Concrete pile body structure and manufacturing method thereof

A concrete pile and concrete technology, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of long-term use safety hazards, the impact of the overall strength of the pile structure, unreasonable installation and distribution, etc., to reduce safety hazards, The operation method is convenient and convenient, and the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

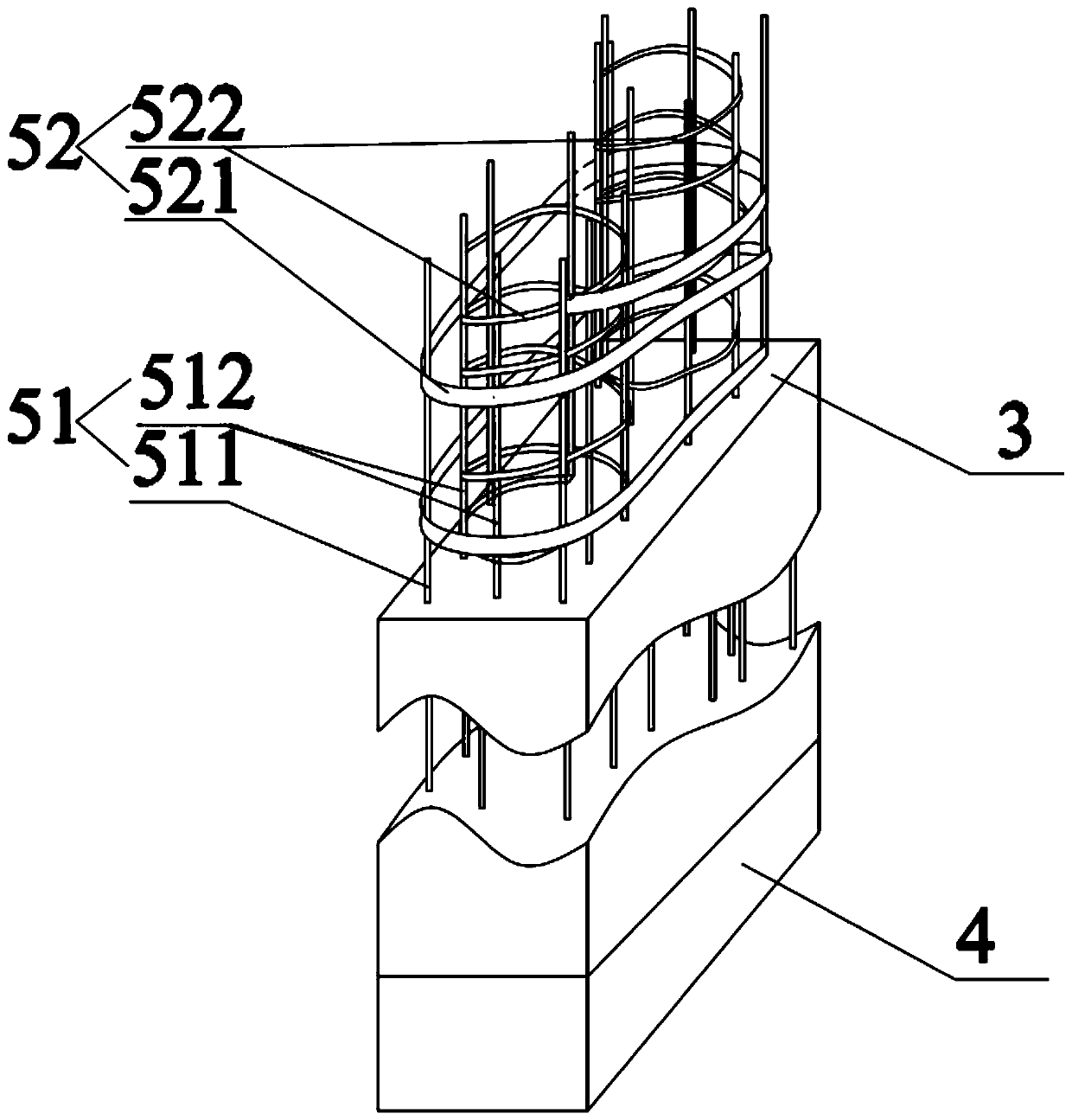

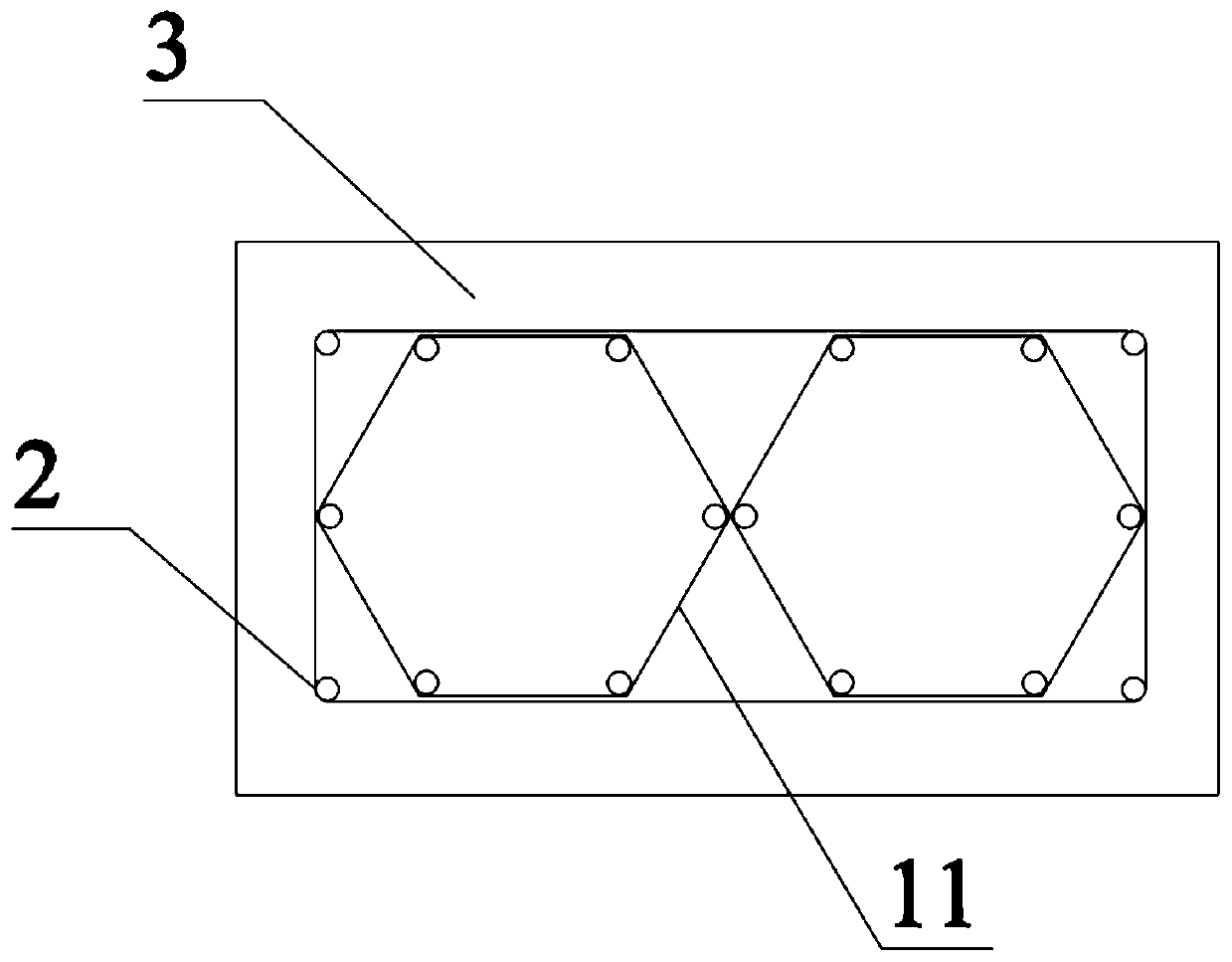

[0050] This embodiment provides a concrete pile structure, such as figure 1 with figure 2 As shown, it includes: the base 4 and concrete 3 poured pile body, the ends of the concrete pile body are provided with base 4 at the ends of the axial two ends, the concrete pile body includes concrete 3 and two layers of cylindrical support cages, the support cages are along the concrete In the axial extension of the pile body, the cylindrical supporting cages are stacked and sleeved; wherein, the outer sidewalls of adjacent supporting cages are fixedly connected with the inner sidewalls of the supporting cages arranged outside them. As in this embodiment, an inner support cage and an outer support cage 2 are provided, specifically, only one side of the inner support cage is provided, that is, the first inner support cage 11 .

[0051] In this example, if figure 2 As shown, the cross-section of the outer support cage 2 is rectangular, and the cross-section of the first inner support...

Embodiment 2

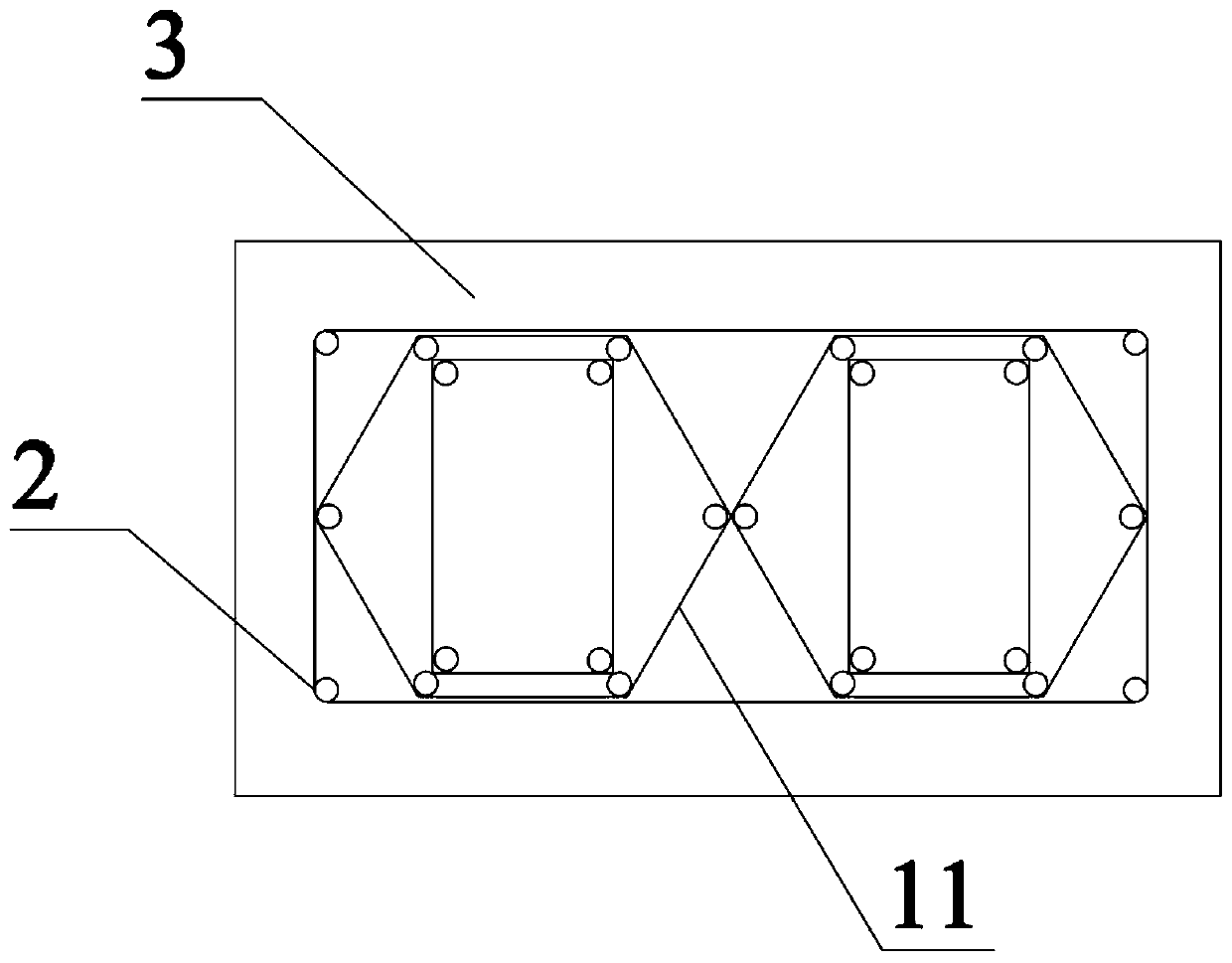

[0066] This embodiment provides a concrete pile structure, which differs from the concrete pile structure provided in Embodiment 1 in that only the first inner support cage 11 and the outer support are provided in Embodiment 1 Cage 2 two-layer support cage, and in the present embodiment, the inner support cage is provided with such as image 3 Two layers are shown, such as Figure 4 Three-layer, or four-layer inner support cages are shown. The cross-section of the inner support cage from the outside to the inside is alternately arranged in hexagons and rectangles. In this embodiment 2, if image 3 As shown, the inner support cage includes a first inner support cage 11 and a second inner support cage 12, the cross section of the first inner support cage 11 is a regular hexagon and the second inner support cage 12 has a rectangular cross section, the second inner support cage 12 is sleeved inside the first inner support cage 11; in this embodiment, the edges of the second inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com