Pre-stressing carbon-cloth tension system and tension reinforcing method

A carbon fiber cloth, prestressing technology, applied in building maintenance, building material processing, construction and other directions, can solve the problems of inflexibility, low tensioning efficiency, complex structure, etc., to achieve simple and fast tensioning and high work efficiency , the effect of easy anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

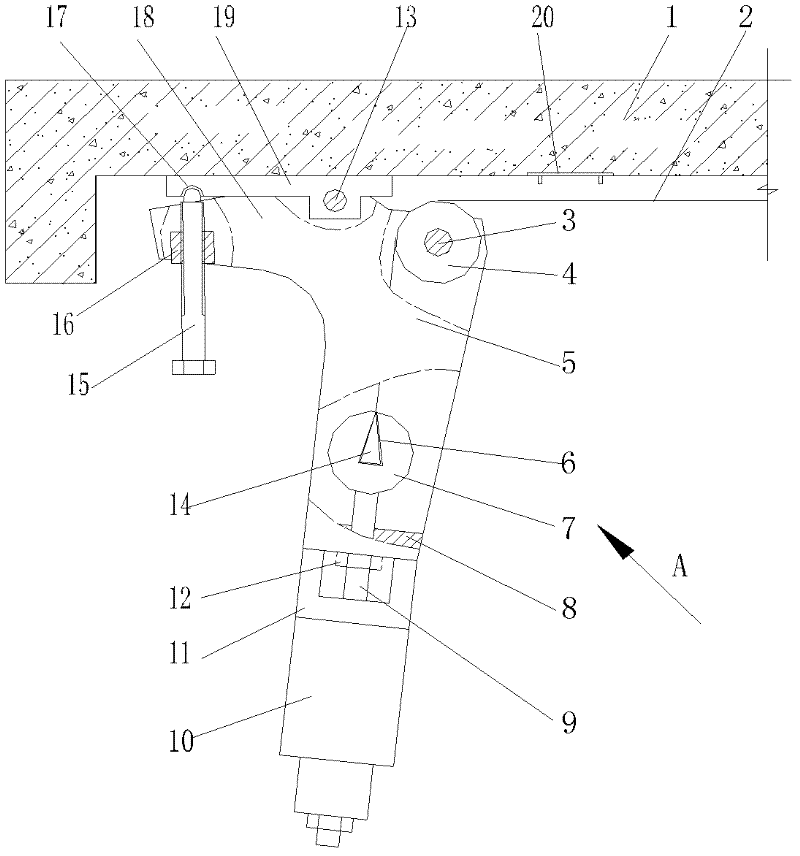

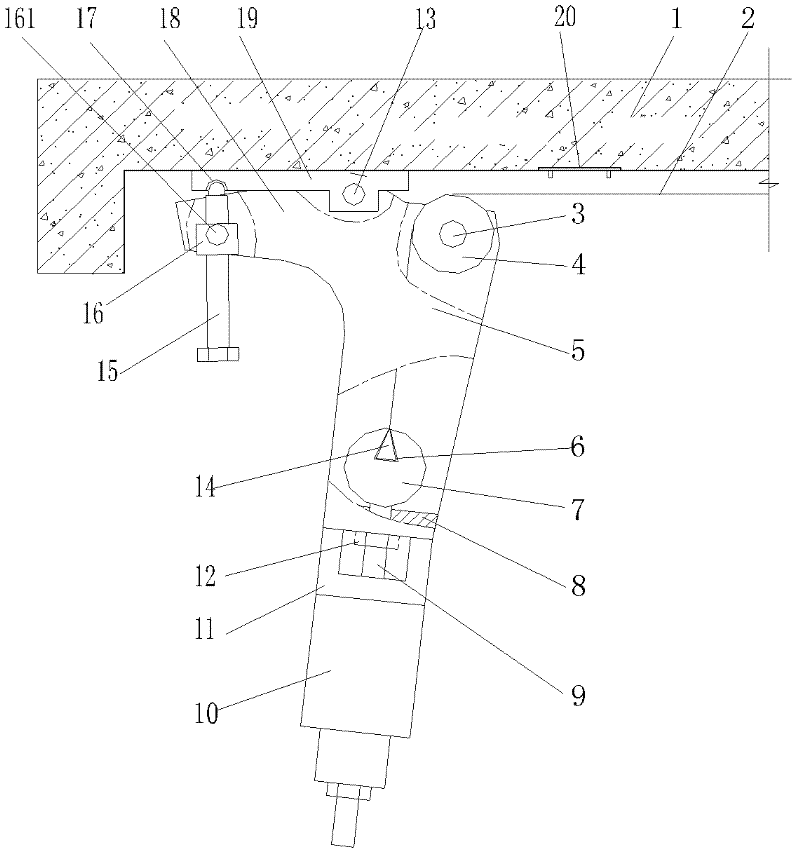

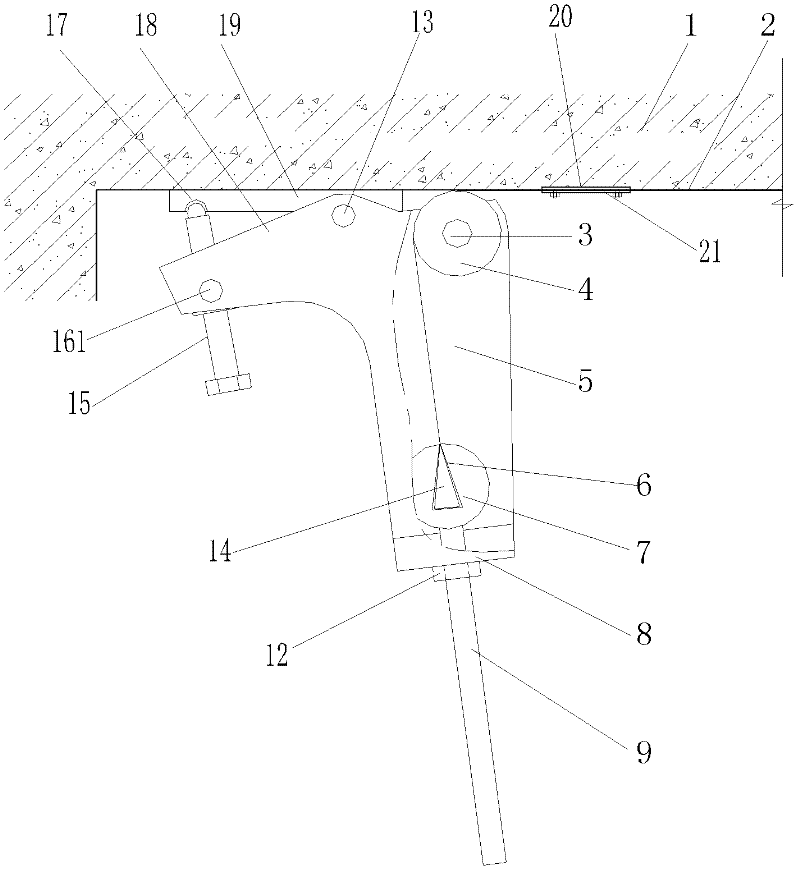

[0033] figure 1 It is a schematic diagram of the structure before tensioning of the present invention, figure 2 It is a schematic diagram of the structure of the stretching completion of the present invention, image 3 It is a schematic diagram of the structure after removing the tensioning equipment, Figure 4 It is a schematic diagram after the construction is completed, Figure 5 for figure 1 Schematic diagram of the tension frame structure along the A direction, Figure 6 It is a schematic diagram of the anchorage structure of the present invention, as shown in the figure: the prestressed carbon fiber cloth tensioning system of this embodiment includes a prestressed tensioning assembly, a steering shaft 4 and a tensioning frame;

[0034] The tensioning frame is hinged to the reinforced part 1 to form a lever structure, and the steering shaft 4 is arranged on the resistance arm 5 of the tensioning frame in a manner that can rotate around its own axis; the power arm 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com