Optical lens and injection molding mold thereof

An optical lens and injection molding technology, applied in the field of optical lenses, can solve the problems affecting the optical performance of the lens, fast flow rate, etc., achieve the effect of strengthening stress intensity, strong force and tolerance tolerance, and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

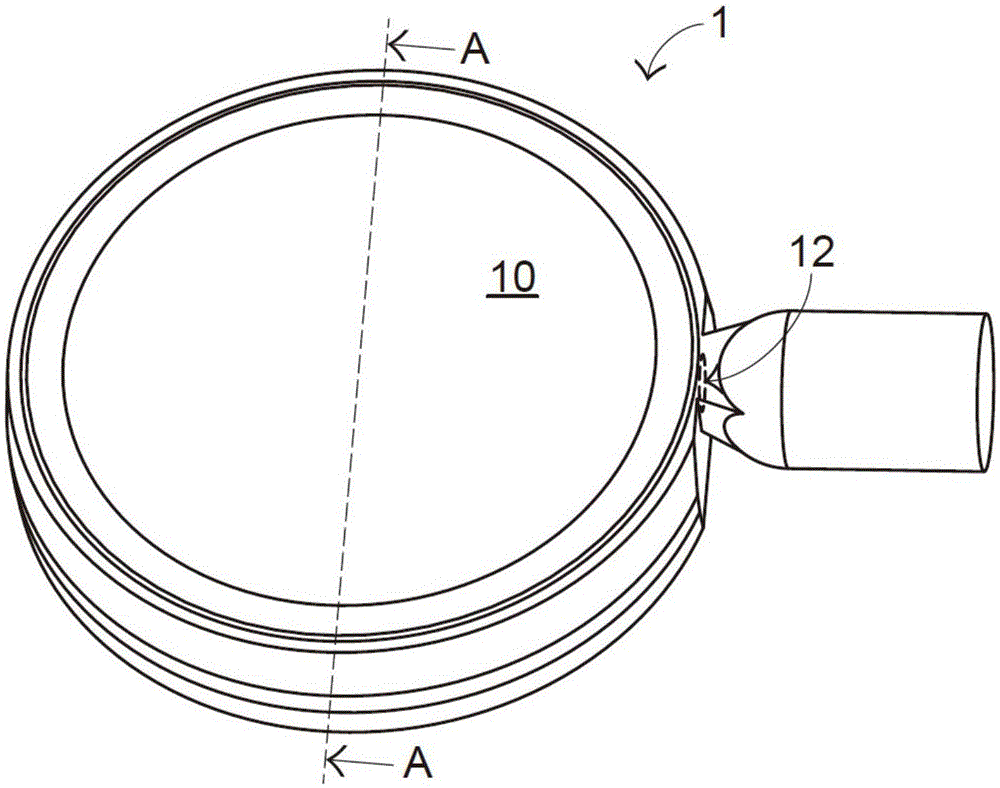

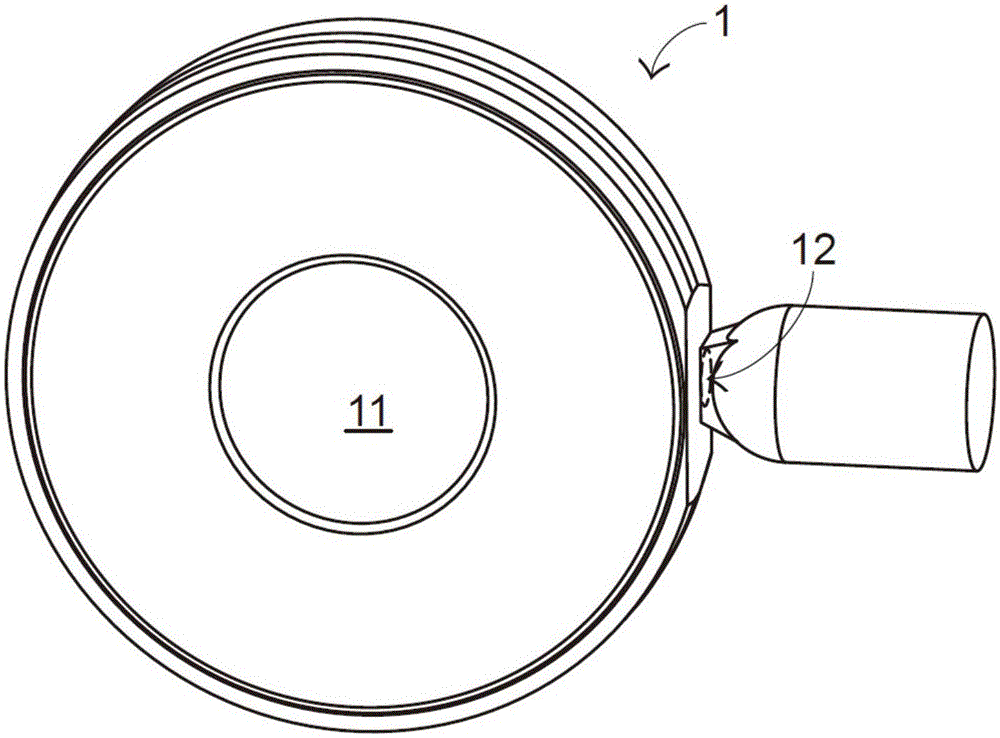

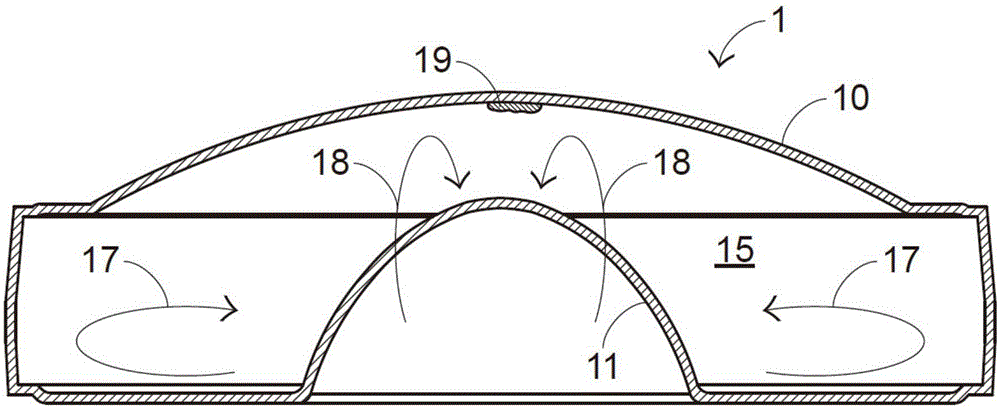

[0035] Figure 5 It is a three-dimensional schematic diagram of the injection molding mold of the optical lens of the present invention; Image 6 It is a three-dimensional schematic diagram of another angle of the injection molding mold of the optical lens of the present invention; Figure 7 for Figure 5 The sectional view in the direction of the B-B line segment. Such as Figure 5 to Figure 7 As shown, the optical lens injection molding mold 2 of the present invention includes a disc-shaped mold base 21 and a nozzle 22, the nozzle 22 is connected with the disc-shaped mold base 21, and its internal space is also communicated. The upper surface of the disc-shaped mold base 21 arches upwards in an arc shape, and a curved surface vertex P is formed at the central point to manufacture an optical lens with a similar curved surface.

[0036] A mold cavity chamber 210 is defined inside the disc-shaped mold base 21 (please refer to Figure 7 ) and the gate 211 communicating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com