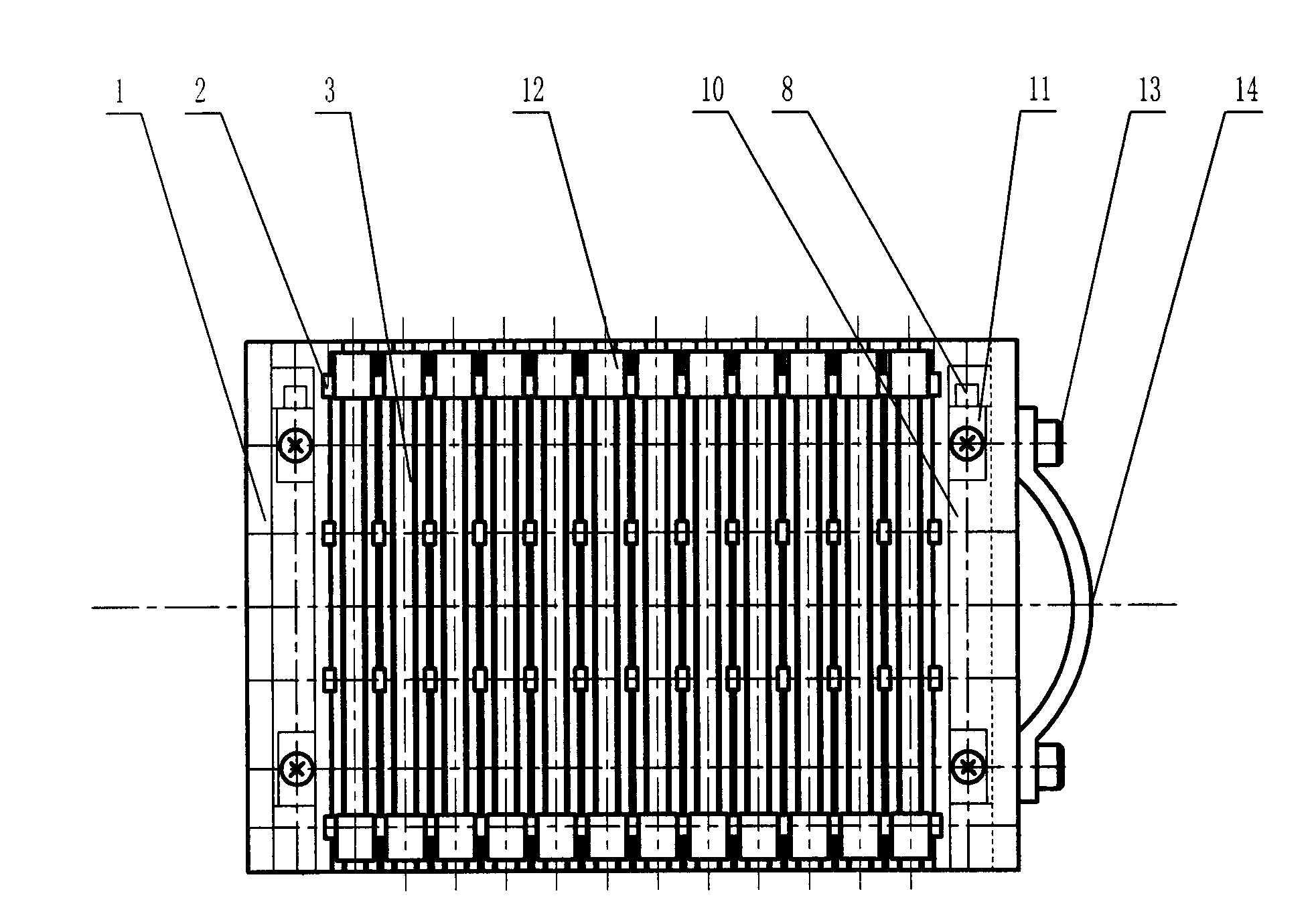

[0016]Embodiment 1: Overcome the special lifting platform 4. The spring force pushes upwards (Z direction) 2. The T-shaped pressing piece, and put the good conductor mirror strip that has been injected into the Z-shaped electrode sideways into 1. On the carrying platform 3. In the cavity of the loading platform (the front end is aligned with the positioning edge of the cavity), the lifting platform is lowered so that the lower edge of the 2. T-shaped pressing piece is covered with the edge of the good conductor mirror strip under the action of 4. the spring force. And press it into 3. The cavity of the carrying platform. 1, the carrying platform of the good conductor mirror profile bar with the Z-type electrode will be installed again. Put it from top to bottom (Z direction) into 9. Between the flange limiters of the two side plates of the fixture body. Make 1. The lower plane of the carrying platform and 7. Fit the flange of the bottom plate of the fixture. Because 6Z-direc...

Embodiment 2

[0017] Embodiment 2: place 1. the carrying platform in reverse on the workbench, and introduce the lower mold cavity bonded with the Z-shaped electrode sheet into the 12. lower cavity groove of the carrying platform according to the set position pressure. Then place 1. the carrying platform on the special lifting platform in the forward direction, overcome 4. the elastic force of the spring and push it up (Z direction) 2. T-shaped pressing piece, to the side of the good conductor mirror strip that has not been injected into the Z-shaped electrode Put it into 1. on the carrying platform 3. in the cavity of the carrying platform. And make the front end of the molded bar seamlessly align with the head end of the cavity of the carrying platform. 1, the carrying platform of the good conductor mirror profile strip with the Z-shaped electrode is installed, and put into 9, between the two side plates of the fixture body from top to bottom (Z direction). Make 1. The lower plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com