Manufacturing process of high-elasticity PP cotton and manufactured PP cotton

A manufacturing process and high-elasticity technology, applied in the field of PP cotton manufacturing, can solve the problems of low comfort, collapse deformation, general structural strength, etc., to achieve a good sense of experience, high compressive elastic recovery rate, and high product stress intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

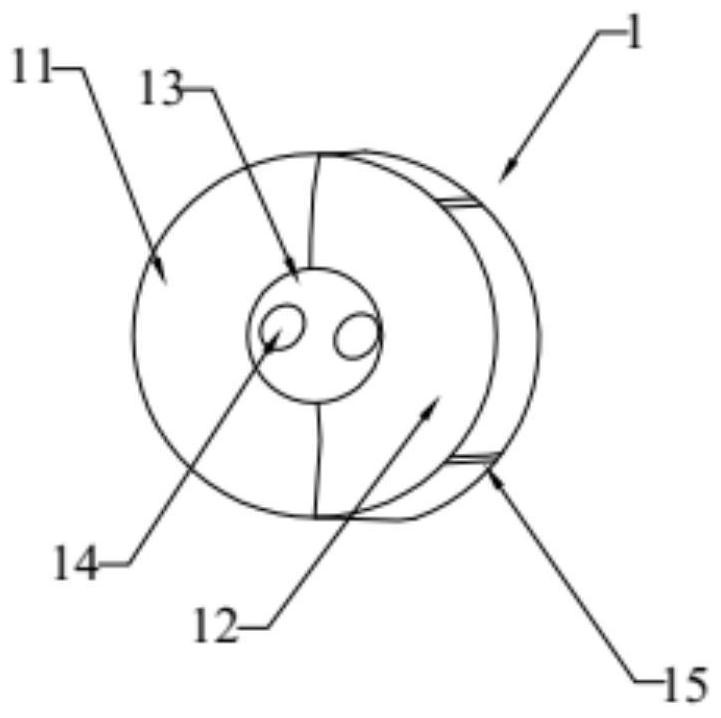

Image

Examples

Embodiment 1

[0038] The manufacturing process of a kind of highly elastic PP cotton provided by the present invention uses two kinds of raw materials of polyester and nylon. When processing, the use ratio of these two kinds of raw materials is 1:1, and its processing steps are as follows:

[0039] In the first step, the polyester raw material and the nylon raw material are respectively put into the screw extruder for heating and melting, so that both materials are in a state that can be molded.

[0040] In the second step, the melted polyester raw materials and nylon raw materials are respectively fed into the spinning box for filtration to filter out the impurities inside each.

[0041] The third step is to put the polyester raw material and nylon raw material filtered by the spinning box into the metering pump for quantitative feeding, so that the ratio of the two is strictly controlled to keep the amount of the two at 1:1, and at the same time control each The content of polyester and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com