Patents

Literature

46results about How to "Increased stress intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

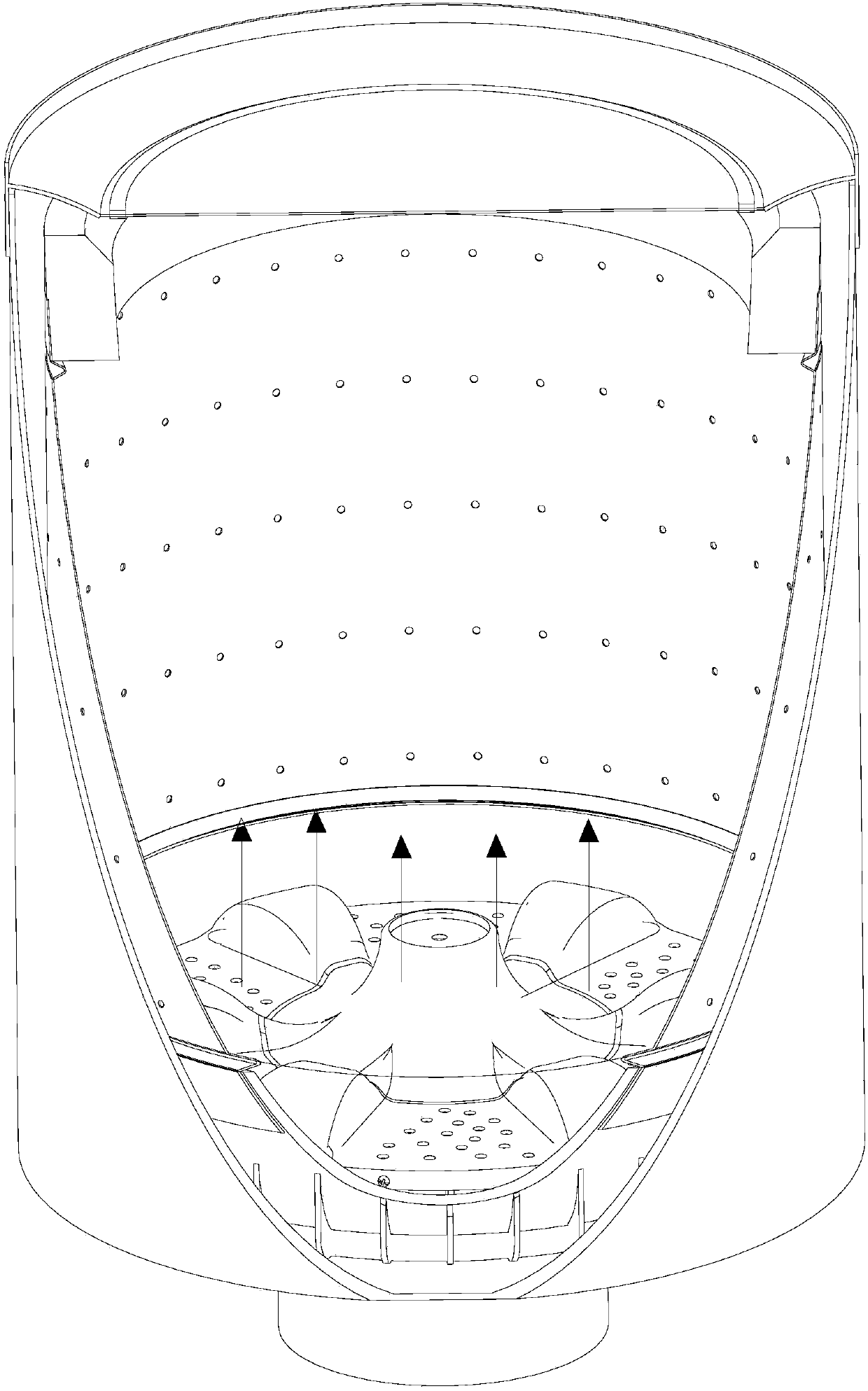

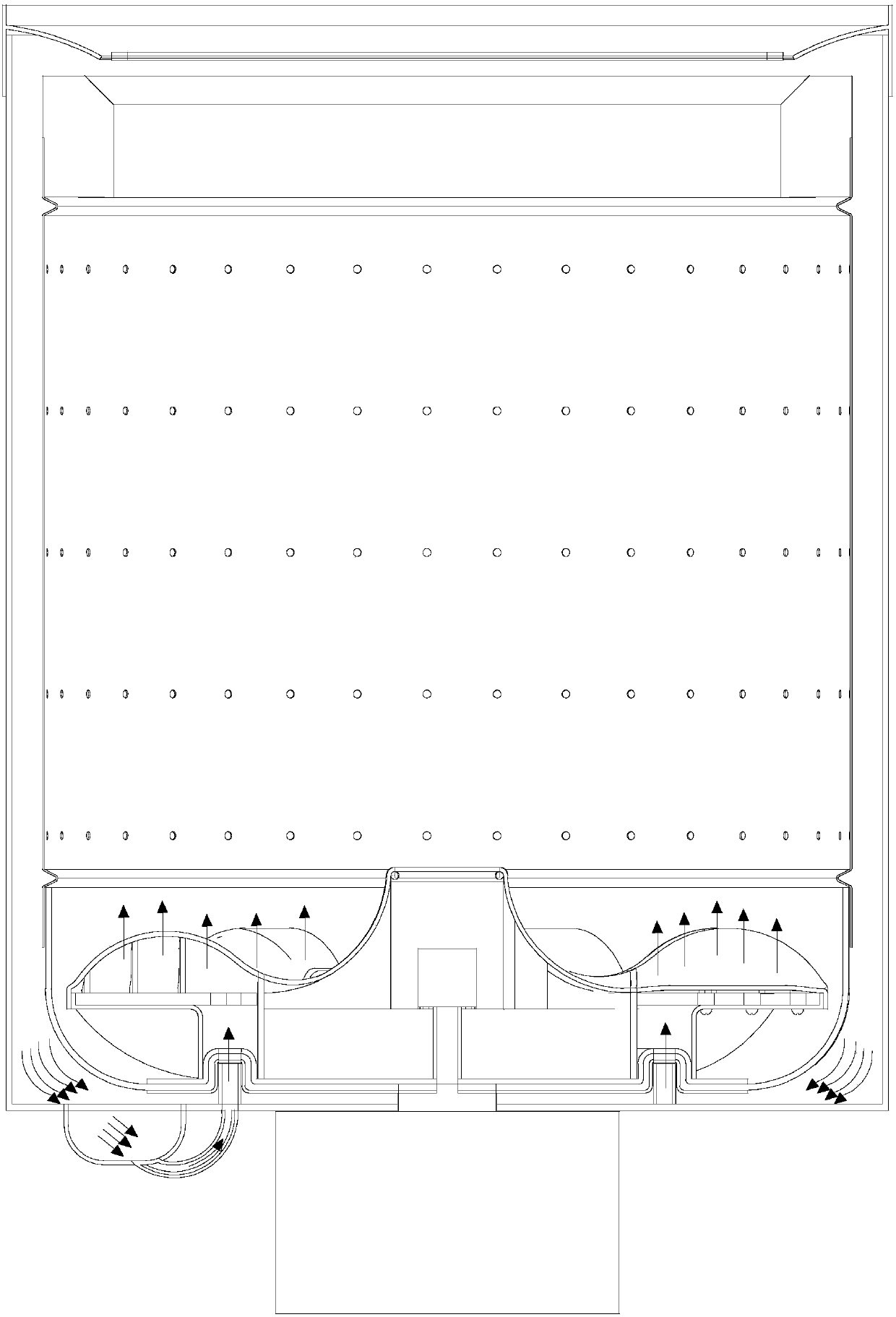

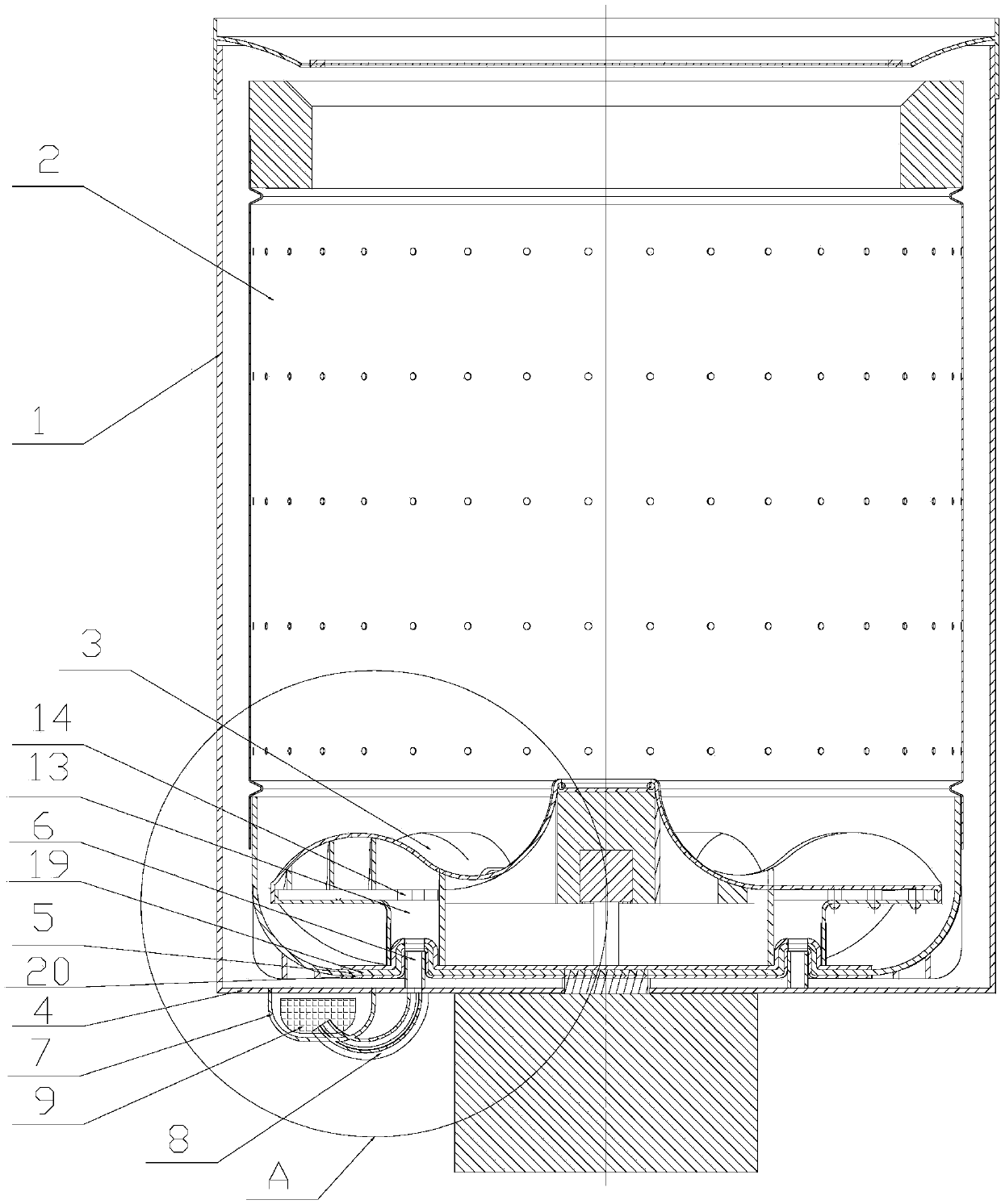

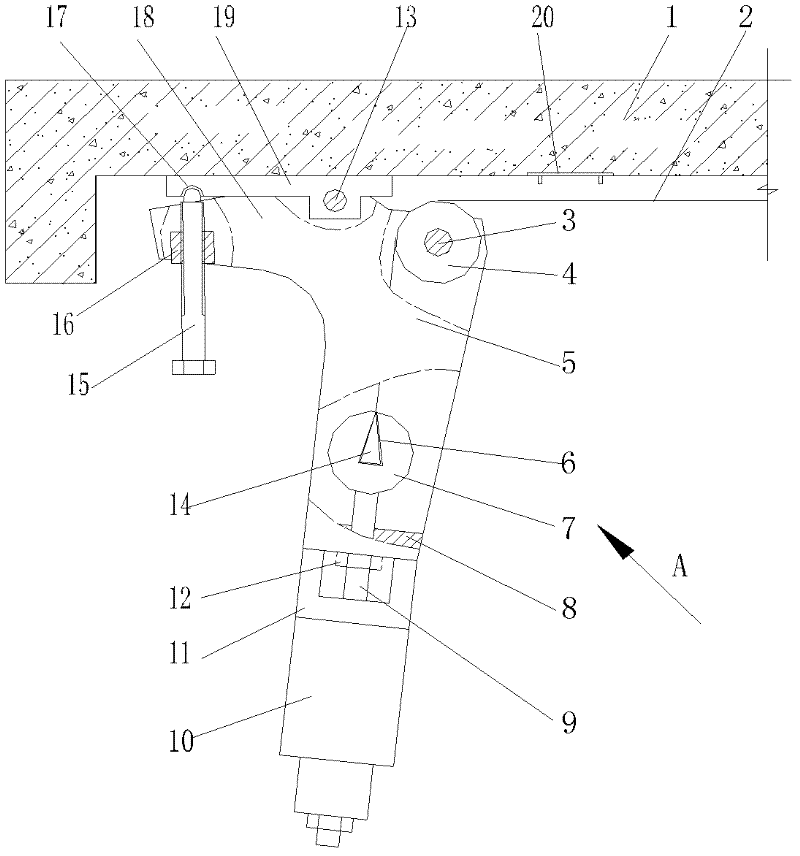

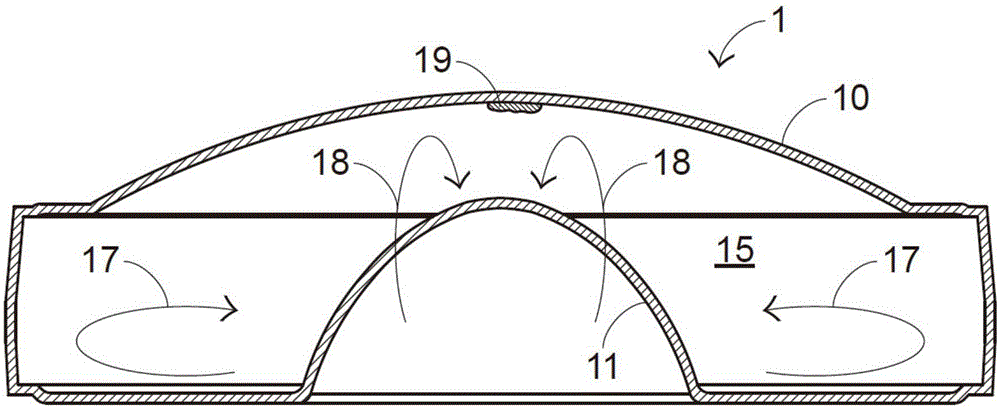

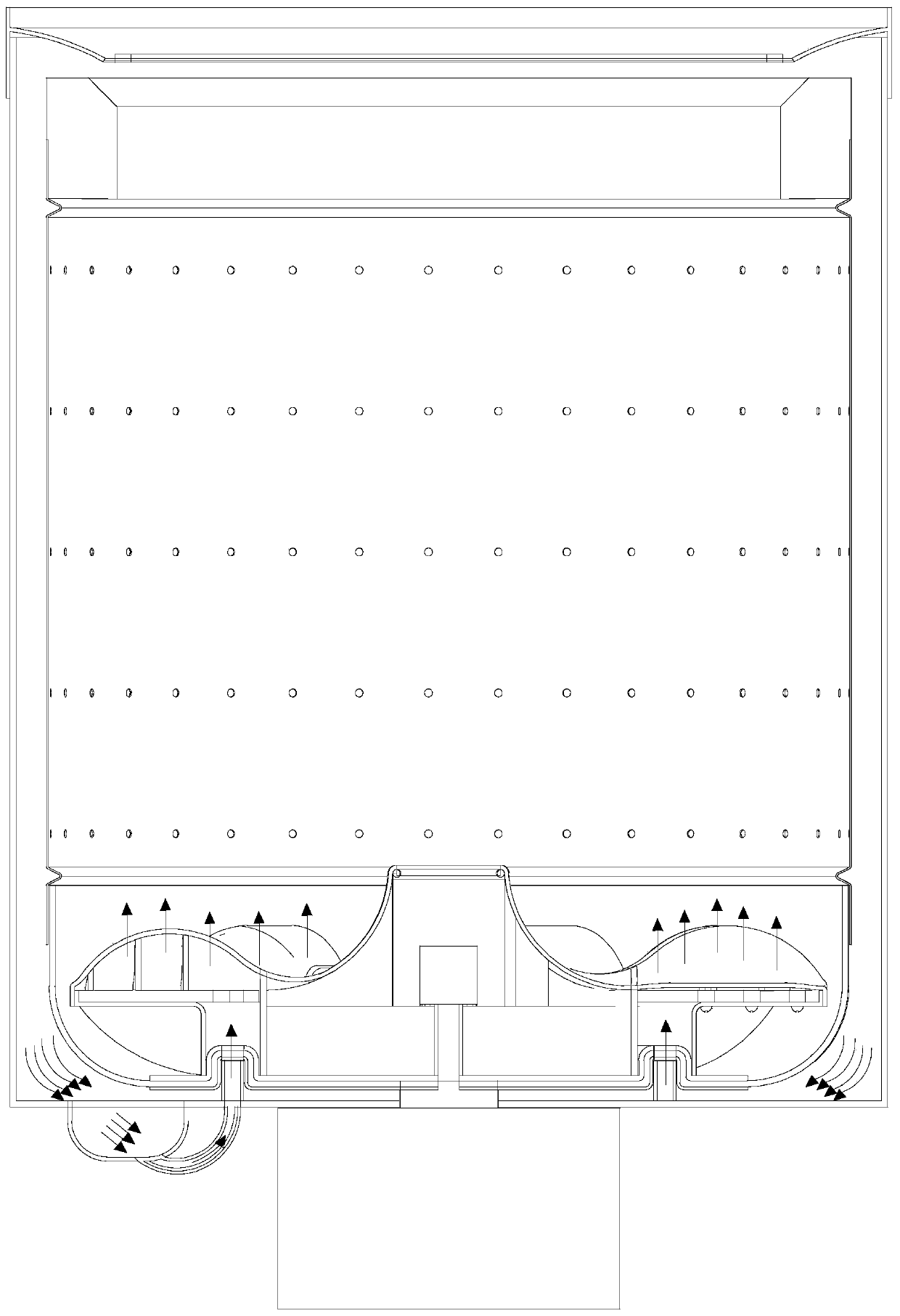

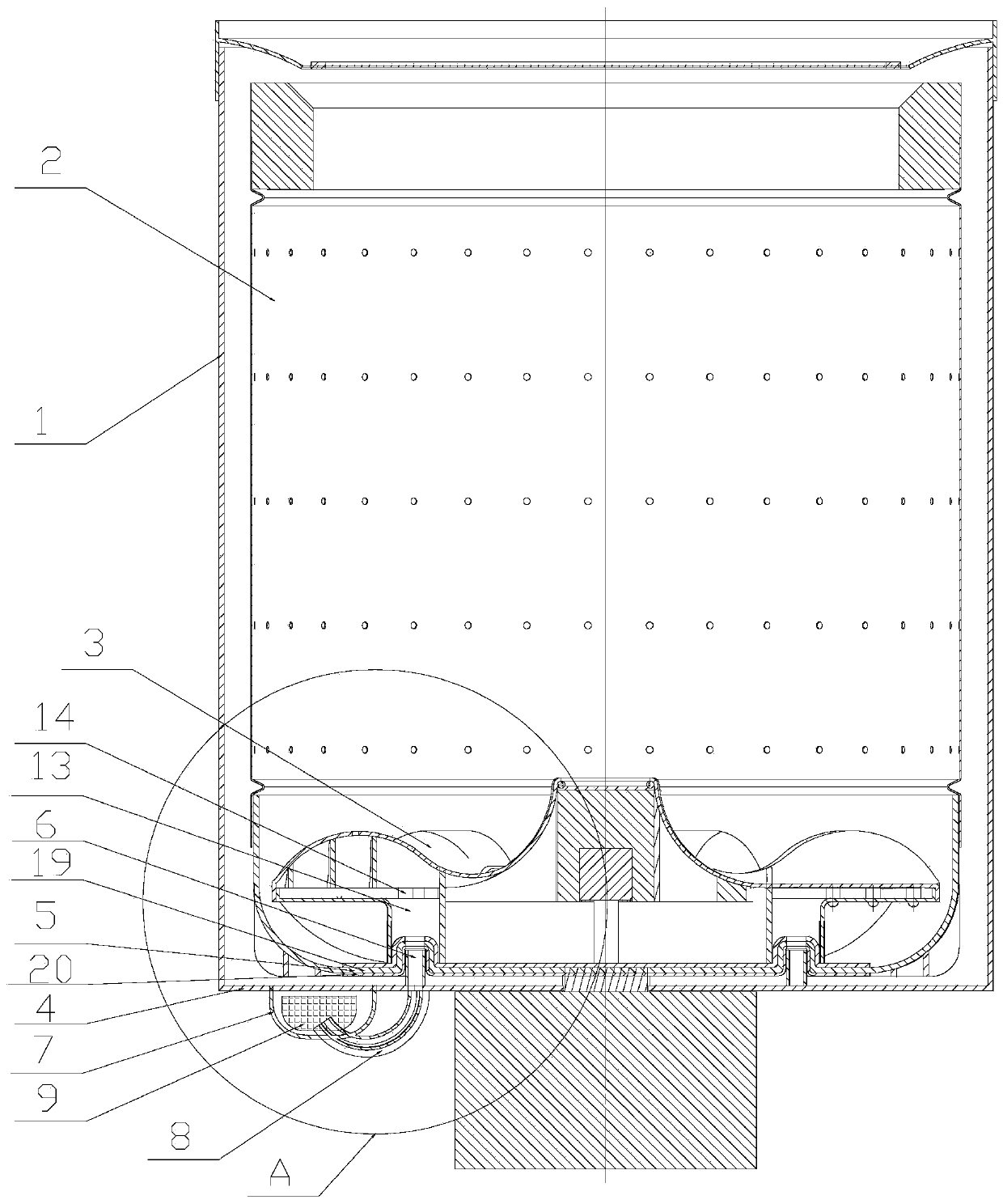

Washing machine with spray-rinsing function

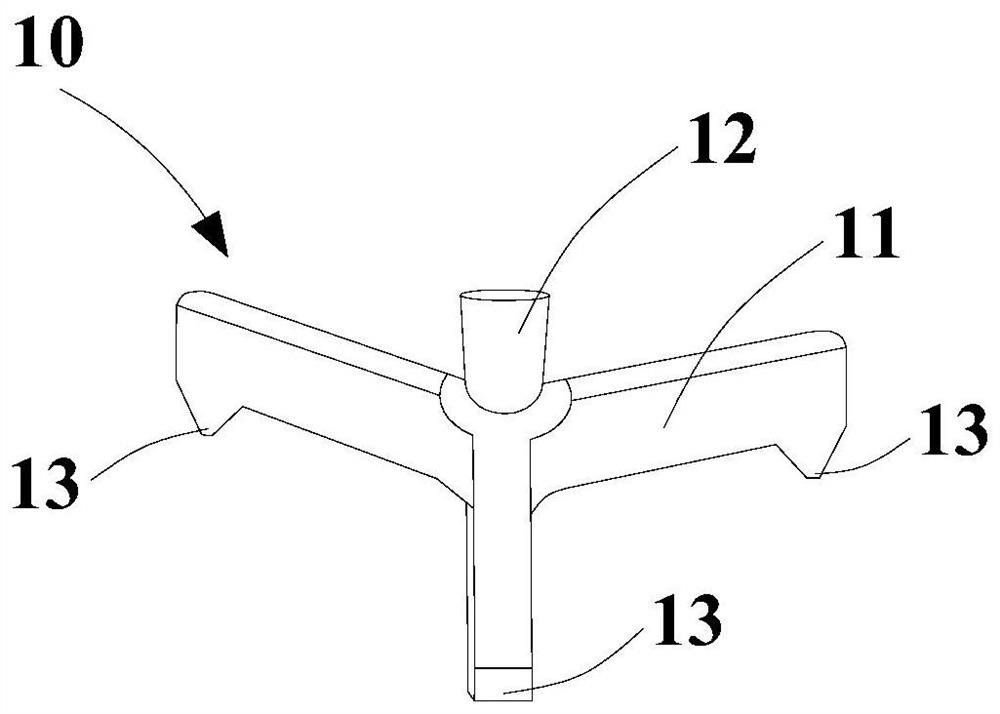

ActiveCN108018667AImprove washing effectAvoid entanglementOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

The invention relates to a washing machine with a spray-rinsing function. A gap between an inner drum and an outer drum is communicated with a water channel in an impeller through a connection water channel with a water pump, rinsing water between the inner drum and the outer drum flows through the connection water channel and the water channel in the impeller and then is sprayed into the inner drum through spraying holes formed in the surface of the impeller, and water columns ejected upwards are formed in the inner drum for rinsing clothes. Through the arrangement above, the water columns flushing upwards can be constantly formed in the inner drum, correspondingly the clothes are scoured, and the phenomenon that the clothes are wound due to reciprocating inverse rotation can be alleviated, so that damage caused by winding to the clothes is avoided. Meanwhile, since the clothes are constantly turned over during clothes washing, the contact areas between the clothes and the rinsing water are increased, friction is generated among the clothes, and the rinsing effect is effectively improved. Furthermore, the washing machine is simple in structure, remarkable in effect and suitable for popularization and application.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

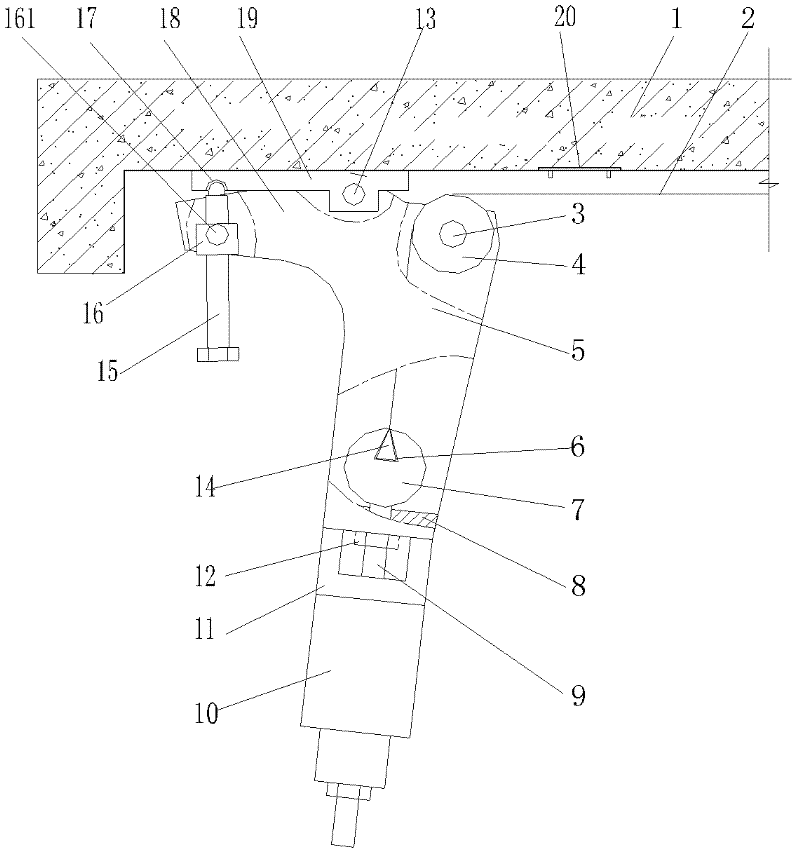

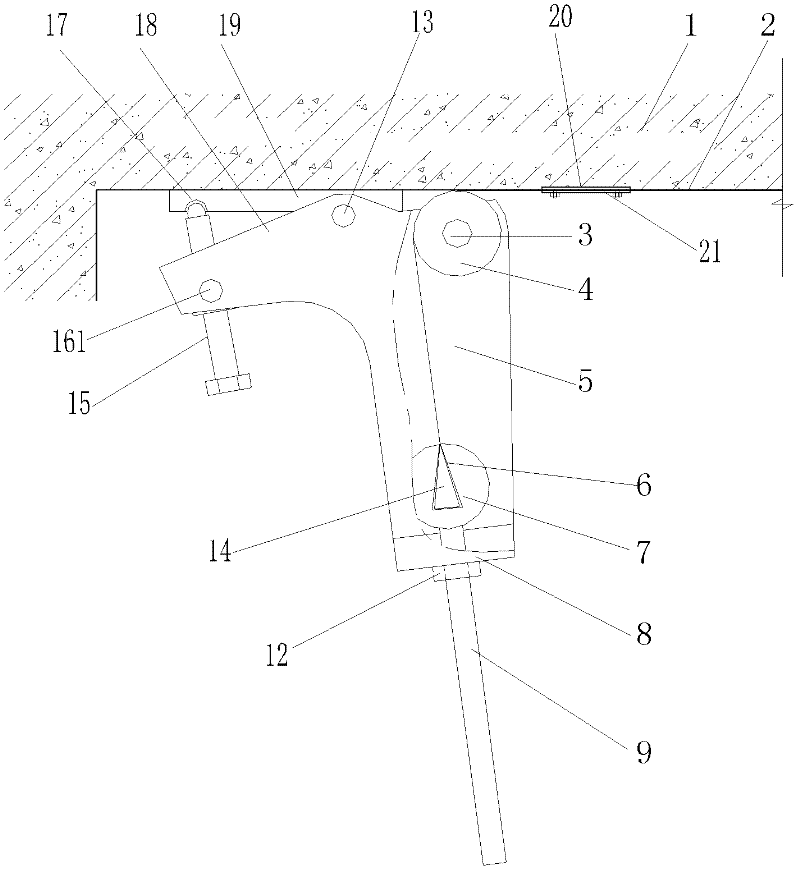

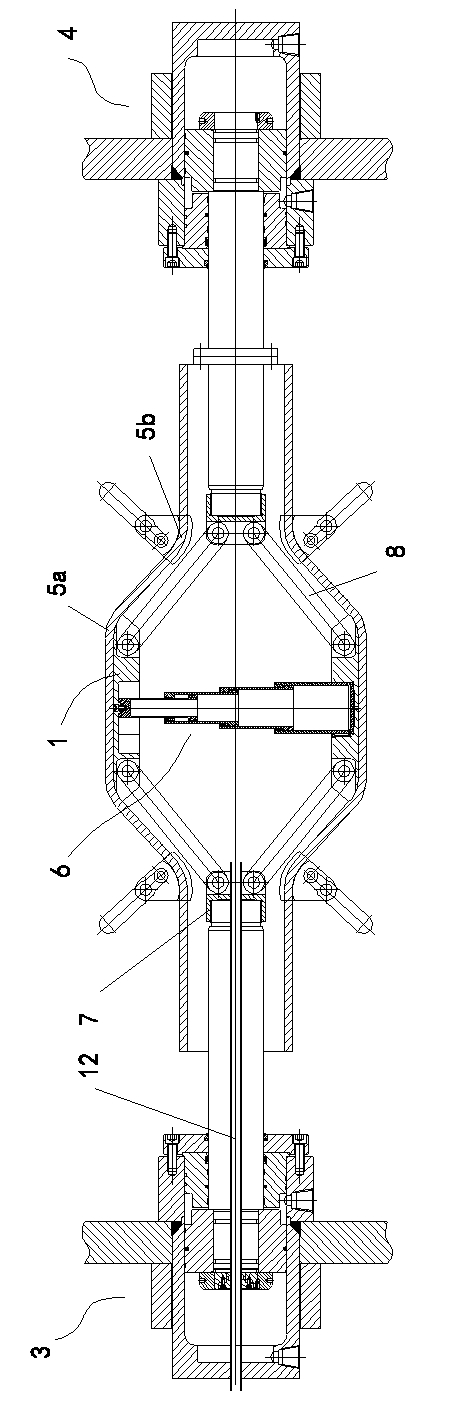

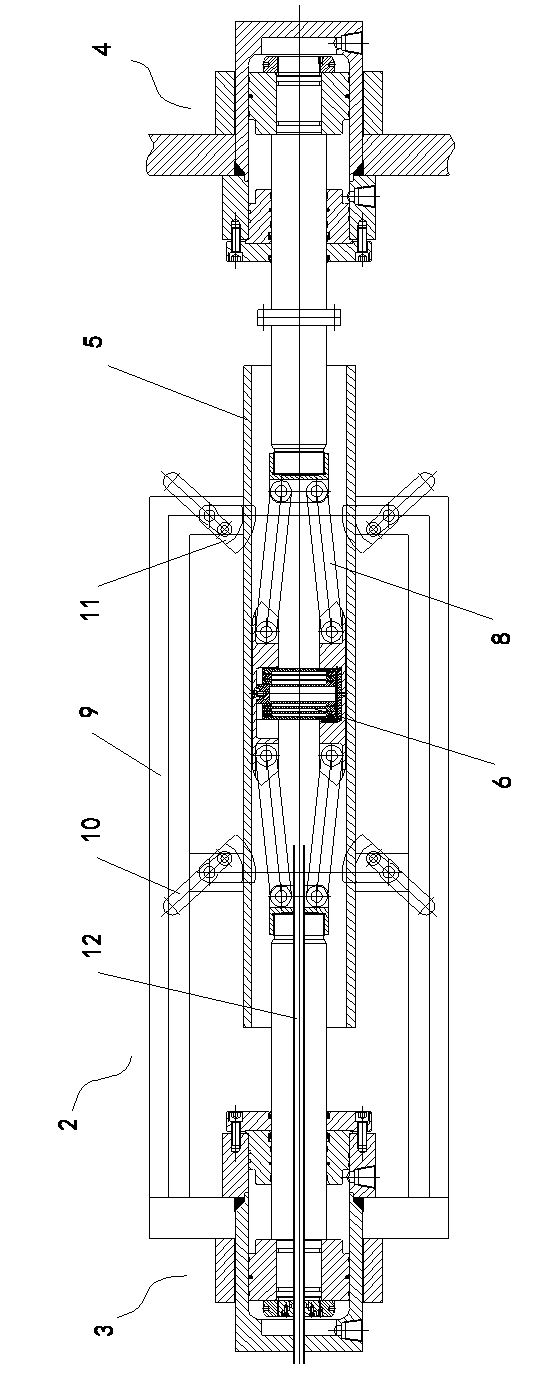

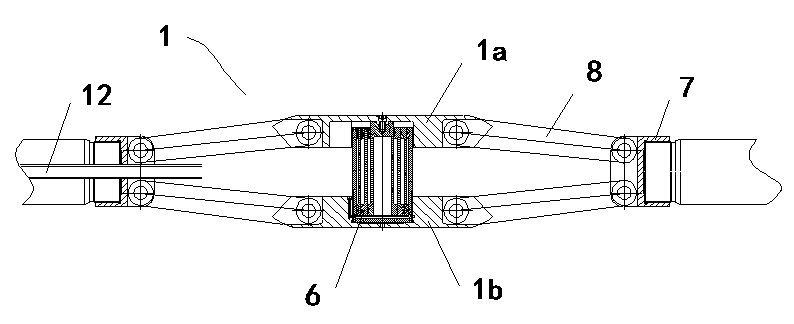

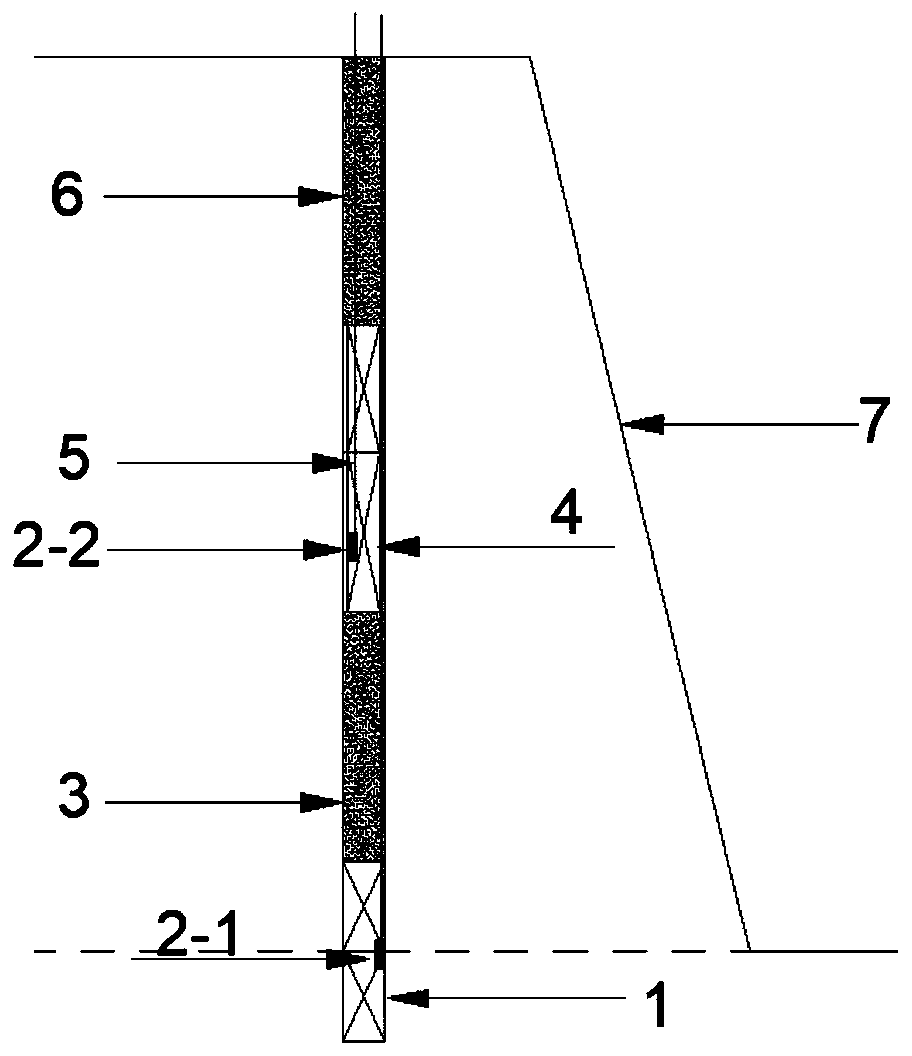

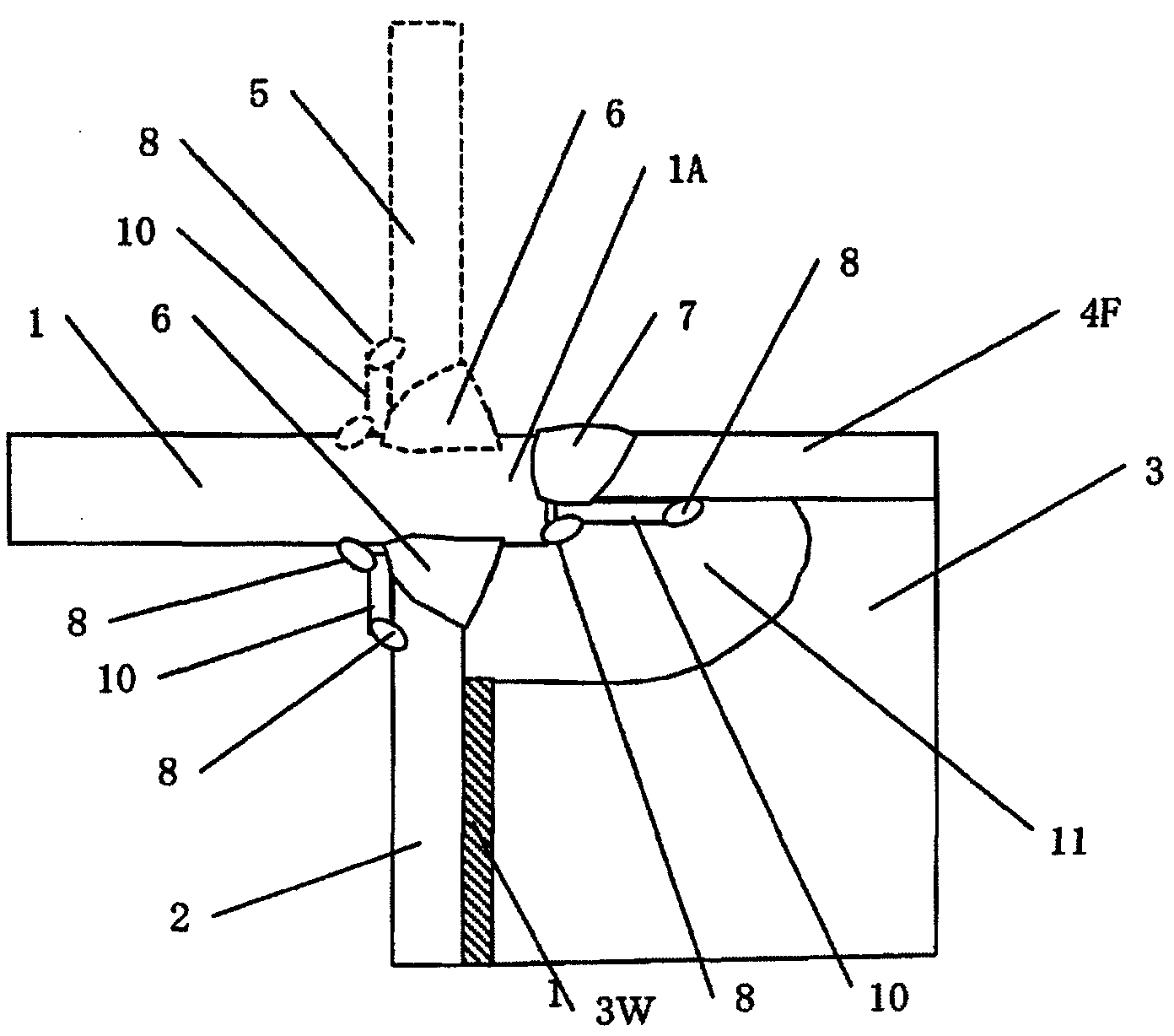

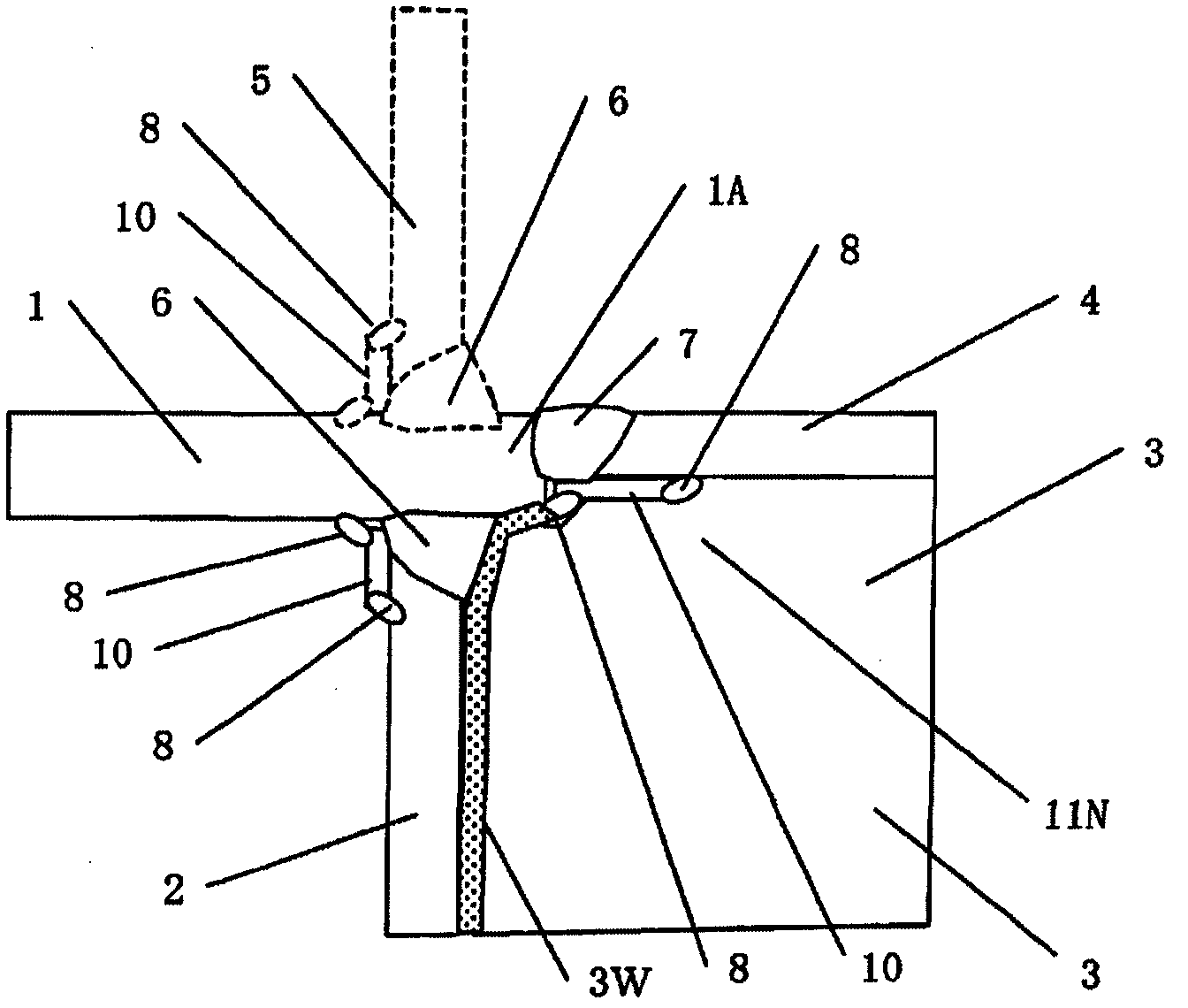

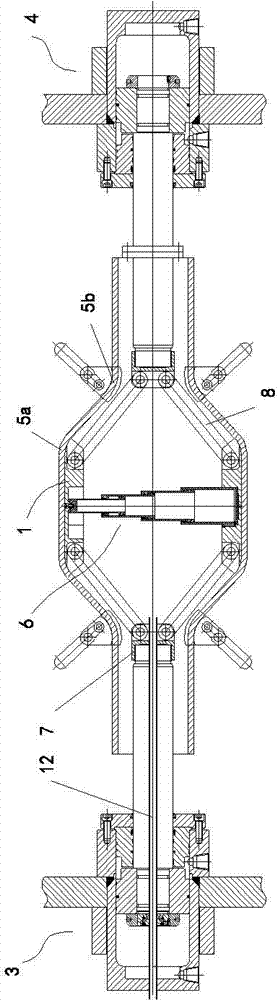

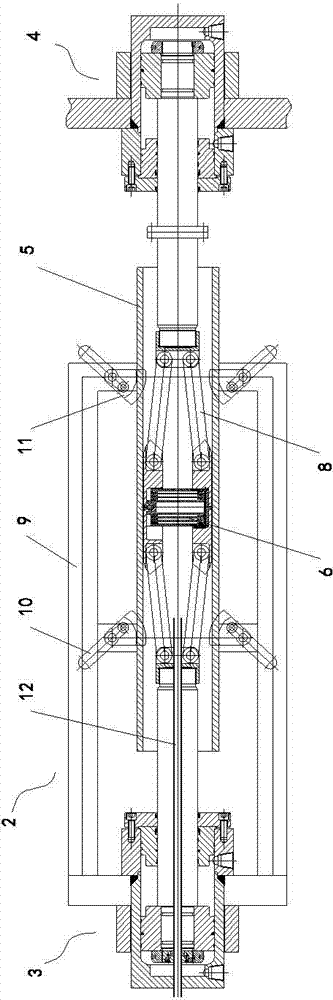

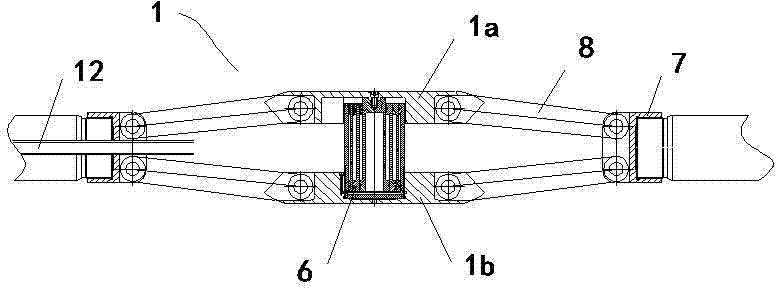

Pre-stressing carbon-cloth tension system and tension reinforcing method

ActiveCN102505858AIncreased stress intensityIncrease profitBuilding repairsBuilding material handlingFriction lossPre stressing

The invention discloses a pres-stressing carbon-cloth tension system and a tension reinforcing method. The pre-stressing carbon-cloth tension system comprises a pre-stressing tension assembly, a steering shaft and a tension stand; the tension stand is hinged with a reinforced assembly to form a lever structure, the steering shaft is arranged on the resistance arm of the tension stand in a manner of rotating around the axis of the steering shaft; the power arm of the tension stand is provided with a drive assembly for driving the resistance arm of the tension stand to rotate toward the surface of the reinforced assembly; and the pre-stressing tension assembly is used for connecting a carbon cloth to be tensioned around the upper part of the steering shaft and applying a tension force onto the carbon cloth to be tensioned. The pre-stressing carbon-cloth tension system disclosed by the invention is totally suitable for engineering application environment, does not need any regulation within a certain span, can perform tensioning simply, quickly and conveniently, and does not need excavating any channels on the reinforced assembly as channels for movement of clamps. A tensioning operation does not cause damage to an original concrete structure basically; a gap is reserved between the carbon cloth and the bottom of a component during tensioning, thus friction loss caused by the contact of the carbon cloth and the component is avoided, and an adhesive is conveniently coated at the same time.

Owner:CHONGQING UNIV

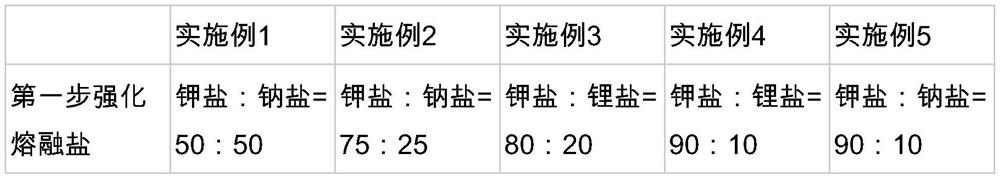

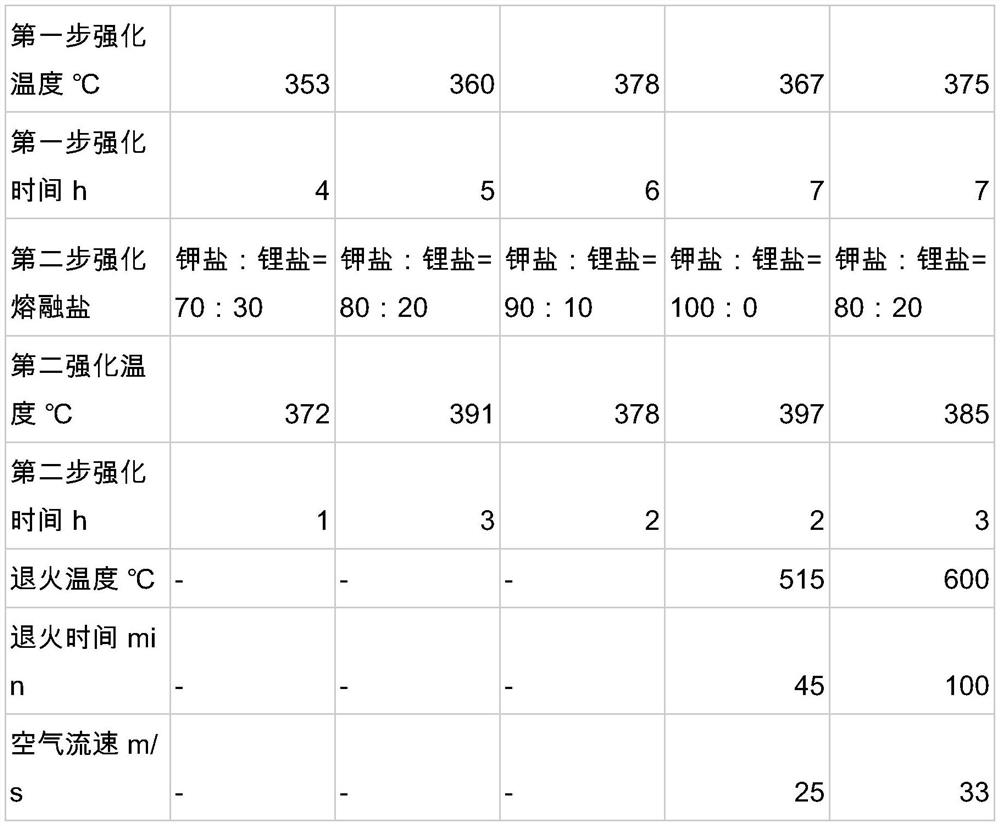

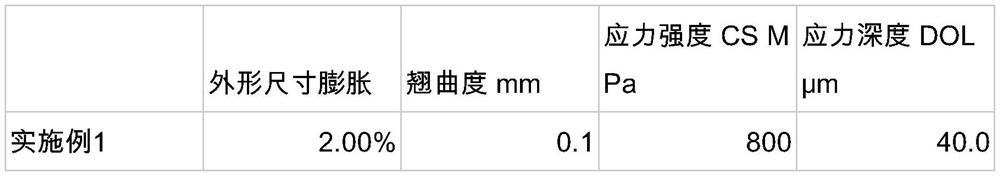

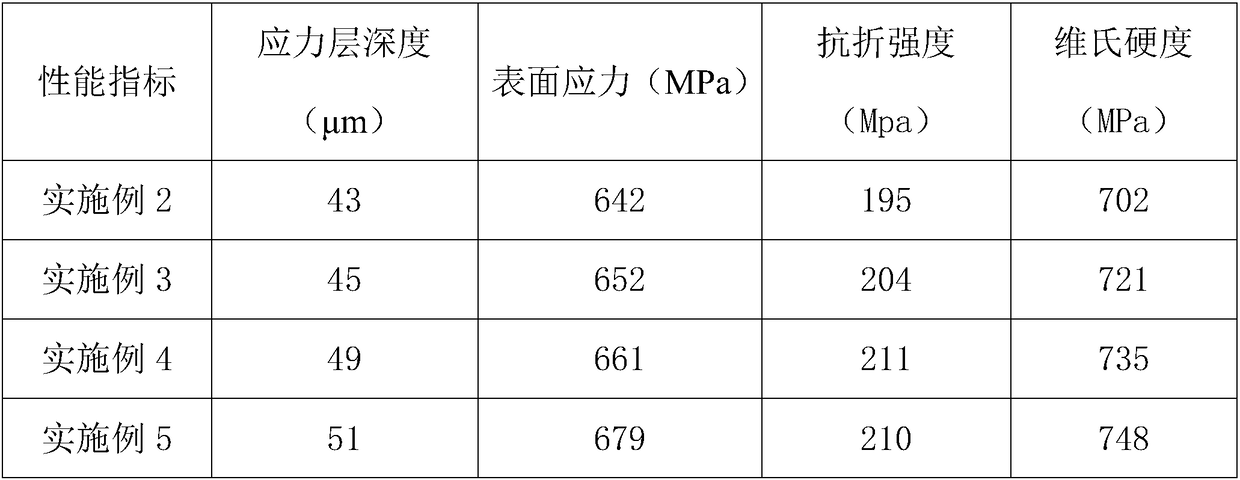

Cover plate glass strengthening process

ActiveCN111875264ADepth of protectionIncrease the surface compressive stressGlass tempering apparatusSurface cleaningPhysical chemistry

A cover plate glass strengthening method comprises the following steps: primary strengthening: cleaning the surface of cover plate glass to be strengthened, immersing the cover plate glass into ion exchange molten salt in a strengthening furnace, controlling the temperature at 350-380 DEG C, immersing the cover plate glass for 4-7 hours, and carrying out ion exchange, wherein the molten salt beinga molten liquid of more than one of potassium salt, sodium salt and lithium salt; secondary strenthening: controlling the temperature of a strengthening furnace to be 370-400 DEG C, soaking the coverplate glass into molten salt liquid of potassium salt and lithium salt with the mass fraction being 70-100:0-30, soaking is conducted for 1-3 hours, then putting the cover plate glass in a closed container to be cooled to the room temperature, so that the strengthened cover plate glass is obtained. The stress depth of the reinforced cover plate glass is 40-65 microns, the surface stress strengthis 800-1300 MPa, the warping degree is lower than 0.1 mm, and the boundary dimension expansion rate is lower than 2%.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

Integral compound bulging process for automotive driving axle

The invention discloses an integral compound bulging process for an automotive driving axle. The process comprises the following steps of: 1) placing an opened axle housing workpiece into an external bulging mold; 2) extending the internal bulging mold into a bulged deformed area of the axle housing workpiece from an inner hole at one end of the axle housing workpiece; 3) closing the external bulging mold; 4) applying equal thrust parallel to the axial direction of the axle housing workpiece to the internal bulging mold by utilizing thrust devices at the two ends of the internal bulging mold respectively, and applying pressure perpendicular to the axial direction of the axle housing workpiece to an upper module and a lower module by utilizing a pressure generation device, wherein the thrust is decomposed into a perpendicular thrust component which acts on the upper and lower module and is perpendicular to the axial direction of the axle housing workpiece and a parallel thrust component parallel to the axial direction of the axle housing workpiece under the action of a link mechanism, bulging force on the axle housing workpiece is the resultant force of the perpendicular thrust component and the pressure, and the axle housing workpiece is bulged and deformed under the action of the bulging force; and 5) performing unloading and demolding.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

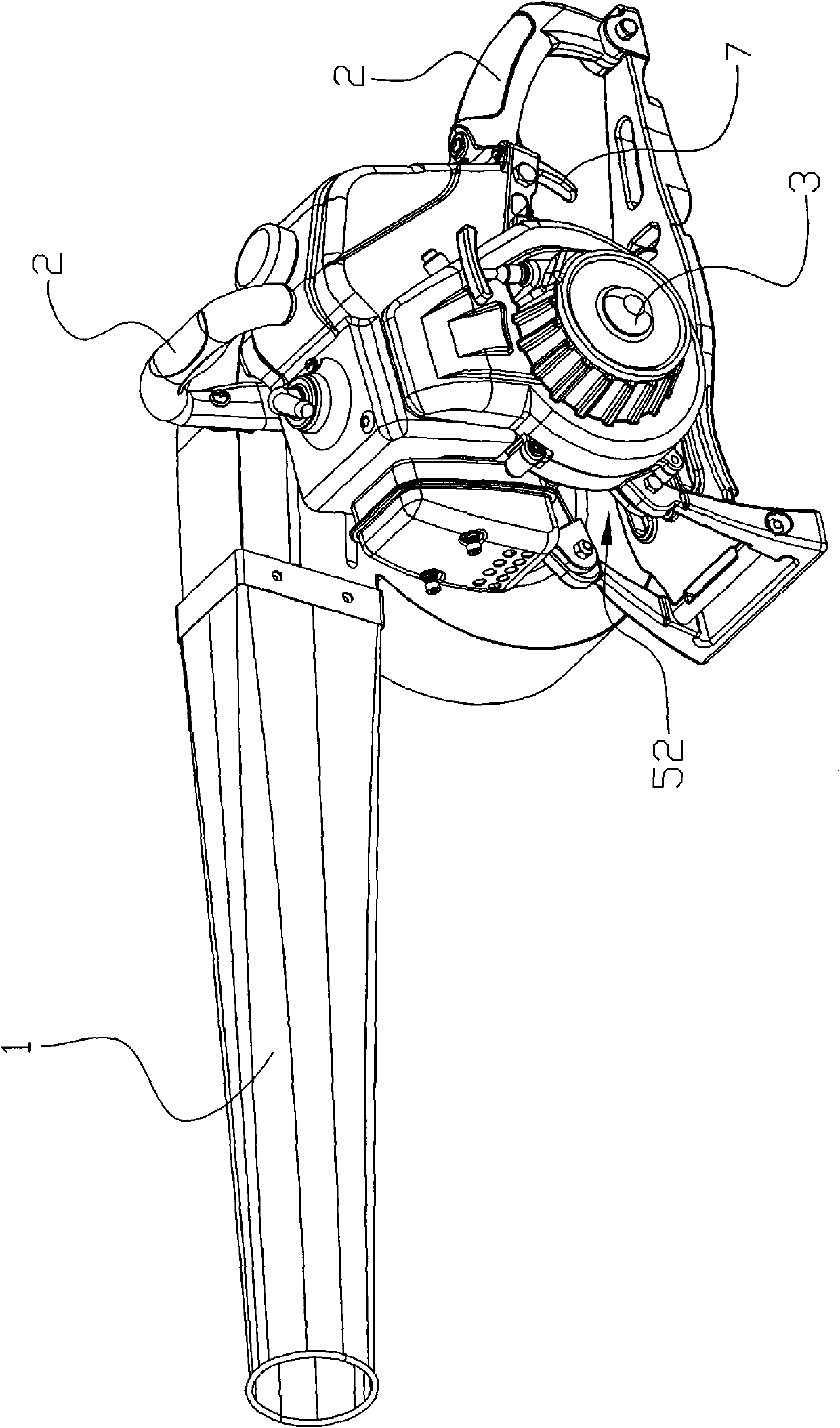

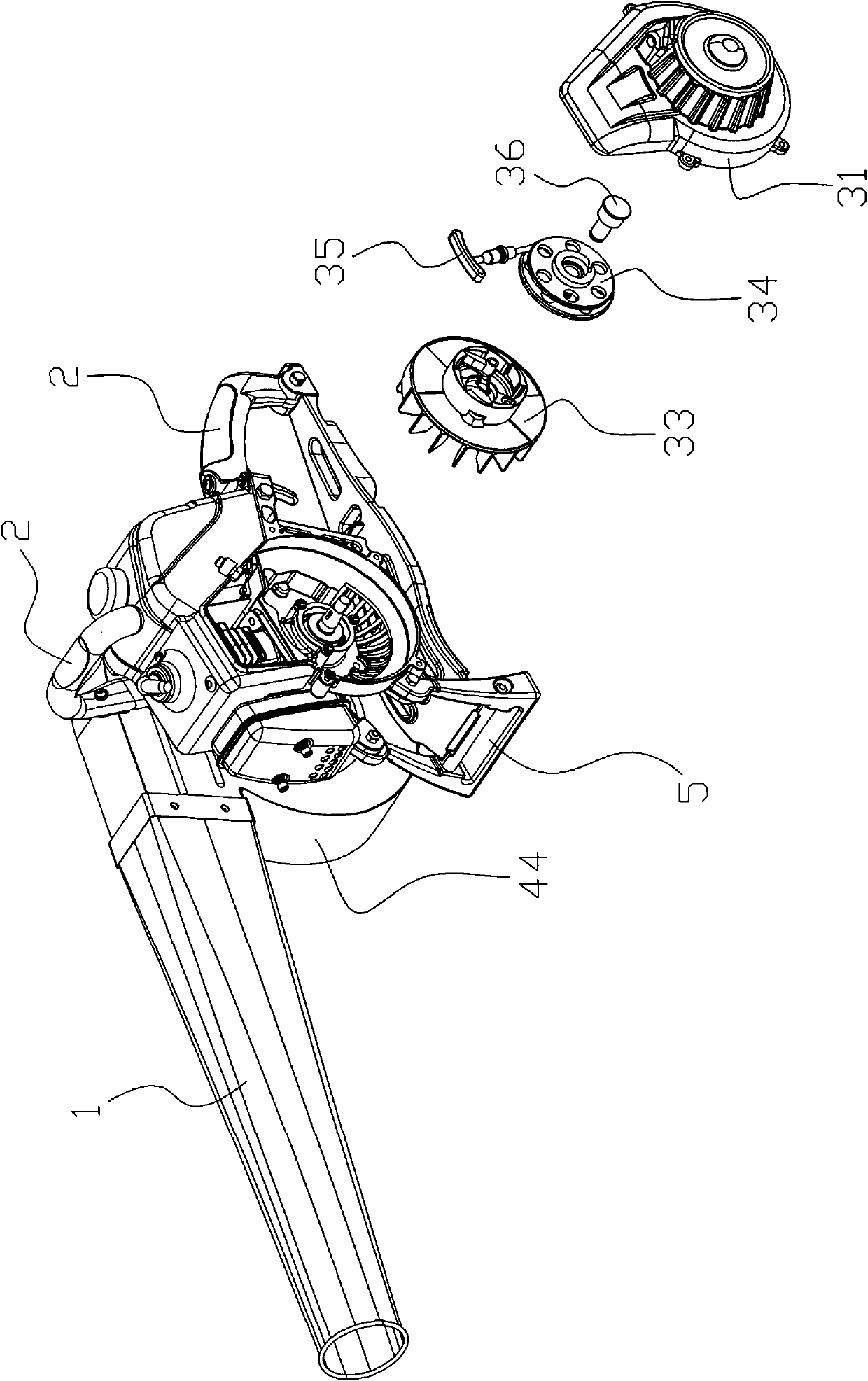

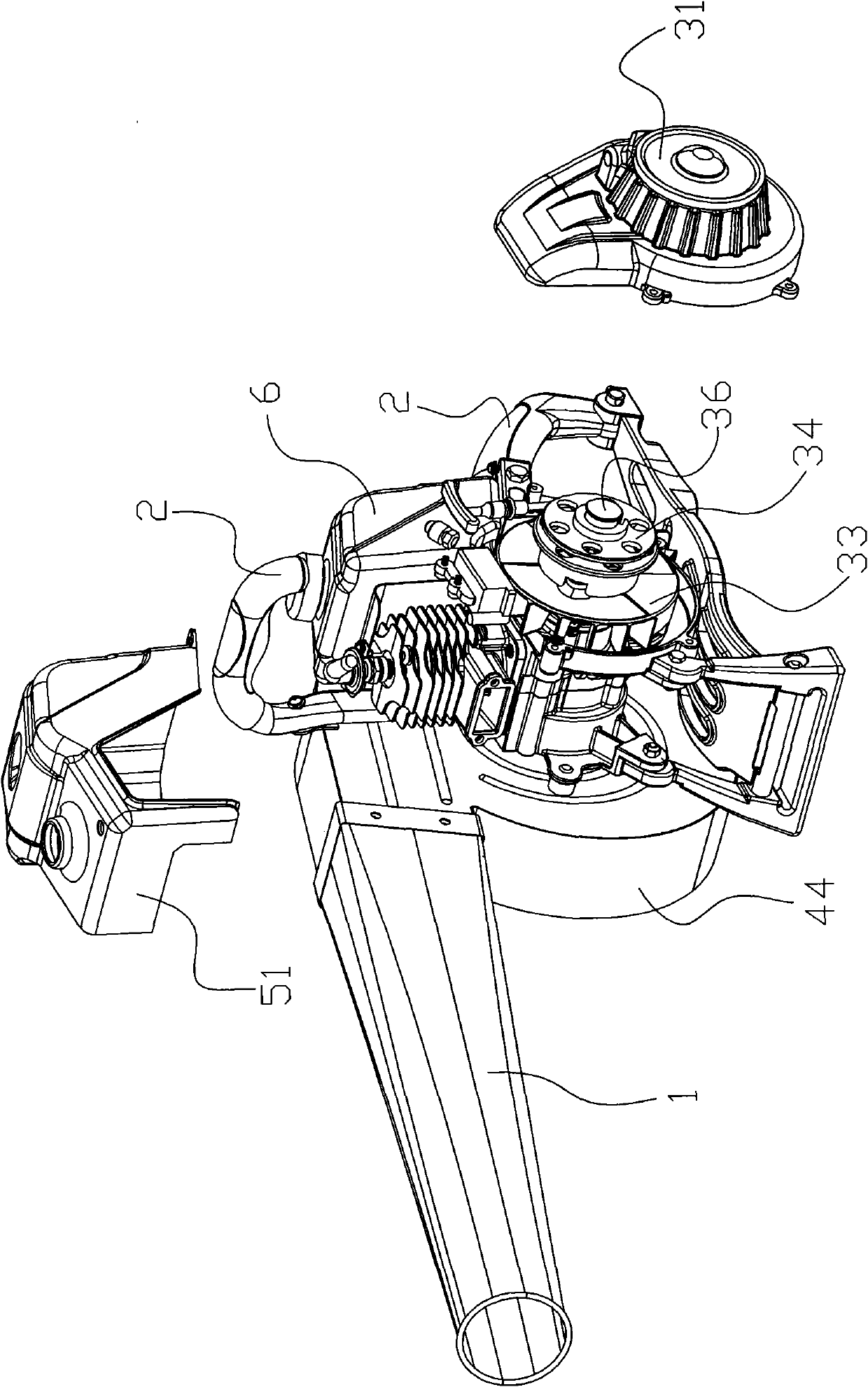

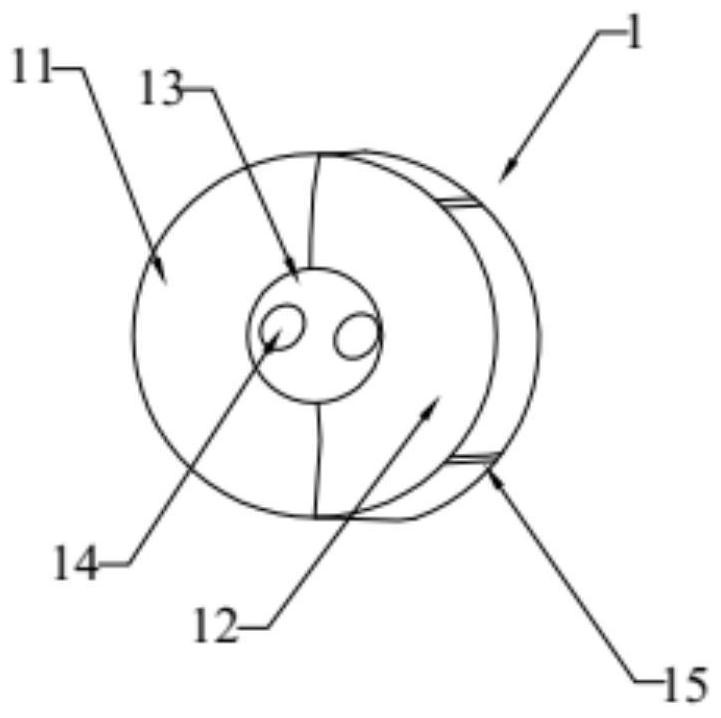

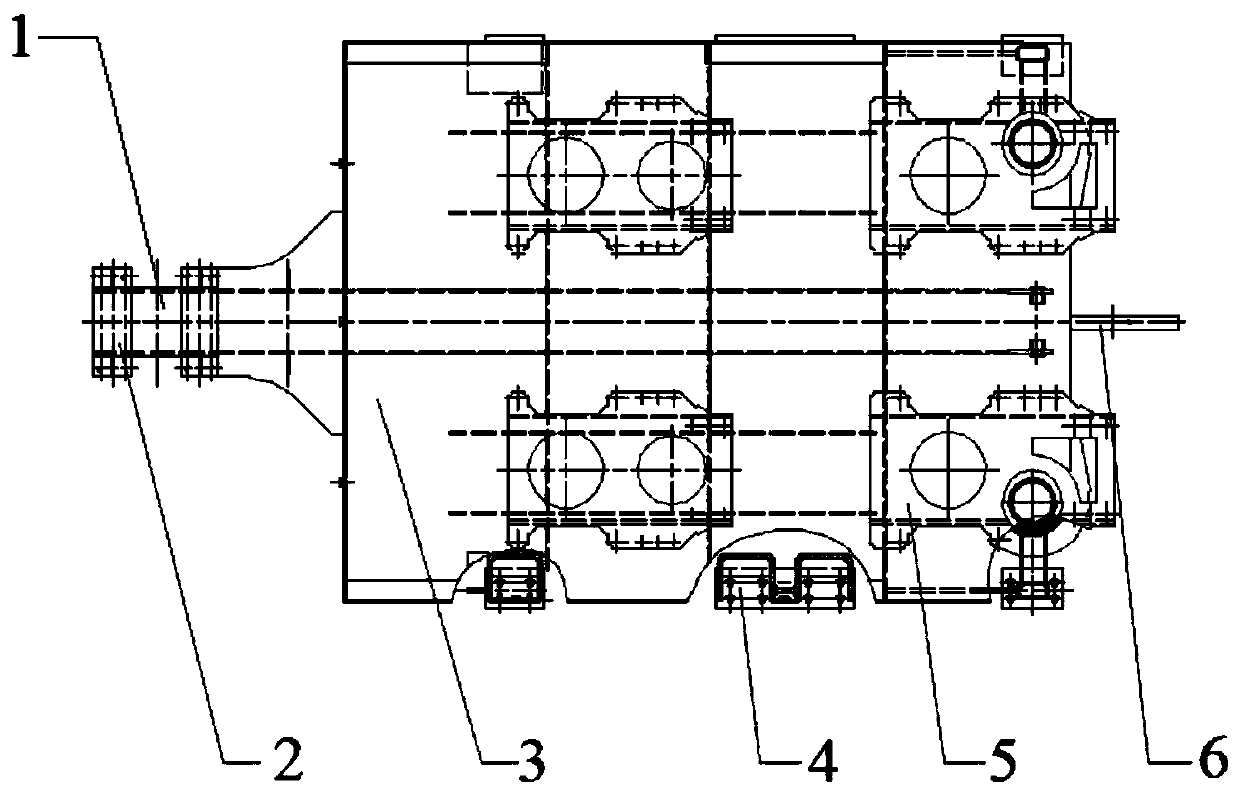

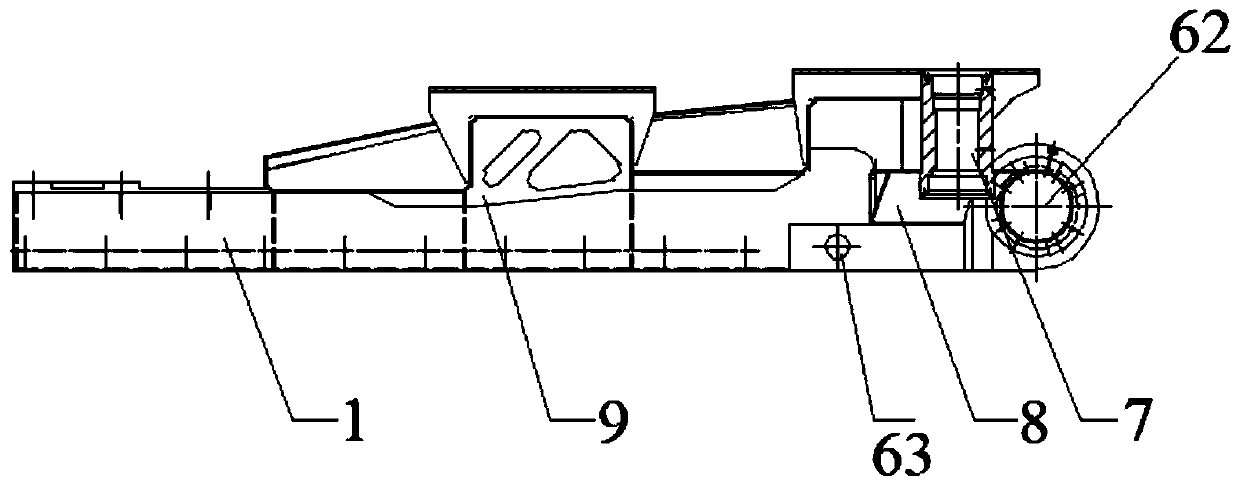

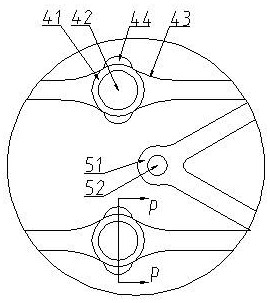

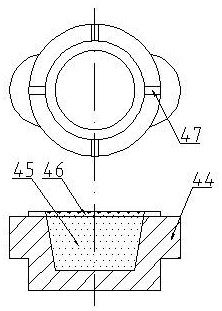

Pneumatic extinguisher

InactiveCN102430219AIncreased stress intensityExtended service lifeFire rescueForeign matterImpeller

The invention relates to a pneumatic extinguisher which comprises an engine (10), an extinguisher body (5), a starting part (3), a handle part (2) arranged on the extinguisher body (5), a cooling air part and an impeller of an injection air part (4), wherein the cooling air part and the injection air part (4) are arranged at the left and right sides of the extinguisher body (5), and the injection air part (4) is communicated with an airflow injection barrel (1). The pneumatic extinguisher is characterized in that the impeller (43) of the injection air part (4) and a fixing ring (42) arranged at the outer side are fixed together by bolts. The pneumatic extinguisher has the advantages of the impeller and the fixing ring are combined in a split manner so that the impeller is firmer and has longer service life; and the cooling air part can effectively prevent foreign matters and dust from entering air ducts, thereby avoiding part wear and faults such as high temperature caused by the blockage of the air ducts, protecting the engine from generating high temperature and being burnt out because external air cannot pass through the air ducts, and effectively prolonging the service life of the pneumatic extinguisher.

Owner:黄以良

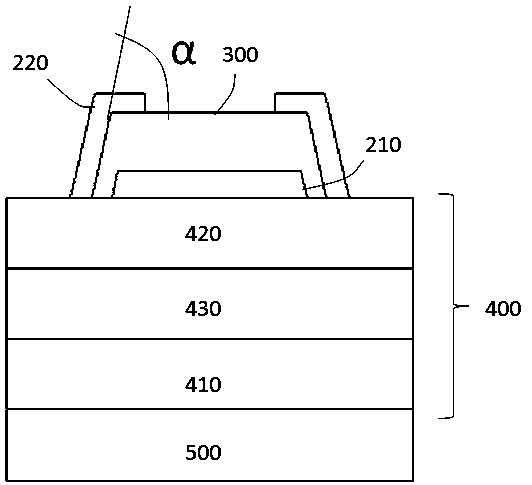

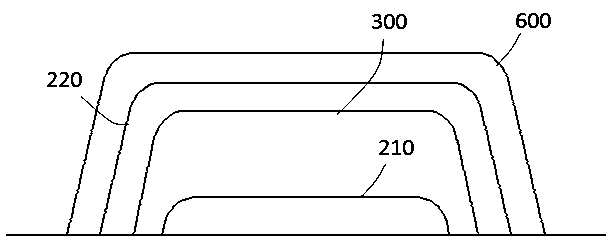

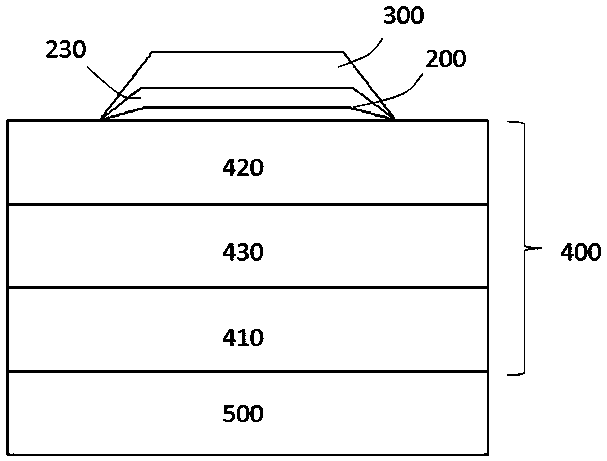

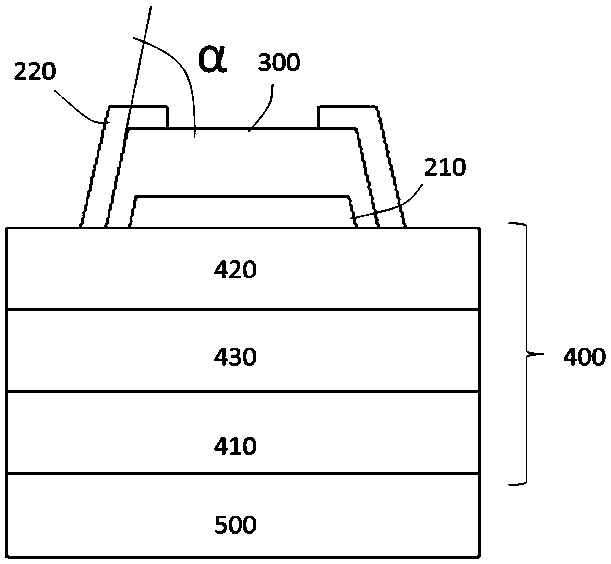

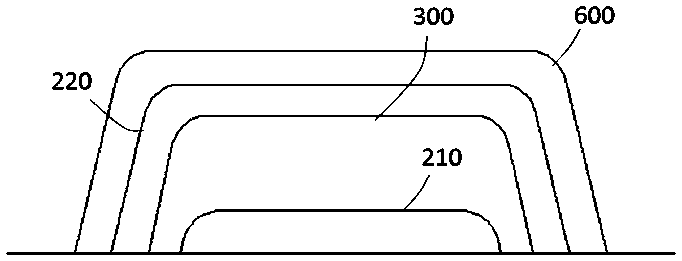

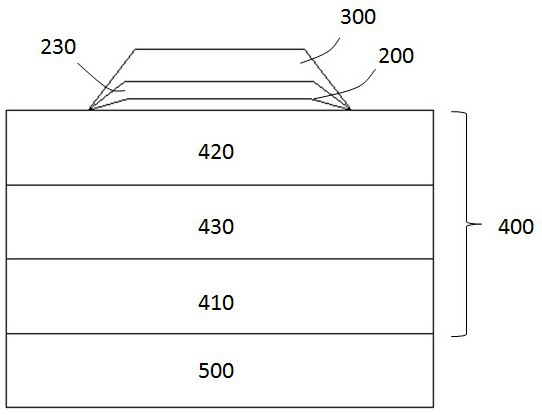

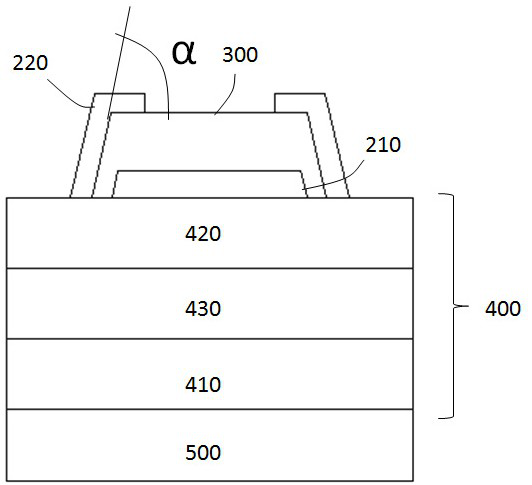

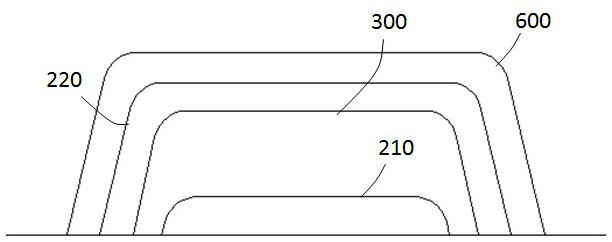

Light-emitting diode and manufacturing method thereof

ActiveCN111048642AIncrease interlaminar stress intensityImproved Metal MigrationSemiconductor devicesPhysicsEngineering

The invention discloses a light emitting diode, which comprises a first electrode connected with a first semiconductor layer and a second electrode connected with a second semiconductor layer, whereinthe first electrode and / or the second electrode sequentially comprise / comprises a first reflecting layer, a connecting cushion layer and a second reflecting layer at least partially coating the connecting cushion layer, the material of the second reflecting layer comprises rhodium, platinum or ruthenium, and the first reflecting layer and the second reflecting layer are manufactured into a large-angle electrode structure through good stress characteristics, so that the photoelectric characteristics of the light-emitting diode is facilitated to be improved, and the product reliability is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

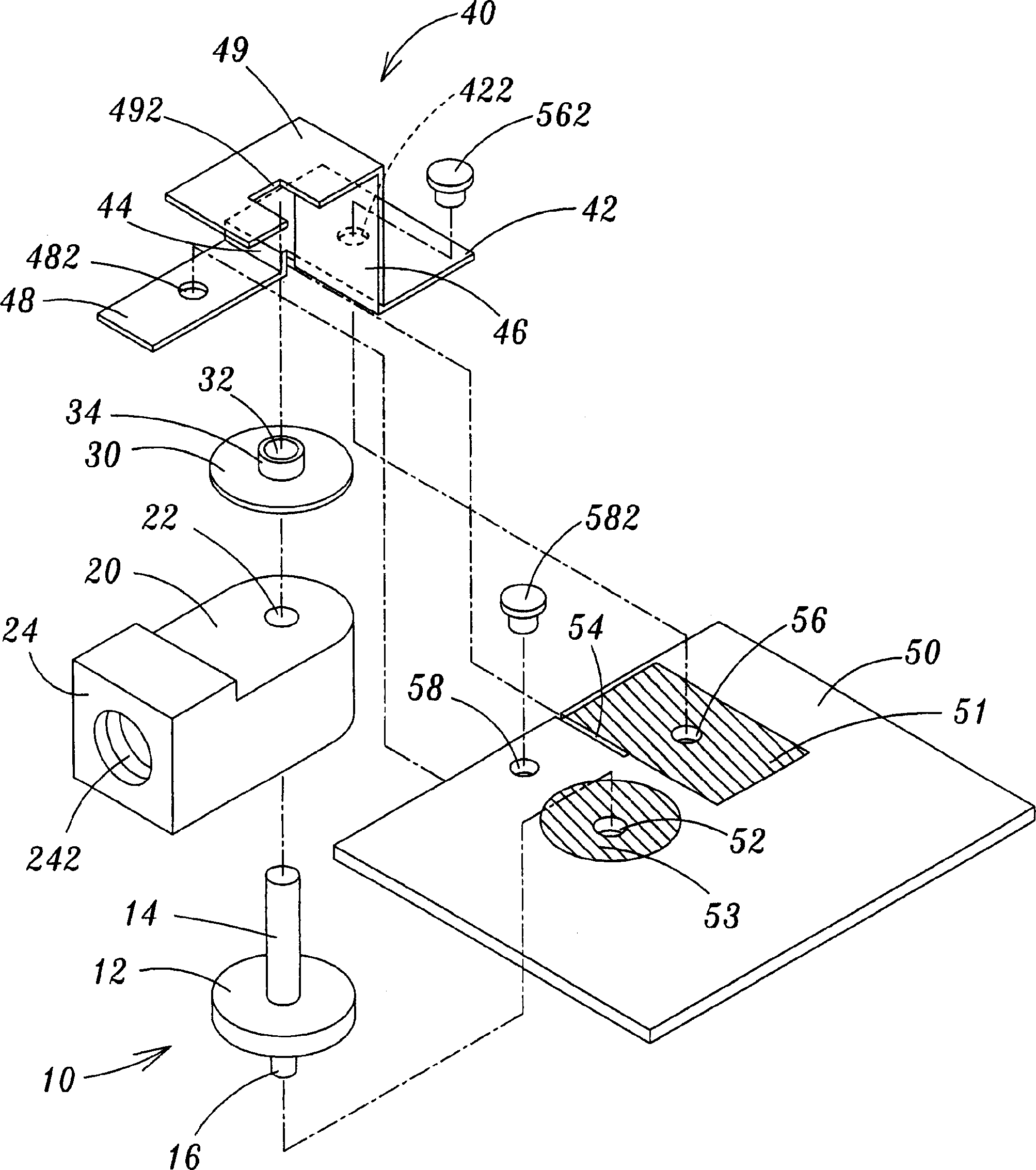

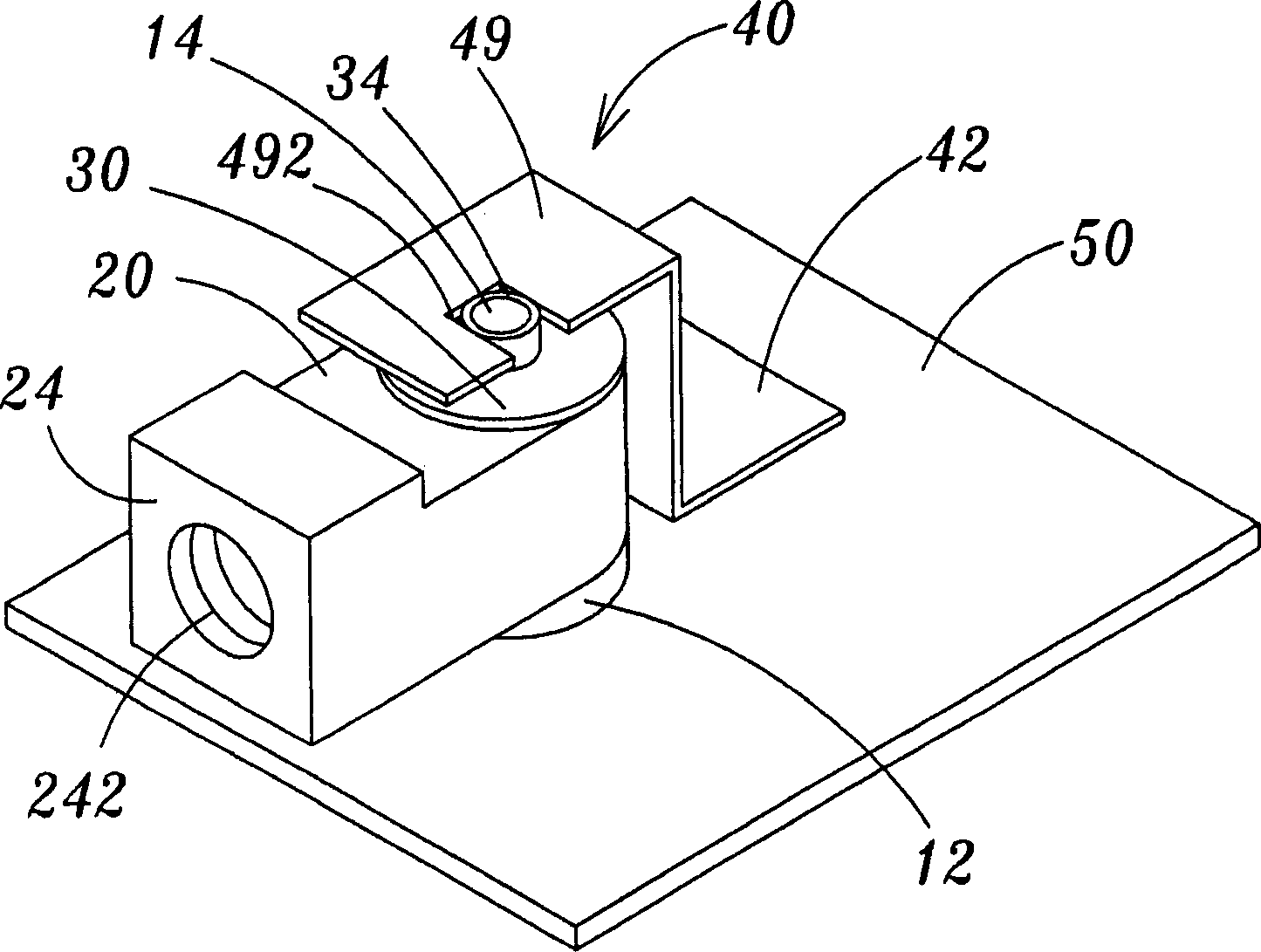

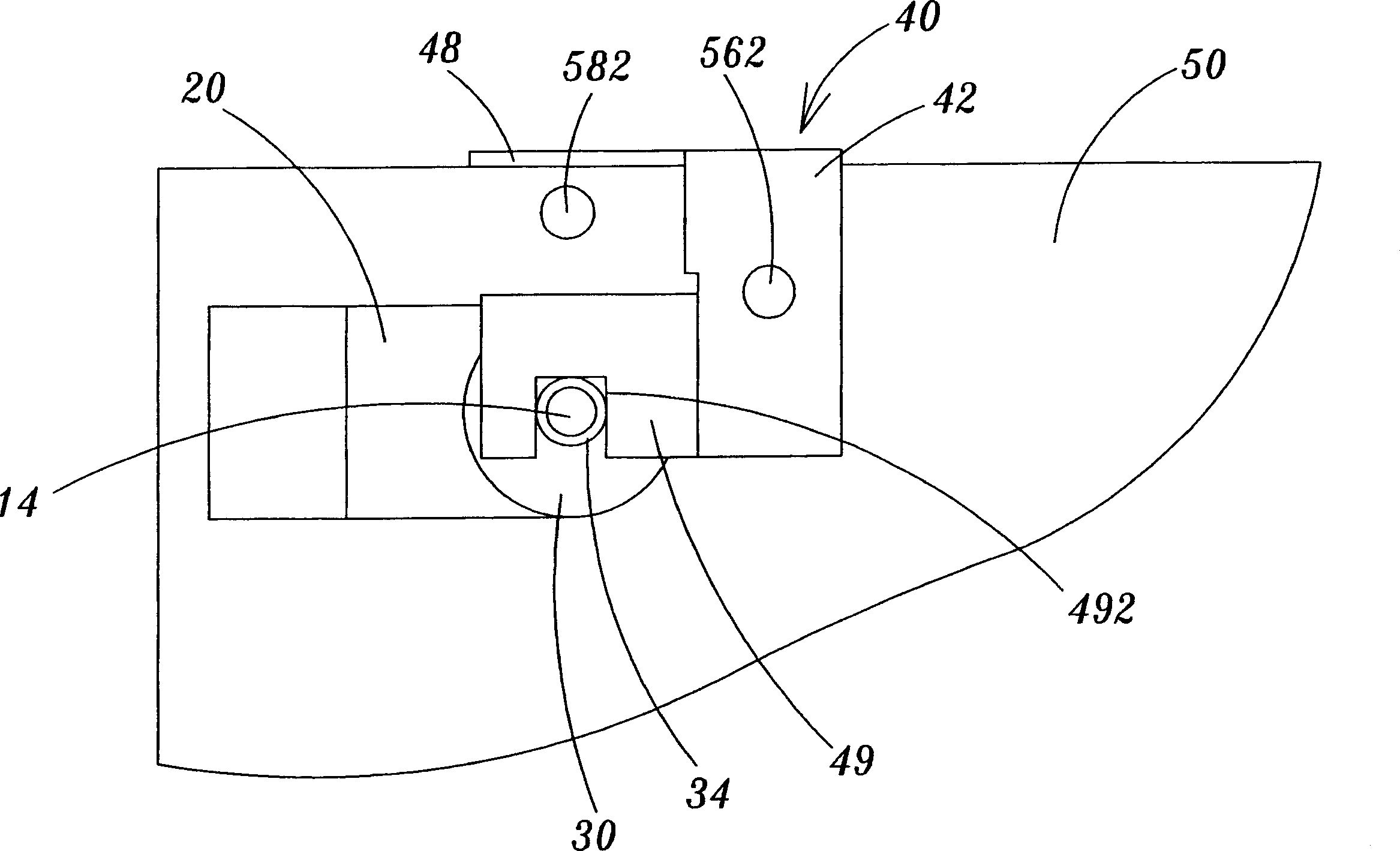

Antenna joint device capable of adjusting direction

InactiveCN1790806AReally solid setupIncreased stress intensityAntenna supports/mountingsTerminal equipmentWireless signal

The invention relates to an antenna terminal device with adjustable direction, which comprises: a rotation member fixed on a circuit board with an axial fixed base and a fixed pad on upper end, and a securing member arranged on said circuit board. This invention can regulate the position of angle rotation of base to increase receive / send effect for wireless signal.

Owner:E-TEN

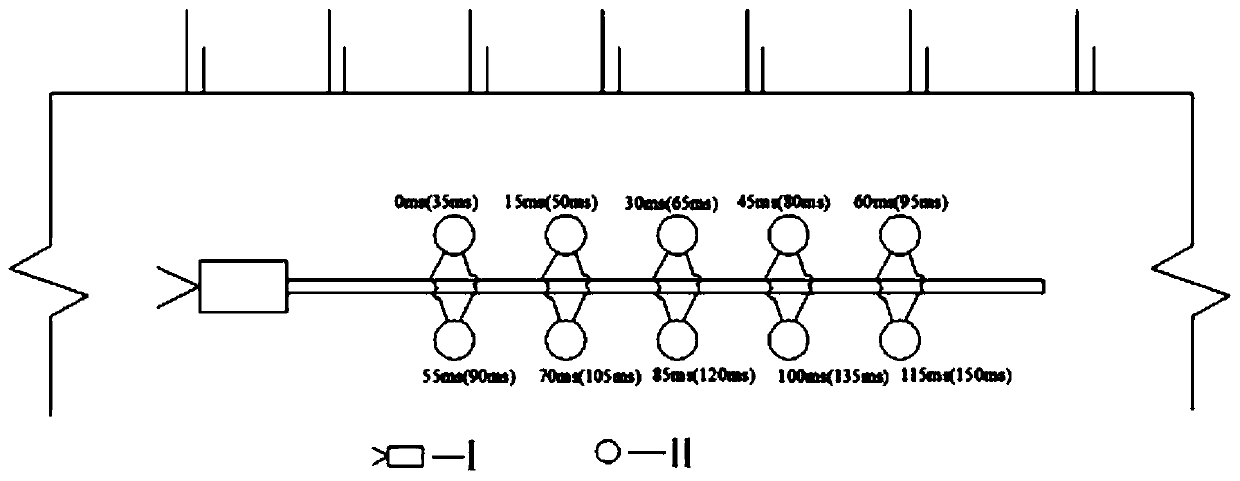

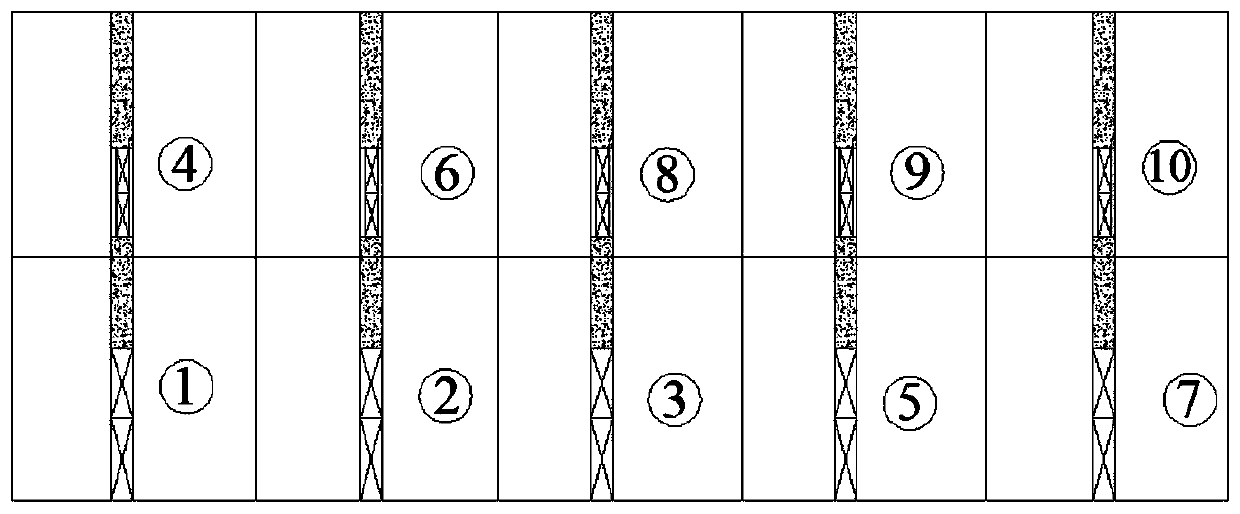

Deep hole blasting charging and detonating method for lowering foundation based on digital detonators

The invention discloses a deep hole blasting charging and detonating method for lowering the foundation based on digital detonators. The method comprises steps of drilling; in-hole section division, including a lower charging section, a lower blocking section, an upper charging section and an orifice blocking section; charging in the sections; networking detonation and the like. During detonation,the detonation sequence and the time interval are strictly set through digital detonators. The method is advantaged in that in-hole segmented blasting is carried out, the blasting sequence and the time interval are strictly set through the digital detonators, rockfill generates relative dislocation in space after a front-row lower charging section is blasted, a free face is created for the bottomof a rear-row hole step, the clamping effect of front-row rock on the bottom of the step is reduced, and constraint conditions are changed; moreover, due to the blocking effect of the bottom blockingsection, explosion gas can be prevented from escaping too early, the action time of the explosion gas at the bottom of the hole is prolonged, explosion energy is fully utilized, the stress strength of a chassis resistance line part is improved, rock mass at the chassis part is fully crushed, generation of explosion roots is greatly reduced, and flatness of a bottom plate is improved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

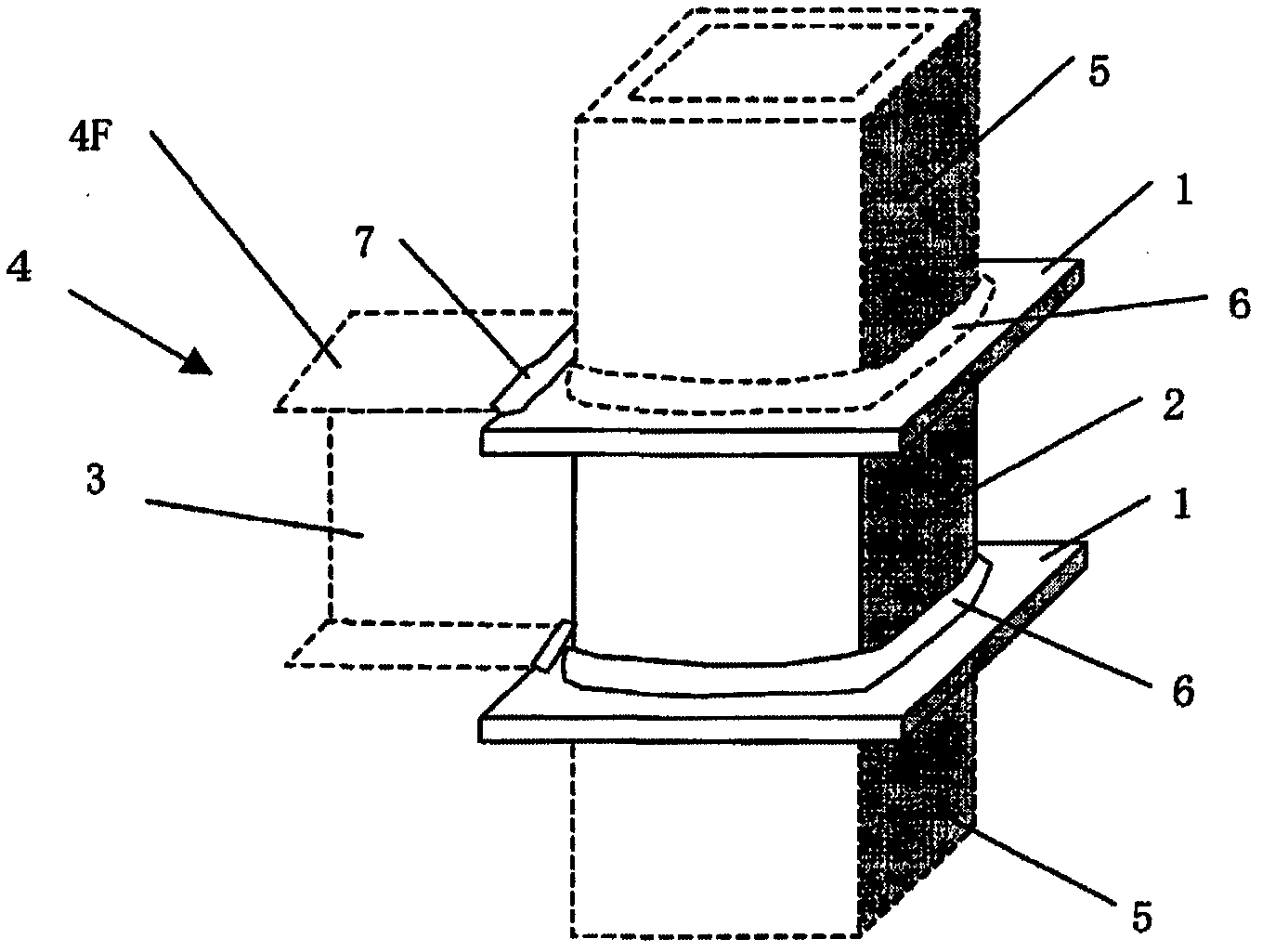

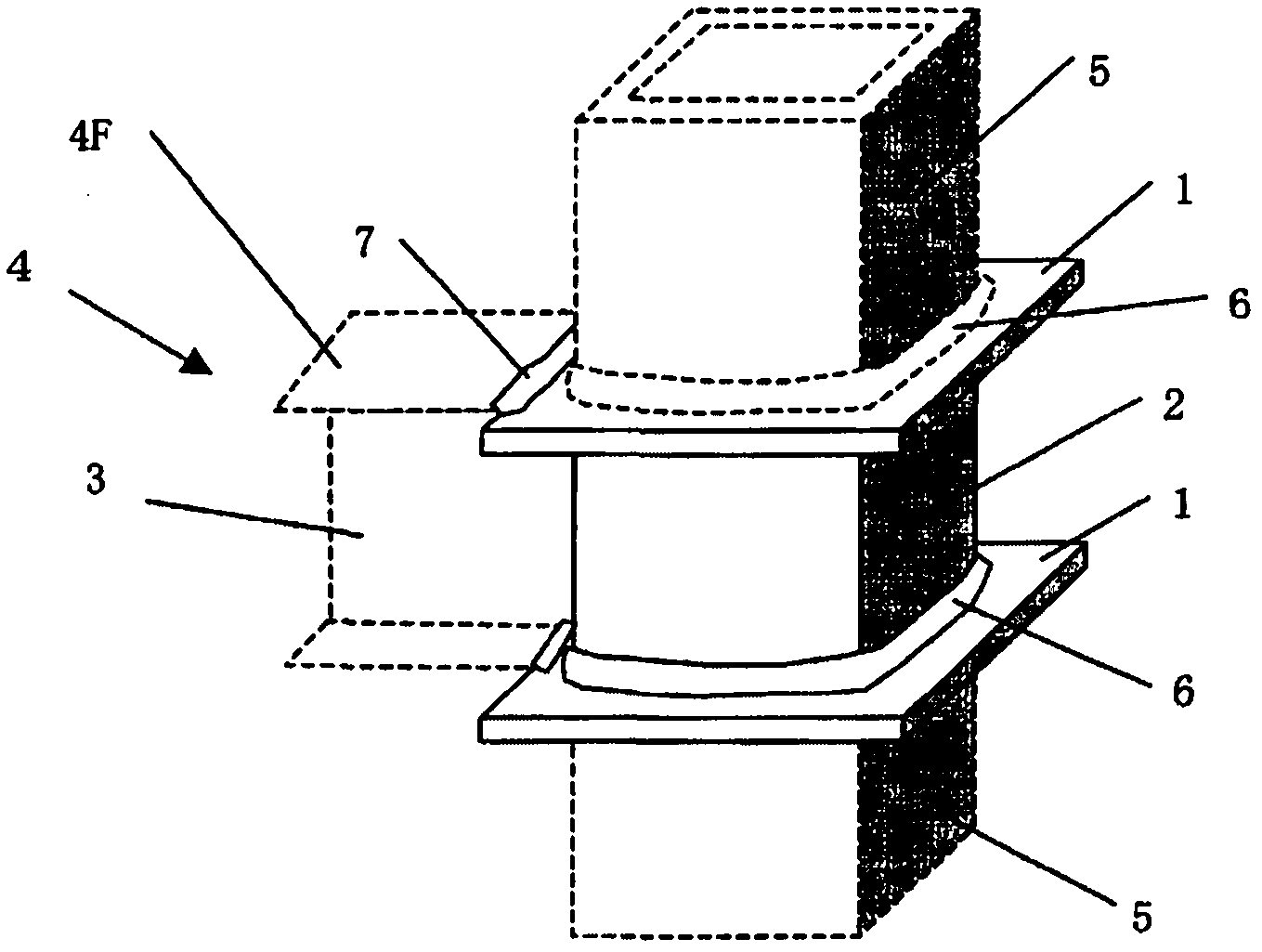

Column-beam connection structure

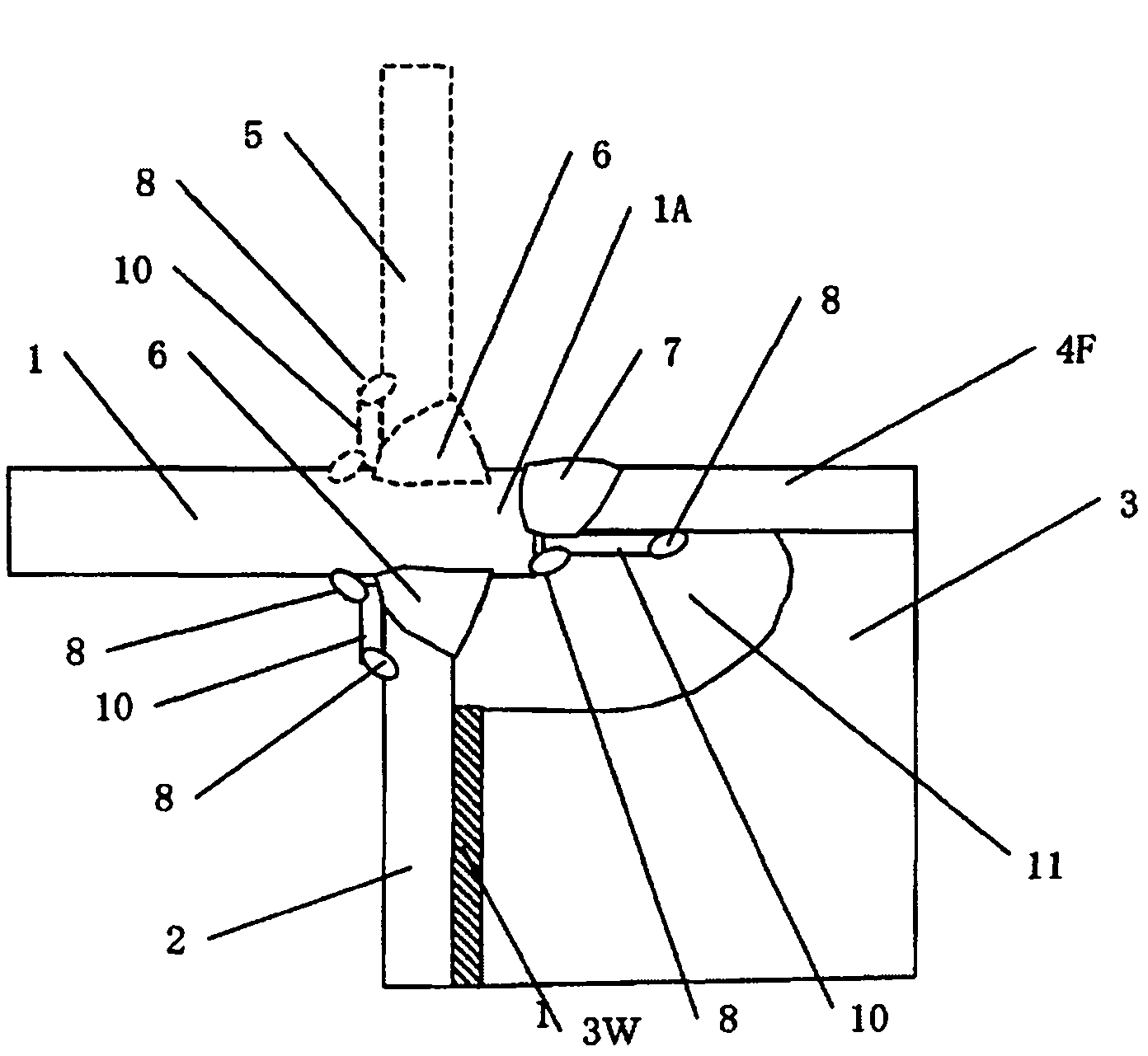

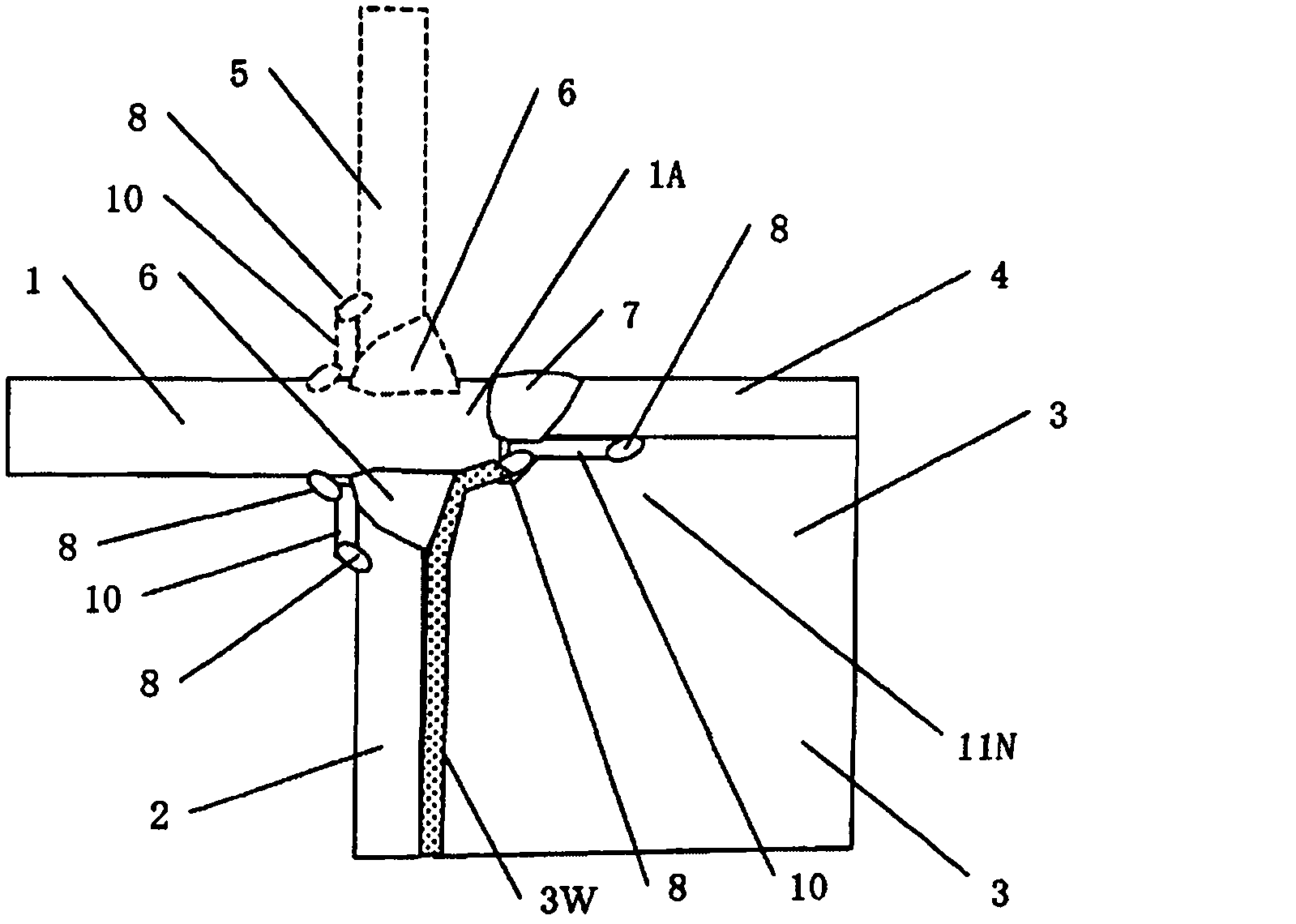

InactiveCN102209817BWeight increaseAvoid embrittlementArc welding apparatusBuilding constructionsEngineeringHot working

Bending moment applied to a beam causes out-of-plane deformation to a panel when the panel zone is hollow, and thereby a load bearing by a web cannot be expected in an elastic region. Since the section modulus of a beam end is limited to the section modulus of only the flange not including the web, the beam end has a low strength. Therefore, a beam larger in size which bears bending moment on the entire section of the beam must be used and an extra beam depth is required, thus causing an increase in the weight of a steel beam. As the result of various studies, it has been found that various problems could be resolved by increasing the plate thickness of a diaphragm, applying a backing plate to the top surface or the bottom surface of a beam flange, increasing the strength of the material of the beam flange, increasing the thickness of the diaphragm or the backing plate, notching a web, or hot working the bottom surface of the beam to impart prestress thereto.

Owner:ARCREATE

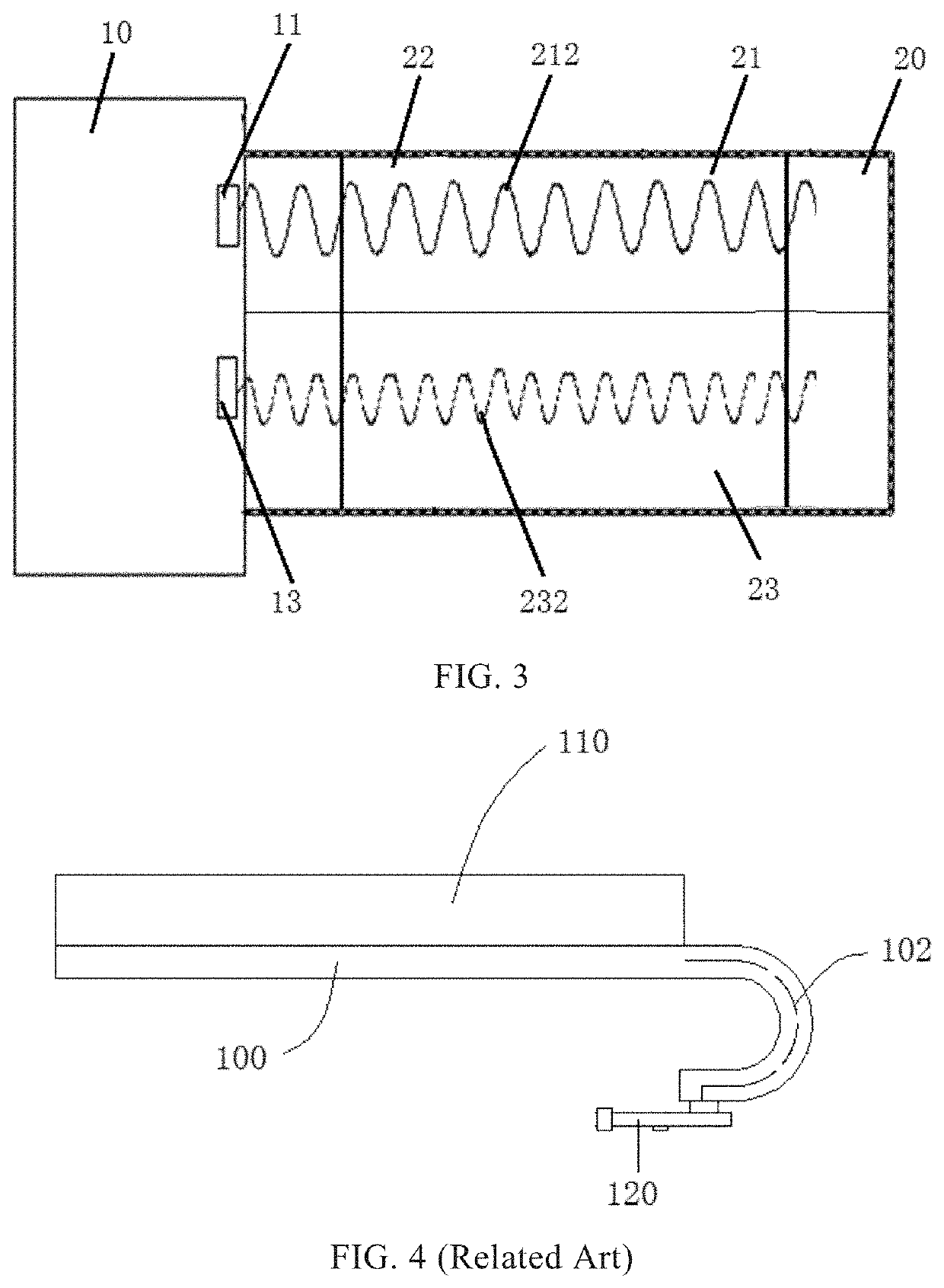

Display device

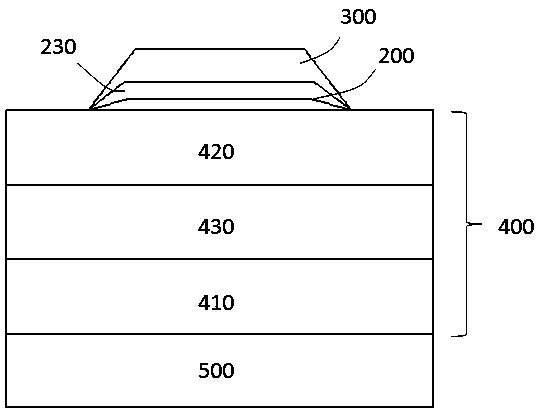

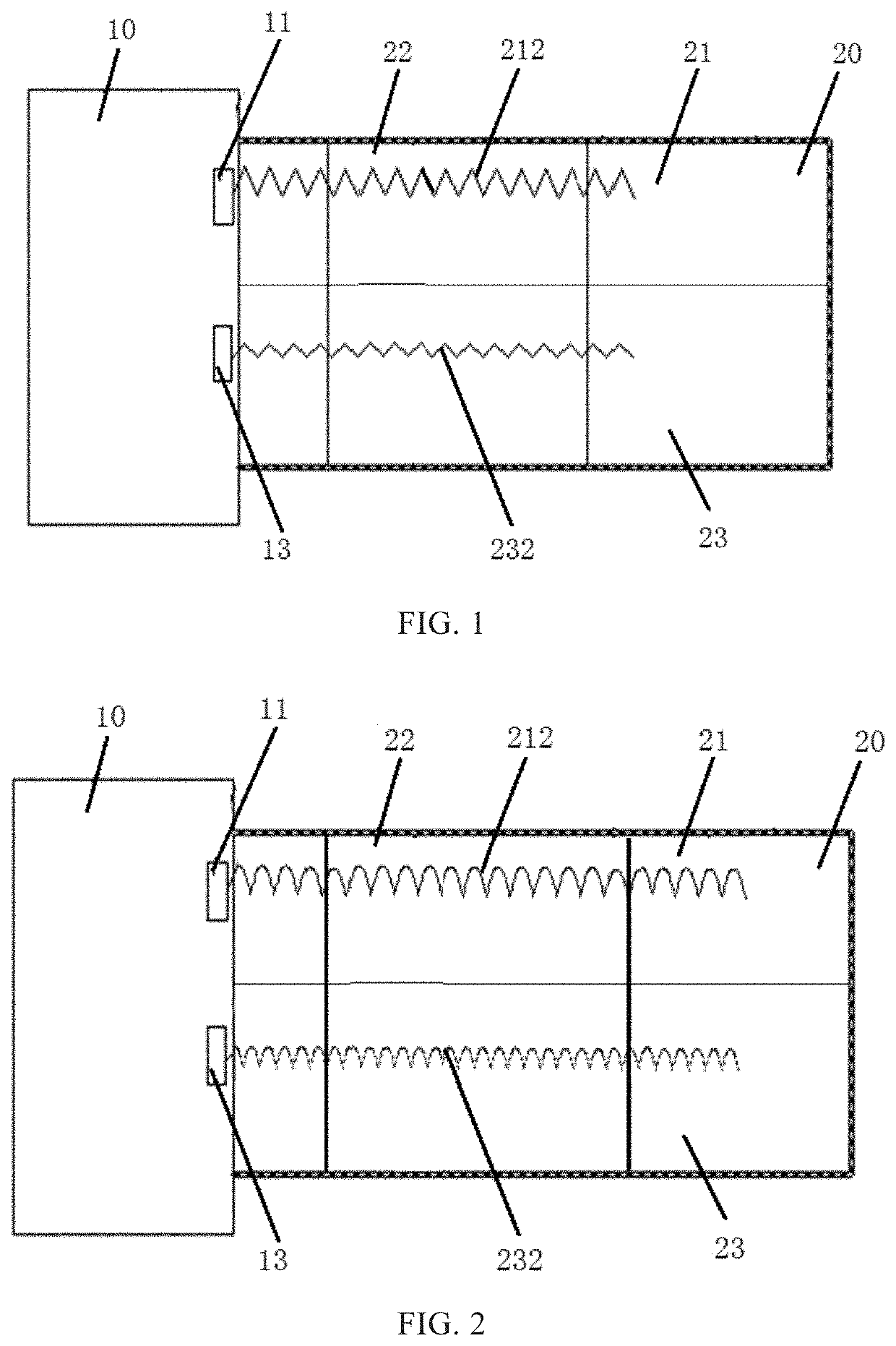

ActiveUS10963013B2Increased stress intensityUniform and stableDigital data processing detailsIdentification meansDisplay deviceEngineering

A display device includes a display panel and a flexible substrate. A first pad and a second pad are arranged on the display panel. The flexible substrate includes a first layer, a first insulating layer, and a second layer on a bending area. A first metal line is arranged in the first layer and connected to the first pad. A second metal line is arranged in the second layer and connected to the second pad. A straightened length of the first metal line is greater than that of the second metal line. The design of a double-layer metal line effectively improves the stress intensity of the metal line in the outer bending area. Therefore, the inner and outer double-line metal line in the bending area is balanced by force, so that the stability of the inner and outer double-line metal line is relatively uniform.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

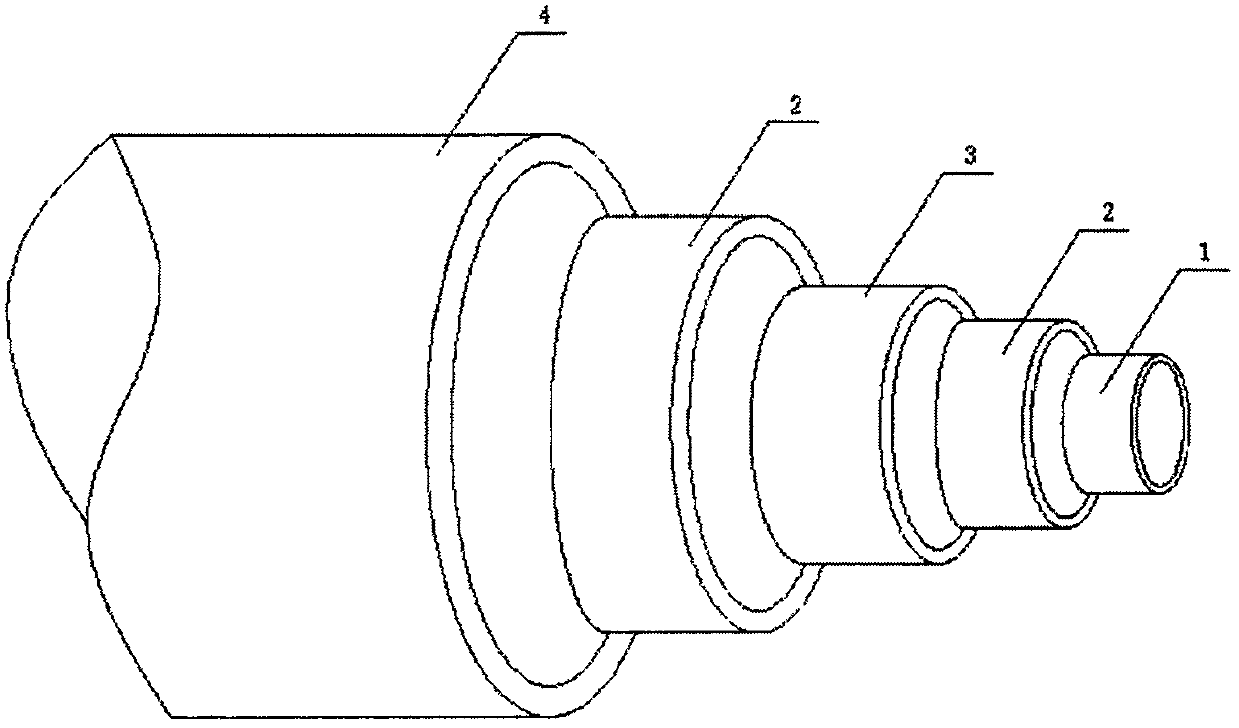

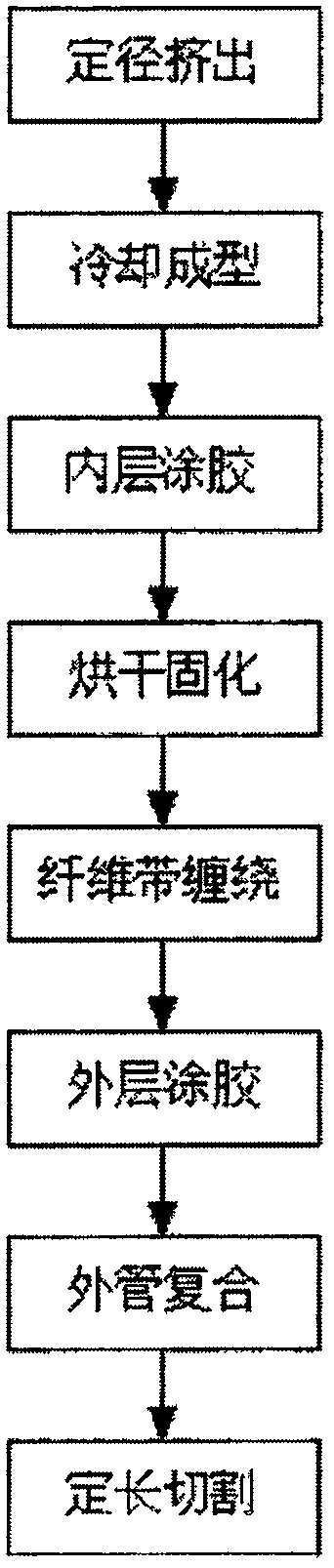

Continuous fiber reinforced thermoplastic pipeline and production method

InactiveCN111059366AReasonable process designIncreased stress intensityRigid pipesTubular articlesPolymer chemistryFibre reinforcement

Belonging to the technical field of pipeline forming, the invention discloses a continuous fiber reinforced thermoplastic pipeline and a production method. The continuous fiber reinforced thermoplastic pipeline includes an inner pipe, the pipeline outer wall of the inner pipe is compounded with a reinforcing layer through an adhesive layer, the surface of the reinforcing layer is coated with an adhesive layer, and an outer protective layer is covered to the surface of the adhesive layer through hot melting extrusion. According to the invention, the process design is reasonable, the stress strength of the pipeline can be improved, and a one-step molding technology is adopted, so that the production procedures are reduced, the yield is increased while the production cost is reduced, and thelarge-scale popularization and application of the product are facilitated.

Owner:HUNAN YIJING ENVIRONMENTAL PROTECTION TECH CO LTD

Column-beam connection structure

InactiveCN102209817AWeight increaseAvoid embrittlementArc welding apparatusBuilding constructionsEngineeringHot working

Bending moment applied to a beam causes out-of-plane deformation to a panel when the panel zone is hollow, and thereby a load bearing by a web cannot be expected in an elastic region. Since the section modulus of a beam end is limited to the section modulus of only the flange not including the web, the beam end has a low strength. Therefore, a beam larger in size which bears bending moment on the entire section of the beam must be used and an extra beam depth is required, thus causing an increase in the weight of a steel beam. As the result of various studies, it has been found that various problems could be resolved by increasing the plate thickness of a diaphragm, applying a backing plate to the top surface or the bottom surface of a beam flange, increasing the strength of the material of the beam flange, increasing the thickness of the diaphragm or the backing plate, notching a web, or hot working the bottom surface of the beam to impart prestress thereto.

Owner:ARCREATE

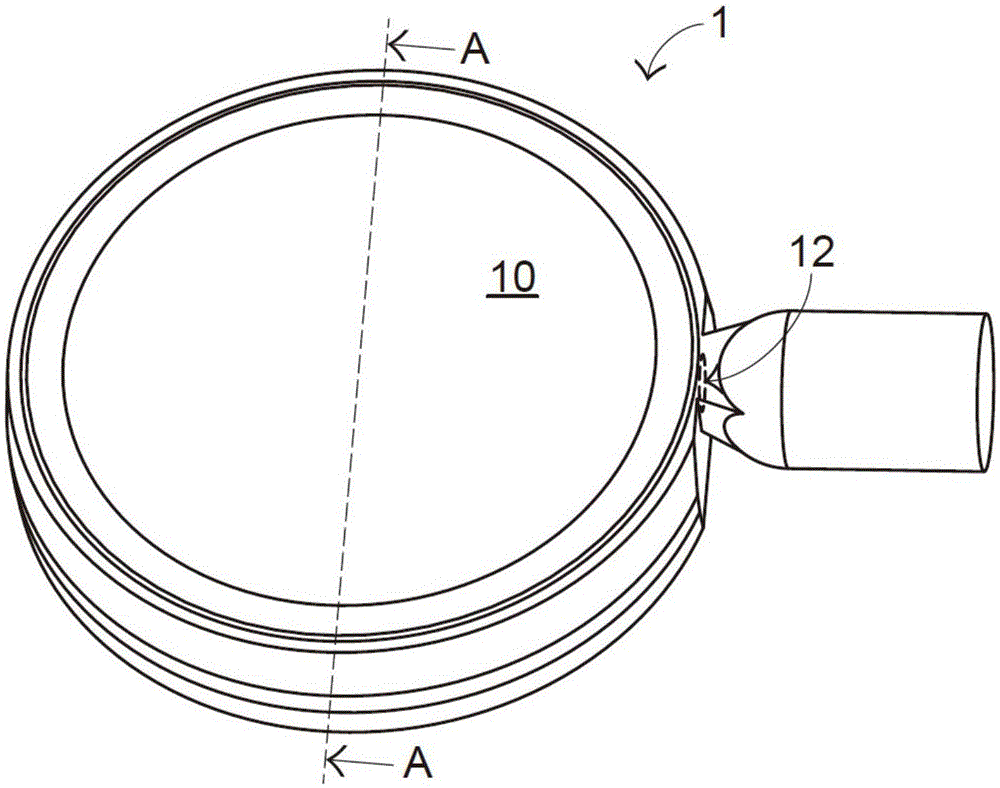

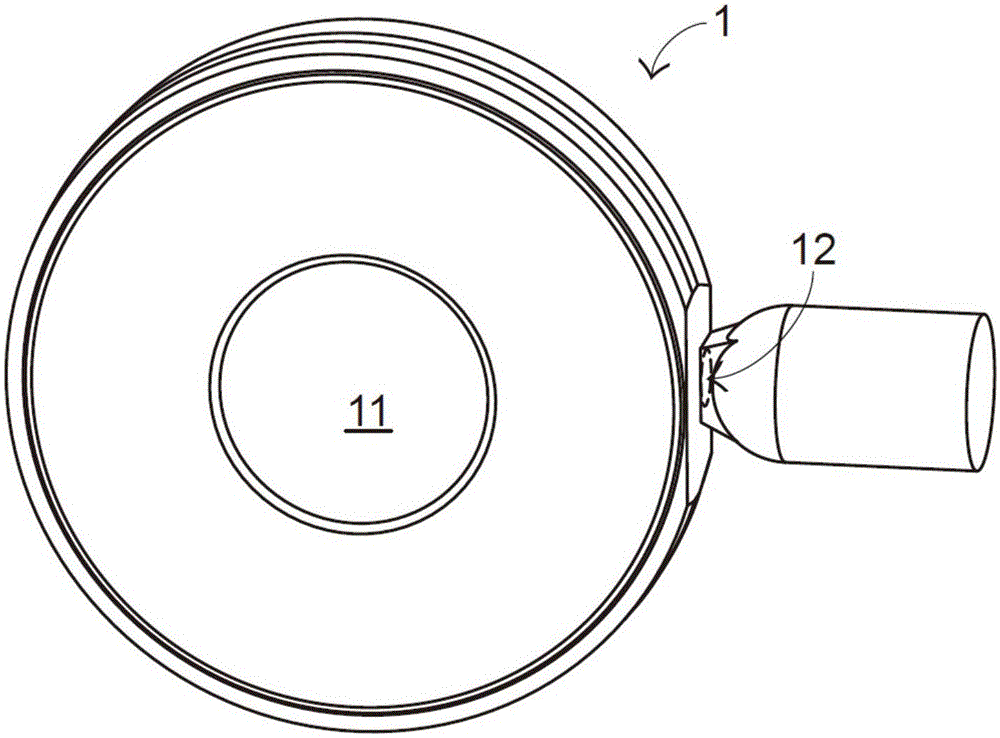

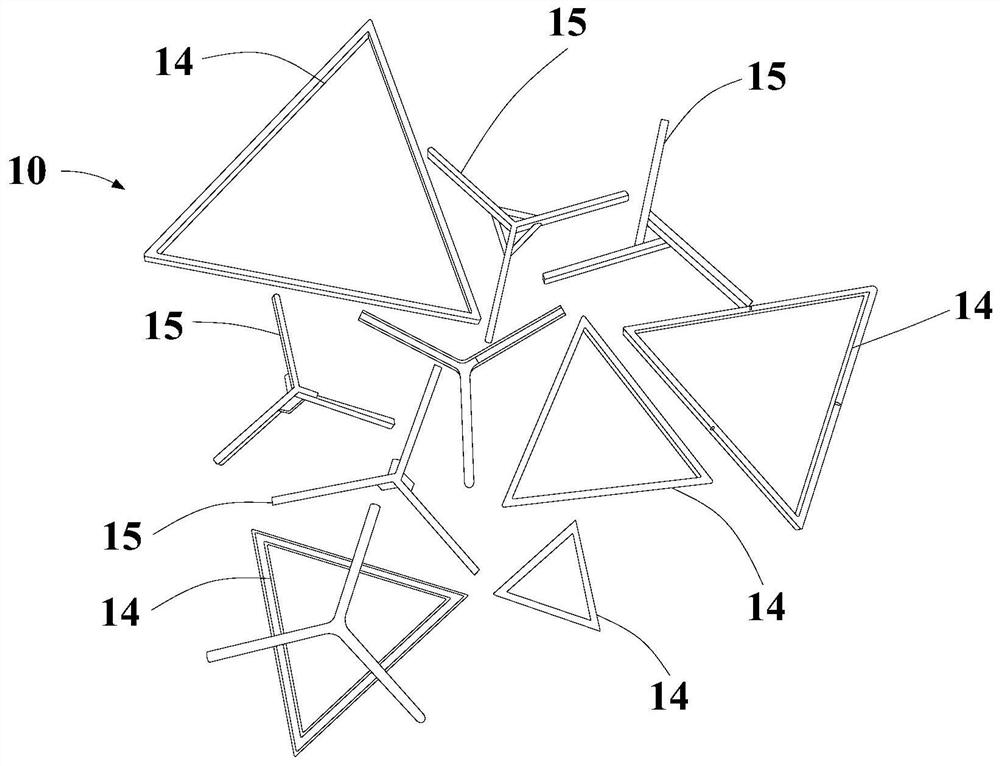

Optical lens and injection molding mold thereof

InactiveCN106514957AImprove yieldIncreased stress intensityOptical articlesLensOptic lensInjection molding machine

The invention provides an optical lens and an injection molding mold thereof. The injection molding mold of the optical lens comprises a disc-shaped mold seat and a nozzle. A mold cavity chamber and a sprue communicating with the mold cavity chamber are defined by the disc-shaped mold seat. The mold cavity chamber comprises an optical effective area center runner and a non-optical effective area circumferential runner. The optical effective area center runner is defined between an upper curved surface and a lower curved surface in the disc-shaped mold seat. The non-optical effective area circumferential runner surrounds and communicates to the optical effective area center runner and communicates with the sprue. A plurality of turbulent flow structures are formed at the positions, on the non-optical effective area circumferential runner, of the disc-shaped mold seat. The nozzle is connected to the disc-shaped mold seat. Melt is injected into the mold cavity chamber through the sprue. The flow speed of the melt on the non-optical effective area circumferential runner is disturbed by the multiple turbulent flow structures, the optical effective area center runner is preferentially filled with the melt, and therefore an optical effective area of the optical lens cannot be generated with defects so as to increase the yield of the optical lens.

Owner:EVERREADY PRECISION IND

Light-emitting diode and manufacturing method thereof

ActiveCN111433920AImprove reliability drop problemIncreased stress intensitySemiconductor devicesEngineeringReflective layer

The present invention discloses a light emitting diode, comprising: a first electrode electrically connected to a first semiconductor layer of the light emitting diode, and a second electrode electrically connected to the second semiconductor layer; and the first electrode and / or the second electrode sequentially comprise(s) the first reflective layer, a pad layer and a second reflective layer atleast partially covering the pad layer, the Young's modulus of the material of the first reflective layer and / or the second reflective layer is not less than 150 Gpa and the bulk modulus is not less than 200 Gpa, and it is helpful to improve the photoelectric characteristics of light-emitting diodes and improve product reliability.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

Glass toughening liquid and glass toughening treatment method

The invention discloses glass toughening liquid. The glass toughening liquid is prepared from the following raw materials in parts by weight: 65 to 80 parts of potassium nitrate, 5 to 15 parts of diethanolamine borate, 5 to 8 parts of N-methyl diethanolamine, 2 to 8 parts of cerous nitrate and 3 to 5 parts of magnesium oxide. The invention also discloses a glass toughening treatment method which comprises the following steps: S1, carrying out preheating treatment on glass; S2, soaking the pretreated glass obtained the S1 into any one of glass toughening liquid in claims 1 to 4, keeping the strengthening temperature at 380 to 420 DEG C and carrying out thermal reaction; S3, carrying out annealing treatment on the toughened glass obtained in the S2 and carrying out air cooling to obtain thetoughened glass. The glass toughening treatment method disclosed by the invention has the advantages that the components and the use amount of the glass toughening liquid are optimized and the strengthening time is shortened; meanwhile, the depth of a stress layer is significantly increased and the surface strength of the glass is improved.

Owner:安徽朗旭玻璃器皿有限公司

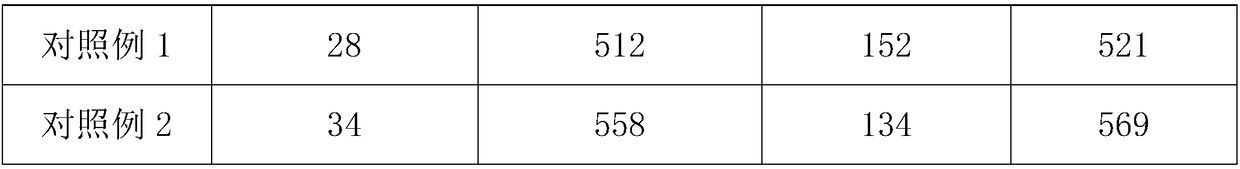

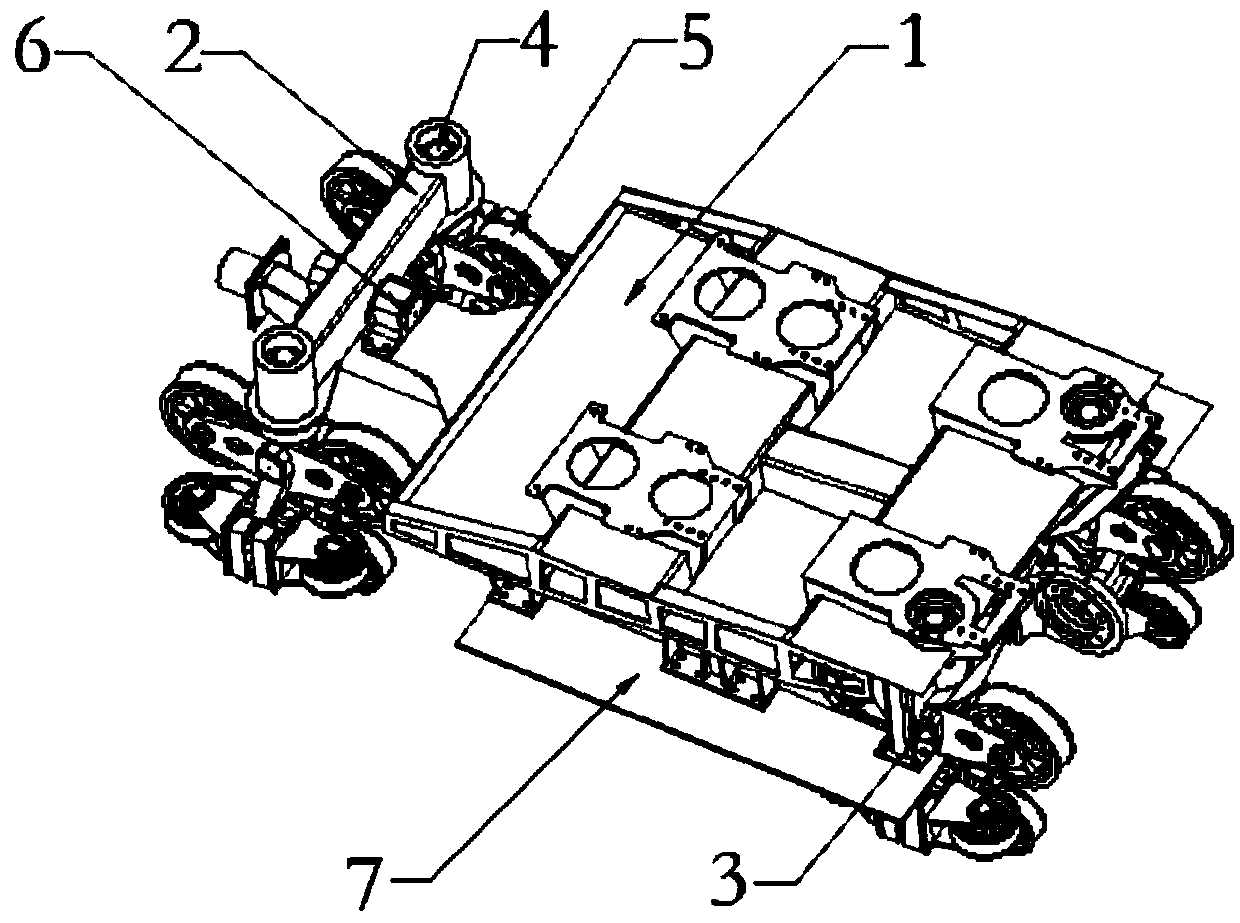

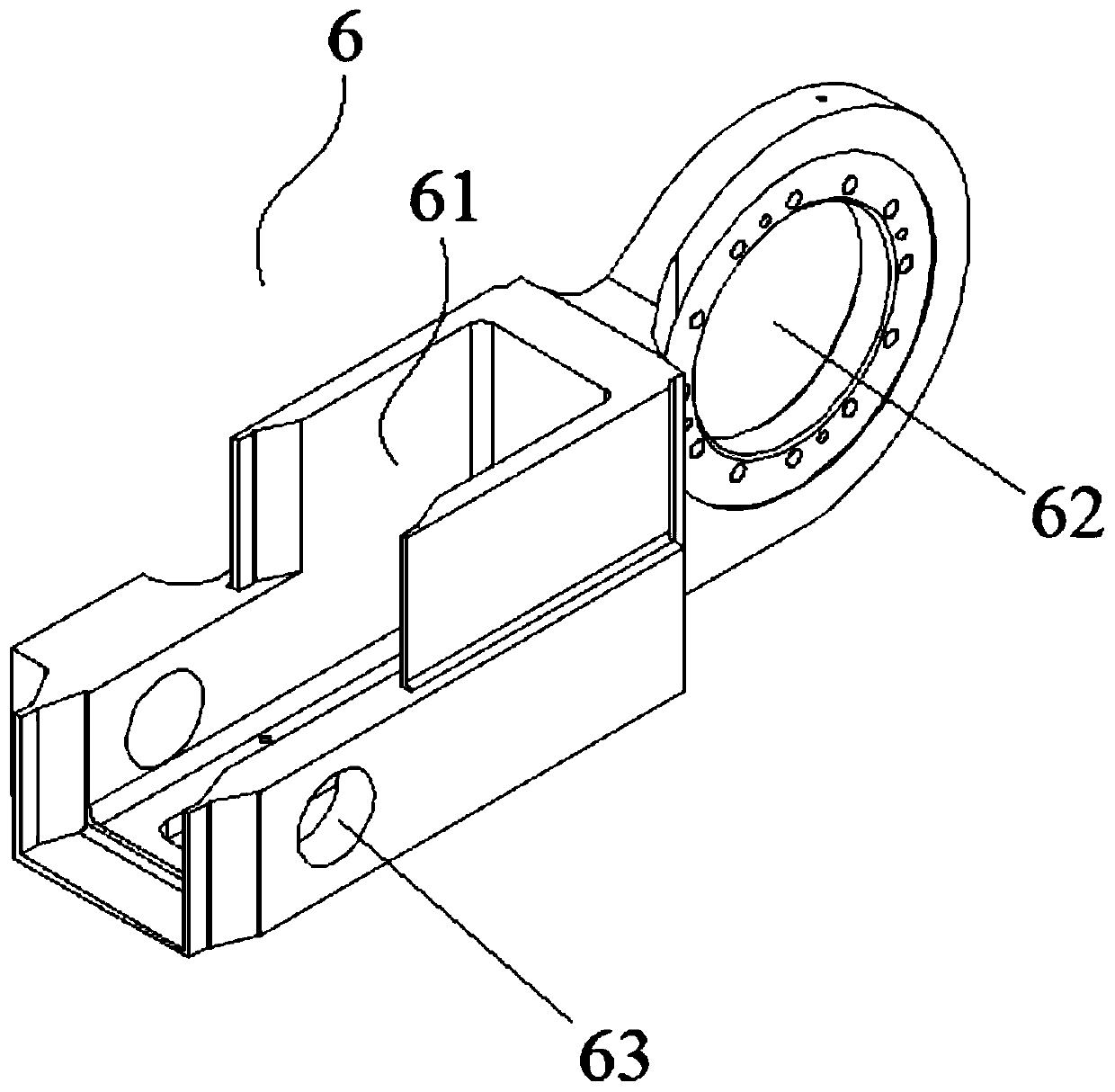

Roller coaster device

The invention provides a roller coaster device, which comprises a plurality of train units which are sequentially connected, wherein the train units comprise a frame, wherein the frame is horizontallyarranged; a bridge frame, the bridge frame is arranged at the front end of the frame and is connected with the frame, the bridge frame comprises concave'-shaped connectors, two ends of each connectorare respectively provided with a vertical shaft, and the vertical shaft is used for being connected and fixed with a gear train; a tail seat, the tail seat is arranged at the central position of thetail part of the frame, a gear train which is consistent with the vertical shaft is fixed on the tail seat, the tail seat is used for mounting a spherical hinge connector, and the tail seat is connected with a plurality of train units through the spherical hinge connector. The roller coaster device has the advantages of simple structure, easy realization, capability of improving the integral stress intensity of the roller coaster, capability of respectively keeping independent rotation angles of the gear train in the direction changing or track changing process, ensuring uniform stress distribution of the gear trains, enabling the roller coaster to run on the tracks with sufficient degrees of freedom, so that the driving safety and the service life of the roller coaster device are furtherimproved.

Owner:北京中冶设备研究设计总院有限公司

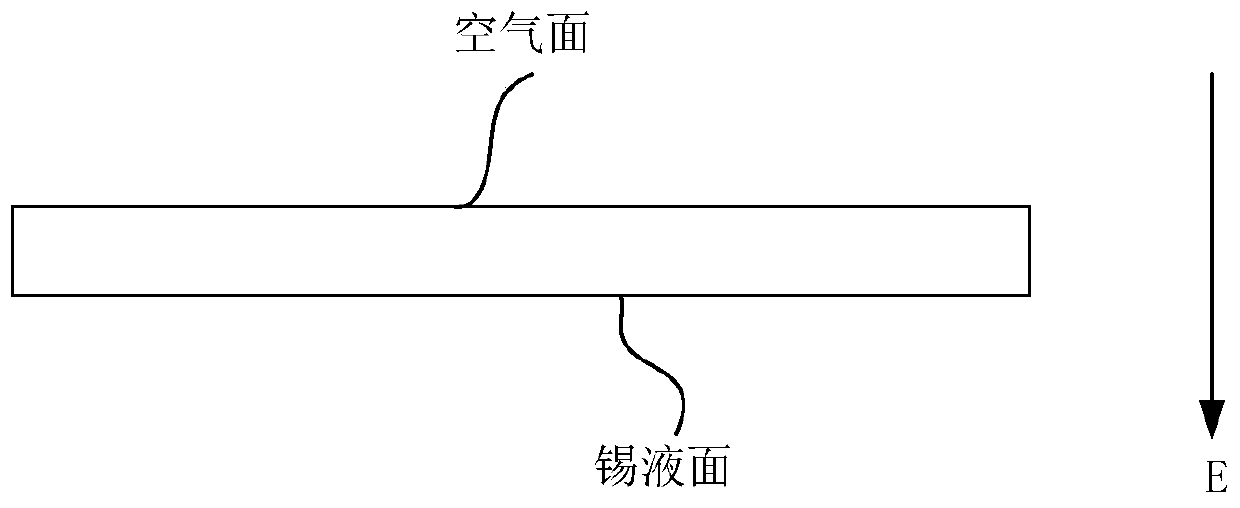

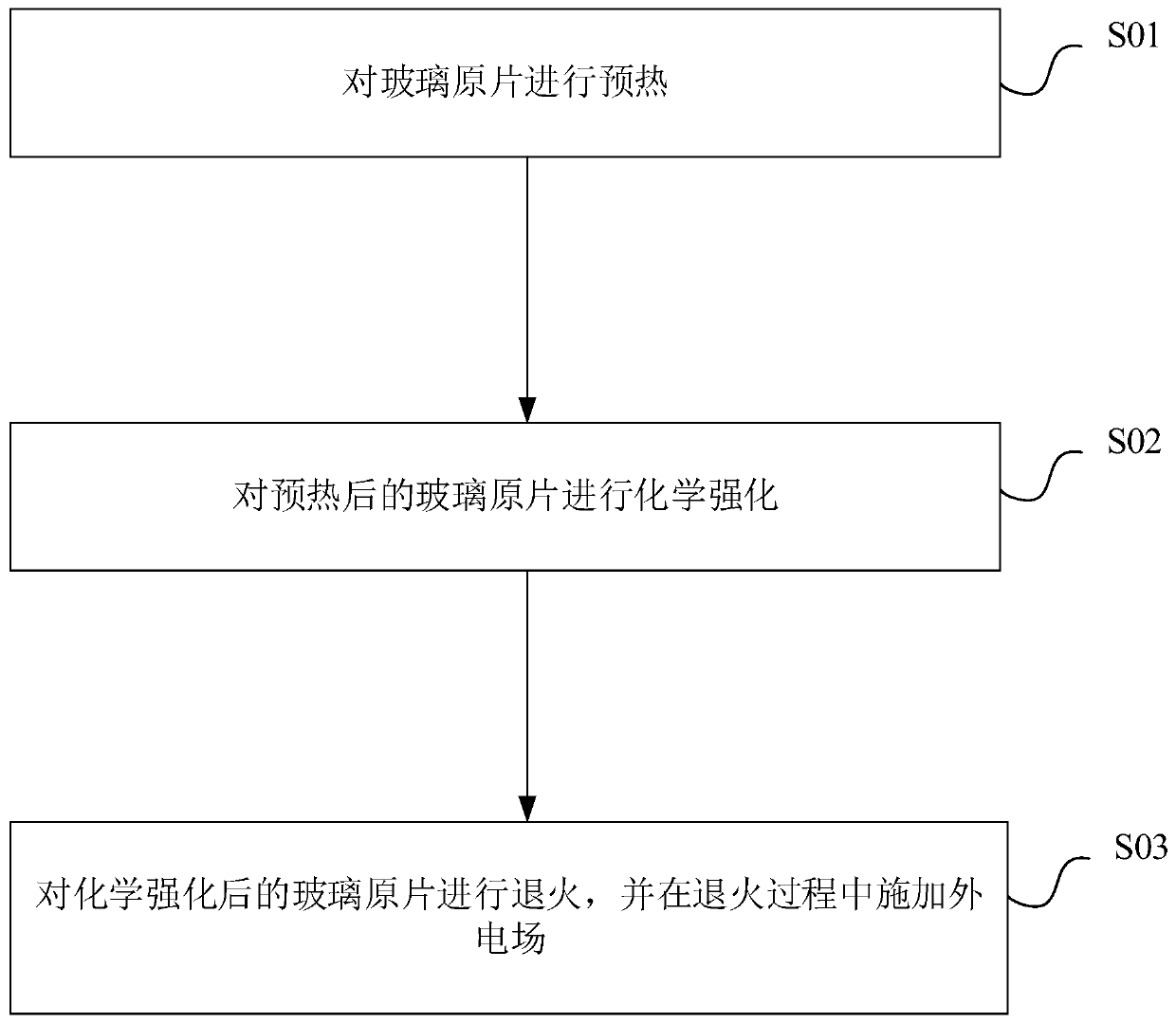

Chemical strengthening method, chemical strengthening apparatus, and chemically strengthened glass

The invention discloses a chemical strengthening method, a chemical strengthening device and chemically strengthened glass, and the chemical strengthening method comprises the following steps: preheating a raw glass sheet; carrying out chemical strengthening on the preheated raw glass sheet; and annealing the chemically strengthened raw glass sheet, and applying an external electric field in the annealing process, the direction of the external electric field being perpendicular to the raw glass sheet, and the direction of the external electric field being from the air surface to the tin liquidsurface. The chemical strengthening method provided by the invention can effectively inhibit warping of the strengthened glass.

Owner:LILING KIBING ELECTRONIC GLASS CO LTD

Manufacturing process of high-elasticity PP cotton and manufactured PP cotton

PendingCN113604893AImprove breathabilityImprove experienceFilament/thread formingYarnPolyesterPolymer science

The invention discloses a manufacturing process of high-elasticity PP cotton and the manufactured PP cotton. The manufacturing process comprises the following processing steps: respectively heating and melting a polyester raw material and a chinlon raw material; respectively filtering the molten polyester raw material and chinlon raw material; respectively feeding the filtered polyester raw material and chinlon raw material into a metering pump for quantitative material taking; feeding the polyester raw material and the chinlon raw material which are quantitatively taken into a spinneret plate respectively to be converged at a yarn outlet panel of the spinneret plate; adhering each group of converged polyester raw material and chinlon raw material through heat setting and hot pressing to form integral fiber; perforating the formed integral fiber through a perforating wire to form a through hole; enabling the integral fiber with the through holes to pass through shaping filaments capable of extending out of convex points to form concave parts; and enabling the integral fiber forming the concave parts to pass through a molding sleeve capable of extending out of convex strips to form an air duct. The manufactured PP cotton has the following beneficial effects that the compression elastic recovery rate is high, the product stress intensity is high, and the elastic recovery rate and the bulkiness are not changed after multiple times of compression and water washing.

Owner:HANGZHOU CHINA HOME TEXTILES IND CO LTD

Long-service-life furnace burden matching method

InactiveCN105256090AIncrease stiffnessHigh hardnessBlast furnace detailsProcess efficiency improvementFerrosiliconTemperature resistance

The invention provides a long-service-life furnace burden matching method. The method is characterized in that all raw material components comprise, by weight, 20 to 30 parts of pig iron, 50 to 70 parts of scrap steel, 8 to 12 parts of foundry returns, 15 to 30 parts of silicon iron, 0.1 to 0.5 parts of a vanadium-titanium material, 0.1 to 0.3 part of carburant, 4 to 15 parts of graphite nodules and 8 to 12 parts of chromic oxide. By the adoption of the method, the materials are prepared comprehensively and matched reasonably, a microstructure made of the mixed and fused synthetic materials is high in degree of sphericity and large in grain size, the impurity content is small after screening operation, the high-temperature resistance of a blast furnace can be improved, and the tenacity and the stress intensity of the materials are high; due to the addition of a small amount of chrome, the rigidity and harness of the materials can be effectively improved, and the service life of the materials is prolonged; and due to the addition of the vanadium-titanium material, the furnace protecting and fettling effects are achieved, the use performance of the materials is further improved, and the service life of the furnace is prolonged.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

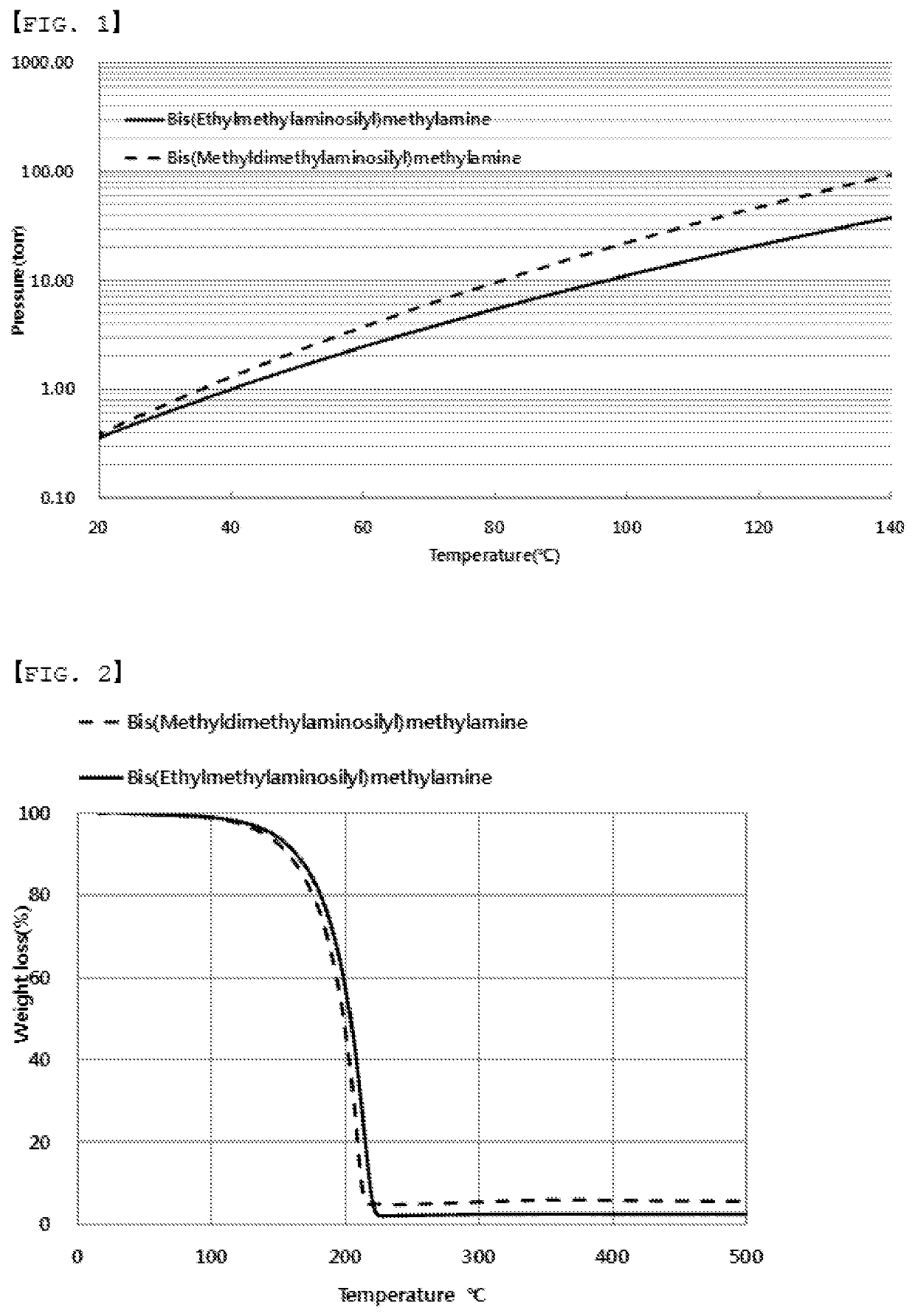

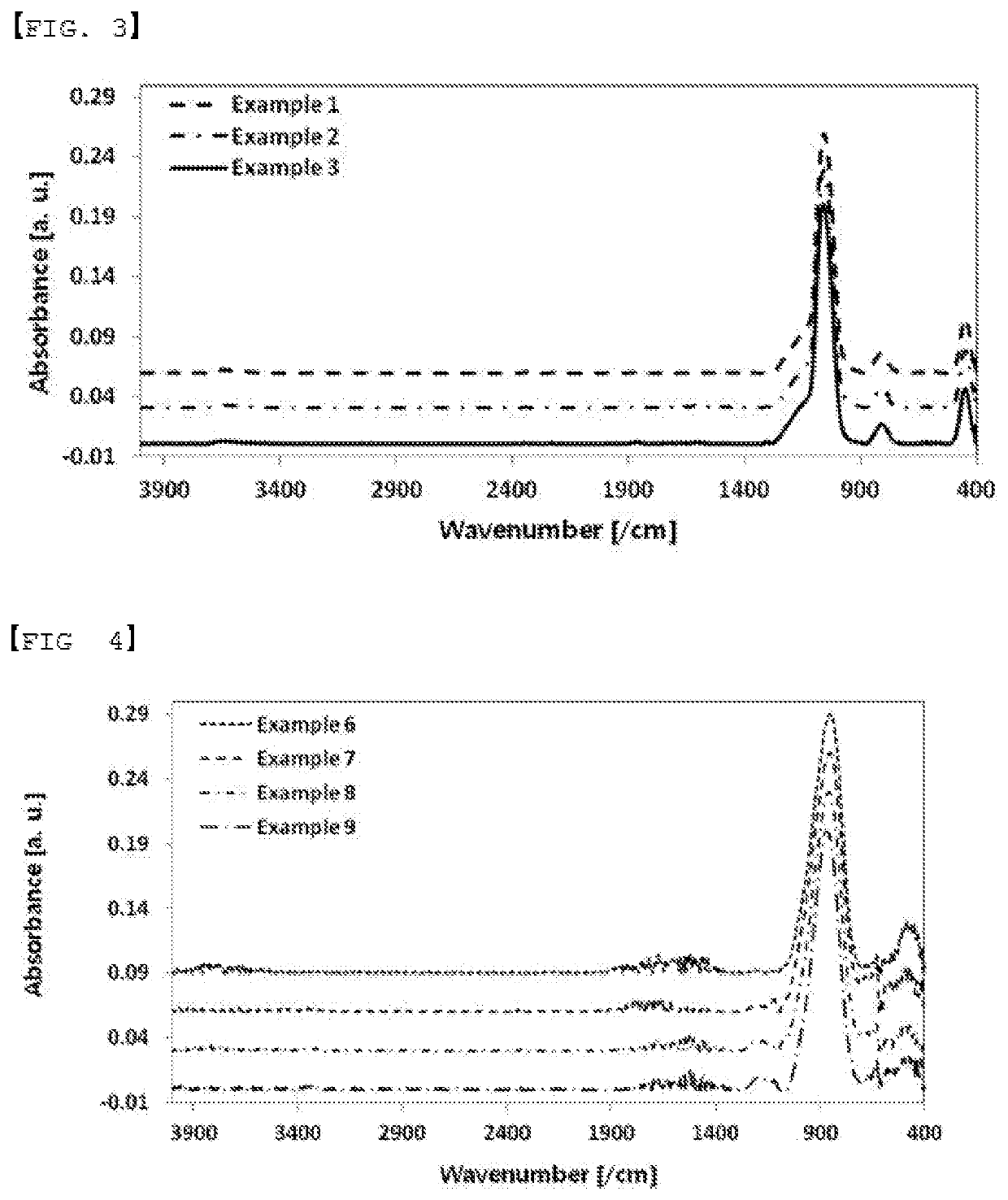

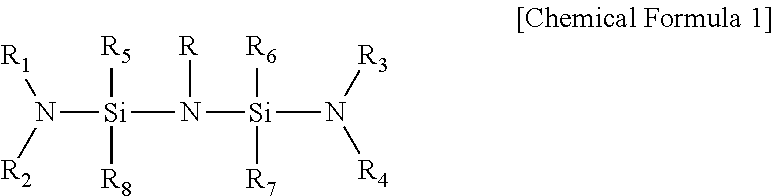

Composition for depositing silicon-containing thin film containing bis(aminosilyl)alkylamine compound and method for manufacturing silicon-containing thin film using the same

ActiveUS20200111664A1Increase relative volatilityImprove thermal stabilityGroup 4/14 element organic compoundsSilicaPhysical chemistryThin membrane

Provided are a composition for depositing a silicon-containing thin film containing a bis(aminosilyl)alkylamine compound and a method for manufacturing a silicon-containing thin film using the same, and more particularly, a composition for depositing a silicon-containing thin film, containing the bis(aminosilyl)alkylamine compound capable of being usefully used as a precursor of the silicon-containing thin film, and a method for manufacturing a silicon-containing thin film using the same.

Owner:DNF

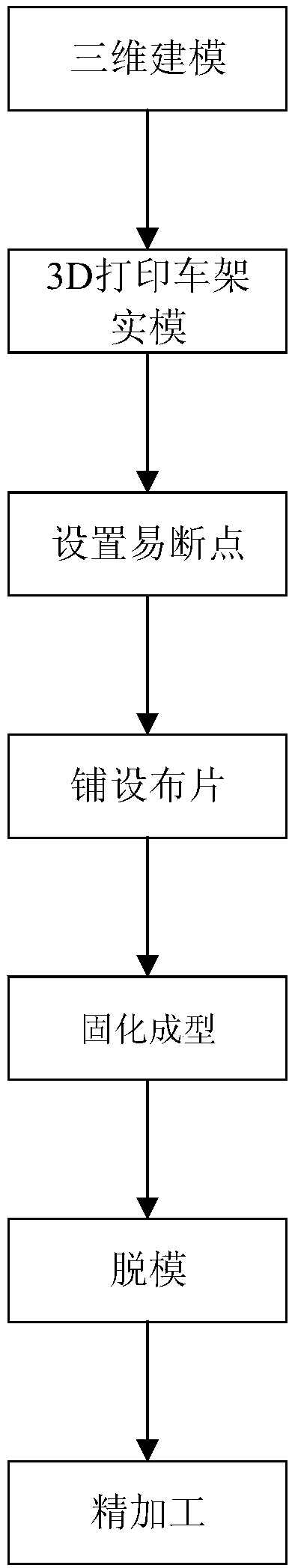

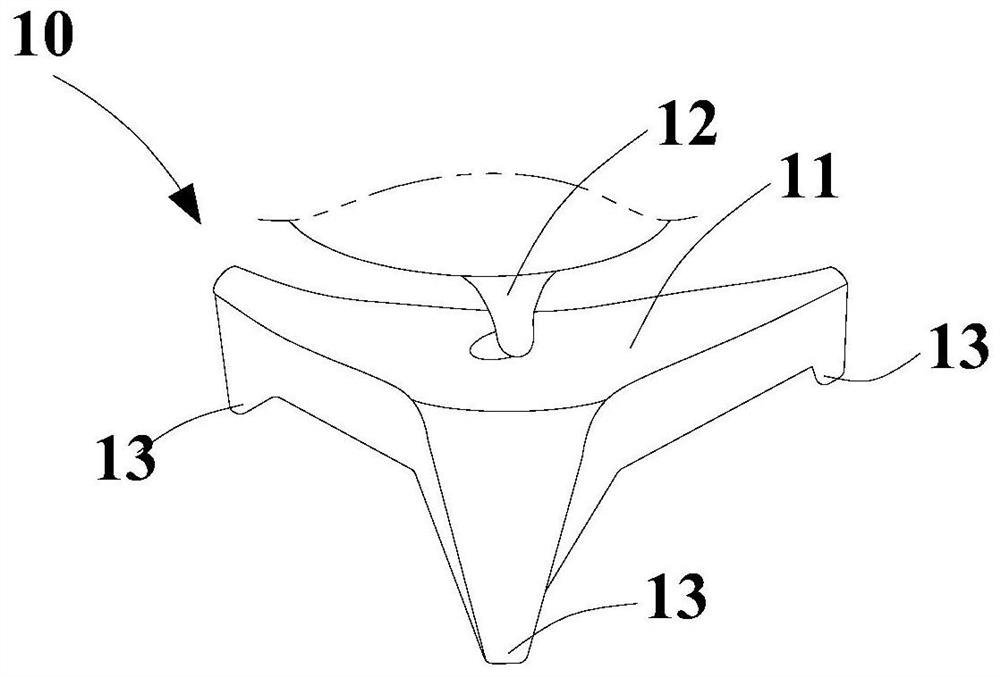

Production process of carbon fiber bicycle frame

InactiveCN108501396AHigh strengthSimplify production stepsAdditive manufacturing apparatusDomestic articlesFiberVehicle frame

The invention discloses a production process of a carbon fiber bicycle frame, and relates to the technical field of machining of bicycle frames. The production process comprises the steps that a three-dimensional drawing model of the bicycle frame is established; the three-dimensional drawing model is input to a 3D printer, and a real bicycle frame model is obtained through 3D printing operation;fragile points are set on the real bicycle frame model; prepreg cloth pieces are laid on the real bicycle frame model layer by layer in different directions and in different sequences and then are compacted; the whole real bicycle frame model laid with the prepreg cloth pieces is placed into a forming mold for solidification and formation, so that a blank is formed; the blank is separated from themold, so that the carbon fiber bicycle frame is obtained; and finish machining is conducted on the carbon fiber bicycle frame. According to the production process, the 3D printing method is adopted for the whole bicycle frame, so that the defect that molds are needed for machining bicycle frames in the prior are is overcome; glue-based assembling is not needed, so that the production steps are simplified, the production efficiency is high, the integration degree is high, and the strength of part joints is high.

Owner:无锡智高点技术研发有限公司

Anti-vibration device for audio equipment and audio equipment rack with anti-vibration device

Owner:B LAM LTD

A roller coaster frame device

ActiveCN109529364BReduce stress concentrationSimple structureHelter-skeltersRoller coasterVehicle frame

Owner:北京中冶设备研究设计总院有限公司 +1

A light emitting diode and its manufacturing method

ActiveCN111048642BImprove reliability drop problemIncreased stress intensitySemiconductor devicesRutheniumEngineering

The invention discloses a light-emitting diode, which comprises a first electrode connected to a first semiconductor layer, a second electrode connected to a second semiconductor layer, and the first electrode and / or the second electrode sequentially include a first reflection layer and a pad Layer and a second reflective layer at least partially covering the pad layer, the material of the second reflective layer includes rhodium, platinum or ruthenium, the first reflective layer and the second reflective layer make a large-angle electrode structure through good stress characteristics, and have It is conducive to improving the photoelectric characteristics of the light-emitting diode and improving product reliability.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

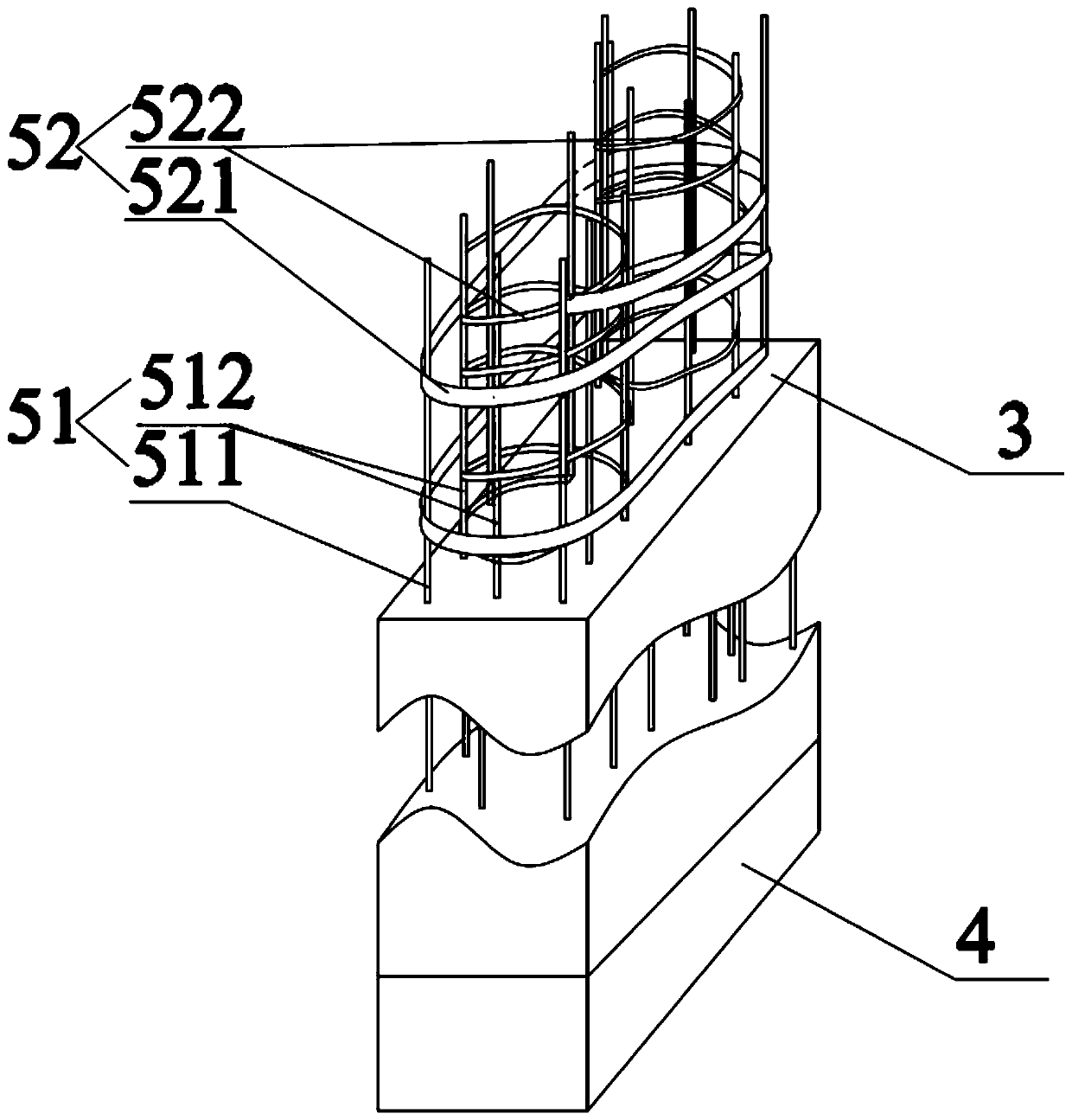

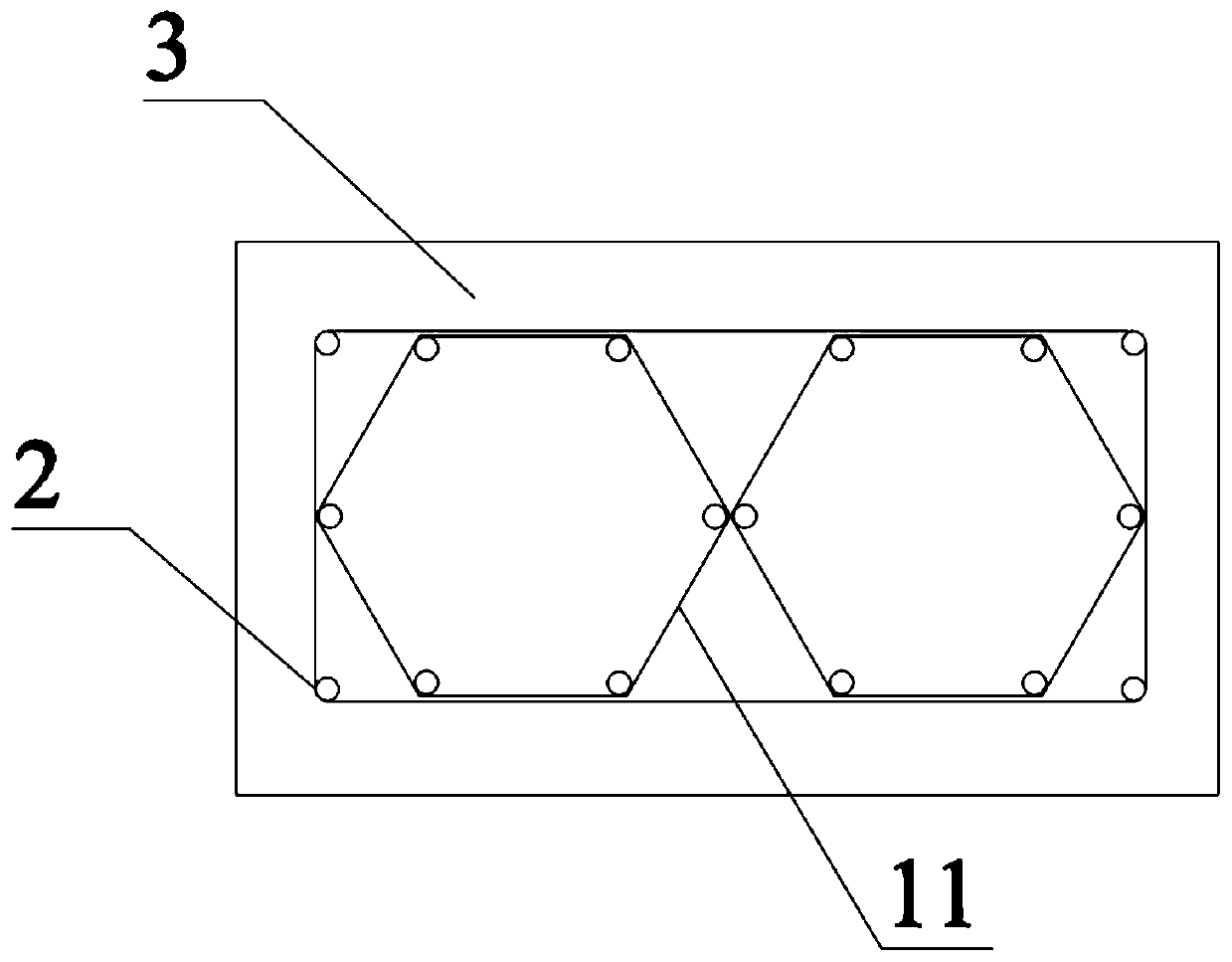

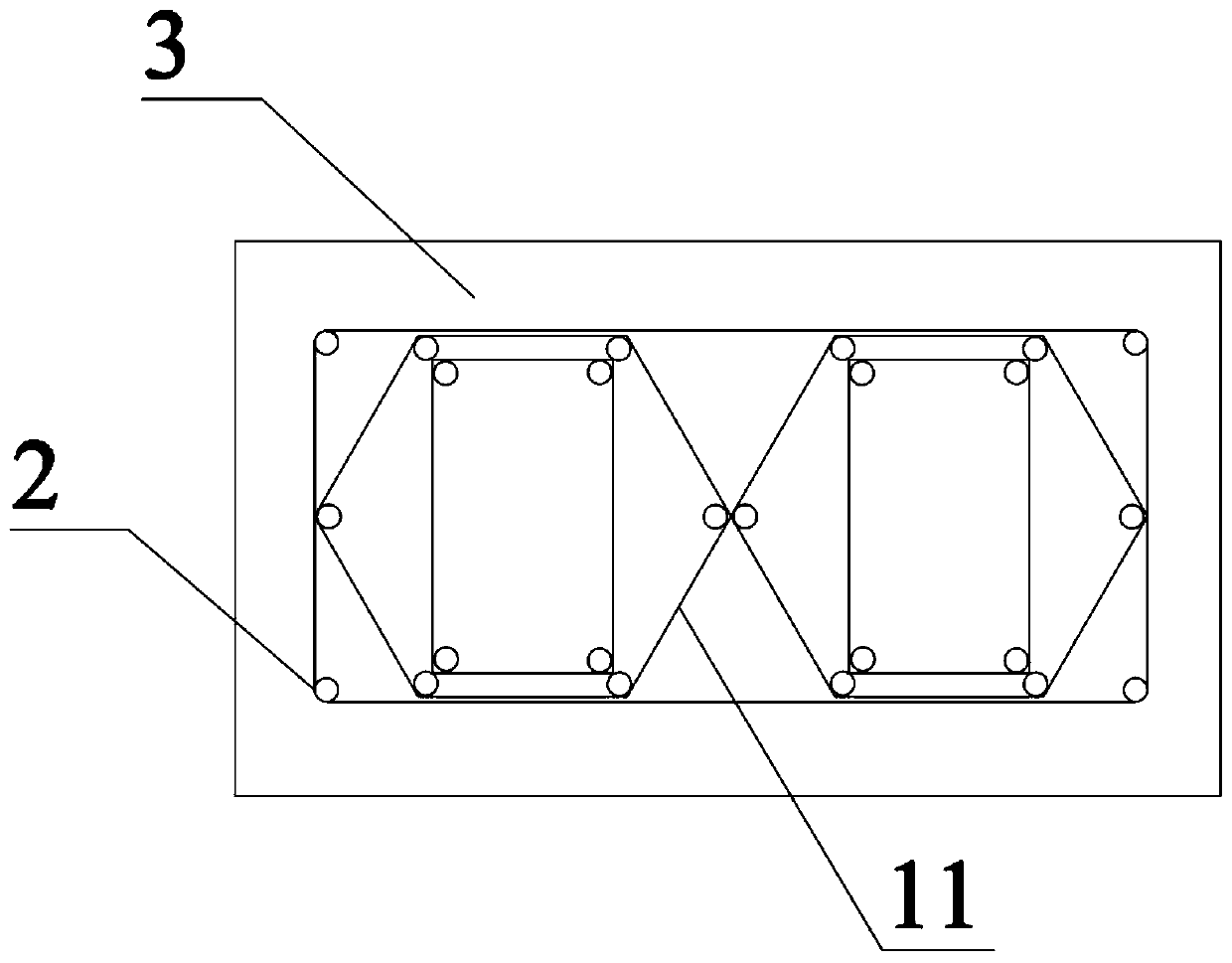

Concrete pile body structure and manufacturing method thereof

The invention discloses a concrete pile body structure and a manufacturing method thereof. The concrete pile body structure comprises a base and a concrete pile body, the base is arranged on the at least one axial end of the concrete pile body, the concrete pile body comprises concrete and at least two layers of cylindrical supporting cages, the supporting cages extend in the axial direction of the concrete pile body, the structure of the pile body adapts to the reinforcing steel bar structure, supporting of reinforcing steel bars to the pile body in the axial direction can be effectively ensured, and the cylindrical supporting cages are sleeved in a stacked manner; whole stress strength in the pile body can be effectively ensured, mutual supporting through the supporting cages is achieved, and the outer side walls of at least one pair of adjacent supporting cages and the inner sides of the supporting cages on the outer sides are fixedly connected; and through fixed connection of the side wall faces of the supporting cages on the adjacent layers, face contact between the supporting cages on the adjacent layers can be formed, the strength of the pile body structure formed through mutual arranging of the supporting cages can be further improved, and safety hidden danger in the use process can be greatly reduced.

Owner:盐城市双强管桩有限公司

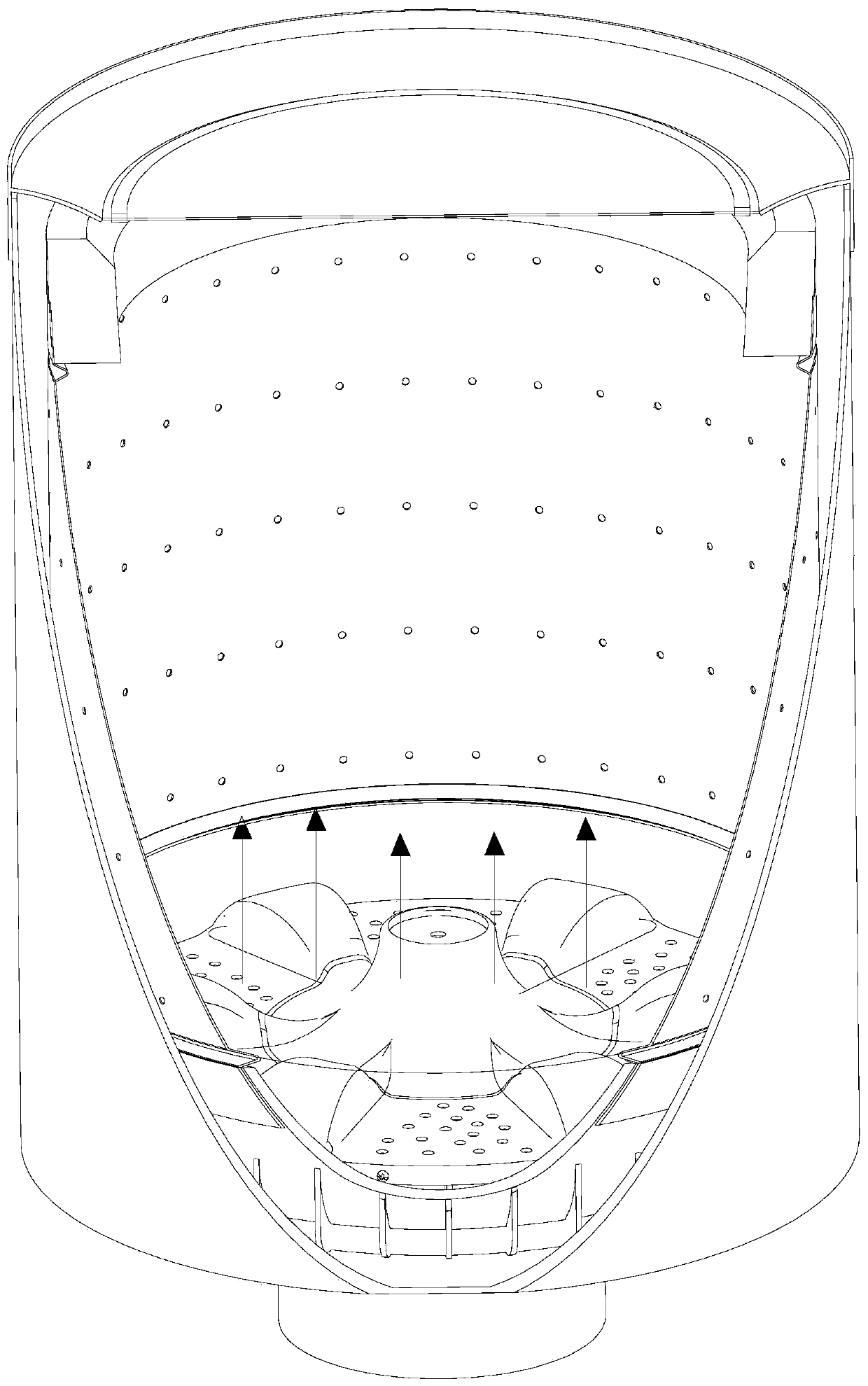

A washing machine for jet-floating washing

ActiveCN108018667BImprove washing effectAvoid entanglementOther washing machinesWashing machine with receptaclesLaundry washing machineProcess engineering

The invention relates to a washing machine for spray-floating washing. The gap between the inner and outer tubs is connected with the inner waterway of the pulsator through the connecting waterway provided with a water pump, and the washing water between the inner and outer tubs is passed through the connecting waterway and the inner waterway of the pulsator by the pulsator. The spray holes arranged on the surface spray into the inner tub, forming an upwardly sprayed water column in the inner tub to wash clothes. Through the above arrangement, an upwelling water column is continuously formed in the inner tub, thereby washing away the clothes and reducing the entanglement of the clothes caused by repeated reversals, thereby avoiding the damage caused by the entanglement of the clothes. At the same time, since the clothes are constantly tumbling during the washing process, the contact area between the clothes and the washing water is increased, and the clothes rub against each other, which effectively improves the washing effect. Also, the present invention is simple in structure and remarkable in effect, and is suitable for popularization and use.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Overall Composite Bulging Technology of Automobile Drive Axle

The invention discloses an integral compound bulging process for an automotive driving axle. The process comprises the following steps of: 1) placing an opened axle housing workpiece into an external bulging mold; 2) extending the internal bulging mold into a bulged deformed area of the axle housing workpiece from an inner hole at one end of the axle housing workpiece; 3) closing the external bulging mold; 4) applying equal thrust parallel to the axial direction of the axle housing workpiece to the internal bulging mold by utilizing thrust devices at the two ends of the internal bulging mold respectively, and applying pressure perpendicular to the axial direction of the axle housing workpiece to an upper module and a lower module by utilizing a pressure generation device, wherein the thrust is decomposed into a perpendicular thrust component which acts on the upper and lower module and is perpendicular to the axial direction of the axle housing workpiece and a parallel thrust component parallel to the axial direction of the axle housing workpiece under the action of a link mechanism, bulging force on the axle housing workpiece is the resultant force of the perpendicular thrust component and the pressure, and the axle housing workpiece is bulged and deformed under the action of the bulging force; and 5) performing unloading and demolding.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

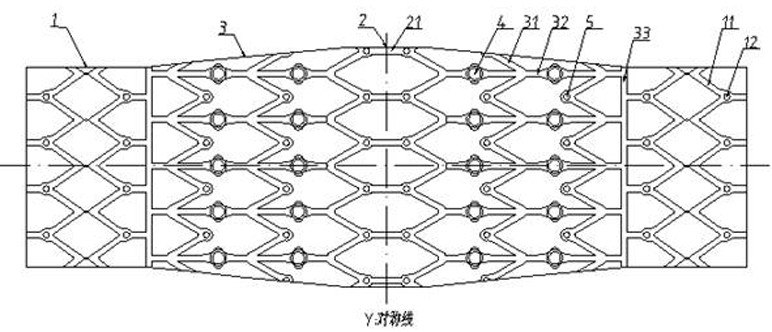

A kind of vascular stent structure

ActiveCN110448396BImprove support strengthImprove stabilityStentsMedical devicesPharmaceutical drugEngineering

Owner:THE FIFTH PEOPLES HOSPITAL OF SHANGHAI

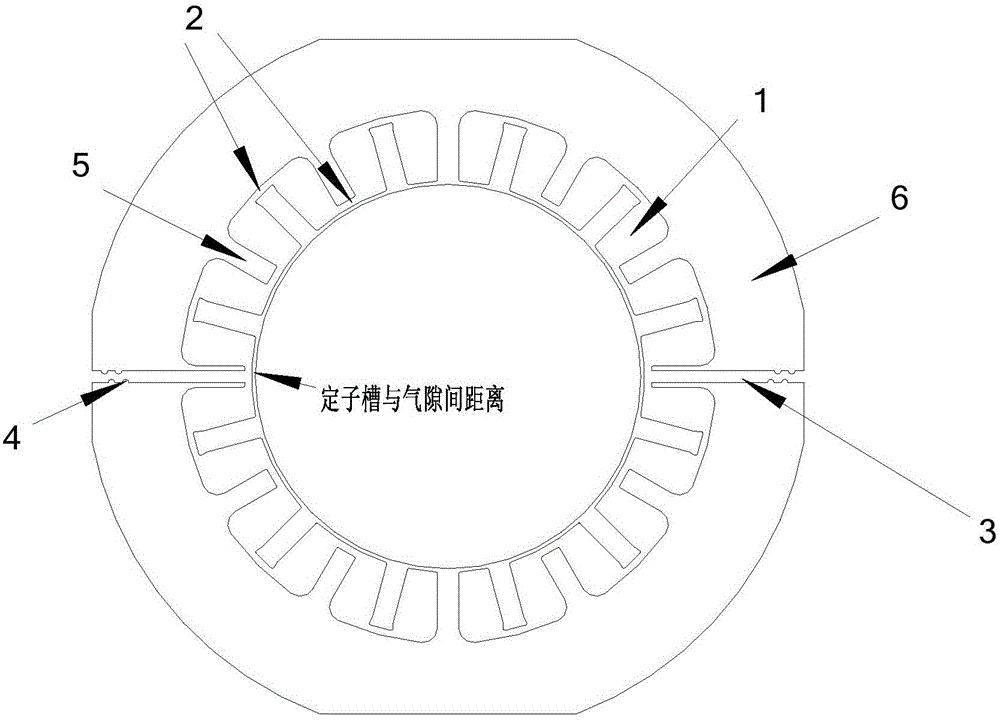

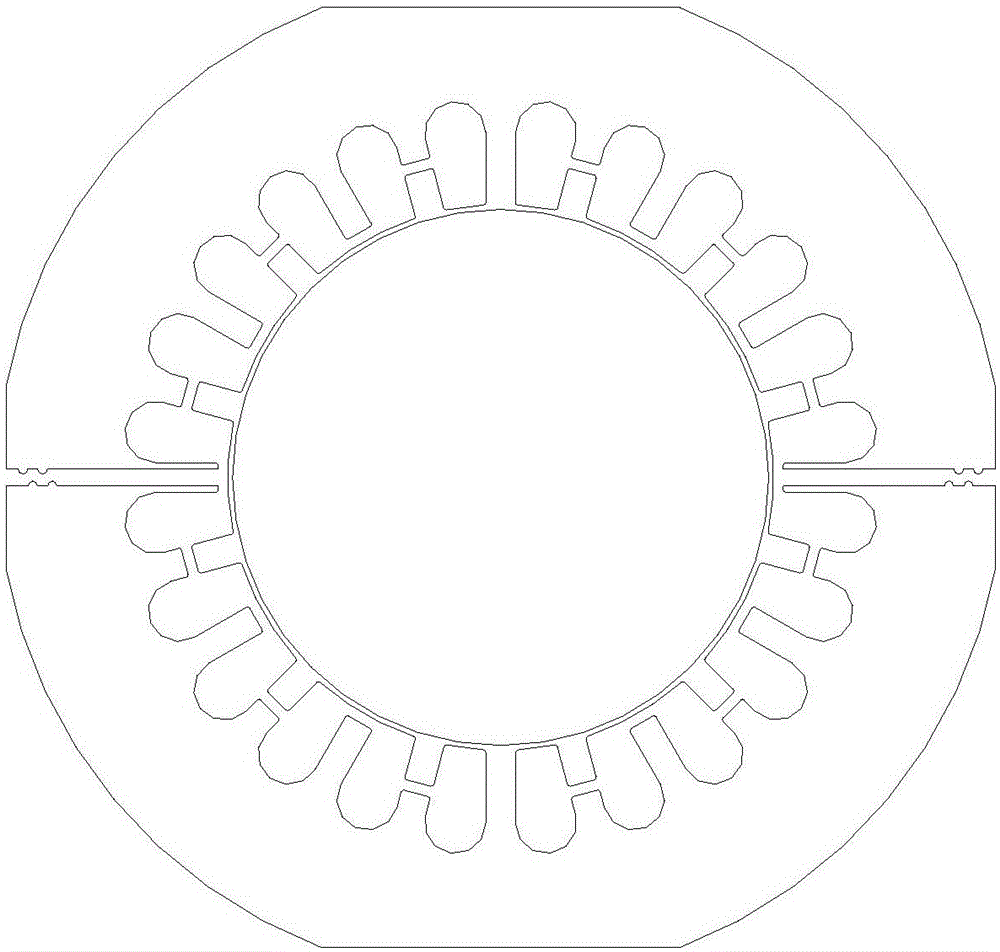

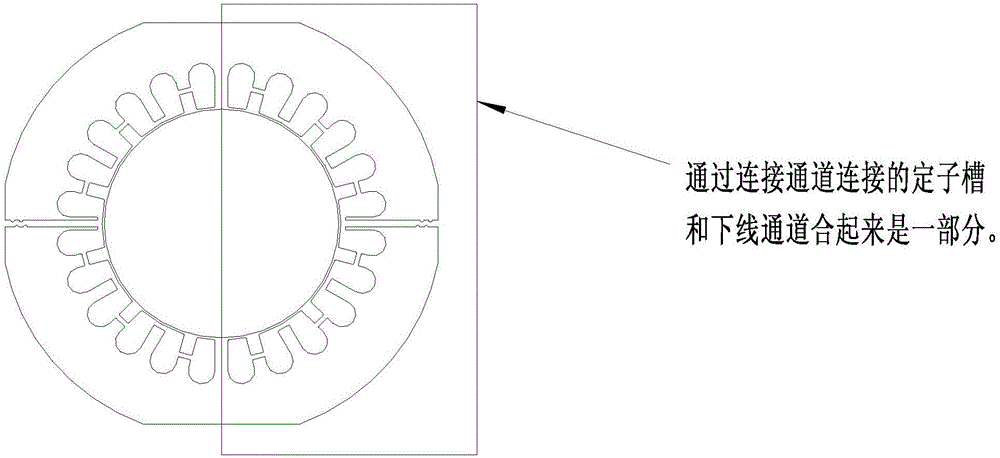

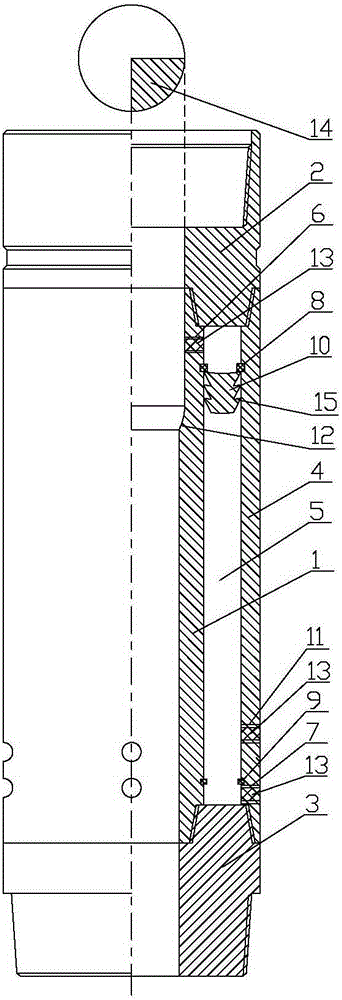

Compressor, motor and stator punching sheet structure

ActiveCN105071565AImprove efficiencySmall starting currentMagnetic circuit stationary partsPunchingExcitation current

The invention discloses a stator punching sheet structure. On the basis of a general stator punching sheet structure, each of stator slots is divided into two parts (two parts share one winding installation channel, and the part of stator slots connected via connection channels serves as one part), the two parts share the same winding installation channel, and the stator slots in each part are connected through the connection channels, winding installation is conducted through one winding installation channel, welding is performed at stator core welding points after winding installation is finished, and thus the intensity of a stator core is ensured. According to the above structure, stator notches are removed, so the influence of notches upon a stator is avoided; starting currents are minimized, stray loss is reduced, excitation currents are reduced, the power factor is increased, and the motor efficiency is improved by means of such a design; and the stress intensity of the stator itself is improved after welding at the welding points are finished. The invention also discloses a motor applying the above stator punching sheet structure. The invention further discloses a compressor applying the motor.

Owner:GREE ELECTRIC APPLIANCES INC +1

Gel Injection Device While Drilling

The present invention relates to Technical field of gel injection device in oil drilling , is a gel injection device while drilling, which includes an inner cylinder, an upper joint, a lower joint and an outer cylinder; the upper outer wall and the lower outer wall of the inner cylinder are respectively fixed and installed together with the lower inner wall of the upper joint and the upper inner wall of the lower joint , the upper inner wall and the lower inner wall of the outer cylinder are fixedly installed with the lower outer wall of the upper joint and the upper outer wall of the lower joint respectively, and an annular temporary storage chamber is formed between the inner cylinder, the outer cylinder, the upper joint and the lower joint. The present invention is reasonable and compact in structure, easy to use, injectable After the gel is flocculated in the easily collapsed section, the stress intensity of the section is enhanced, It effectively prevents downhole sticking accidents caused by downhole blocks, provides a strong downhole guarantee for subsequent safe and fast drilling, improves drilling operation efficiency and drilling engineering quality, shortens drilling operation cycle, and the present invention can be used repeatedly, which can effectively reduce operation cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com