Chemical strengthening method, chemical strengthening apparatus, and chemically strengthened glass

A technology for strengthening glass and glass, which is applied in the field of chemical strengthening method, chemical strengthening glass, and chemical strengthening device, and can solve the problems of increased production cost, limited adjustment ability, excessive polishing waste liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

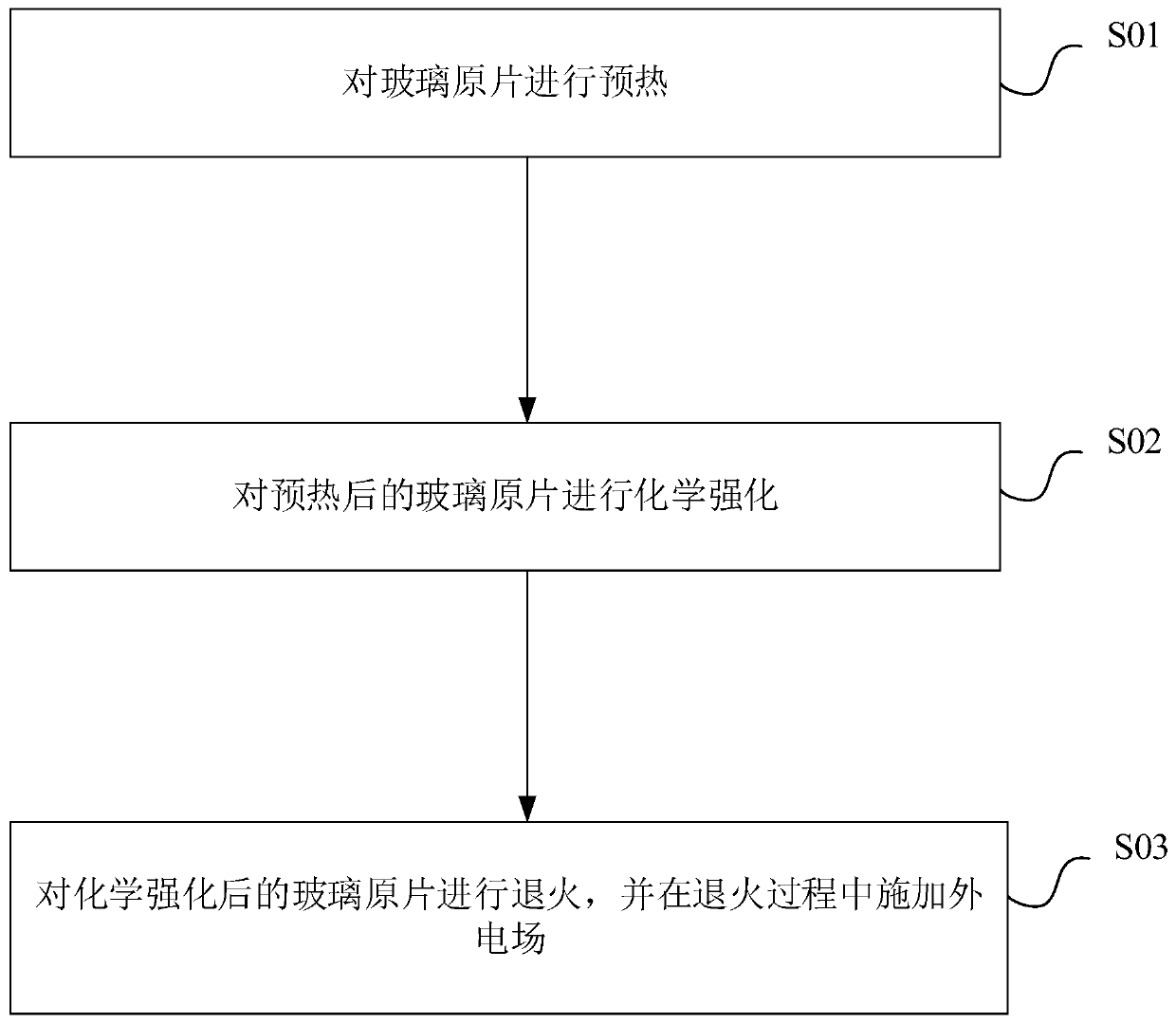

[0051] Strengthening process:

[0052] (1) Preheat to 360°C for 1 hour and hold for 15 minutes;

[0053] (2) Conduct a salt bath at 420°C for 5 hours; after the salt bath is over, lift the original glass sheet and drop salt for 12 minutes;

[0054] (3) Anneal and cool from 360°C to 150°C within 1.5h, no electric field is applied during the annealing process.

[0055] Test results:

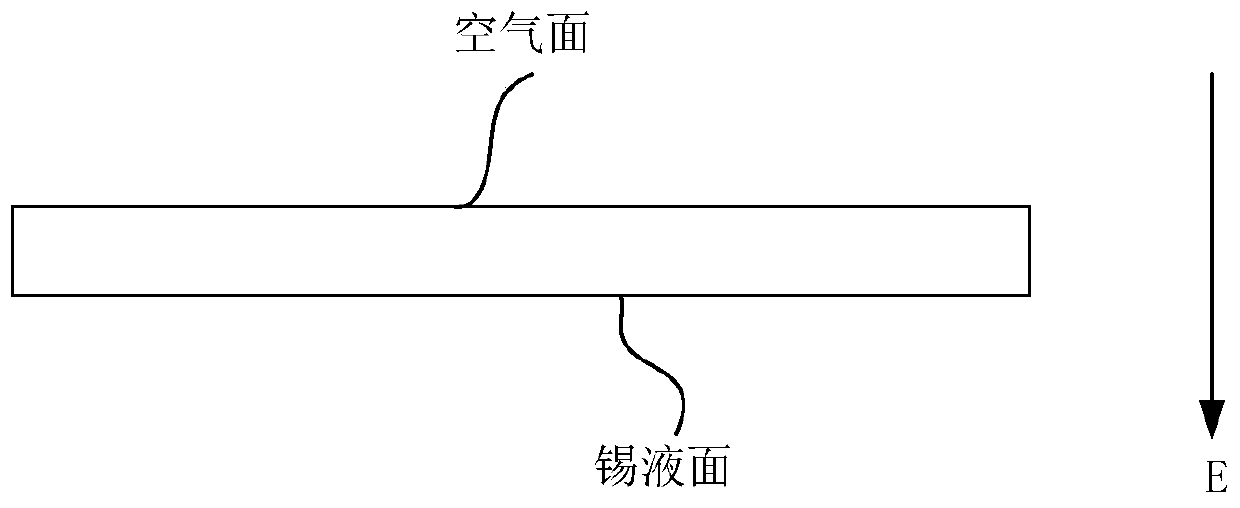

[0056] Air surface: CS 850MPa DOL 43.5μm

[0057] Tin liquid level: CS 852MPa DOL 42.7μm

[0058] Warpage: 0.22mm.

Embodiment 2

[0060] Strengthening process:

[0061] (1) Preheat to 360°C for 1 hour and hold for 15 minutes;

[0062] (2) Conduct a salt bath at 420°C for 5 hours; after the salt bath is over, lift the original glass sheet and drop salt for 12 minutes;

[0063] (3) Anneal and cool from 360°C to 150°C within 1.5h, and apply an electric field during the annealing process; the magnitude of the electric field is 200V / cm, the action temperature is 360°C, and the action time is 30min.

[0064] Test results:

[0065] Air surface: CS 820MPa DOL 43.8μm

[0066] Tin liquid level: CS 861MPa DOL 42.1μm

[0067] Warpage: 0.05mm.

Embodiment 3

[0069] Strengthening process:

[0070] (1) Preheat to 360°C for 1 hour and hold for 15 minutes;

[0071] (2) Conduct a salt bath at 420°C for 5 hours; after the salt bath is over, lift the original glass sheet and drop salt for 12 minutes;

[0072] (3) Anneal and cool from 360°C to 150°C within 1.5h, apply an electric field during the annealing process, the magnitude of the electric field is 200V / cm, the action temperature is 320°C, and the action time is 30min.

[0073] Test results:

[0074] Air surface: CS 838MPa DOL 43.7μm

[0075] Tin liquid level: CS 857MPa DOL 42.4μm

[0076] Warpage: 0.14mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warpage | aaaaa | aaaaa |

| Warpage | aaaaa | aaaaa |

| Warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com