Pneumatic extinguisher

A technology for a wind-powered fire extinguisher and a body, which is applied to fire rescue and other directions, can solve the problems of increasing the carrying burden of firefighters, the heavy carrying weight of the fire extinguisher, and the unsatisfactory air outlet effect, and achieves the effects of light specific gravity, weight reduction, and production cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

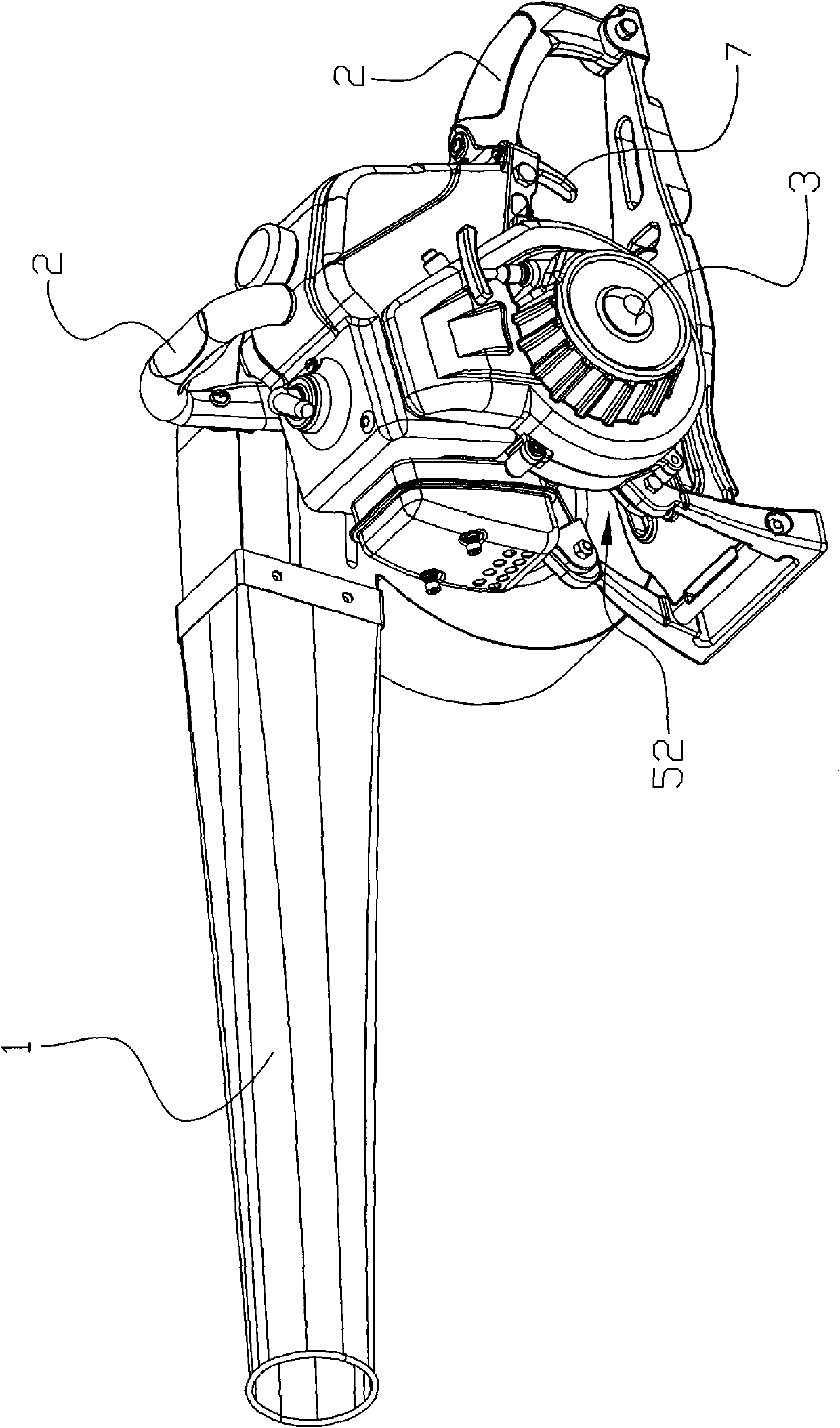

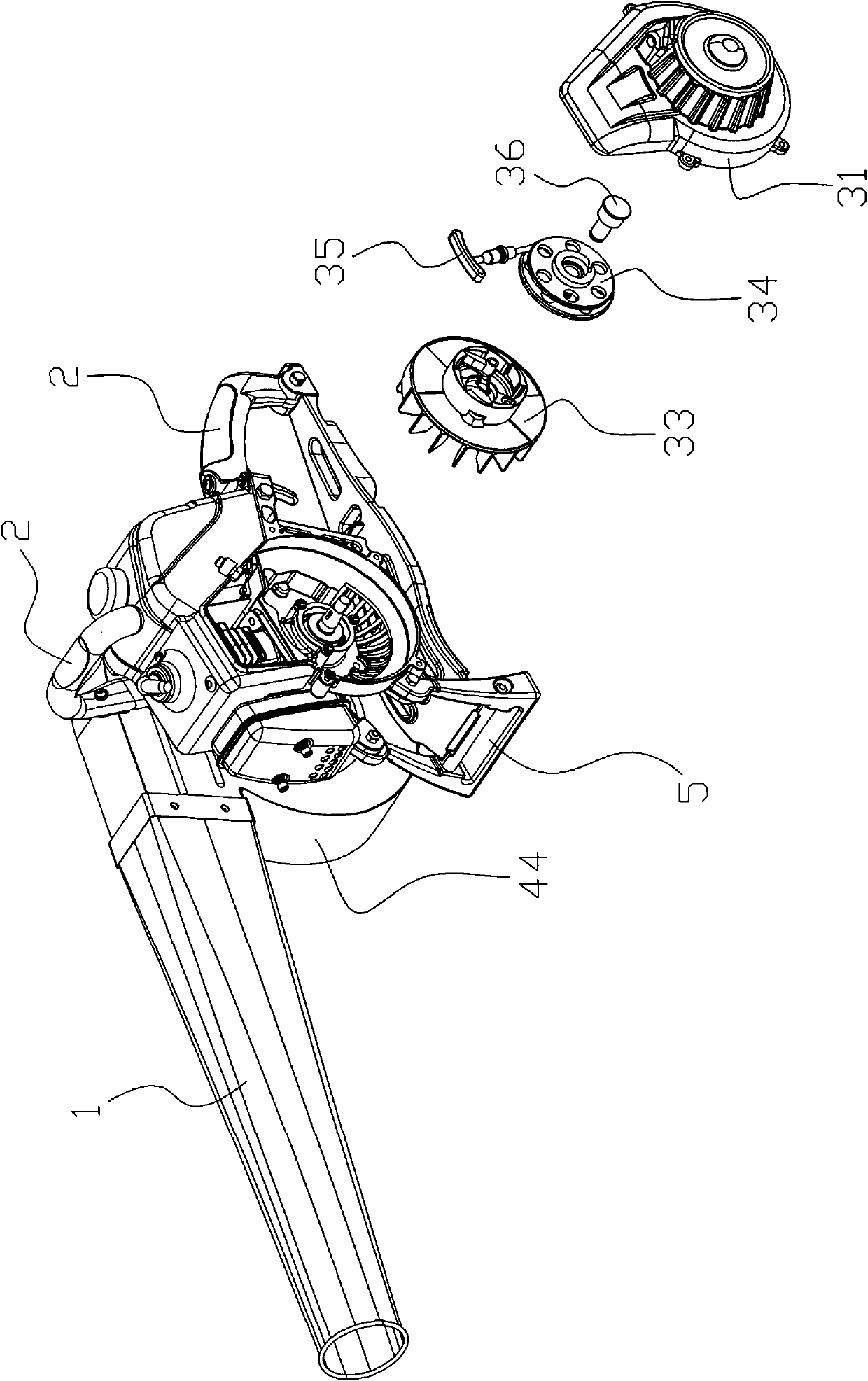

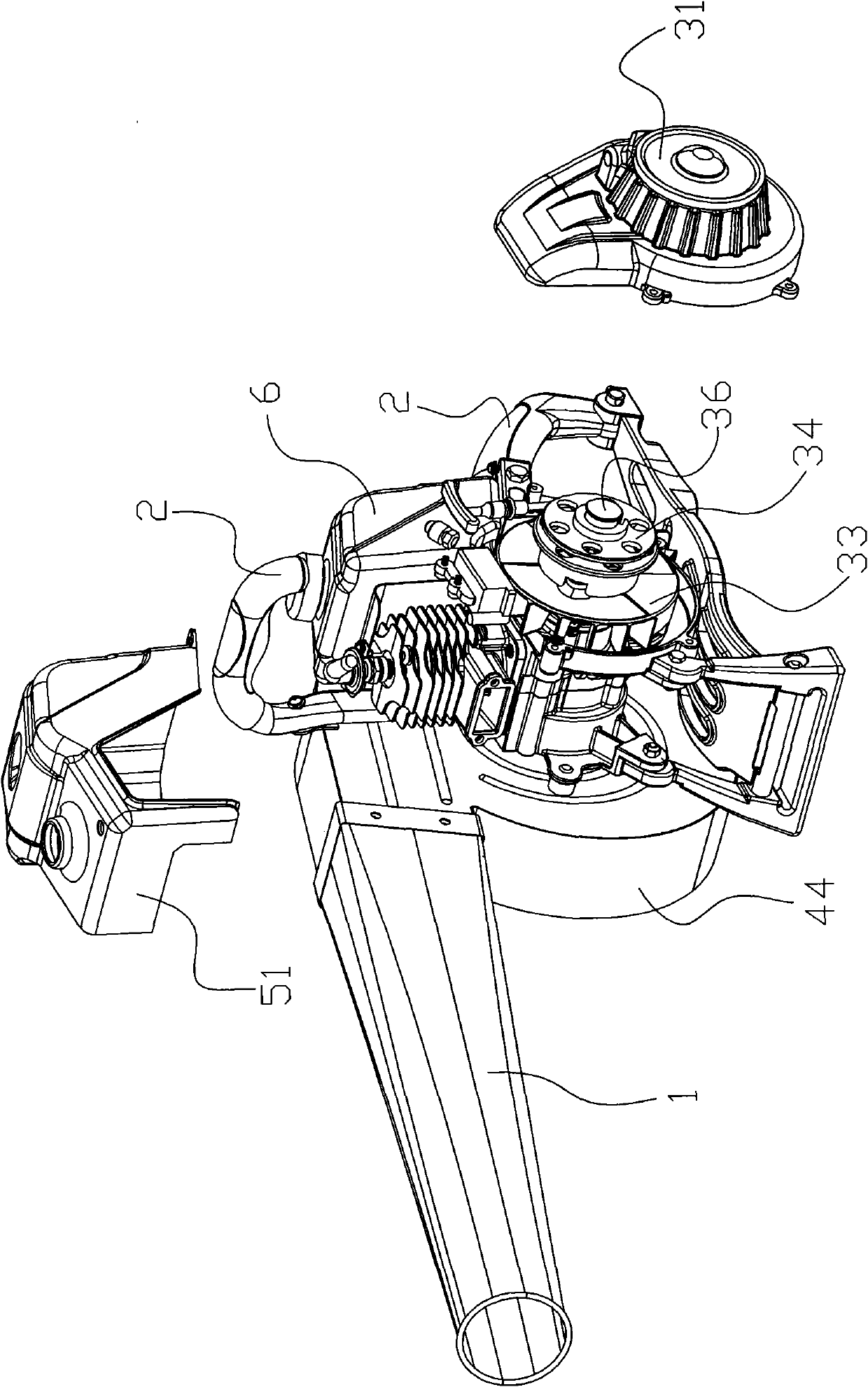

[0025] like Figures 1 to 8 As shown, the wind fire extinguisher of the present embodiment includes an engine 10, a body 5, a starting part 3, a handle part 2 arranged on the body 5, a cooling wind part and an impeller of the jetting wind part 4, on the left and right sides of the body 5 A cooling wind part and a blowing wind part 4 are provided, and the blowing wind part 4 communicates with the airflow spraying tube 1, and the wind impeller 43 of the blowing wind part 4 and the outer fixing ring 42 are fixed together by bolts.

[0026] The specific structure that the wind impeller 43 of the above-mentioned blowing wind part 4 and the outer fixed ring 42 are fixed to each other by bolts is as follows: on the corresponding curved wind piece 431 on the same circumferential surface of the wind impeller 43, axially protruding bosses are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com