Deep hole blasting charging and detonating method for lowering foundation based on digital detonators

A digital detonator and deep hole blasting technology, applied in blasting and other directions, can solve the problems of difficulty in effectively overcoming the clamping effect of the bottom plate, increasing the action time of blasting gas, and complex operation of fan-shaped blasting holes, so as to reduce the amount of explosives and reduce the The generation of blasting foundation, the effect of preventing premature escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0027] In conjunction with the accompanying drawings.

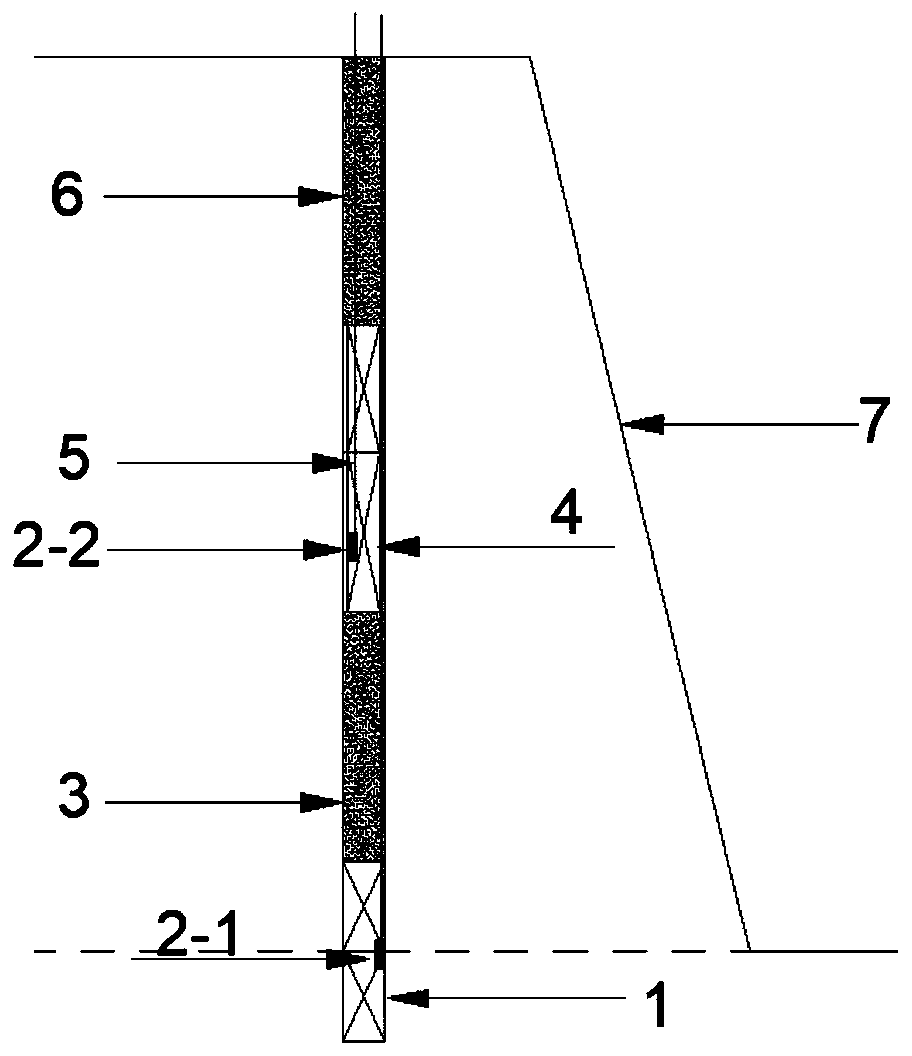

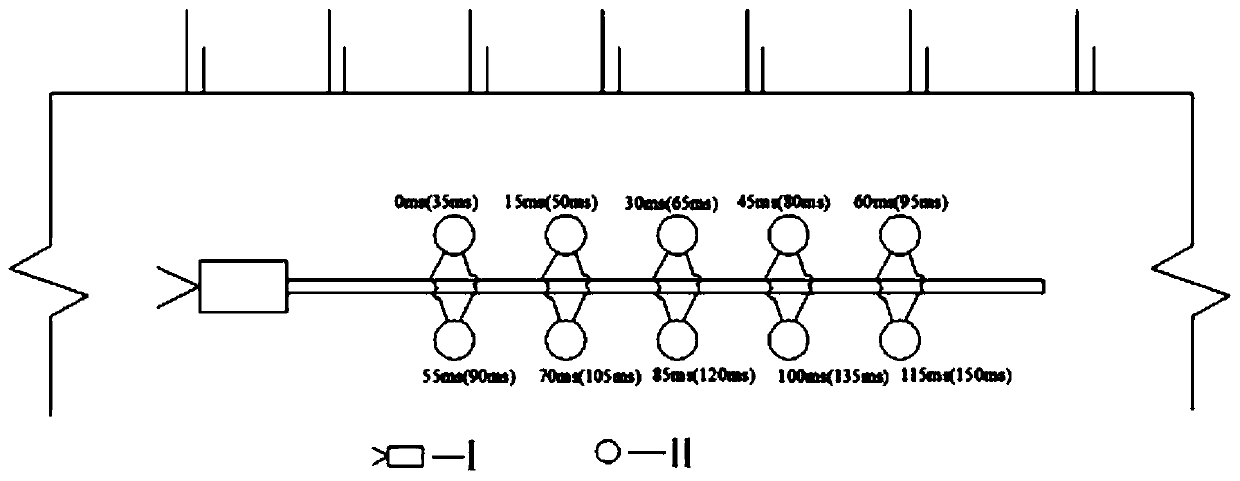

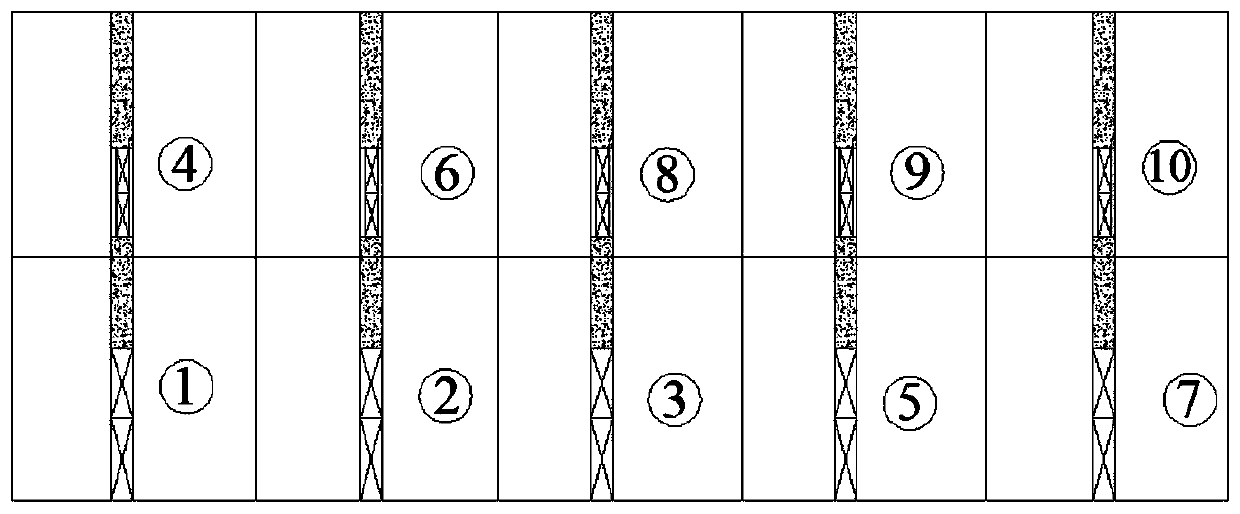

[0028] The design step height of an open-pit stonework mining is 10m, the super-depth is 1.0m, the inclination angle of the drill hole is 90°, the hole depth is 11.0m, the drill hole diameter is 110mm, the row spacing is 4.5*3m, and the blasthole filling is 3.0m. Emulsion explosives with a detonation velocity of 3200-4200m / s were used, but the problem of many blasting roots in the early construction process has not been resolved. Therefore, adopt a kind of blasting method based on digital detonator to reduce the root that the present invention proposes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com